Multilayer film with brushed metal effect layer

A multi-layer film and silk-colored technology, applied in lamination, coating, layered products, etc., can solve problems such as insufficient durability, limited surface protection, and inability to meet automotive interiors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

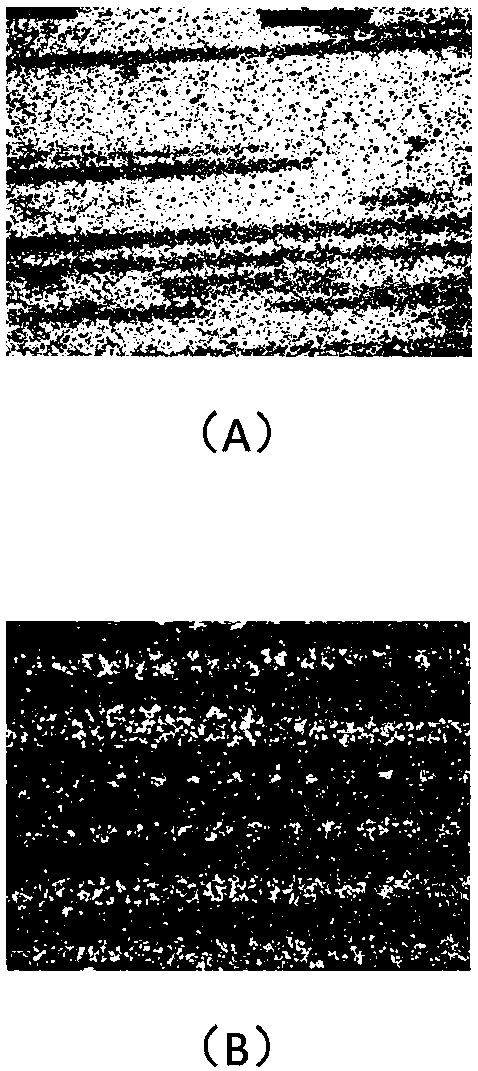

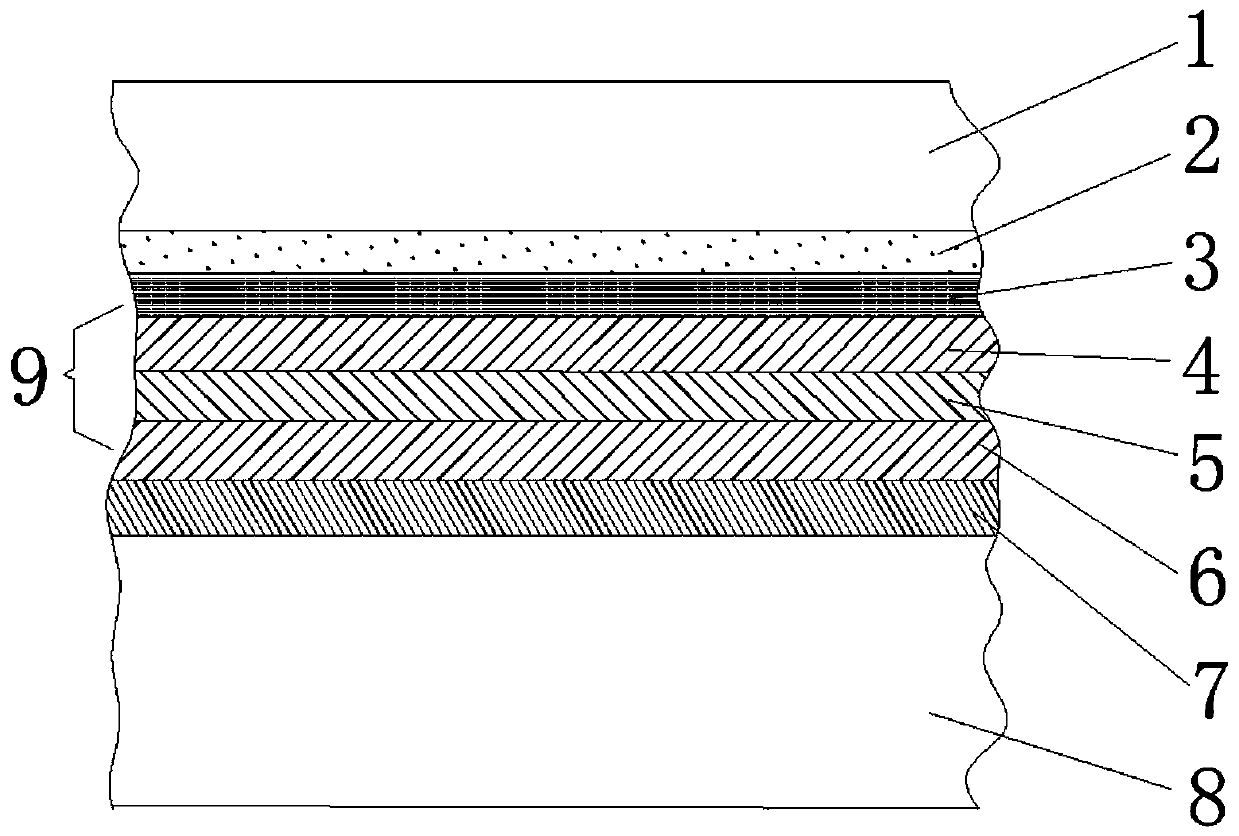

Image

Examples

Embodiment 1

[0049] Preparation of anchor ink-absorbing layer coating solution:

[0050]

[0051] In the container, first add ethyl acetate and butyl acetate, and then add the above-mentioned other components in sequence, and stir at high speed to fully dissolve and disperse to obtain printing paste, which is ready for use.

[0052] Prepare the brushed color layer ink, lining color layer ink, silver layer ink and black background layer ink required for printing and set it aside.

