Edge wrapping method and structure of wrapping press plate controlled by robot

A robot and hemming technology, which is applied in the field of connecting inner and outer panels of automobile panels, can solve the problems of high cost, inflexibility, and low efficiency of press molding hemming, and achieve the effect of hemming efficiency and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

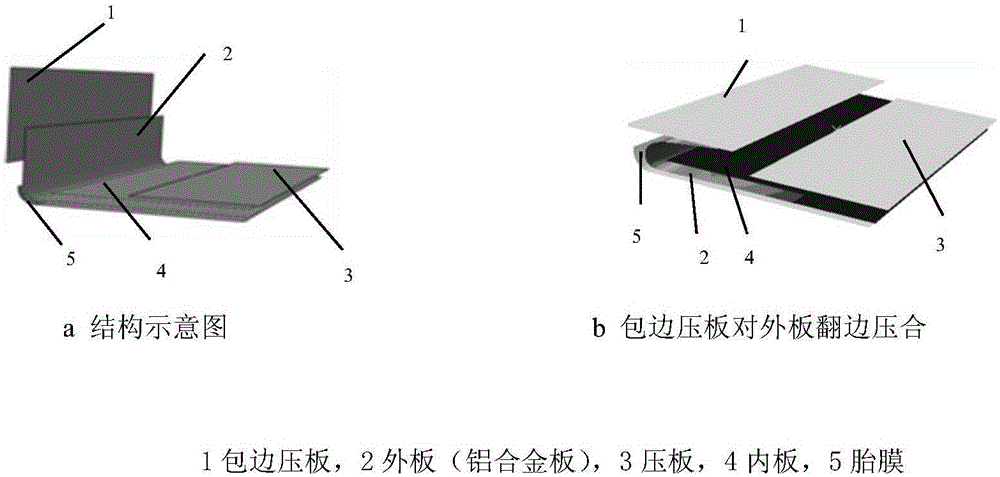

[0022] Such as figure 1 As shown, the present invention is used for edge wrapping of plane straight-edge aluminum alloy plates. 1 edging platen, 2 outer plate, 3 platen, 4 inner plate, 5 membrane.

[0023] Generally, aluminum alloy piping is divided into 3 passes. The outer plate is turned at 90 degrees, and the pressing angle is generally 30, 60, and 90 degrees. The plate flanging realizes the wrapping and pressing, so as to complete the task that the traditional hemming requires a roller to go back and forth 3 times and the attitude of the roller needs to be adjusted in the middle. Therefore, the hemming efficiency is greatly improved.

Embodiment 2

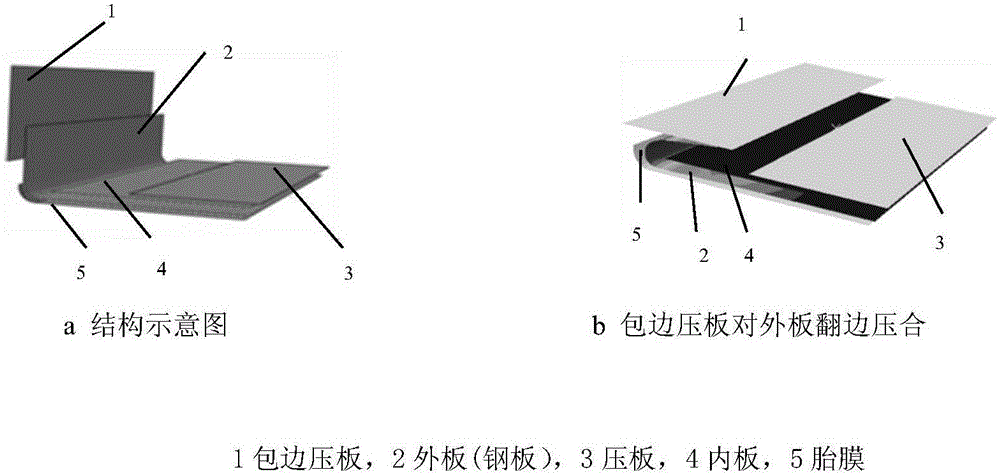

[0025] Such as figure 2 As shown, the invention is used for the hemming of flat straight-edged steel plates. 1 edging platen, 2 outer plate, 3 platen, 4 inner plate, 5 membrane.

[0026] Generally, the steel plate hemming is divided into 2 passes, the outer plate is turned at 90 degrees, and the pressing angle is generally 45 or 90 degrees. However, in this embodiment, the outer plate 2 is turned over by the hemming pressure plate in advance by setting the hemming pressure plate in advance. Complete the hemming, so as to complete the task of traditional hemming that requires a roller to go back and forth twice and adjust the attitude of the roller in the middle. Therefore, the hemming efficiency is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com