Intelligent rolled edge pressing system for robot and process method

A technology of robot intelligence and process method, applied in the field of automobile manufacturing, can solve the problems of difficult hemming, high cost, poor flexibility, etc., and achieve the effect of short work cycle, simple operation and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

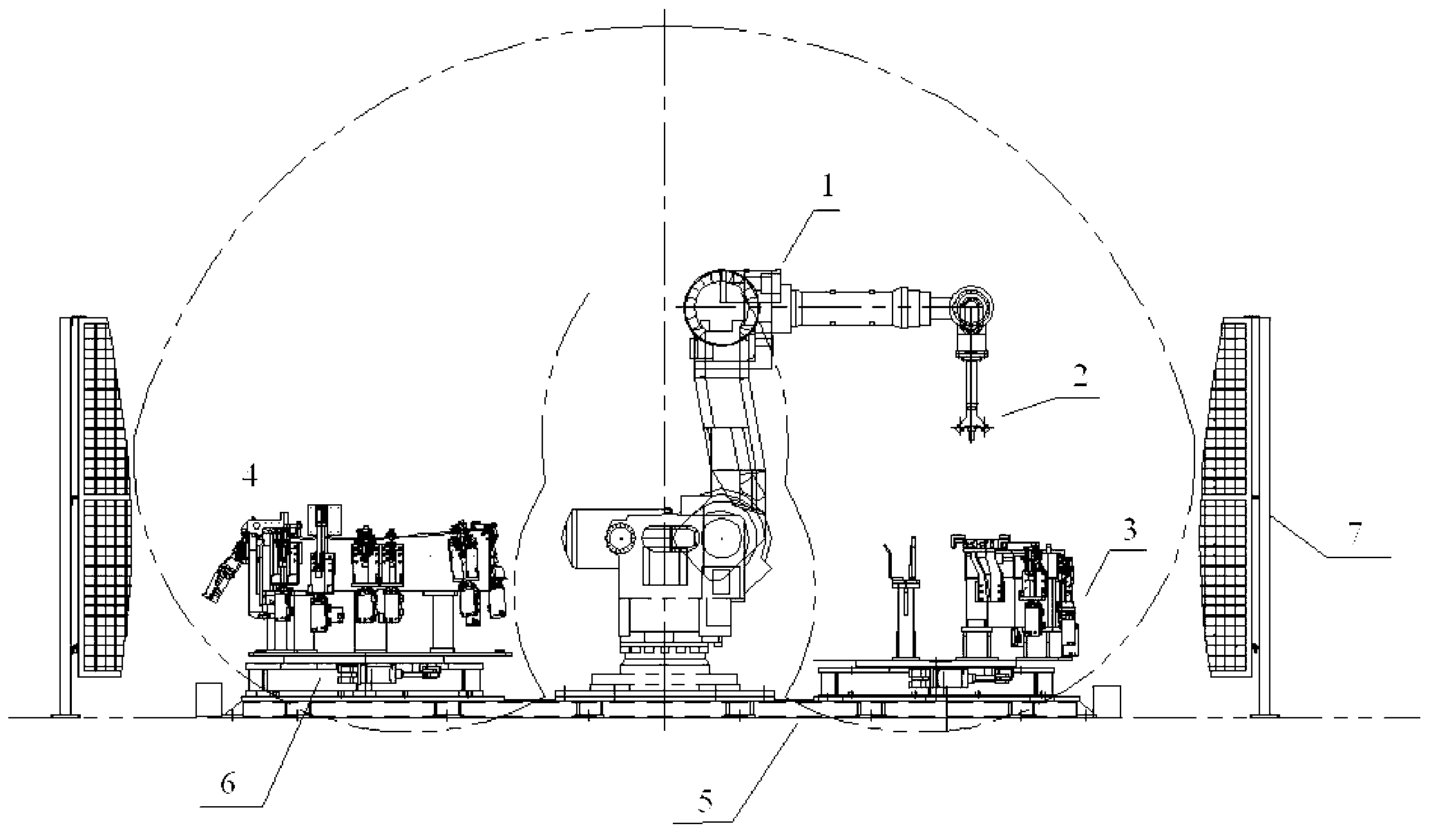

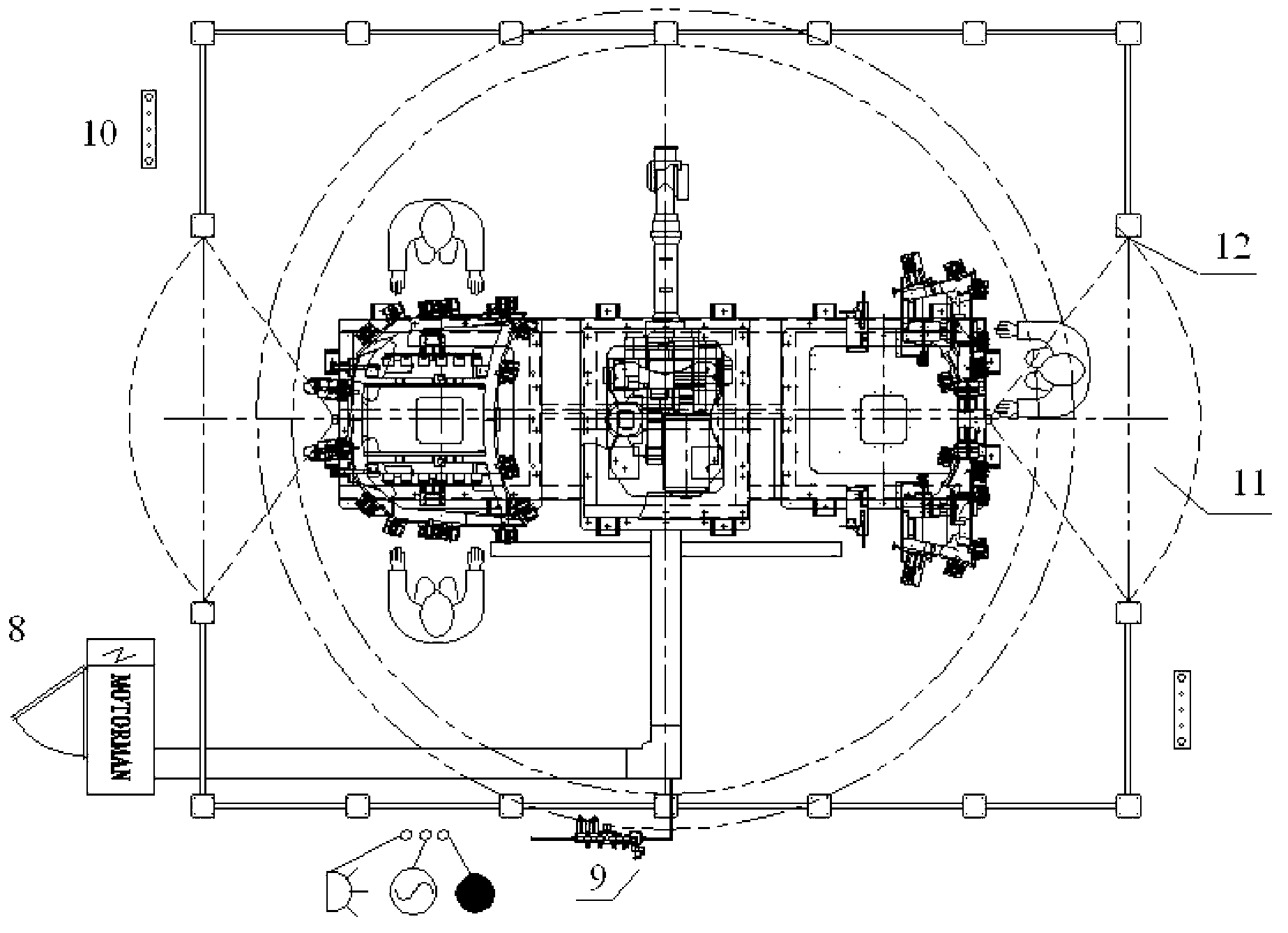

[0030] Please refer to figure 1 and figure 2 , the present invention provides a robot intelligent rolling and pressing system, including a six-degree-of-freedom parallel robot 1, a rolling mechanism, a rotary table 6, a pressing bottom die, automatic control equipment and a safety fence 7, and the robot 1 is placed on both sides Rotary table, robot control cabinet 8, electrical control cabinet, pneumatic triple piece 9 and operating table 10 are respectively arranged on the outer periphery of the safety fence 7, and a laser scanner 12 is arranged on the inner periphery of the safety fence 7, wherein:

