Patents

Literature

57results about How to "Improve hemming quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

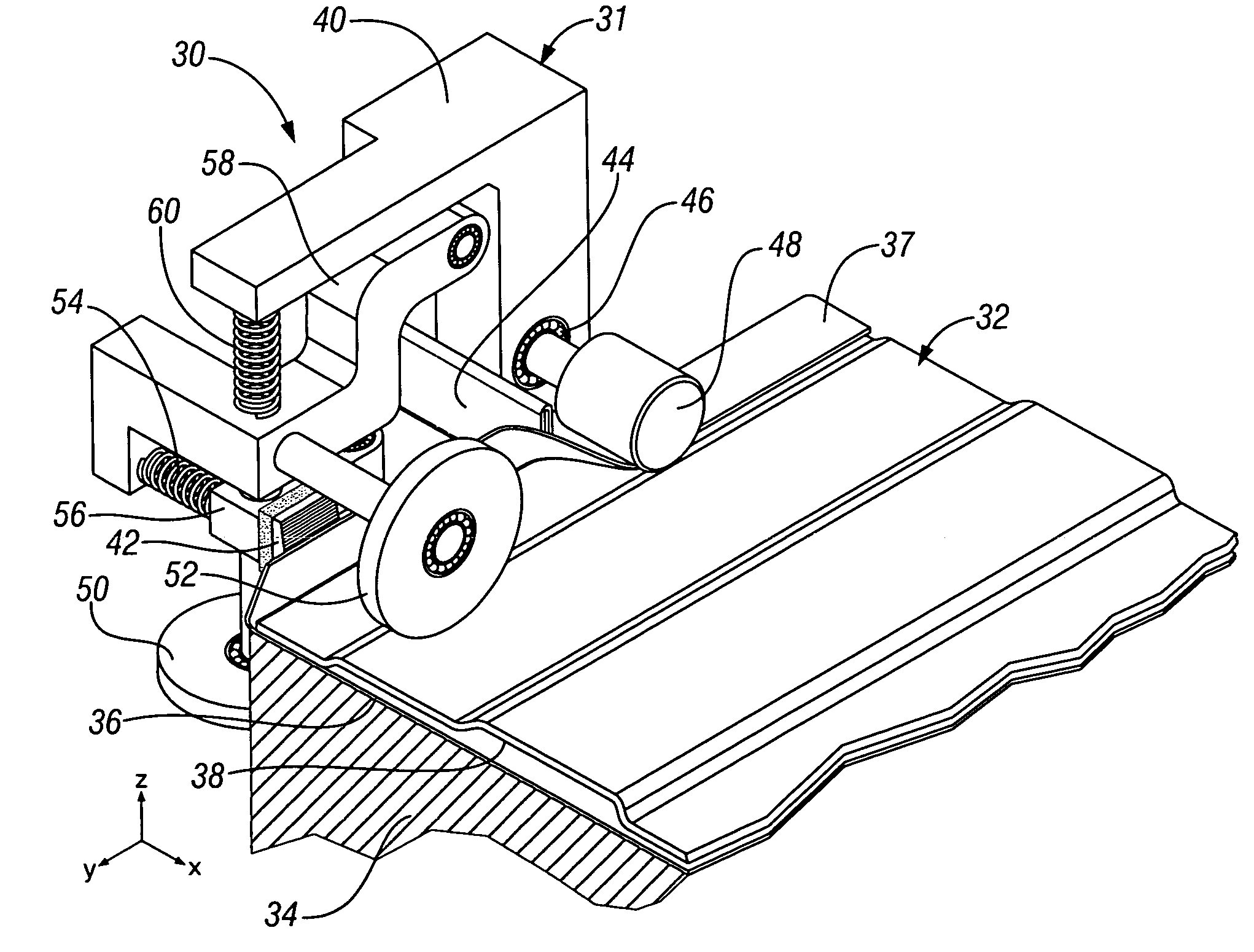

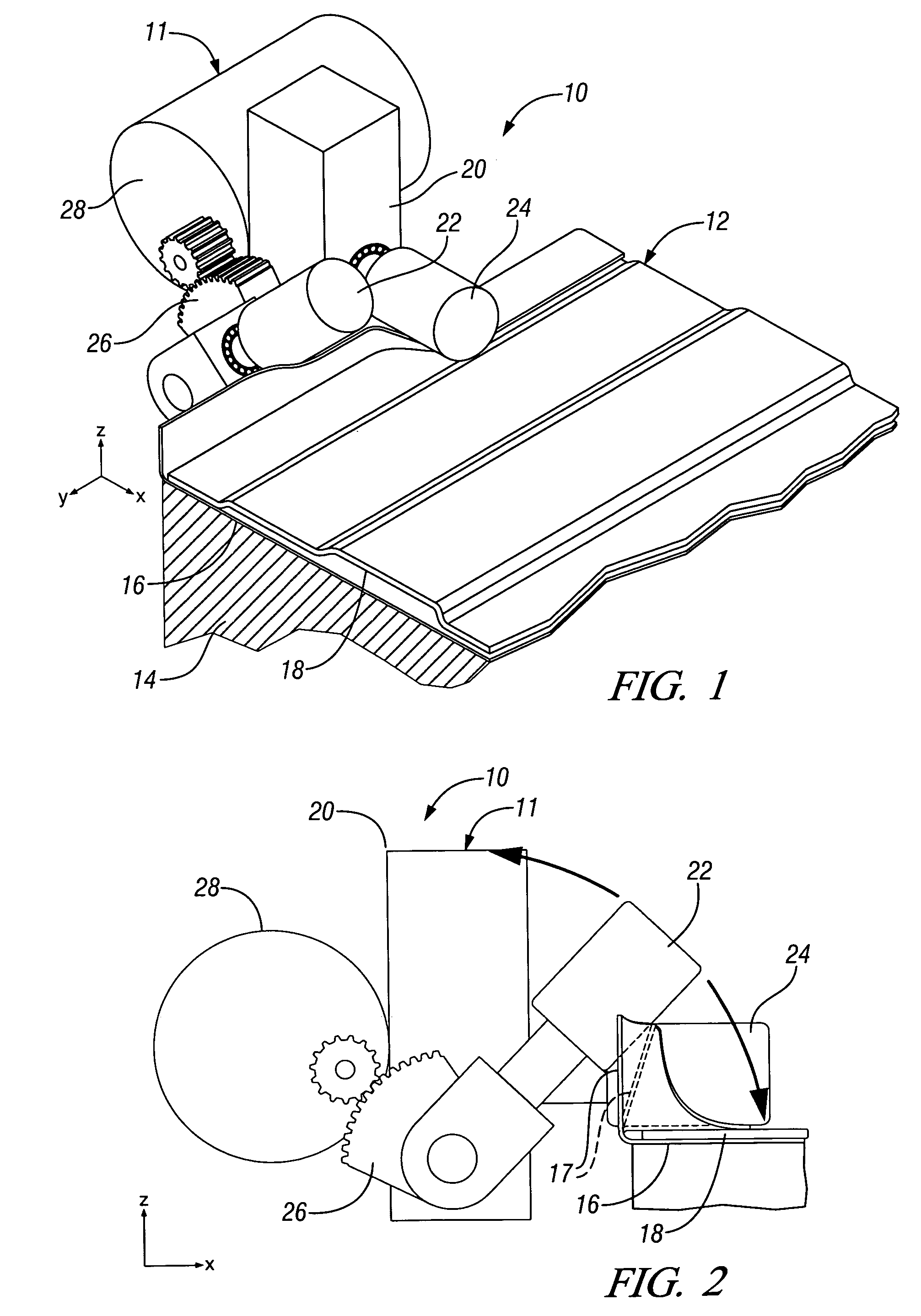

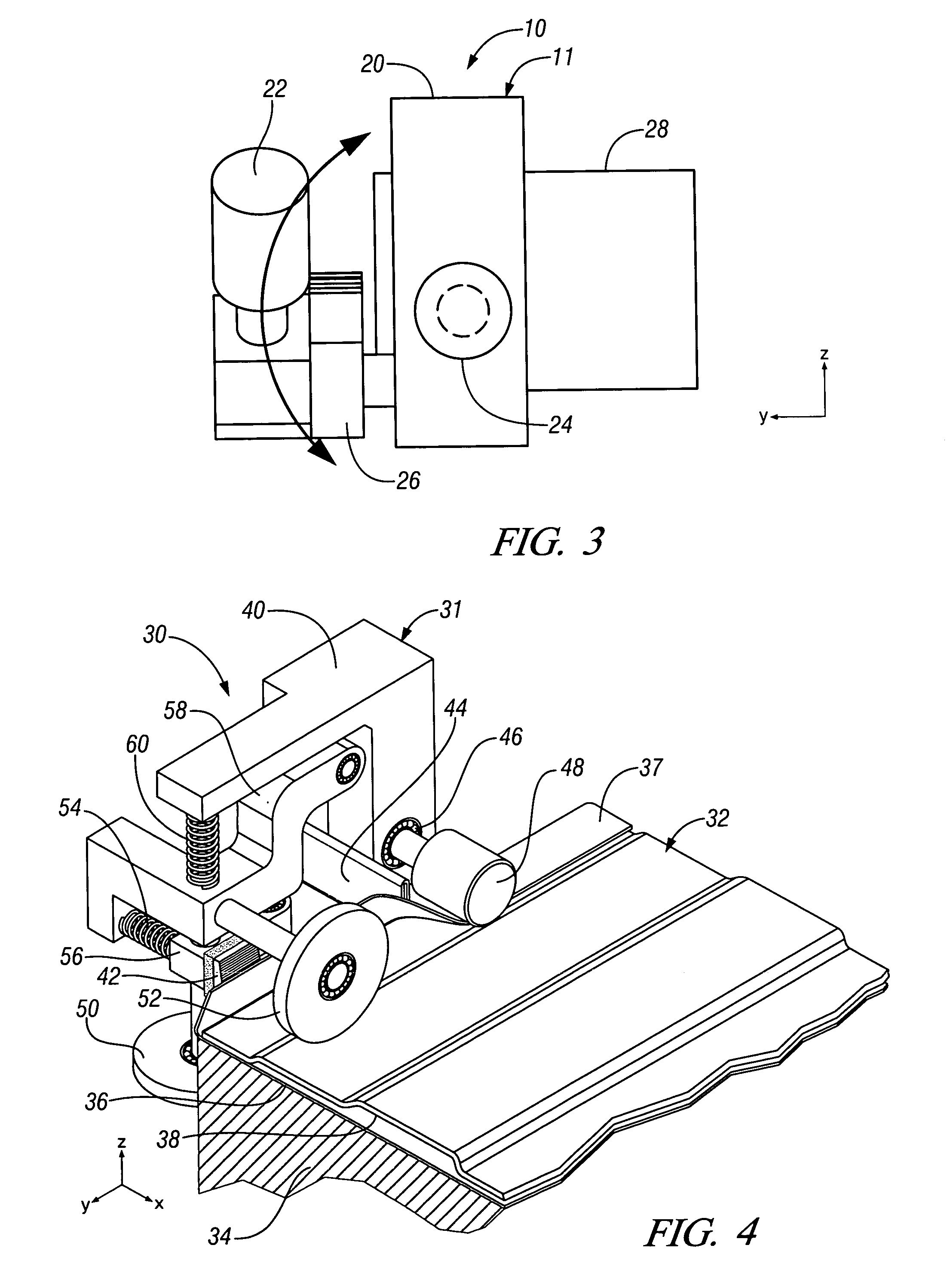

Roller hemming apparatus and method

InactiveUS7290423B2Improve hemming qualityShorten cycle timeHeating/cooling devicesEngineeringQuenching

Various embodiments of roller hemming apparatus and methods are disclosed including one wherein multiple rollers are carried on a single mount to hem a flange in a single pass, another including induction heating and air quenching means movable with a roller to anneal the flange just prior to hem forming, and another in which friction from a rotatably driven roller heats the flange to reduce bending stresses during hemming of the flange.

