Rotary sorting system and use method thereof

A sorting system and rotating body technology, applied in sorting and other directions, can solve the problems of low sorting efficiency of sorting mechanisms, and achieve the effects of amazing processing capacity, reduced customer complaints, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

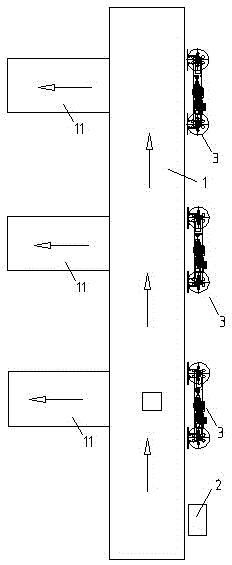

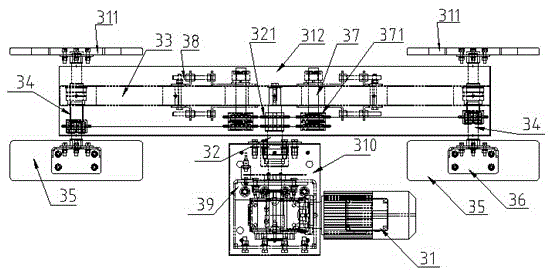

[0034] refer to Figure 1 to Figure 4 , this embodiment provides a rotary sorting system, including a conveyor 1, an automatic cargo identification system 2, a sorting mechanism 3 and a processor 4, one side of the conveyor 1 has a sorting and conveying branch 11, and the sorting mechanism 3 The corresponding sorting and conveying branch 11 is set on the other side of the conveyor 1, and the sorting mechanism 3 is correspondingly equipped with an automatic cargo identification system 2. The automatic cargo identification system 2 is a laser scanner, and the laser scanner scans the barcode of the cargo receiving Scanning, the sorting mechanism 3 includes a motor 31, a drive shaft 32 and a rotating body 33, the drive shaft 32 is arranged vertically, the drive shaft 32 is driven by the motor 31, and the lower end of the drive shaft 32 is provided with a drive support 39, the drive shaft 32 The lower end of the drive support 39 is rotatably arranged on the drive support 39, the dr...

Embodiment 2

[0039] refer to figure 1 , figure 2 , Figure 5 , Figure 6 and Figure 7 , this embodiment provides a rotary sorting system, including a conveyor 1, an automatic cargo identification system 2, a sorting mechanism 3 and a processor 4, one side of the conveyor 1 has a sorting and conveying branch 11, and the sorting mechanism 3 The corresponding sorting and conveying branch 11 is set on the other side of the conveyor 1, and the sorting mechanism 3 is correspondingly equipped with an automatic cargo identification system 2. The automatic cargo identification system 2 is a laser scanner, and the laser scanner scans the barcode of the cargo receiving Scanning, the sorting mechanism 3 includes a motor 31, a drive shaft 32 and a rotating body 33, the drive shaft 32 is arranged vertically, the drive shaft 32 is driven by the motor 31, and the lower end of the drive shaft 32 is provided with a drive support 39, the drive shaft 32 The lower end of the drive support 39 is rotatably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com