Stepping type automatic cleaning device of plastic bowls

An automatic cleaning and plastic bowl technology, which is applied in packaging, packaging protection, transportation and packaging, etc., can solve the problem of inability to realize plastic bowl filling automation, low work efficiency of manual cleaning of plastic bowls, and unsuitable filling speed of matching filling machines and other problems to achieve the effect of meeting the needs of automatic filling production, high degree of automation and coherent action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

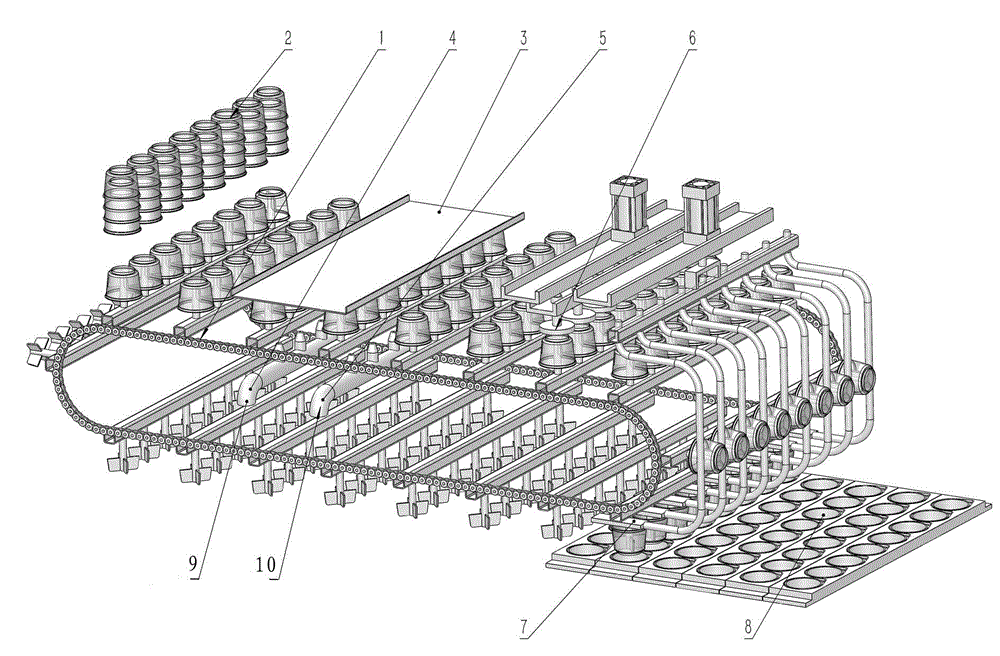

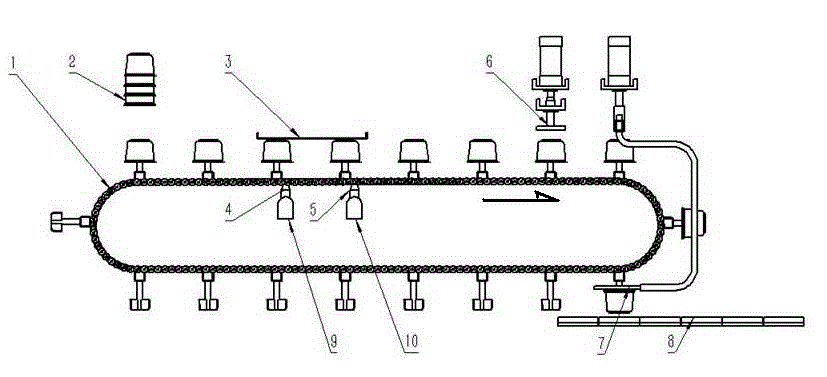

[0007] The step-by-step automatic cleaning device for plastic bowls of the present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

[0008] Referring to the accompanying drawings, the step-by-step automatic cleaning device for plastic bowls of the present invention includes a plastic bowl conveyor belt (1), an automatic bowl-dividing molding mechanism (2), a limit baffle (3), a cleaning water spray mechanism (4), Drying mechanism (5), bowl pressing and fixing mechanism (6), bowl turning mechanism (7) and stepping conveyor belt (8) of plastic bowl automatic filling and sealing machine.

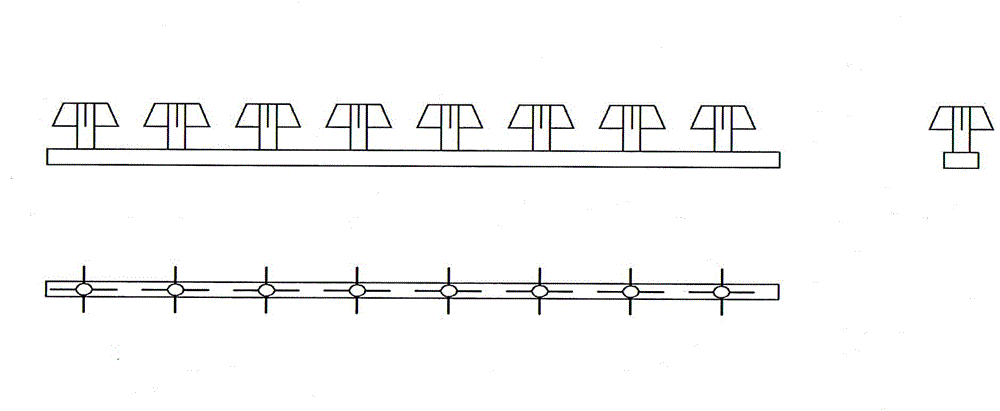

[0009] The plastic bowl conveyor belt (1) includes two crawler conveyor belts driven by the power mechanism and a bowl cover mold frame arranged on the crawler conveyor belt. The bowl cover mold frame should be made to match the plastic bowl used. Matching, plays the role of driving the plastic bowl to advance and fix on the conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com