Owner:GM GLOBAL TECH OPERATIONS LLC

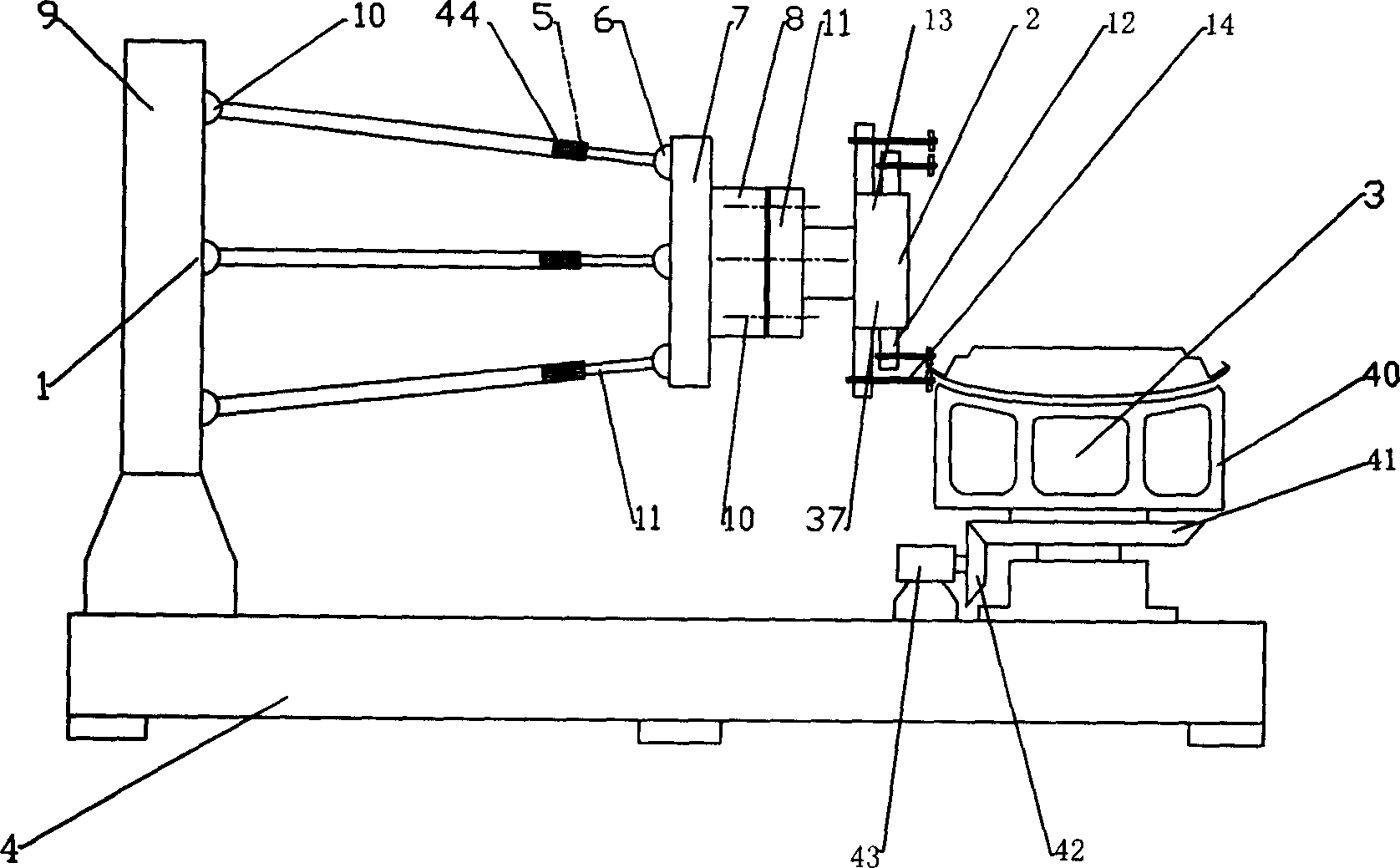

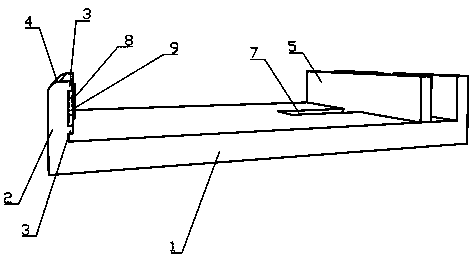

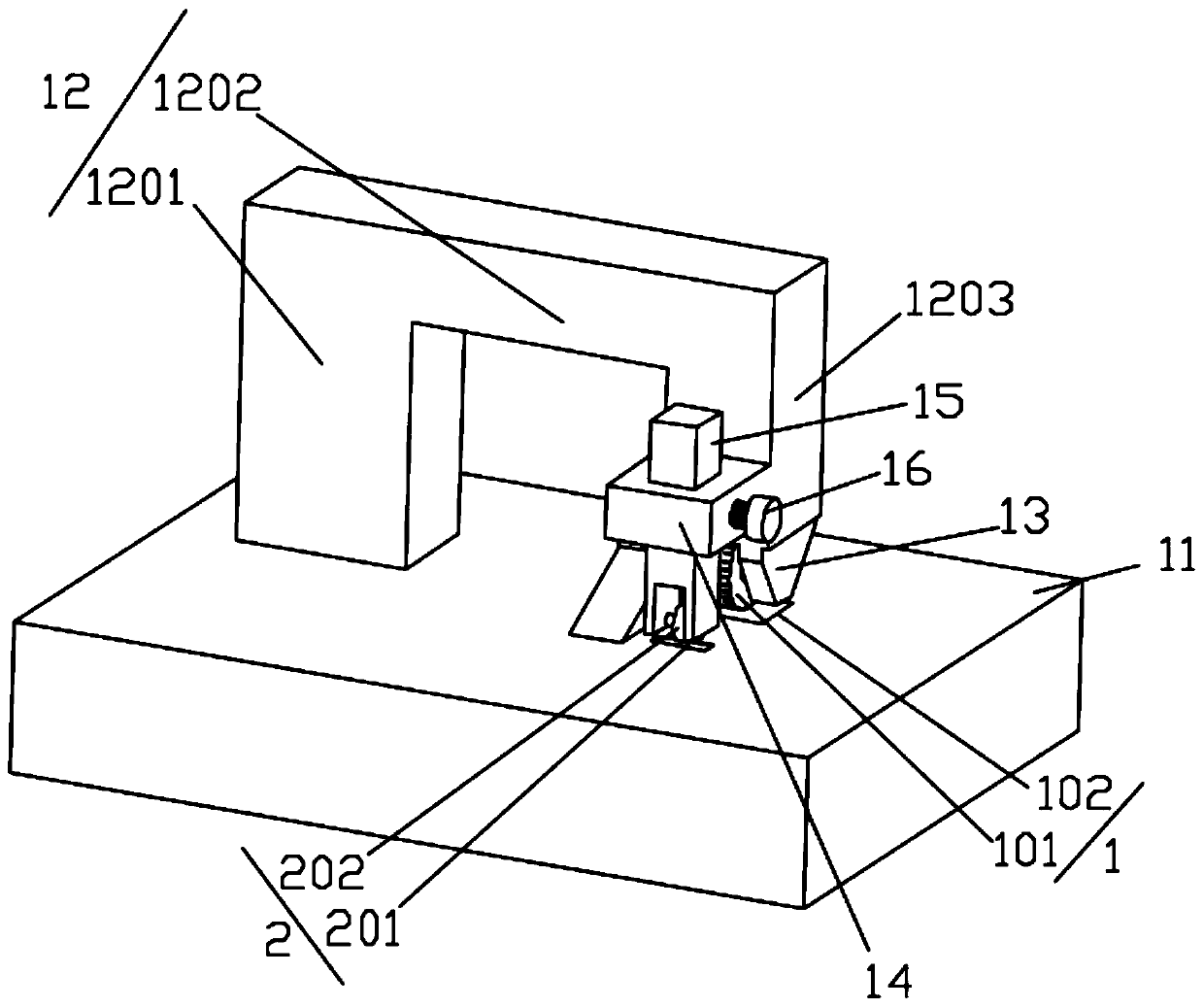

Parallel robot edge-coating system with a rotary table

InactiveCN1669694AHigh precisionTroubleshoot workspace issuesProgramme-controlled manipulatorLarge fixed membersCoating systemEngineering