[0031] The six-degree-of-freedom parallel robot has six servo axes, which include a robot body, a robot power cable, a signal cable, a robot control cabinet 8, a teaching pendant, and a board;

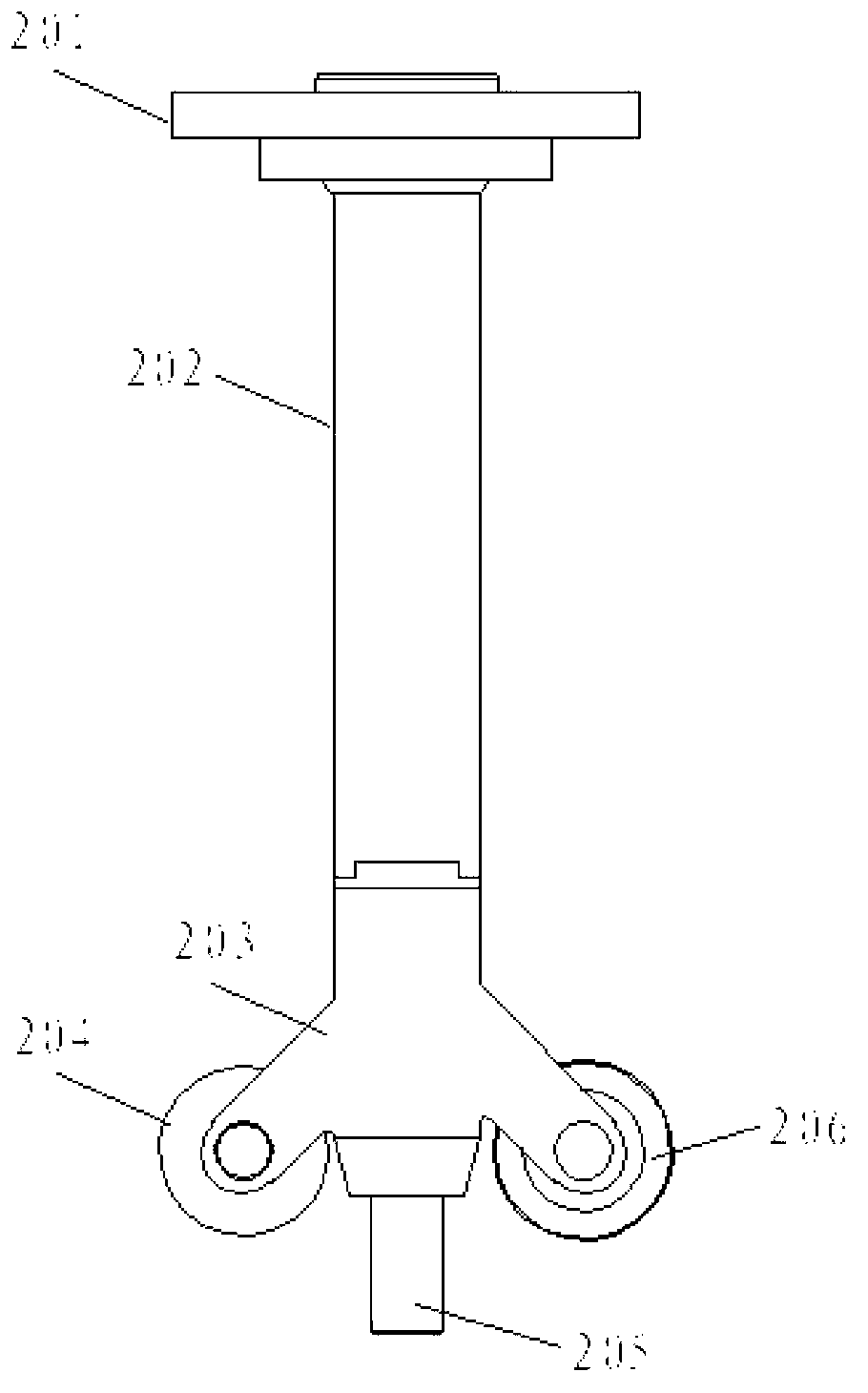

[0032] Please re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com