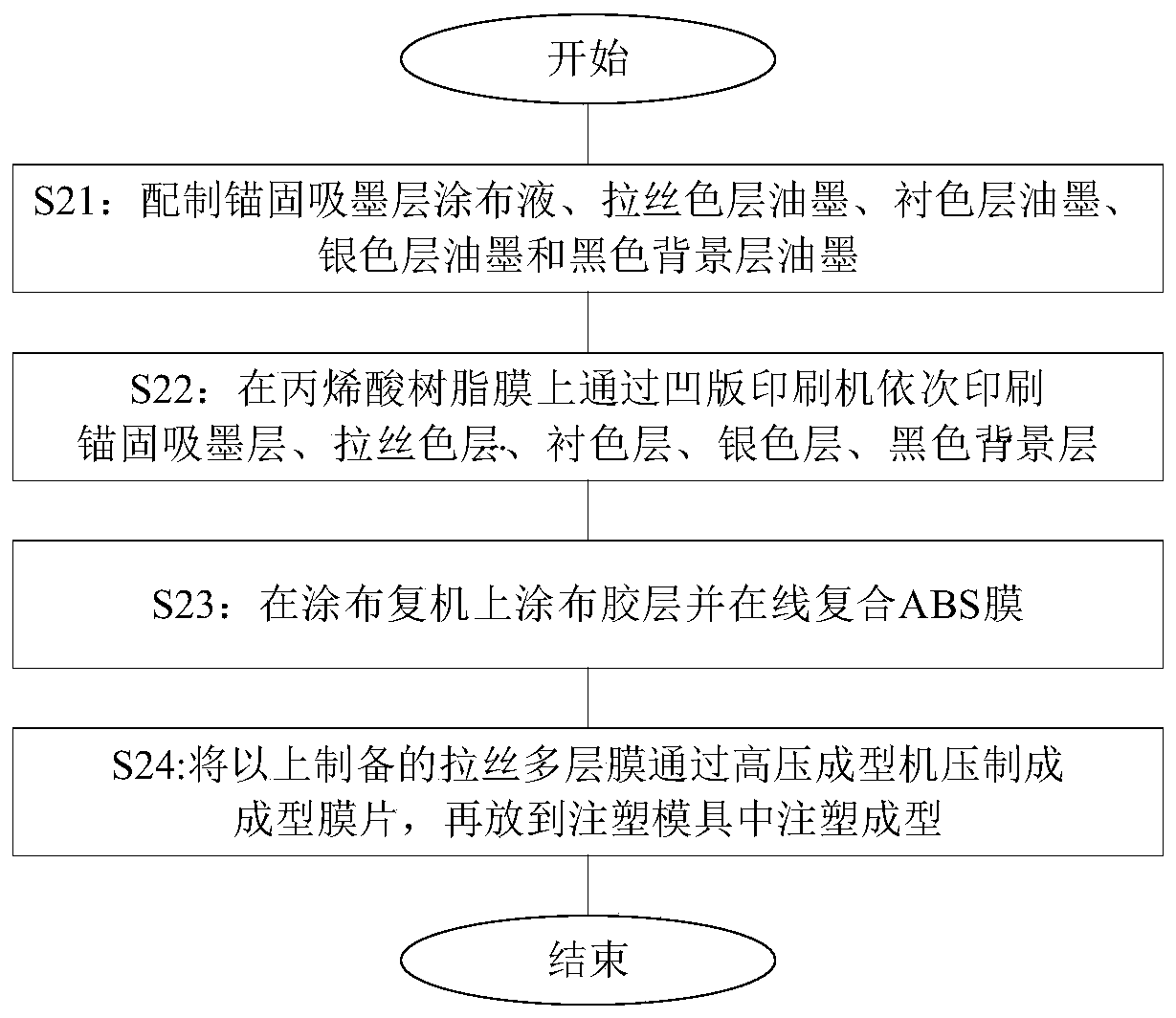

[0053] On a 60-micron thick acrylic resin film, a 0.5-micron anchor ink-absorbing layer, a 0.8-micron brushed color layer, a 0.8-micron lining color layer, a 3-micron silver layer, and a 3-micron black background are sequentially printed by a multi-color gravure printing machine layer, the gravure printing drying temperature is 75°C, the printing speed is 30m / min, and the acrylic resin film with metal wire drawing effect is printed, and then the adhesive layer is coated on the coating laminating machine with a...

Embodiment 2

[0056] Preparation of anchor ink-absorbing layer coating solution:

[0057]

[0058] In the container, first add ethyl acetate and butyl acetate, and then add the above-mentioned other components in sequence, and stir at high speed to fully dissolve and disperse to obtain printing paste, which is ready for use.

[0059] Prepare the brushed color layer ink, lining color layer ink, silver layer ink and black background layer ink required for printing and set it aside.

[0060] On a 75-micron thick acrylic resin film, a 2-micron anchor ink-absorbing layer, a 2-micron brushed color layer, a 2-micron lining color layer, a 5-micron silver layer, and a 3-micron black background are sequentially printed by a multi-color gravure printing machine layer, the gravure printing drying temperature is 75°C, the printing speed is 30m / min, and the acrylic resin film with metal wire drawing effect is printed, and then the adhesive layer is coated on the coating laminating machine with a thick...

Embodiment 3

[0063] Preparation of anchor ink-absorbing layer coating solution:

[0064]

[0065] In the container, first add ethyl acetate and butyl acetate, and then add the above-mentioned other components in sequence, and stir at high speed to fully dissolve and disperse to obtain printing paste, which is ready for use.

[0066] Prepare the brushed color layer ink, lining color layer ink, silver layer ink and black background layer ink required for printing and set it aside.

[0067] On a 75-micron thick acrylic resin film, a 1-micron anchor ink-absorbing layer, a 0.5-micron brushed color layer, a 0.5-micron lining color layer, a 3-micron silver layer, and a 4-micron black background are sequentially printed by a multi-color gravure printing machine Layer, the gravure printing drying temperature is 75 ℃, the printing speed is 30m / min, and the acrylic resin film with metal wire drawing effect is printed, and then the adhesive layer is coated on the coating laminating machine with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com