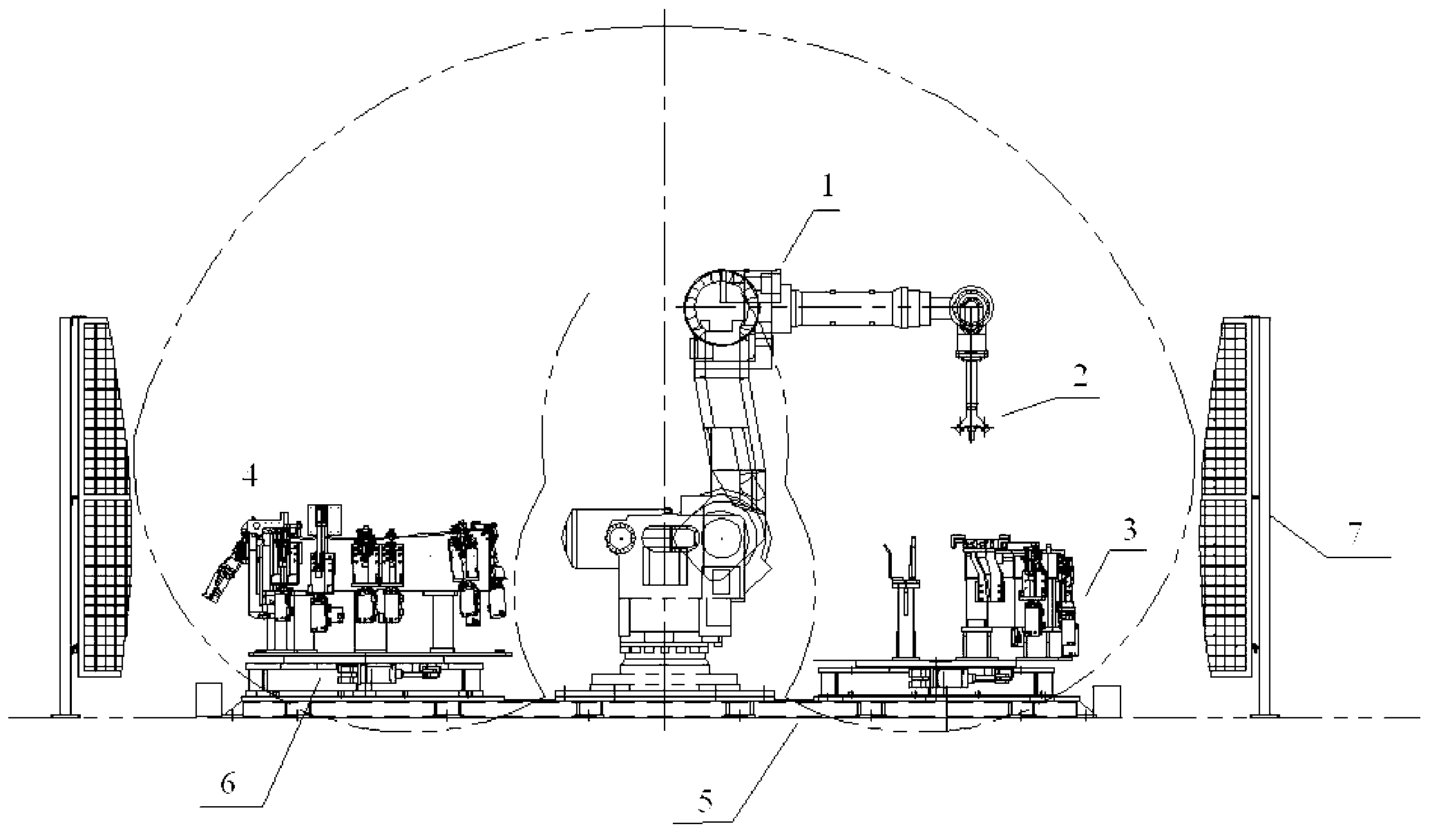

This invention relates to parallel-type robot system for edge covering with rotating table, comprising six-degrees freedom parallel-type robot attached with rolling machine and driving it to move roller along edge direction; rolling machine equipped with work piece and rotating table preparing the other side of work piece to be ready-covered edge. The invention has the advantages of high accuracy to improve edge-covering efficiency and quality.

