A working method of automatic edge wrapping equipment for aluminum alloy doors and windows

A technology for aluminum alloy doors and windows and working methods, which is applied in the direction of mechanical equipment, engine sealing, engine components, etc., can solve the problem that glass and aluminum alloy frames cannot be tightly bonded and assembled together, and aluminum alloy doors and windows cannot be automatically wrapped, The quality of aluminum alloy doors and windows needs to be improved to achieve the effect of facilitating edge wrapping work, reducing processing costs and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

[0046]The drawings are for exemplary description, which is merely a schematic diagram, rather than the experiment, and is not to be understood to be in this patent; in order to better illustrate the embodiments of the invention, there will be omitted, Enlarge or shrink does not mean the size of the actual product.

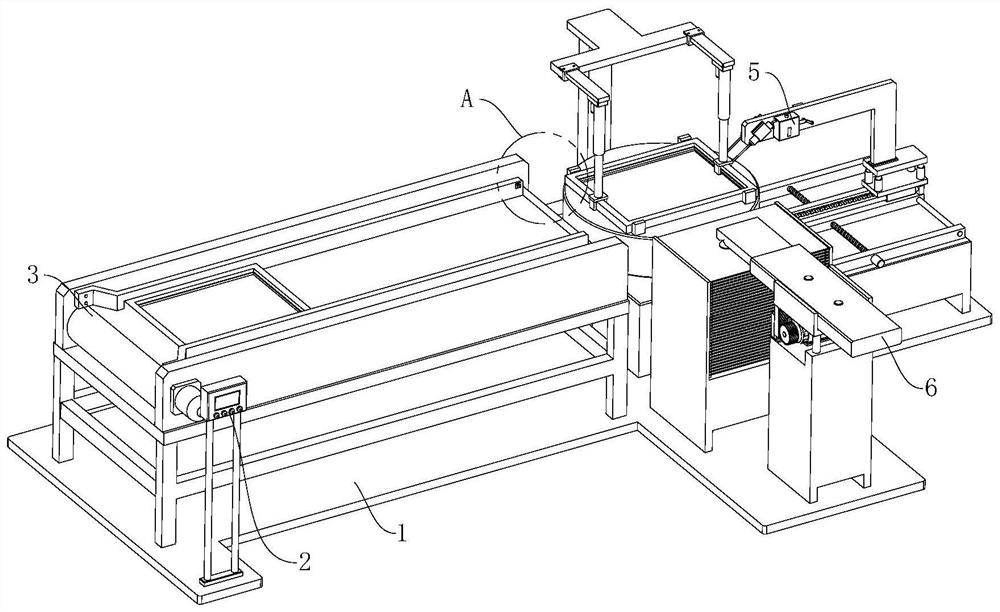

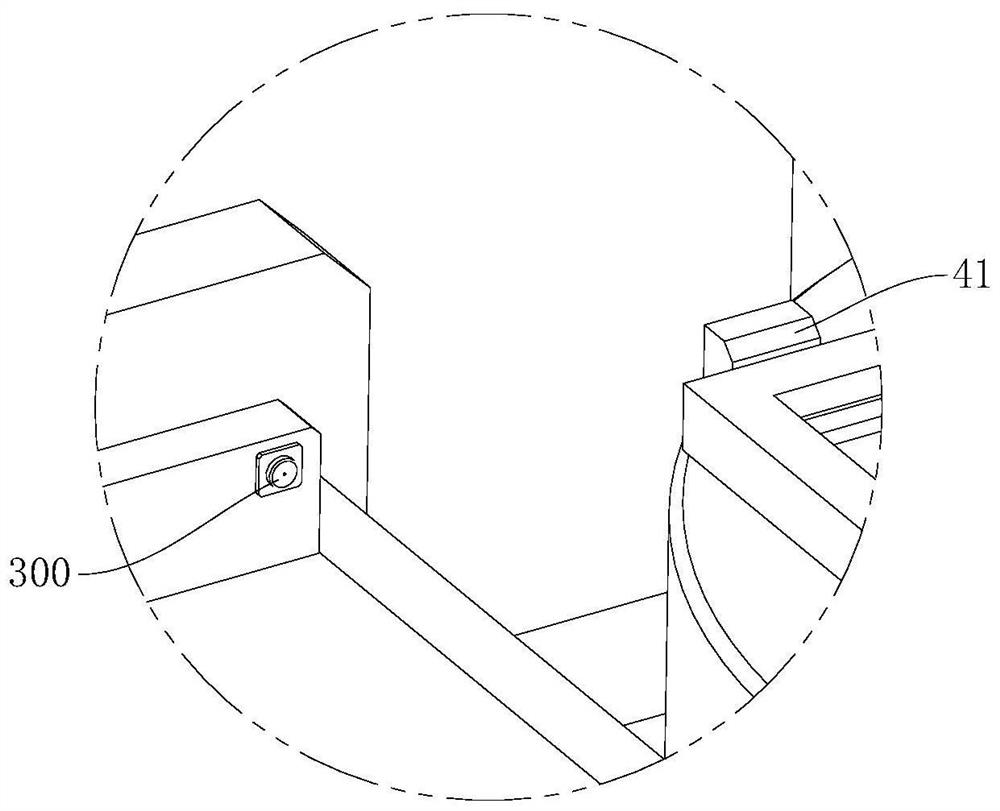

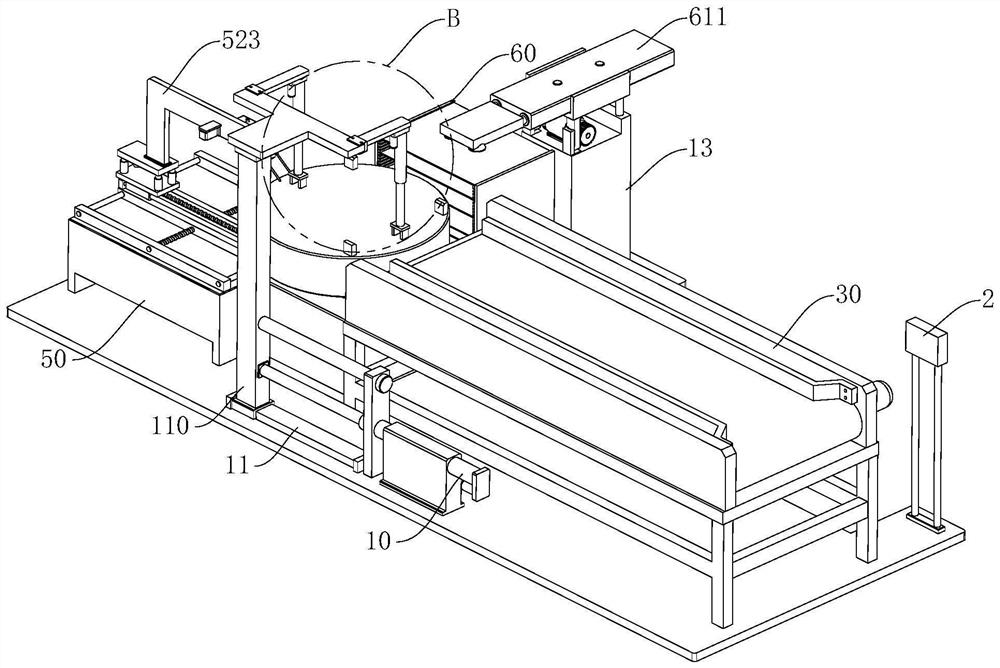

[0047]ReferFigure 1 to 9An aluminum alloy door-to-window automatic edge device, including a base 1, the base 1 is arranged horizontally, further comprising a controller 2, a sheet mechanism 3, a machining station 4, a glue mechanism 5, and mounting mechanism 6, The controller 2 is fixed to the top of the base 1, and the upper mechanism 3 is provided at one end of the top of the base 1 and the upper aluminum alloy frame, the upper mechanism 3 includes a conveyor 30 and a clamp assembly 31, the conveyor 30 The top of the base 1 is provided, the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com