Positive electrode of solid electrolyte and solid state battery

A solid electrolyte and positive electrode technology, applied in the field of solid-state batteries, can solve the problems of poor mechanical properties, large interface resistance, low electrical conductivity, etc., and achieve the effects of high safety, reduced crystallinity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] There is no special limitation on the preparation method of the nano inorganic solid electrolyte, as long as it can have the above particle size. For example, the submicron-sized inorganic electrolyte can be pulverized by planetary ball milling and / or high-energy ball milling to obtain a nano-sized inorganic solid-state electrolyte that meets the particle size requirements.

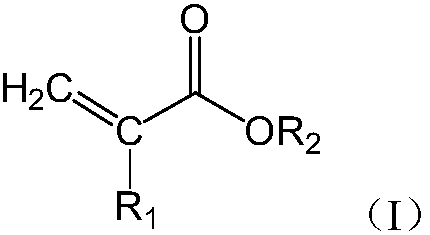

[0042] The polymer graft-modified ceramics may be ceramic particles graft-modified with acrylic acid polymers. Here, the acrylic polymer refers to a homopolymer or a copolymer formed by homopolymerization or copolymerization of acrylic monomers.

[0043] The glass transition temperature (Tg) of the acrylic polymer may range from 50°C to 200°C, preferably from 80°C to 180°C. For example, the acrylic polymer may be polymethyl methacrylate, or methyl methacrylate and methyl methacrylate selected from methacrylic acid, ethacrylic acid, ethyl acrylate, ethyl methacrylate, propyl methacrylate, methyl O...

Embodiment 1

[0102] Preparation of positive electrode sheet containing lithium iron phosphate

[0103] 1) Mix and stir 50g lithium iron phosphate and 130g N-methylpyrrolidone (NMP) at a temperature of 30°C, a rotation speed of 1500rpm / min, and a time of 3h; then add 20g of styrene-acrylic emulsion with a solid content of 50wt%, 6g of carbon fiber, and keep the temperature After stirring at 30°C and 1000rpm / min for 1.5h, the composite cathode slurry was obtained;

[0104] 2) Coating the above-mentioned composite positive electrode slurry on one or both sides of an aluminum foil with a thickness of 10 μm, and then drying, the single coating thickness is 42 μm, to obtain a positive electrode sheet containing lithium iron phosphate.

[0105] Preparation of polymer graft modified ceramics:

[0106] Under a nitrogen atmosphere, add 1.5g of benzoyl peroxide into 100ml of tetrahydrofuran, stir until completely dissolved, then add 7.5g of methyl methacrylate and 75g of alumina particles (D50=1.0μm...

Embodiment 2

[0115] Preparation of positive electrode sheet containing lithium manganese oxide

[0116] 1) Mix and stir 50g of lithium manganate and 130g of N-methylpyrrolidone (NMP) at a temperature of 30°C and a rotation speed of 1500rpm / min for 3h; then add 20g of styrene-acrylic emulsion with a solid content of 50wt% and 6g of carbon fiber to maintain the temperature After stirring at 30°C and 1000rpm / min for 1.5h, the composite cathode slurry was obtained;

[0117] 2) Coating the above-mentioned composite positive electrode slurry on one or both sides of an aluminum foil with a thickness of 10 μm, and then drying, the single coating thickness is 42 μm, to obtain a positive electrode sheet containing lithium manganate.

[0118] Preparation of polymer graft modified ceramics:

[0119] Under a nitrogen atmosphere, add 1.5g of benzoyl peroxide into 100ml of acetone, stir until completely dissolved, then add 7.5g of methyl methacrylate and ethacrylic acid (ratio 1:1) and 75g of magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com