Owner:SHANGHAI JIAO TONG UNIV

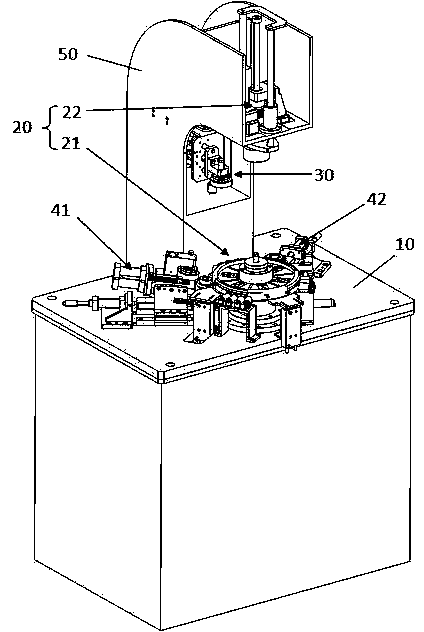

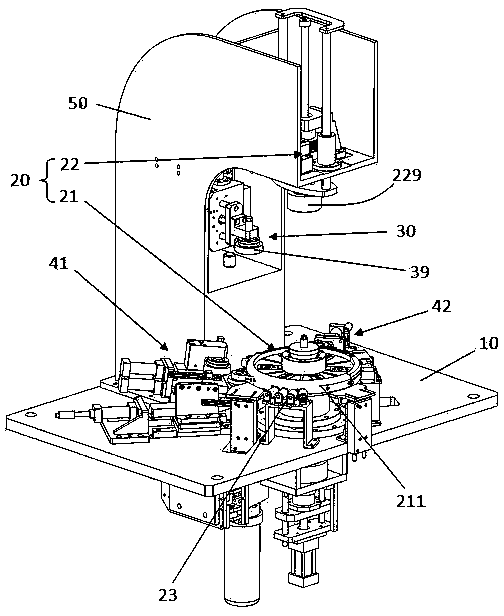

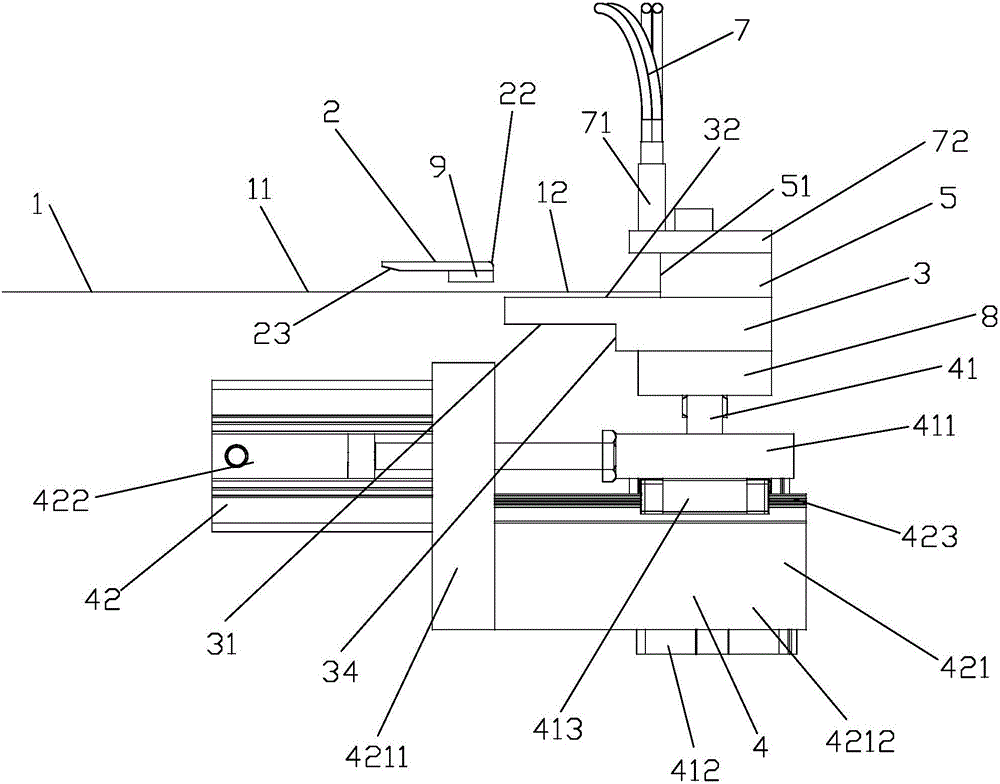

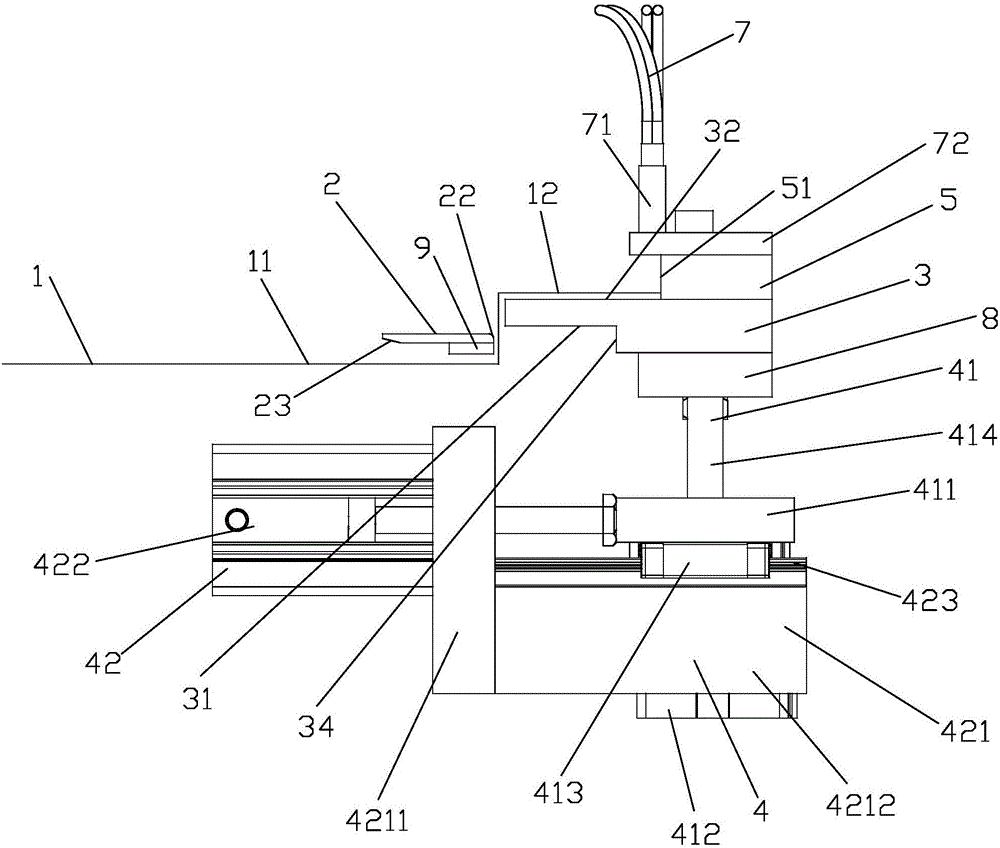

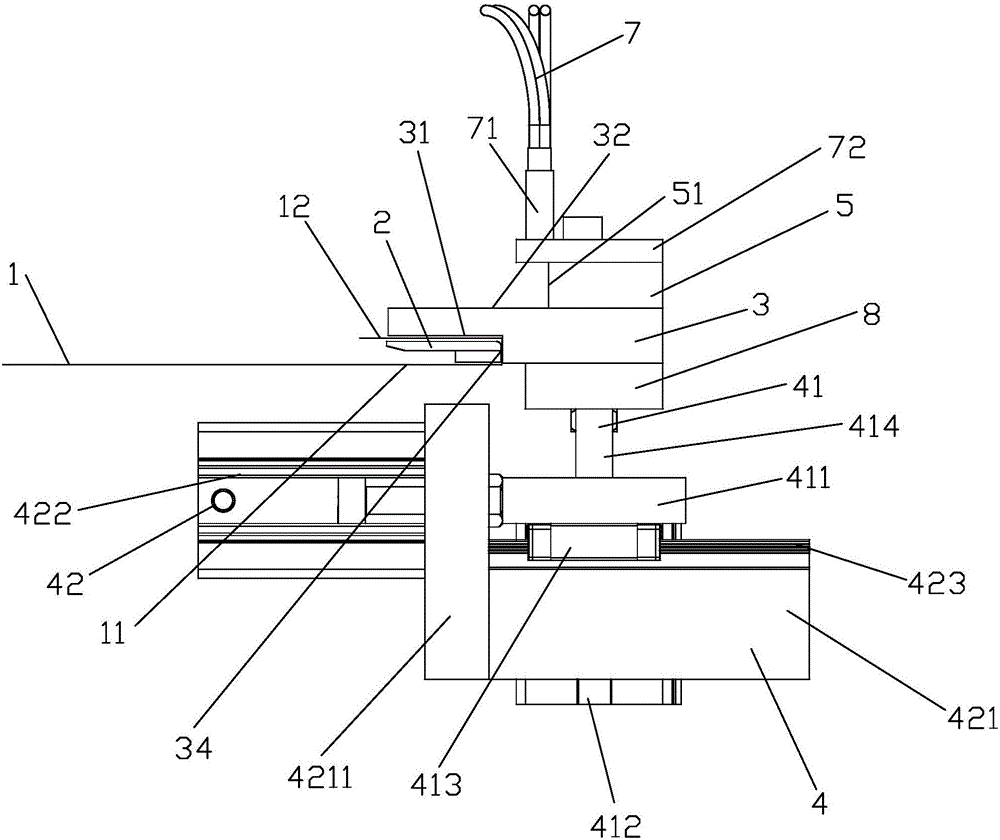

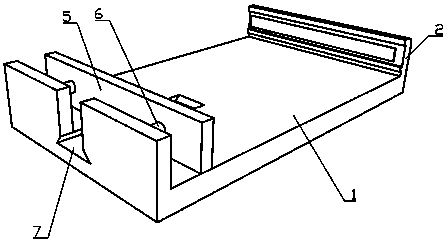

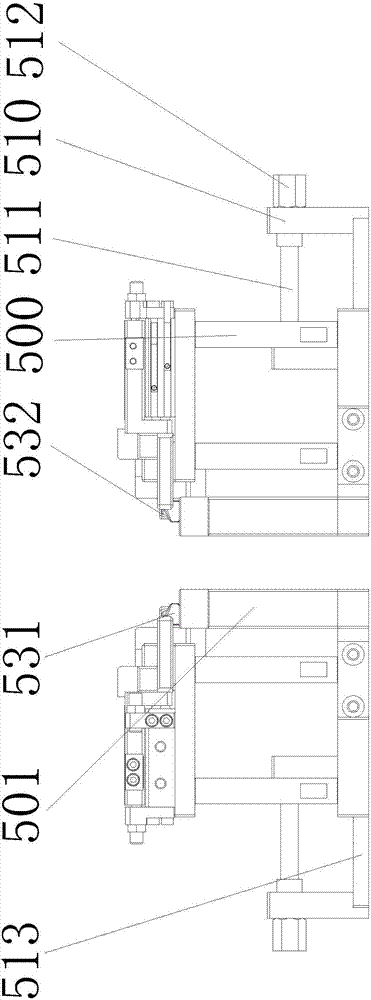

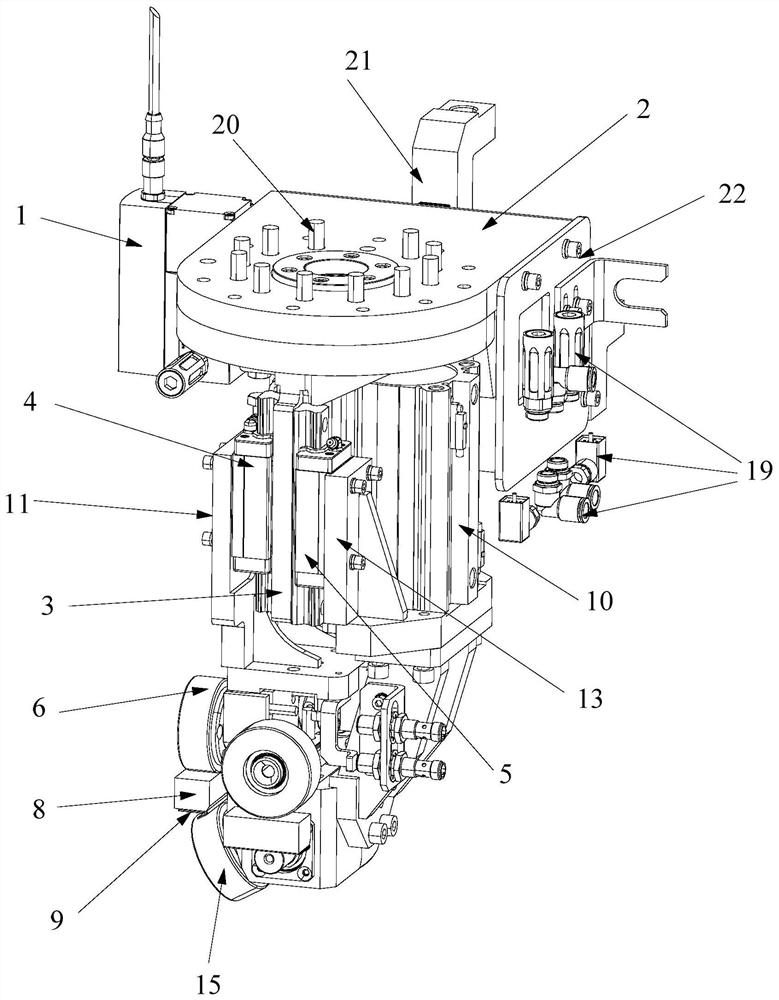

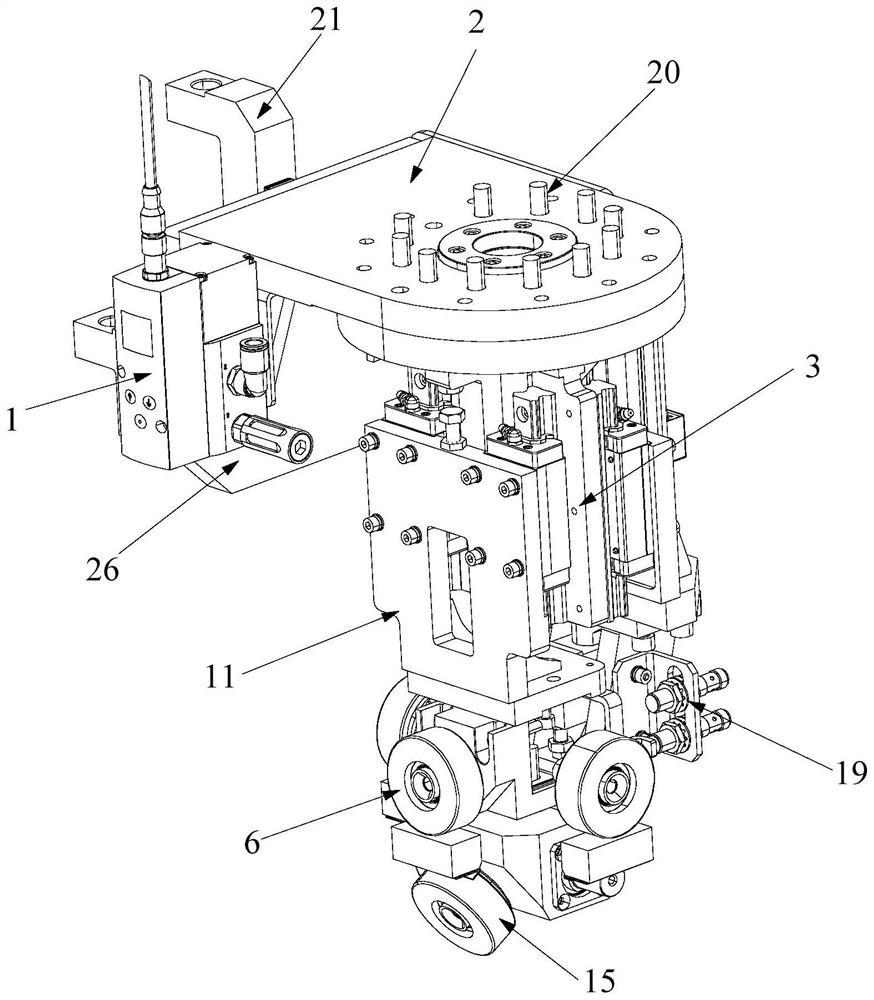

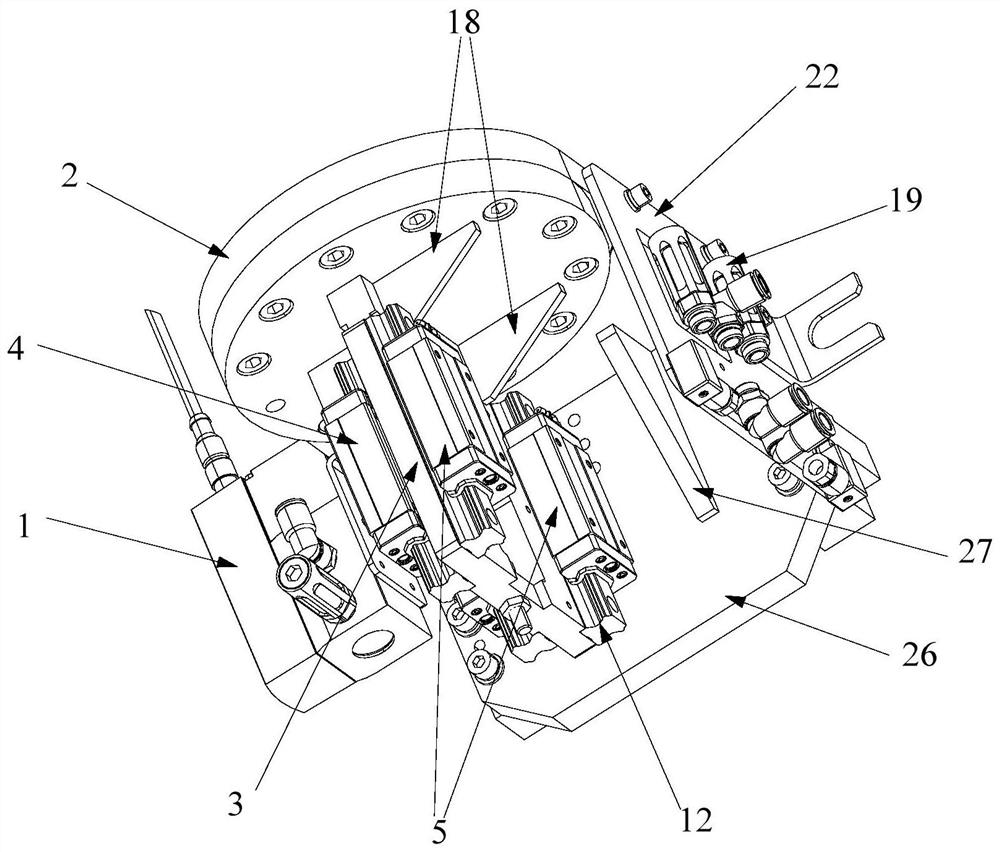

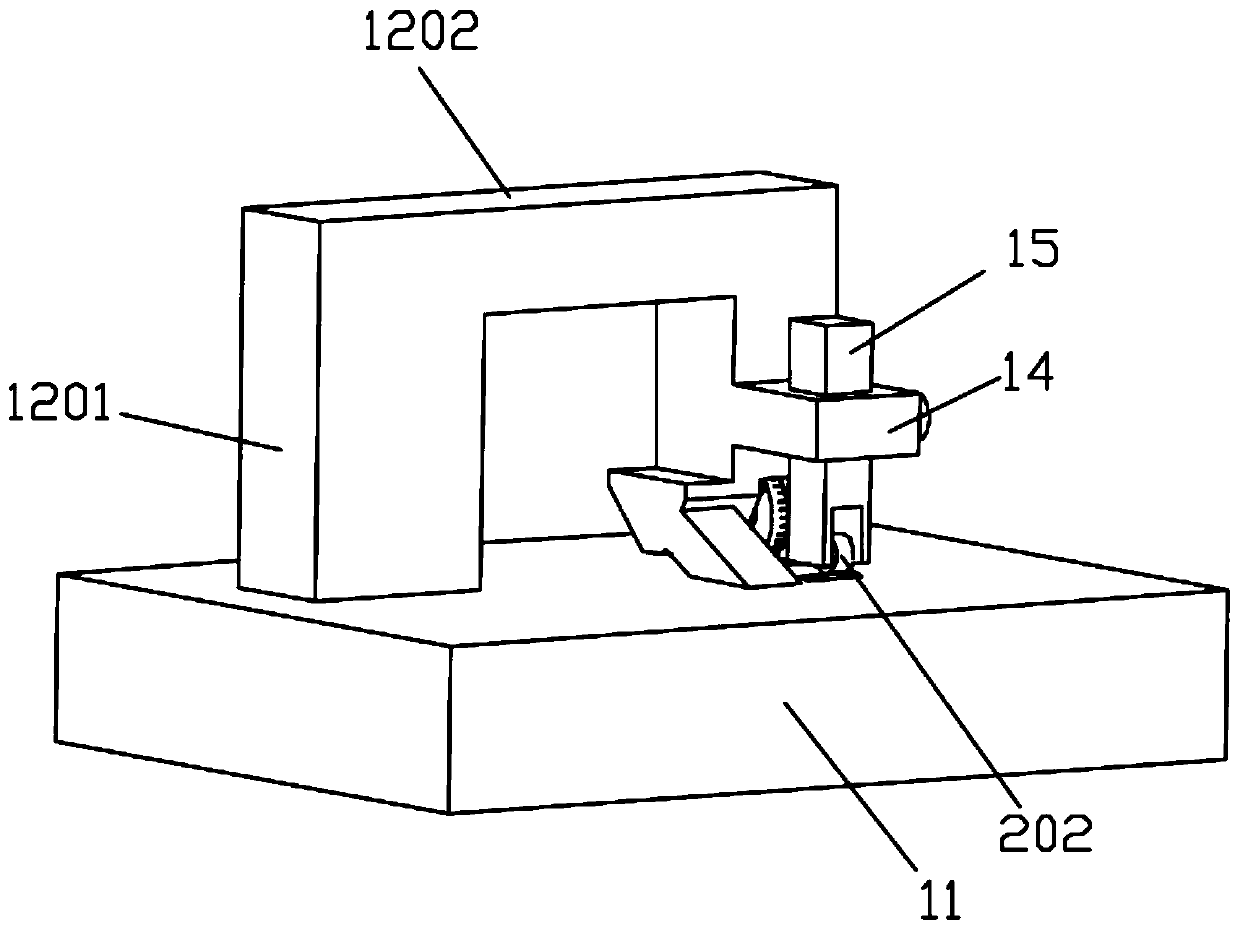

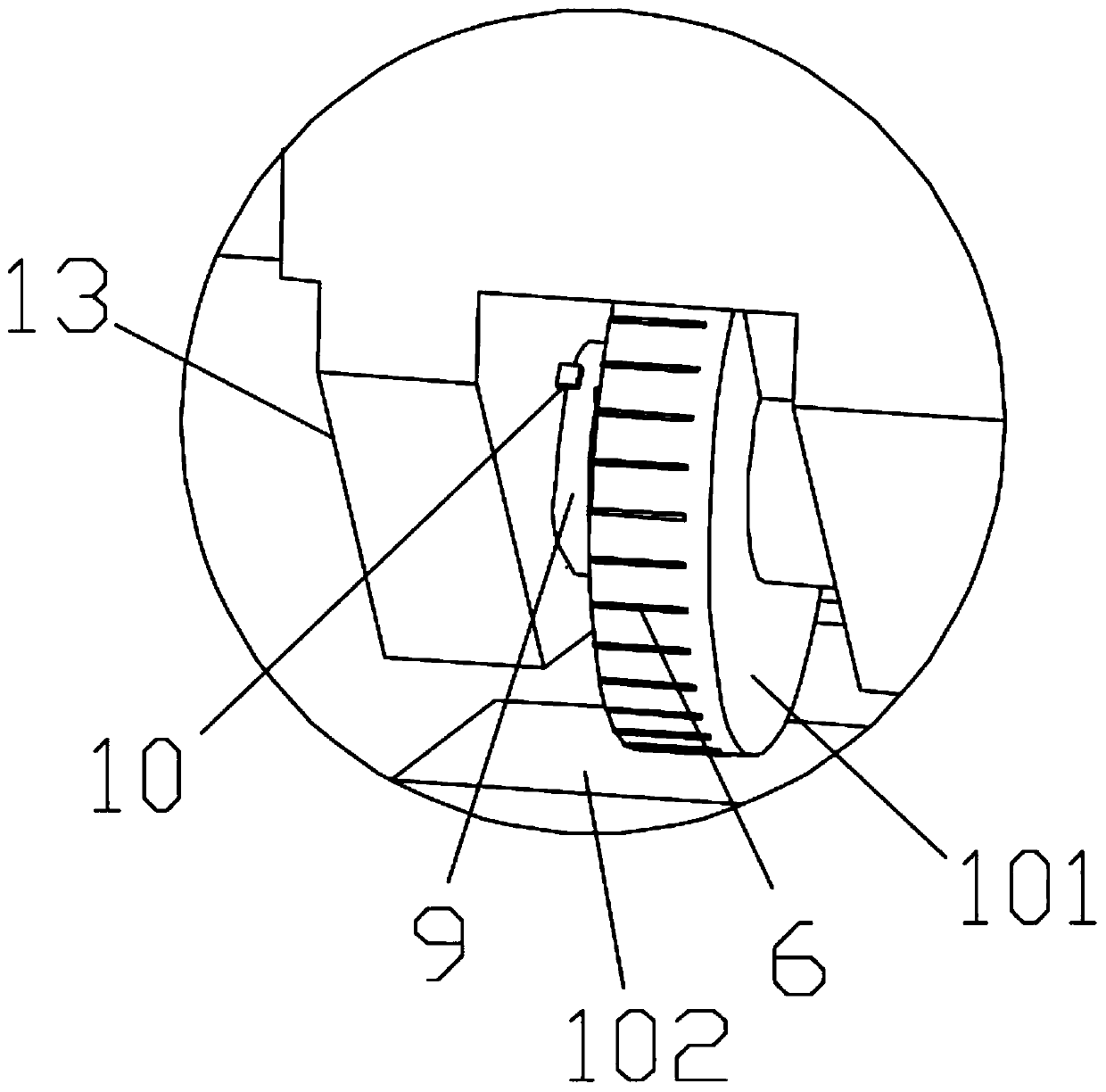

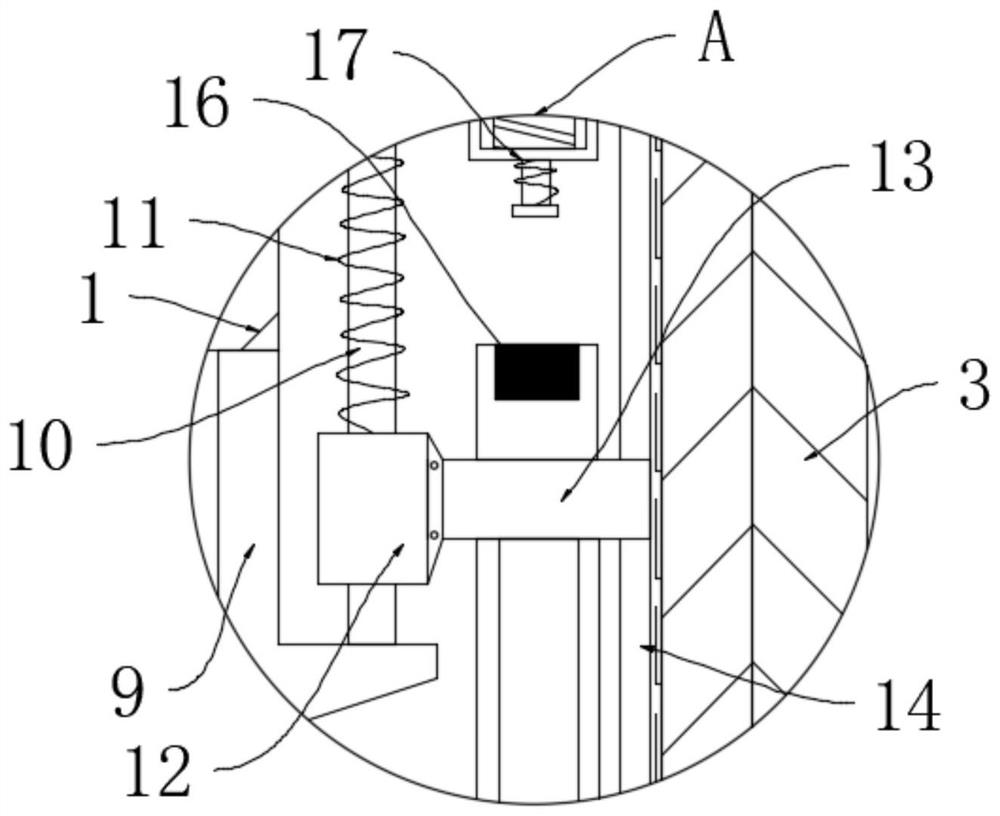

Intelligent rolled edge pressing system for robot and process method

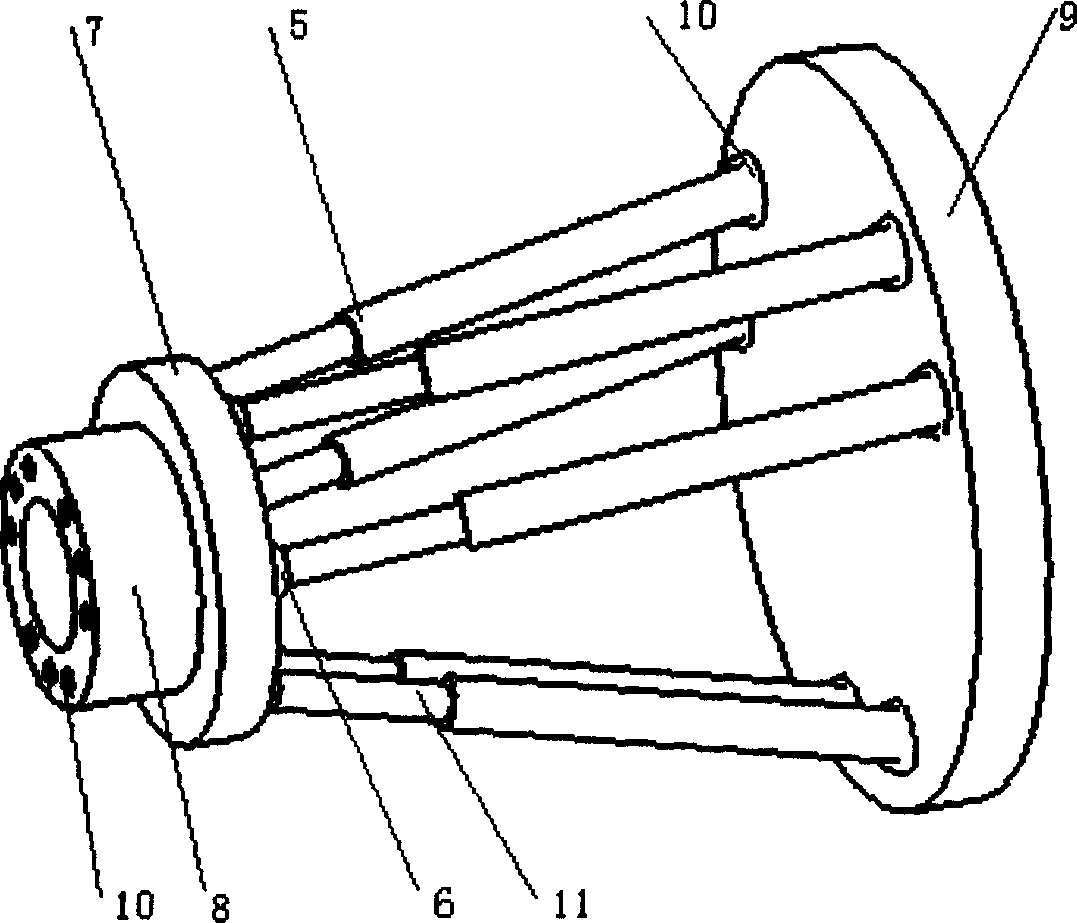

The invention discloses an intelligent rolled edge pressing system for a robot and a process method. The intelligent rolled edge pressing system for the robot comprises a six-degree-of-freedom parallel robot, a rolling mechanism, a rotary workbench, a pressing bottom die, automatic-control equipment and safe equipment, wherein the rolling mechanism consists of a flange plate, a connecting rod, a rolling head mounting block, a flat idler wheel, a straight idler wheel and a step wheel, and the flat idler wheel, the straight idler wheel and the step wheel are installed on the mounting block. The connection relationship of a main body is as follows: the six-degree-of-freedom parallel robot is connected by the flange plate and drives the rolling mechanism to enable a roller to move along the wrapping direction, a workpiece is arranged on the rotary workbench, and the other edge of the workpiece becomes an edge to be wrapped due to the rotation of the rotary workbench. The intelligent rolled edge pressing system for the robot, which is disclosed by the invention, has the advantage of high precision, and the wrapped edge forming quality is enabled to be good; a workbench has a bigger flexibility on workpieces of various shapes due to the controllability of the workbench; arrangement errors introduced in by multi-time clamping are avoided; and the processing time is shortened so as to improve the wrapping efficiency and the wrapping quality.

