Automatic device achieving partial drawing of metal piece

An automated device and metal parts technology, applied in metal processing equipment, grinding workpiece supports, grinders, etc., can solve the problem of not being able to meet the needs of product wire drawing well, unable to achieve partial wire drawing processing of products, and unstable manual wire drawing methods, etc. problems, to achieve the effect of improving market application value, simple structure and good processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

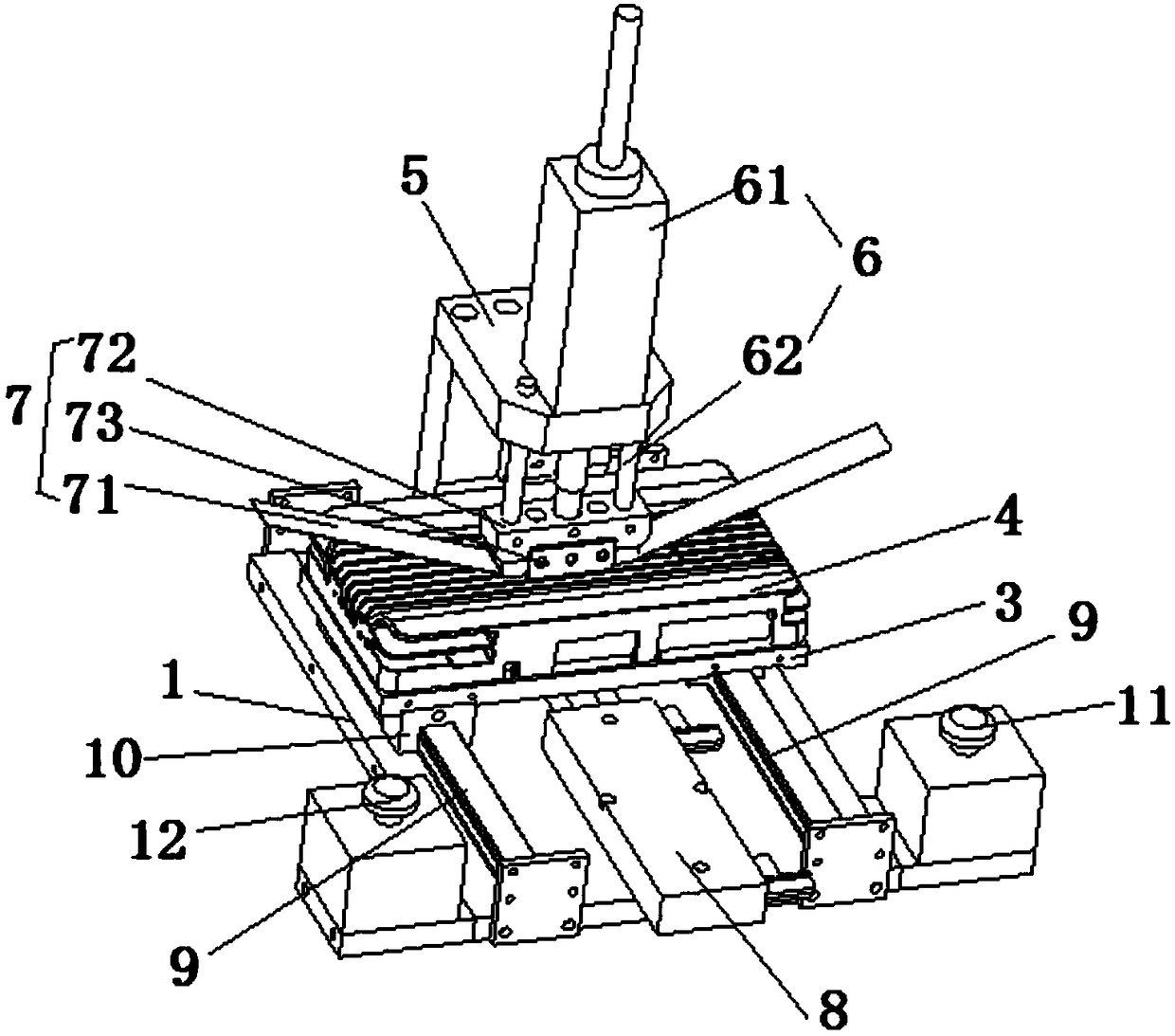

