Scratch resistant brushed metal imitating composite decorative film

A metal-imitation, scratch-resistant technology, applied in the direction of decorative art, synthetic resin layered products, imitation of natural patterns, etc., can solve the problem of low bonding strength, low adhesion fastness and imitation metal wire drawing pattern of composite adhesive layer interface Simulate design difficulties and other issues to achieve soft and non-glare gloss, improved adhesion fastness, and rich and diverse colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

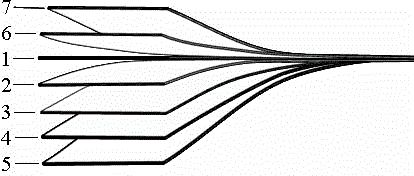

[0027] figure 1 Among them, the lower surface of the BOPET film layer 1 is provided with a primer layer 2; the lower surface of the primer layer 2 is printed with an imitation metal wire drawing pattern layer 3; Bonding: the upper surface of the BOPET film layer 1 is provided with an adhesion-enhancing resin coating 6 ; the upper surface of the adhesion-enhancing resin coating 6 is provided with a scratch-resistant hardened coating 7 .

[0028] In this embodiment, the surface gloss of the BOPET film layer at 60° is 50±5Gs; the primer layer uses polyurethane resin as the main agent, hexamethylene diisocyanate biuret as the curing agent, polyurethane resin and hexamethylene diisocyanate biuret The mass ratio of urea is 100:6; the gravure printing machine is used to print silver ink to realize the imitation metal drawing pattern, the printing process is an oven baking temperature of 90°C, printing speed of 45m / min, baking time of 2.5s, and rubber roller pressure of 0.8 MPa; Scra...

Embodiment 2

[0031]In this embodiment, the surface gloss of the BOPET film layer at 60° is 65 ± 5Gs; the primer layer uses polyacrylate resin as the main agent, hexamethylene diisocyanate biuret as the curing agent, polyacrylate resin and hexamethylene The mass ratio of diisocyanate biuret is 100:8; use gravure printing machine to print silver ink to realize imitation metal drawing pattern, the printing process is oven drying temperature 90 ℃, printing speed 60m / min, baking time 2s, rubber pressing roller Pressure 1.0MPa; Scratch-resistant hardened coating is mixed evenly with polyurethane acrylate resin and silicone acrylate resin according to 50:50wt%, and then coated on the surface of the adhesion-enhancing resin coating with a precision coater, and baked and dried Formed by UV curing, UV radiation energy 600±20mj / cm 2 , the surface pencil hardness is 1H, and the coating thickness is 2.5μm; the BOPET film layer and the PVC film are bonded together by a composite adhesive layer, and the ...

Embodiment 3

[0033] In this embodiment, the surface gloss of the BOPET film layer at 60° is 55 ± 3Gs; the primer layer is mixed with polyurethane resin and polyacrylate resin according to 85:15wt% as the main agent, and hexamethylene diisocyanate biuret is used as the curing agent. The mixed resin composed of polyurethane resin and polyacrylate resin, and the mass ratio of hexamethylene diisocyanate biuret is 100:6; use gravure printing machine to print silver ink to realize the imitation metal drawing pattern, and the printing process is oven drying temperature 100 ℃, printing speed 55m / min, baking time 2s, rubber roller pressure 2.5MPa; scratch-resistant hardened coating using polyurethane acrylate resin, silicone acrylate resin and polyester acrylate resin according to 40:40:20wt% After mixing evenly, use a precision coater to coat the surface of the adhesion-enhancing resin coating, bake and dry it and then cure it with ultraviolet light. The energy of ultraviolet light irradiation is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pen hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com