Owner:CHANGSHA CTR ROBOTICS

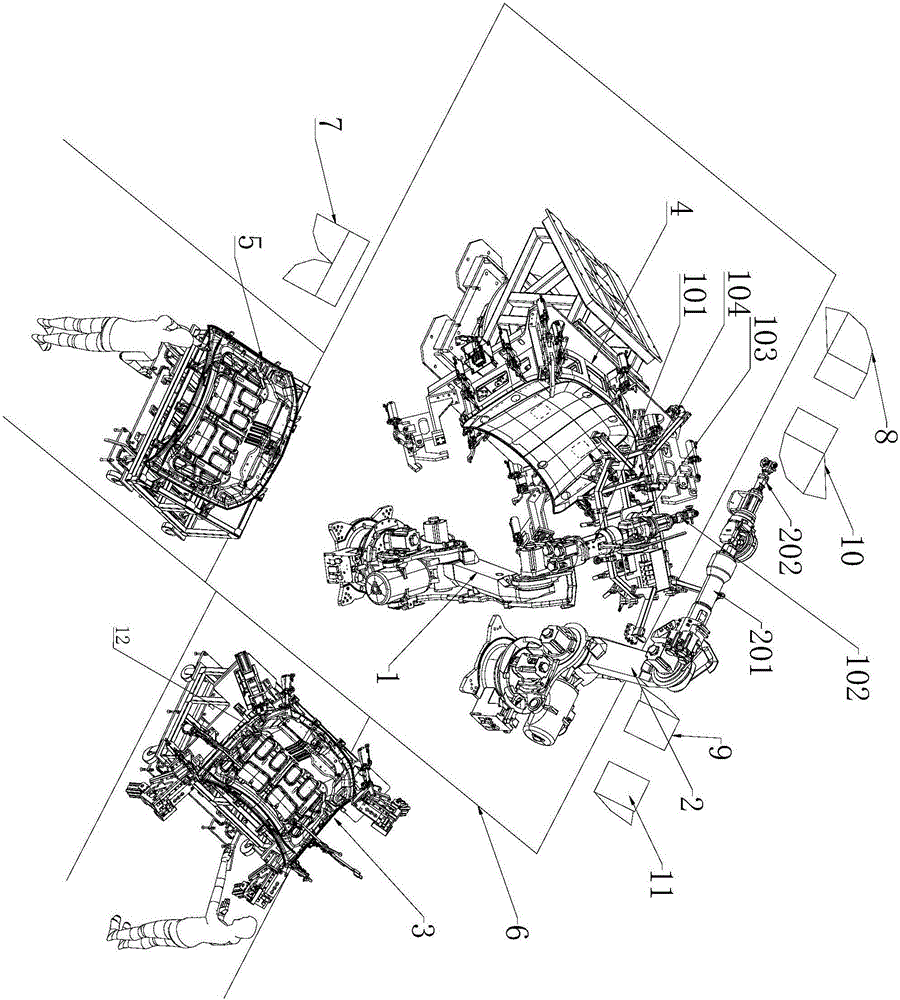

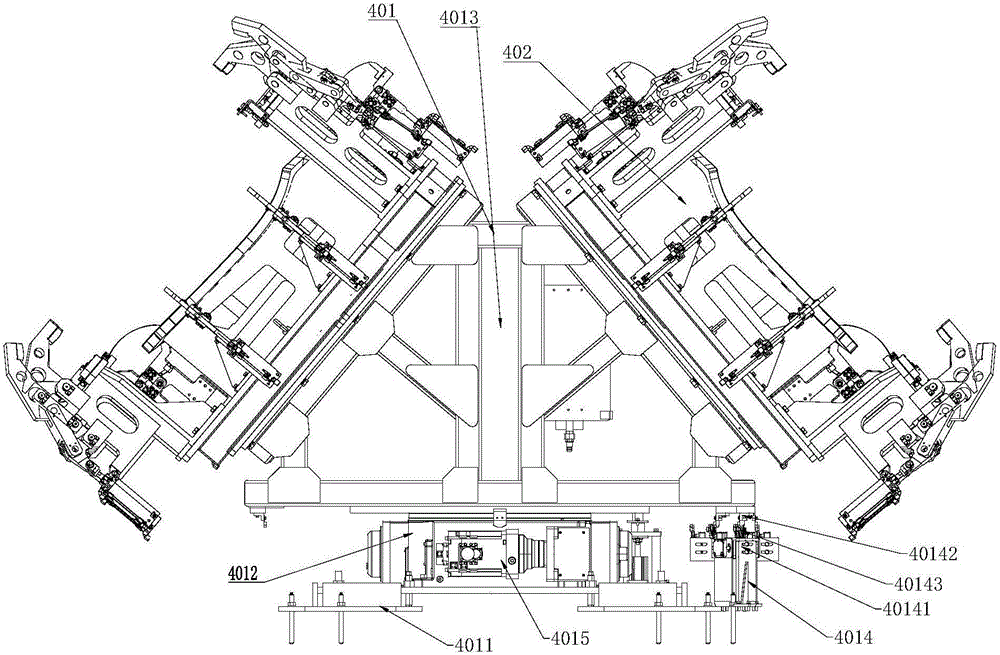

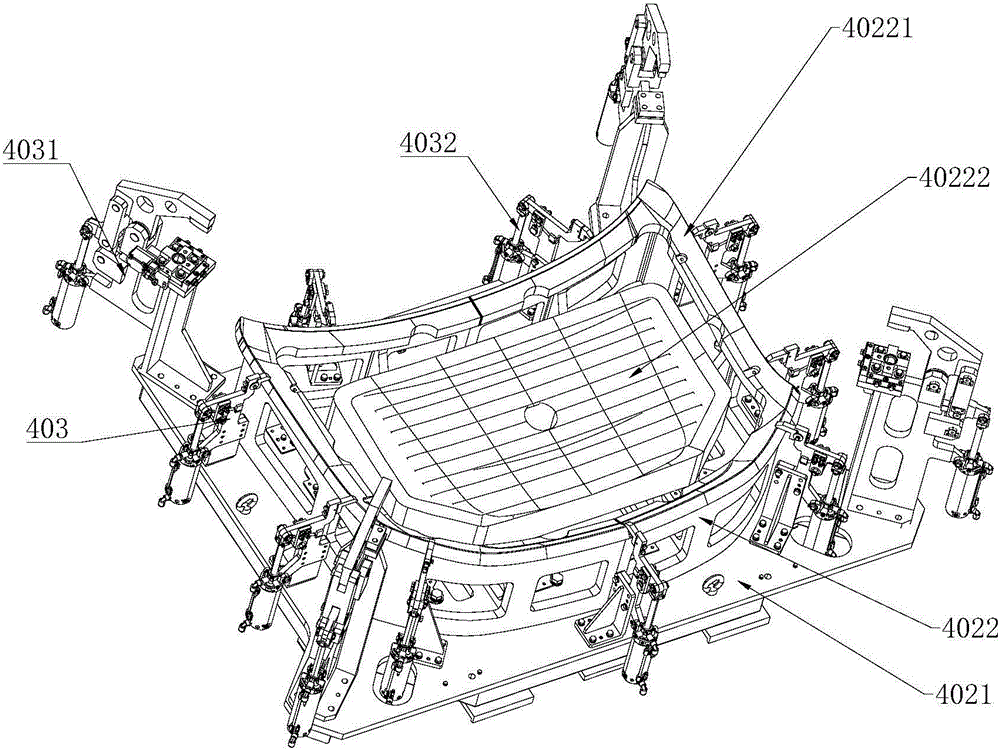

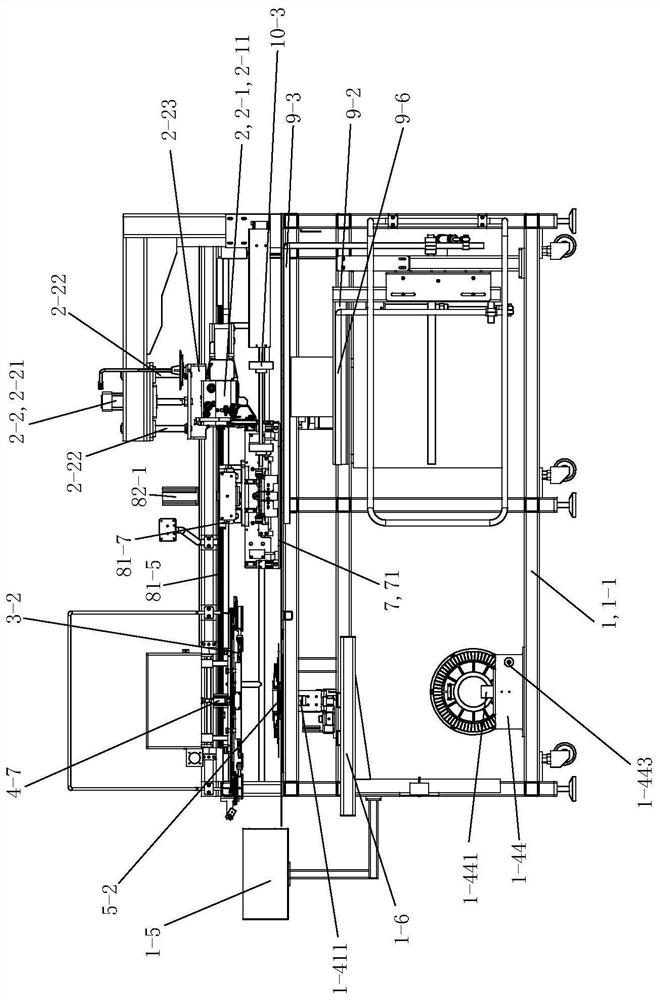

Robot intelligent rolling and edge covering system and robot intelligent rolling and edge covering method

ActiveCN105921629AIncrease flexibilityHigh precisionMetal-working feeding devicesPositioning devicesLocking mechanismCovering system

