Universal three-edging mounting tool for front bumper

A technology for installing tooling and edge strips, which is applied in the direction of material gluing, connecting components, mechanical equipment, etc. It can solve problems such as low work efficiency, affecting the quality of edge wrapping, and large glass size and weight, so as to achieve coherent actions and improve the quality of edge wrapping And the effect of hemming efficiency and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

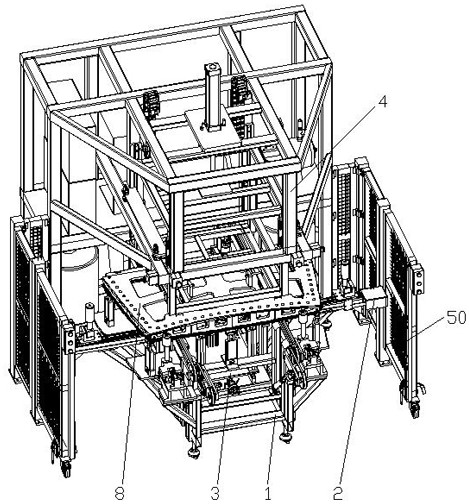

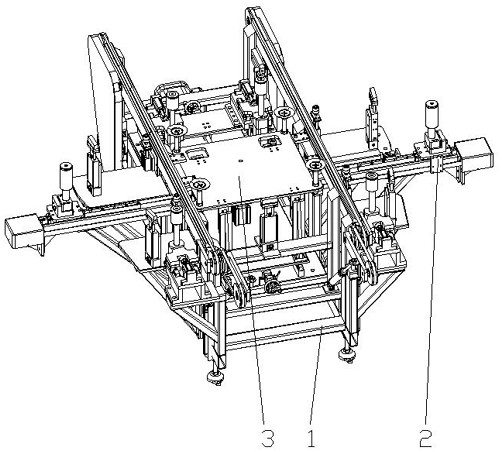

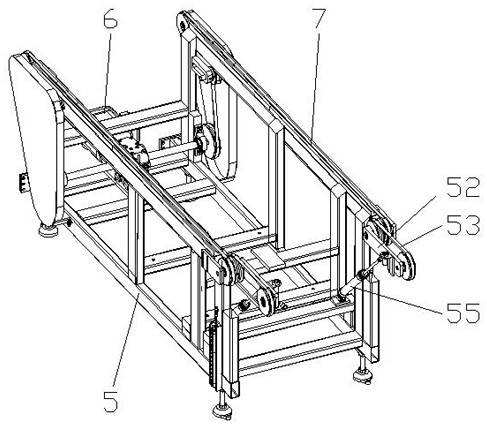

[0022] As shown in the drawings, the present invention includes a glass conveyor 1, a glass centering mechanism 2, a glass lifting mechanism 3, a profiling block lifting mechanism 4 and a profiling pressing block 8, and the glass conveyor 1 includes a conveying frame 5 and a conveying motor The reducer 6 and the two sides of the conveyor frame 5 are respectively provided with a first-stage conveyor belt 7, and the conveyor frame 5 is provided with a drive shaft for controlling the synchronous rotation of the two primary conveyor belts 7, and the conveyor motor reducer 6 is installed on the conveyor frame 5 , and drive the transmission shaft to rotate;

[0023] The glass centering and positioning mechanism 2 includes a synchronous belt transverse centering device, a pair of front-end positioning devices and a pair of end positioning devices. The synchronous belt transverse centering device is located between the pair of front-end positioning devices and a pair of end positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com