Gripper, in particular pneumatically actuated gripper in the form of a suction gripper or gripper jaws

A technology of clamps and clamps, applied in the field of pneumatically operated clamps, which can solve problems such as surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

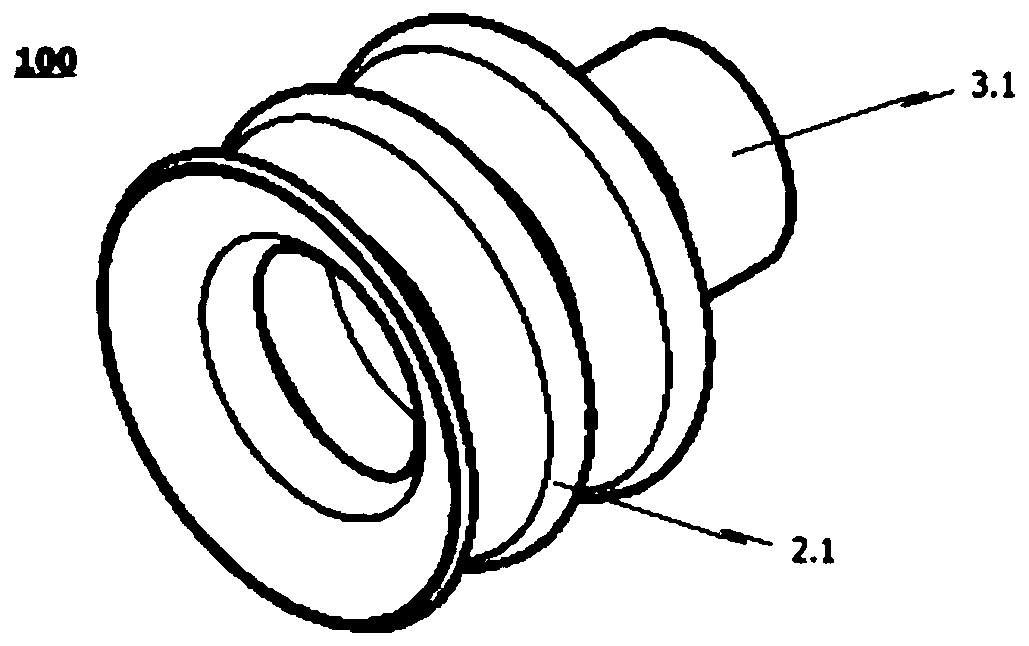

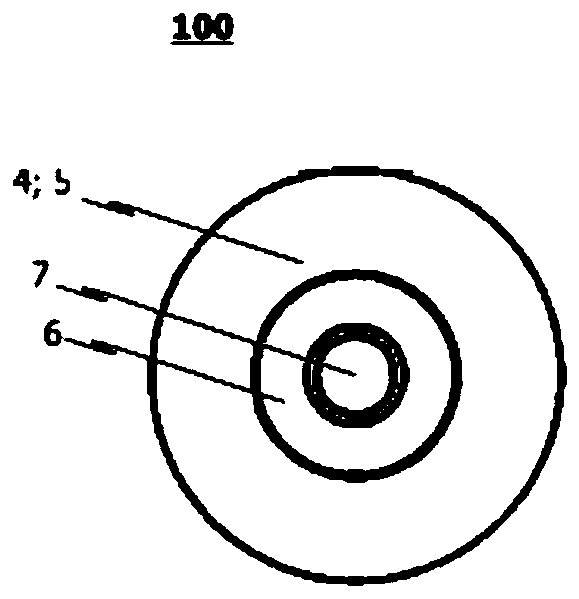

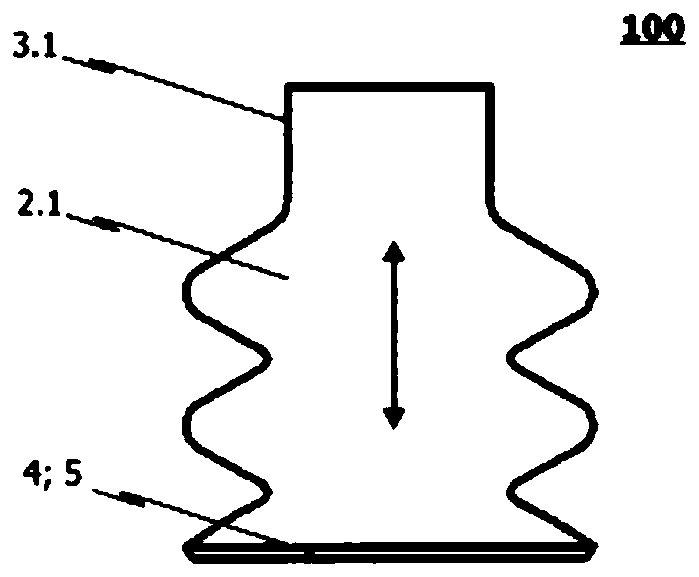

[0031] exist Figure 1a -c presents a first exemplary embodiment of the clamp 100 according to the invention in side view, isometric view and top view from below. This exemplary embodiment is designed in the form of a suction gripper.

[0032] The suction clamp has a generally elongated shape with a longitudinal axis. On the rear side, the suction gripper is equipped or can be equipped with any type of gripper holder, via which the gripper gripper can be fastened preferably detachably to a handling device not shown in the figures. The operating device enables the suction gripper to be moved and positioned, ie corresponding to various intended realizations. The operating device is in particular of the mechanical type and may comprise one or more electric and / or fluidic drives.

[0033] The suction clamp comprises a flexible suction cup 2.1, which serves as a clamping component, which is fastened with its rear end region on the clamp support (suction cup support 3.1). Prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com