Inclined hole tray brush metal brush wire cutting device

A metal brush and oblique hole technology, applied in the field of brushes, can solve the problems of large differences in bending symmetry of metal brush wires, affecting the use effect and life of disc brushes, uneven brush wires, etc., and achieve good promotion and application value, High work efficiency and good uniformity of finished product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

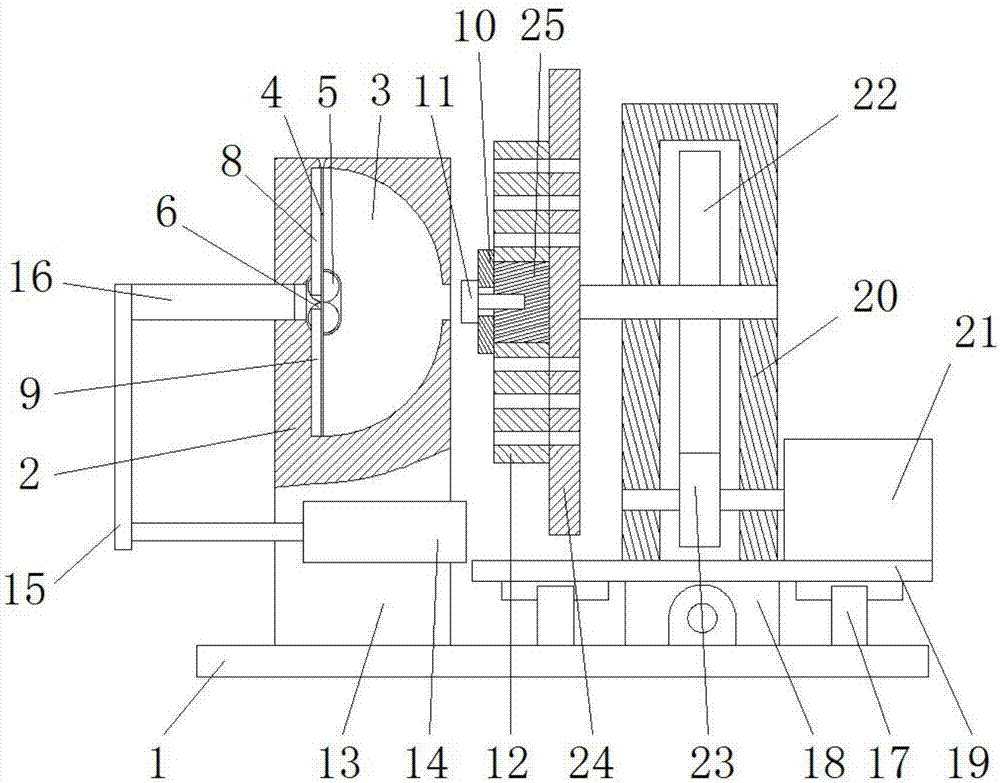

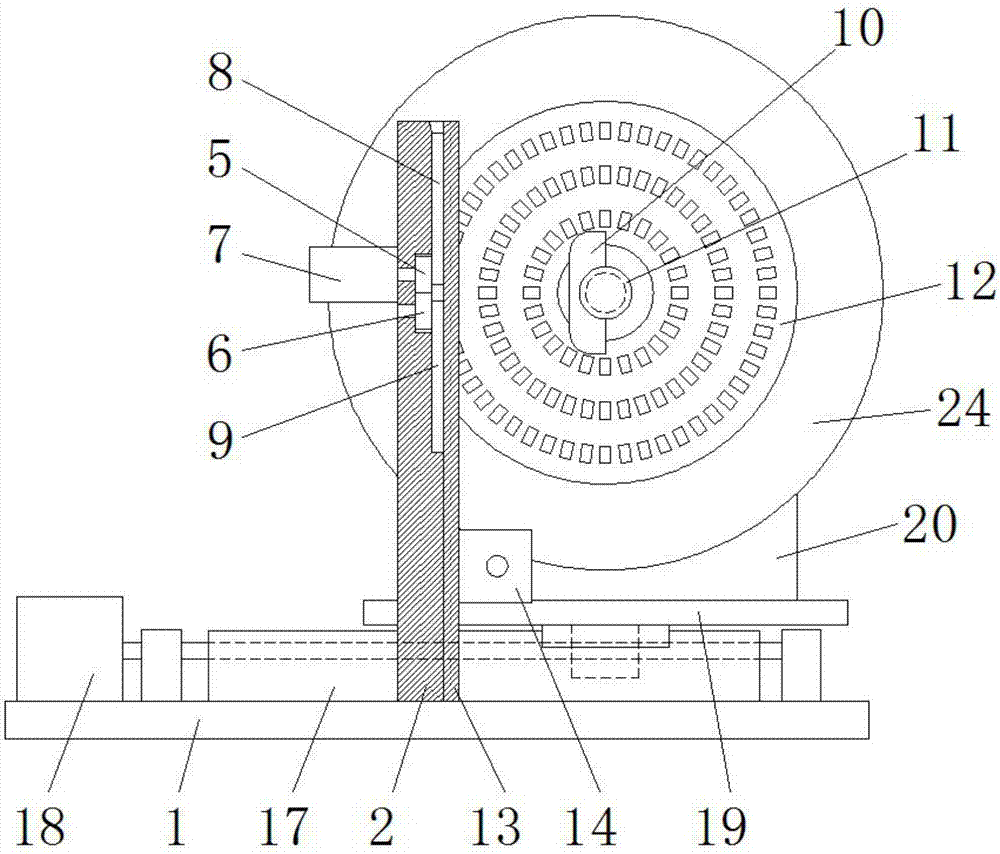

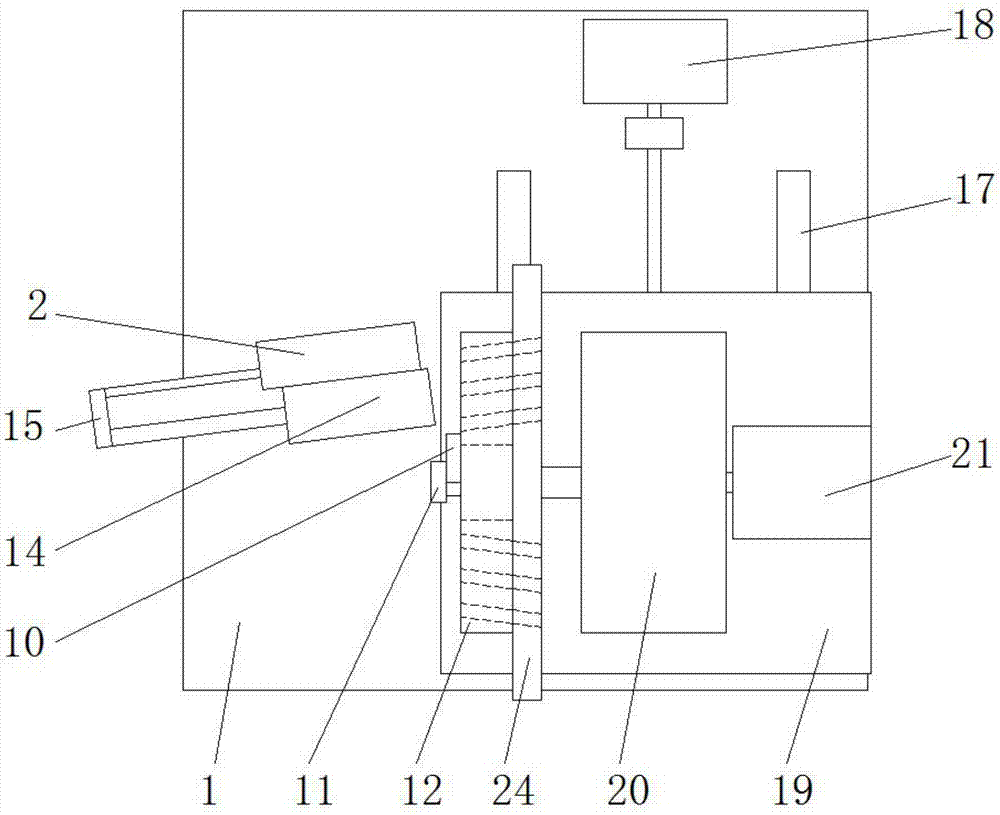

[0021] Referring to the accompanying drawings, a metal brush wire cutting device with oblique hole discs includes a base 1, a bending device and a positioning device, the bending device and the positioning device are respectively installed on the base 1, and the bending device includes a The support plate 2 on the seat 1, the side of the support plate 2 is provided with a semicircular folding arm groove 3, the center of the folding arm groove 3 is provided with a gear groove, and the gear groove is symmetrically provided with an upper meshing connection. Bending gear 5 and lower bending gear 6, the center of folding arm groove 3, the center of upper bending gear 5 and the center of lower bending gear 6 are located on the same vertical line, and the rotating shaft of upper bending gear 5 and The output shaft of the bending motor 7 installed on the back side of the support plate 2 is fixedly connected, and the outer sides of the upper bending gear 5 and the lower bending gear 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com