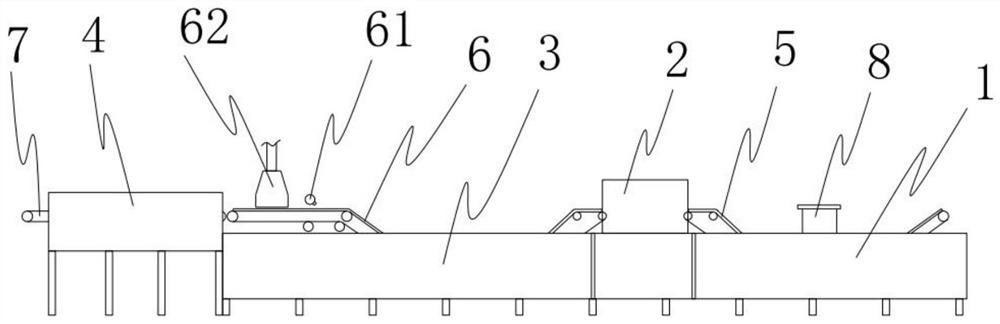

Automatic cleaning equipment for metal parts

A technology for automatic cleaning of metal parts, applied in lighting and heating equipment, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of low cleaning efficiency and high dependence on human labor, achieve high cleaning efficiency and reduce manpower input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] As an embodiment of the present invention, ultrasonic cleaning devices are respectively provided in the clean water cleaning tank 1 and the pure water cleaning tank 2 . Installing an ultrasonic cleaning device can effectively clean metal parts and improve the cleaning effect.

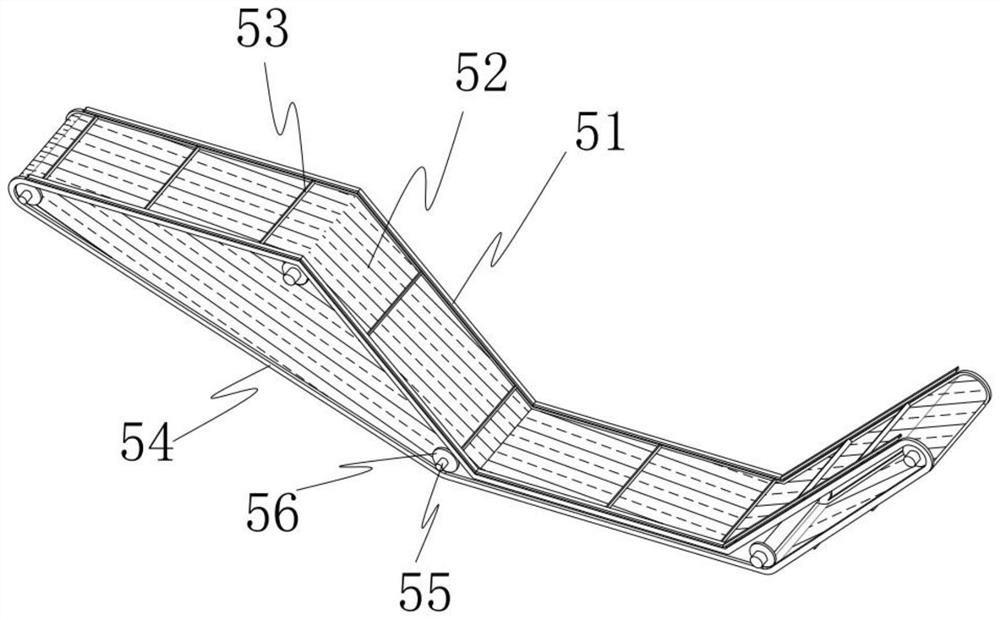

[0036] As an embodiment of the present invention, it also includes a loading tray 9 for loading the metal parts 92, and a plurality of loading holes 91 that can be used to install and fix the metal parts 92 are provided on the loading tray 9 (of course, According to the different structures of the metal parts 92 that are actually cleaned, the loading tray 9 of different structures can be set to fix the loaded metal parts 92), refer to image 3 , the first conveyor belt 5, the second conveyor belt 6 and the third conveyor belt 7 are respectively provided with a plurality of protruding stop bars 53 at intervals, and the loading tray 9 is placed on the first conveyor belt 5, the second conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com