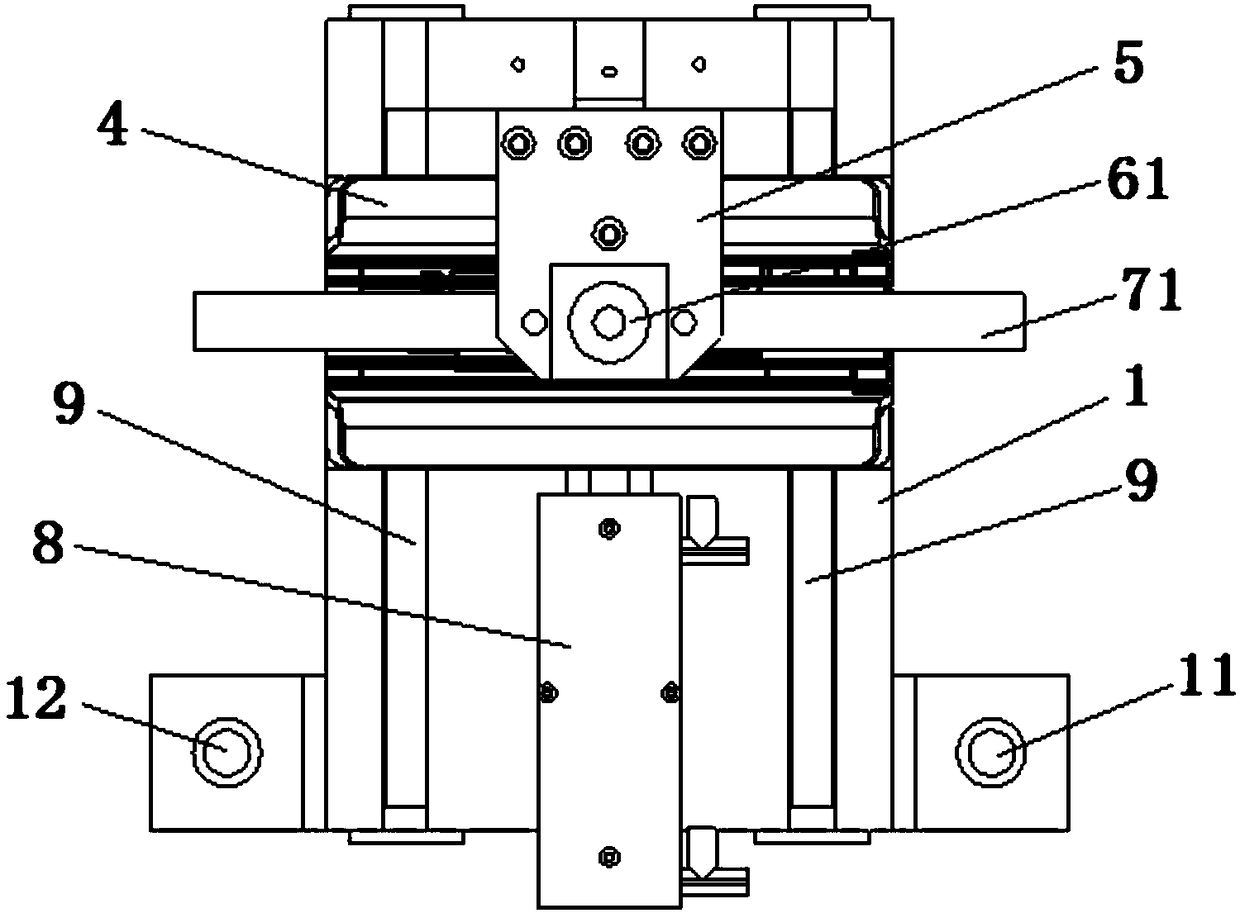

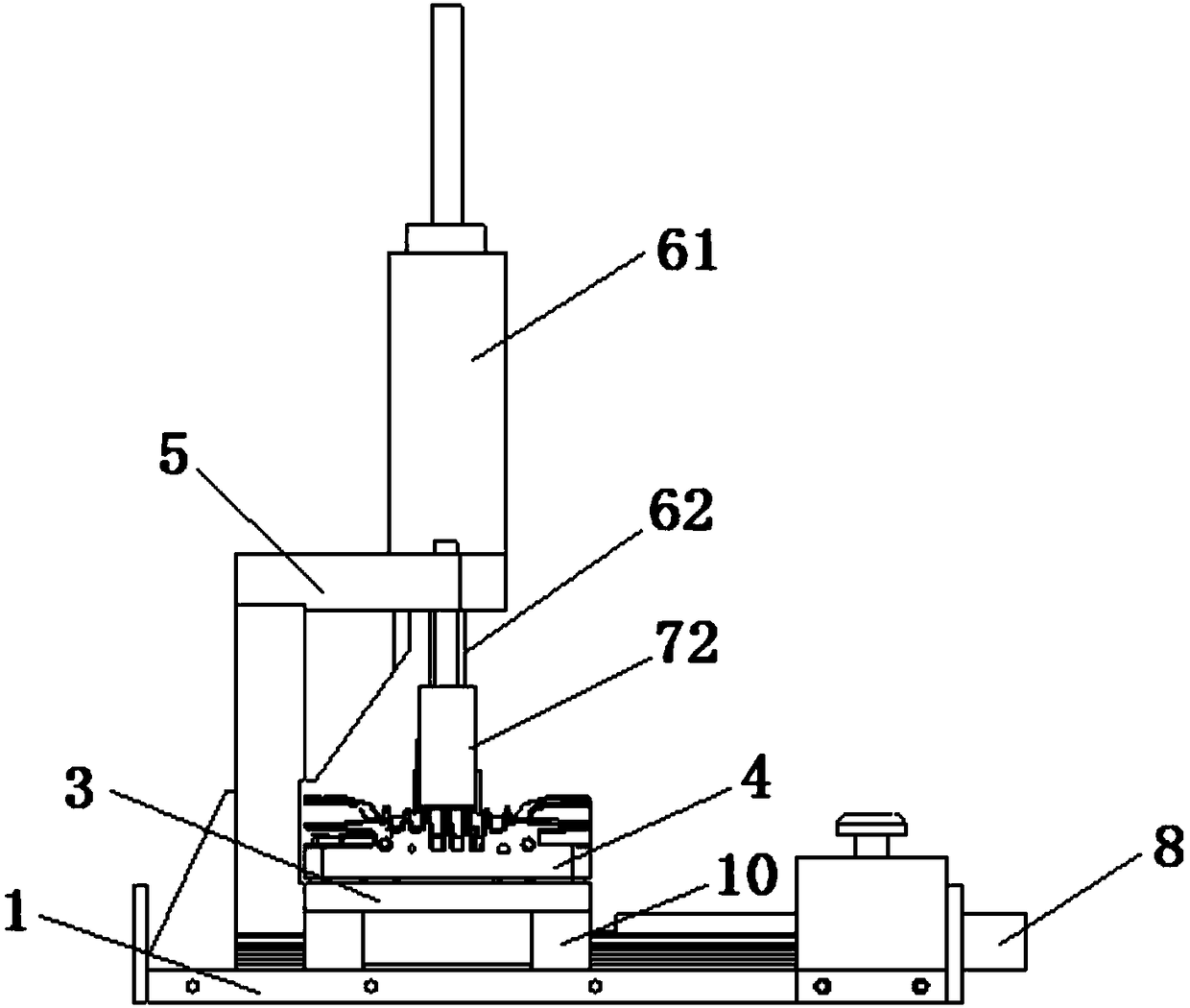

[0027] Please combine Figure 1 to Figure 5 As shown: an automatic device for realizing partial wire drawing of metal parts provided by the present invention, including a base 1 and a control device 2, the base 1 is provided with a horizontally movable positioning table 3, and the positioning table 3 is provided with There is a positioning mechanism compatible with the metal piece 4 to be drawn, a support 5 is vertically provided on the base 1, and a lifting mechanism 6 is provided on the top of the support 5, and the lifting mechanism 6 is connected to a wire drawing mechanism 7, The wire drawing mechanism 7 can move up and down linearly under the action of the lifting mechanism 6. The wire drawing mechanism 7 includes an abrasive belt 71 that can rotate in a vertical plane. The wire drawing parts 41 are parallel, the upper end surface of the abrasive belt 71 is provided with a wire drawing pressing block 72, the drawing pressing block 72 is connected with the lifting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com