Livestock breeding forage swing type crushing device

A swinging, crushing technology, applied in the field of animal husbandry, can solve the problems of low cutting adequacy and fixed cutting position, and achieve the effect of increasing the crushing range, improving the degree of cutting refinement, and promoting full refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

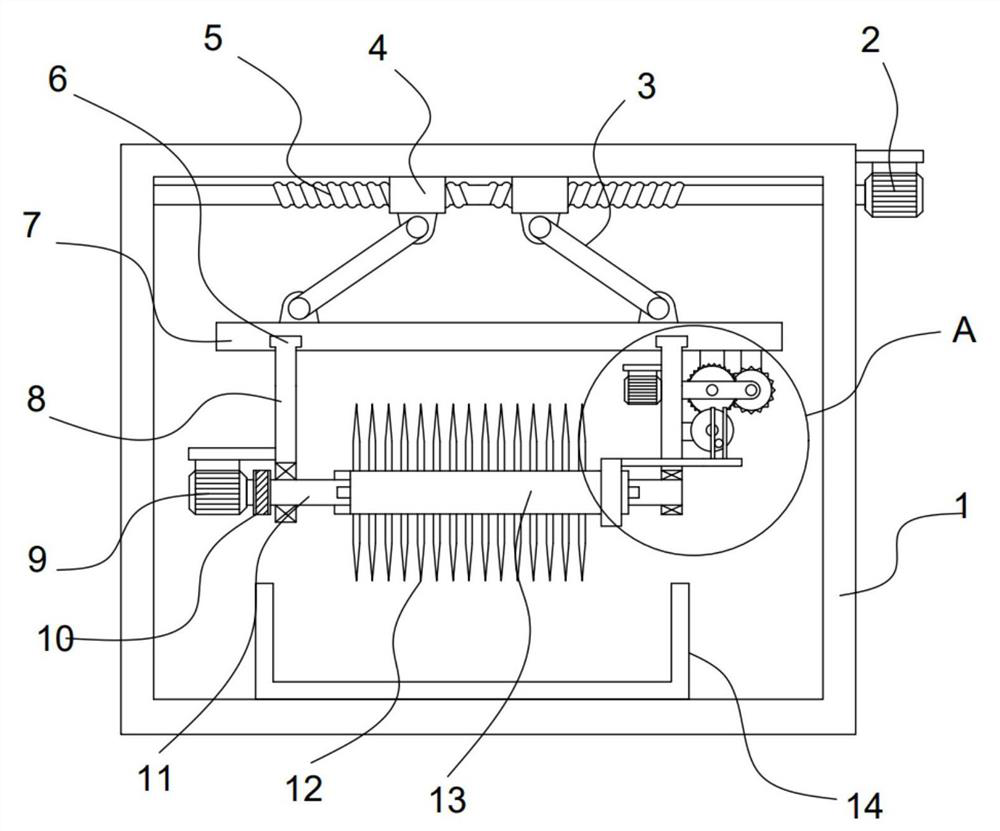

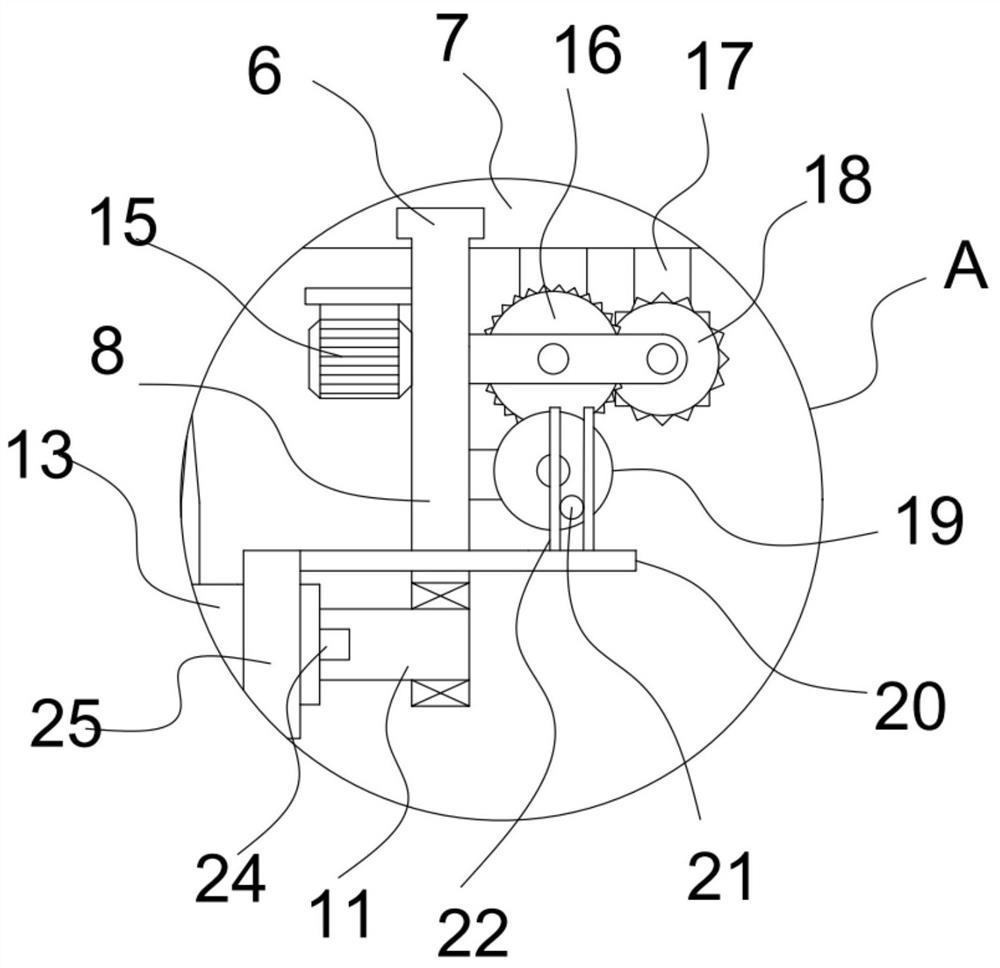

[0024] see Figure 1-6 , a kind of livestock breeding fodder swing type crushing device, comprising a fixed frame 1, a crushing basket 14 is fixed inside the fixed frame 1, a drive motor 2 is fixed on the fixed frame 1, and a height adjustment mechanism is connected to the drive motor 2, The height adjustment mechanism is connected with a horizontally arranged suspension plate 7 in transmission connection, and a T-shaped slider 6 is embedded in the front and rear slides on the described suspension plate 7, and a hanger 8 is vertically fixed on the T-shaped slider 6. A drive motor 9 is fixed on the frame 8, and the drive motor 9 is driven and connected with a crushing mechanism that is rotatably installed on the hanger 8. The hanger 8 is fixed with a servo motor 15, and the output shaft of the servo motor 15 is connected with a drive for driving. The hanger 8 is a translation mechanism that moves back and forth relative to the suspension plate 7, and the servo motor 15 is drive...

