A kind of brush type metal workpiece surface strengthening grinding processing equipment and method

A surface strengthening and grinding technology, which is applied in metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problem of reducing the impact strength of the processing area, failure to adhere, and reduction of residual compressive stress, etc. problems, to achieve the effect of improving overall quality, avoiding air pollution, and increasing recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

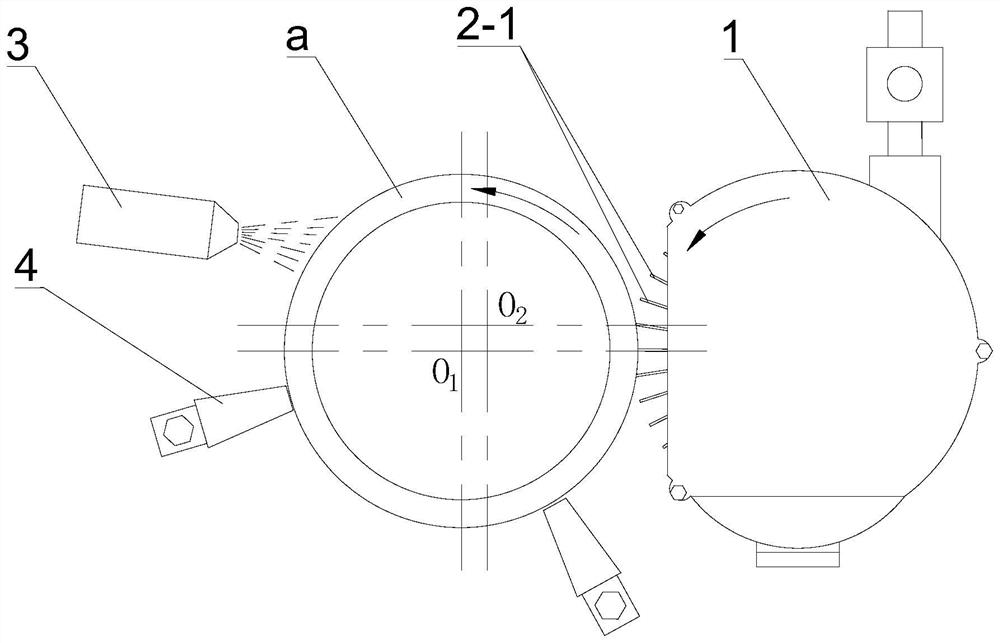

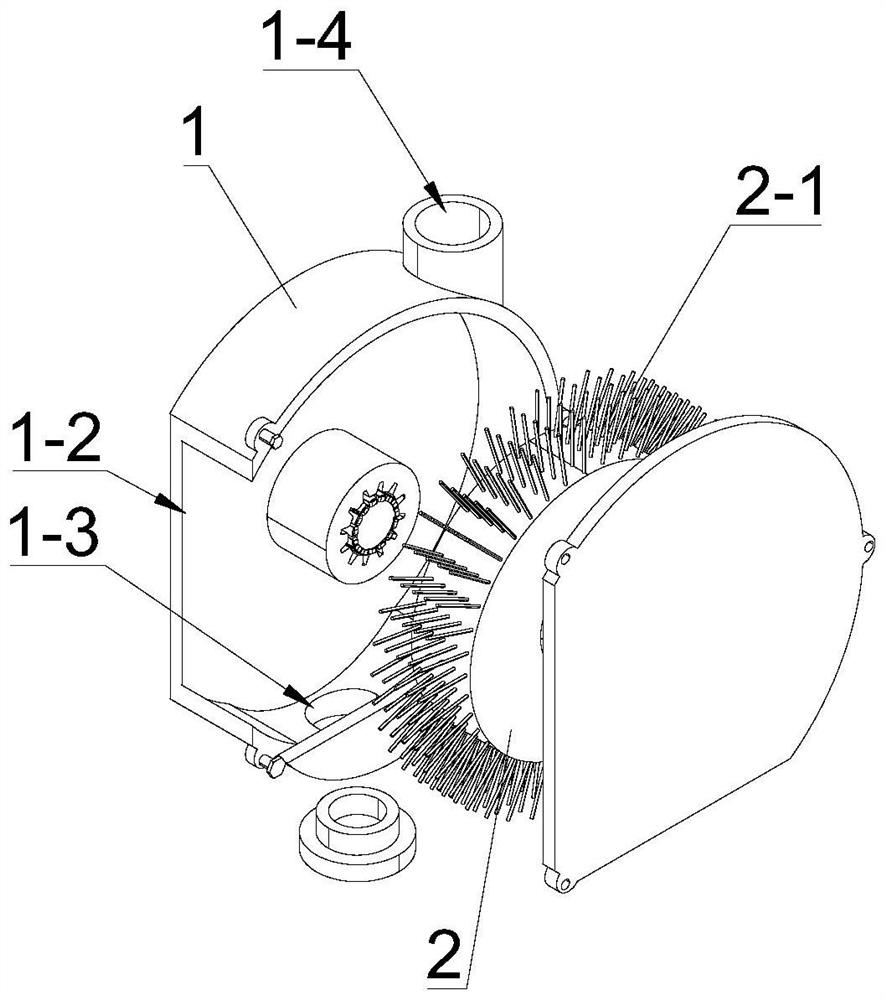

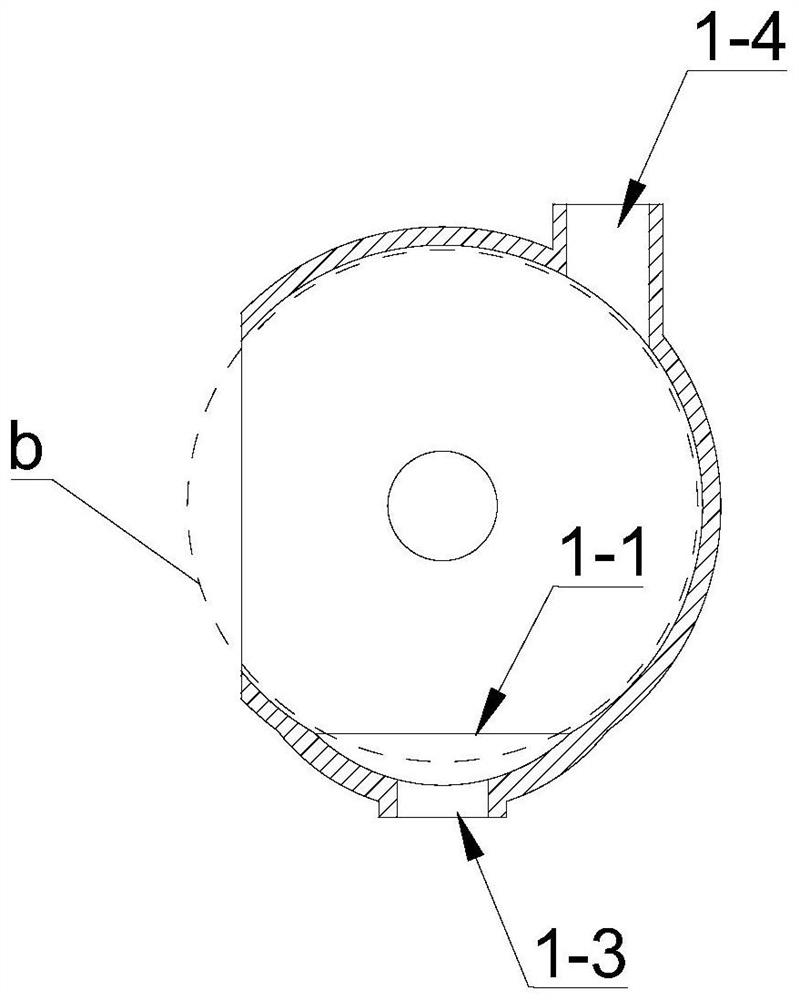

[0044] see Figure 1-3 , the brushing type metal workpiece surface strengthening grinding processing equipment in this embodiment includes a metal frame providing basic support and a rotating clamping device for clamping the workpiece a arranged in the metal frame, for A mixing and brushing device for uniformly coating mixed abrasives on the processing surface of workpiece a and a high-pressure spraying device for spraying high-speed steel balls on the processing surface of workpiece a. The mixed abrasives are semi-fluid of abrasive liquid and abrasive powder shaped mixture. Specifically, in this embodiment, the inner ring of the bearing is taken as an example for processing.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com