Embodiment 2

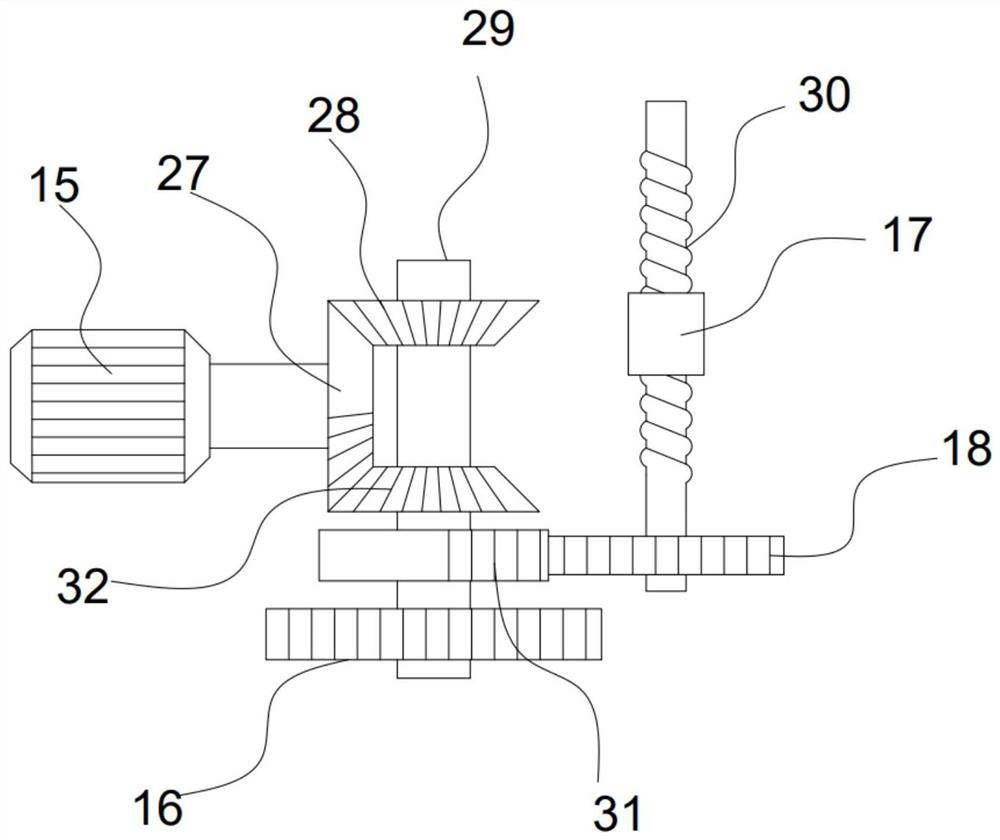

[0030] On the basis of Embodiment 1, in addition, the translation mechanism of the device includes a transmission column 29 that is rotatably installed on the hanger 8, and the transmission column 29 is sleeved with a bevel gear 128 and a bevel gear II32. The driving connection has an incomplete bevel gear 27 meshing alternately with bevel gear 128 and bevel gear II32. The incomplete cylindrical gear 31 is sleeved and fixed on the transmission column 29, and the incomplete cylindrical gear 31 is sleeved and fixed on the incomplete cylindrical gear 31. The driven gear I18 is alternately meshed with the incomplete cylindrical gear 31, and the driven gear I18 is A threaded post 30 is coaxially fixed, and the threaded post 30 is threaded with a transmission block 17 fixed on the hanging plate 7 .

[0031] The set servo motor 15 drives the incomplete bevel gear 27 to rotate, and the incomplete bevel gear 27 alternately meshes with the bevel gear 128 and the bevel gear II32. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com