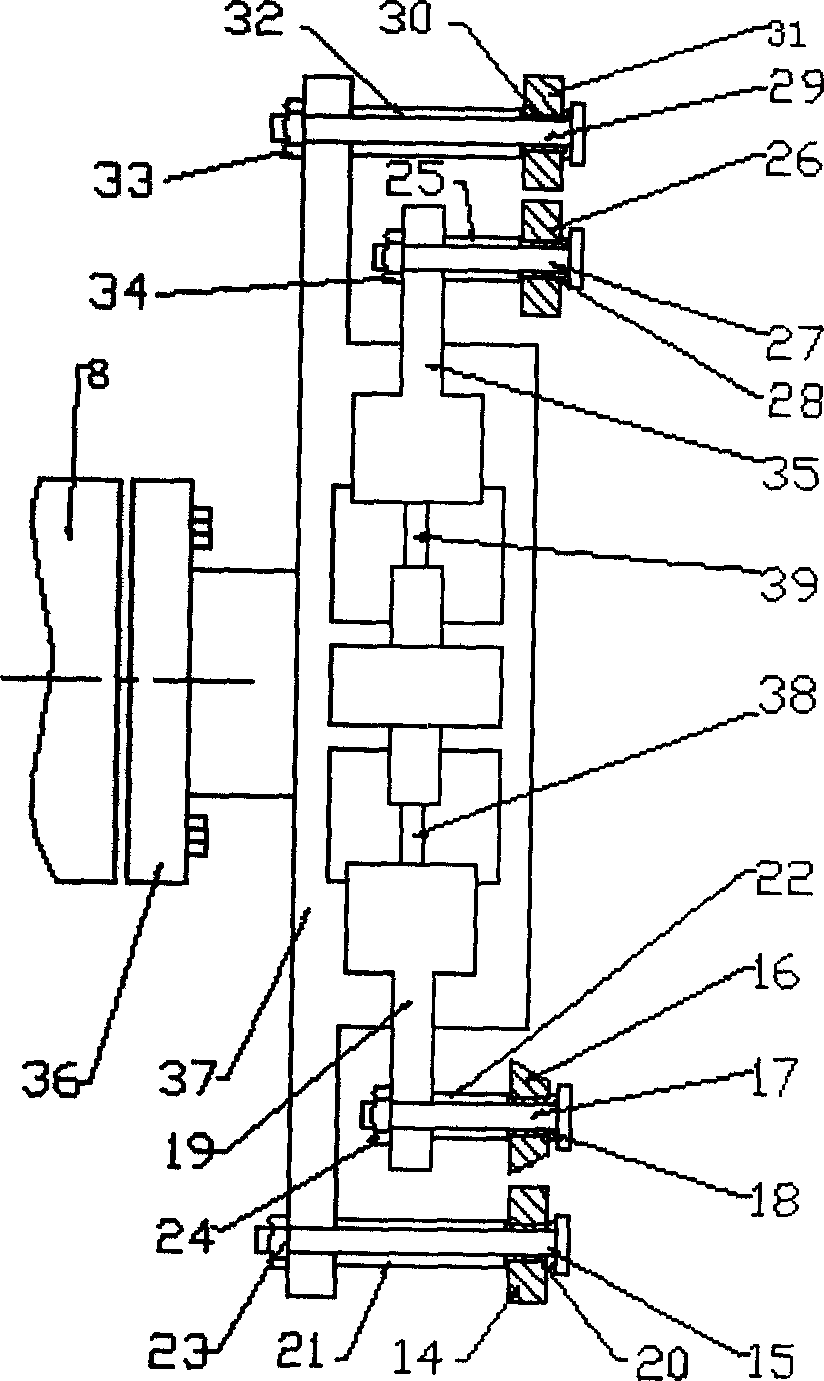

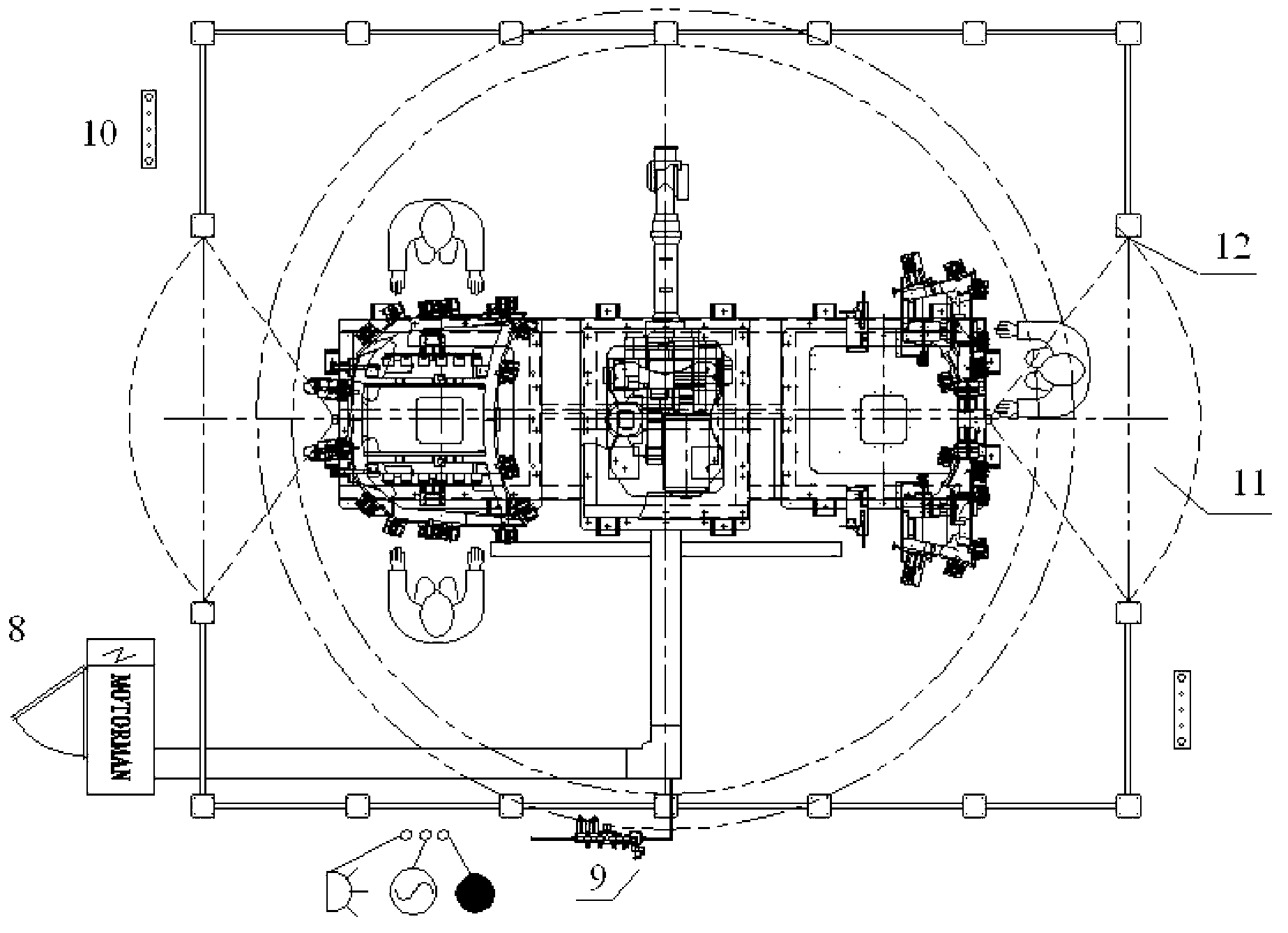

The invention discloses a robot intelligent rolling and edge covering system and a robot intelligent rolling and edge covering method. The system comprises a robot A, a robot B, a part feeding table, a worktable and a part laying-off table; the system is also provided with safety fences, a main control cabinet, a power cabinet and the like; idler wheel systems are respectively mounted on the robot A and the robot B; the robot A is also connected with a work piece positioning claw through a tool automatic-switching device; the worktable comprises a worktable bracket and a tire membrane device; a vacuum plate and a rolling guiding and positioning system are arranged on the tire membrane device; the tire membrane device comprises a claw locking mechanism and outer plate guiding devices; the outer plate guiding devices act in a grouped manner to position outer plates of work pieces. The system disclosed by the invention has the advantage of high precision and is relatively high in flexibility on the shape of each work piece; during a work piece transportation process, setting errors caused by many times of clamping are prevented, the machining time is shortened, and the work efficiency and the edge covering quality are improved; the system is capable of automatically detecting and controlling the machining process, so high flexibility is realized, good technical effects are achieved, and the working procedures are short; therefore, the system is adaptive to the development trend of the overall automobile industry, simple to operate, safe and reliable.

Owner:GUANGZHOU RISONG HOKUTO AUTOMOTIVE EQUIP CO LTD

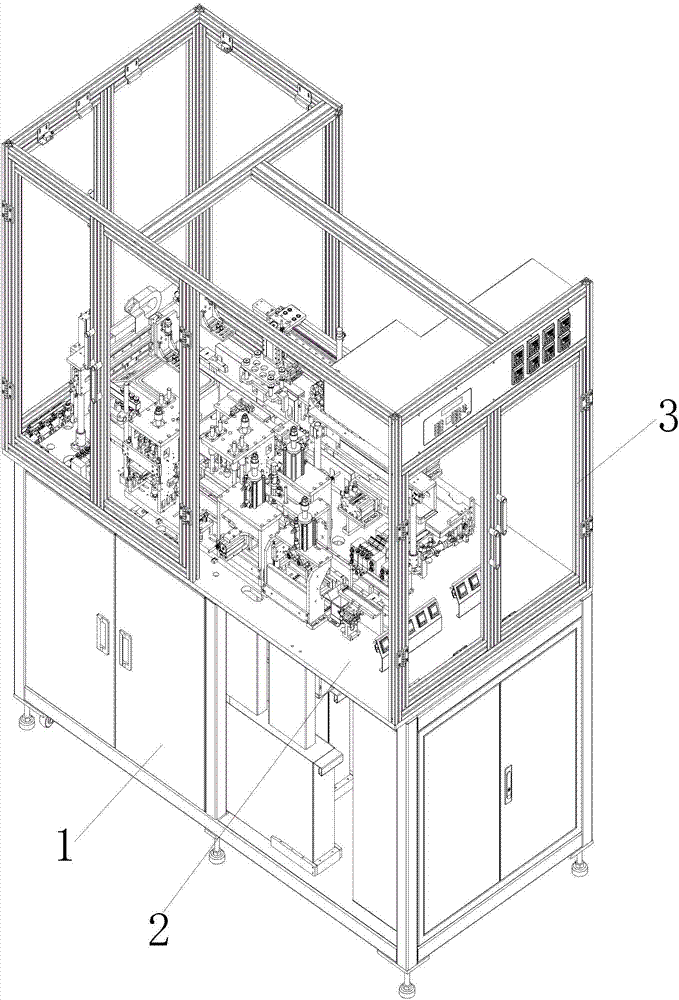

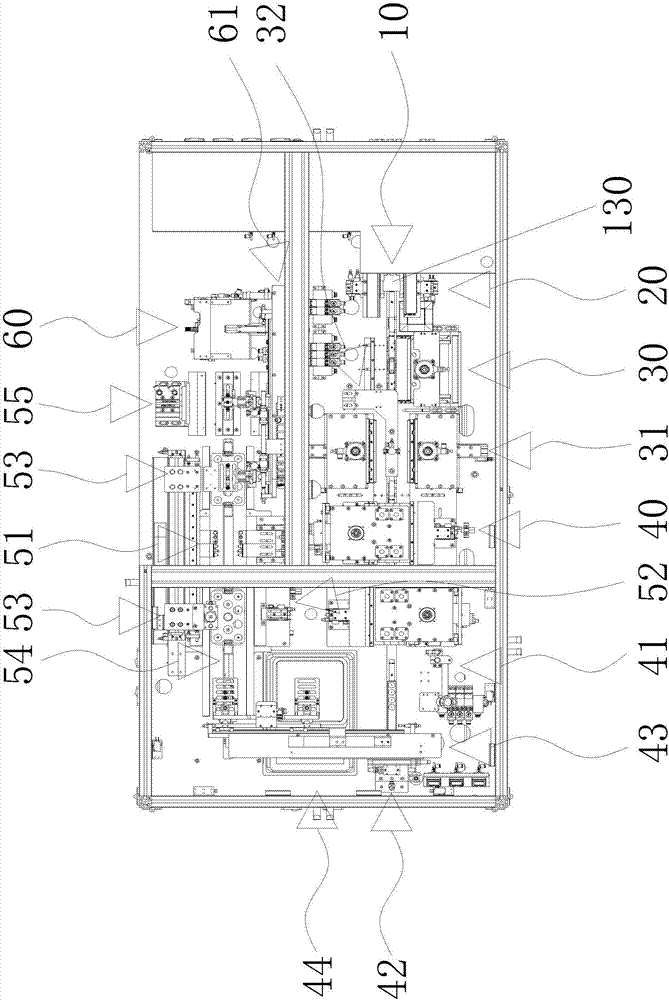

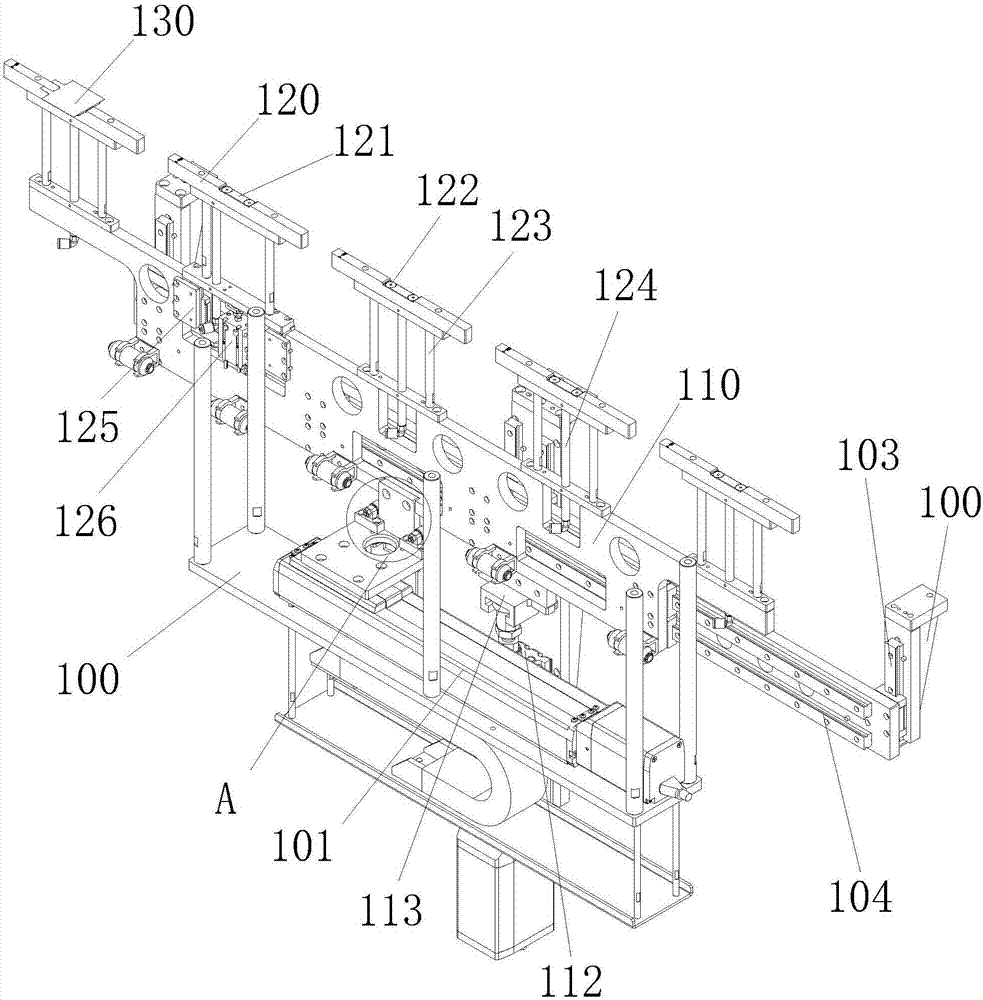

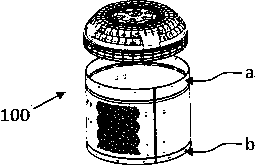

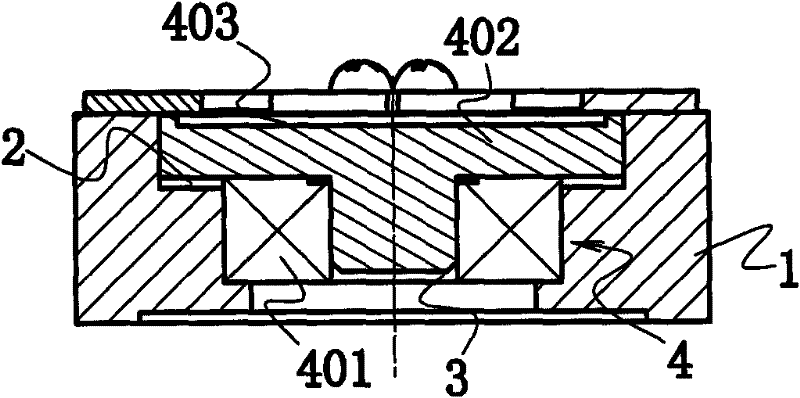

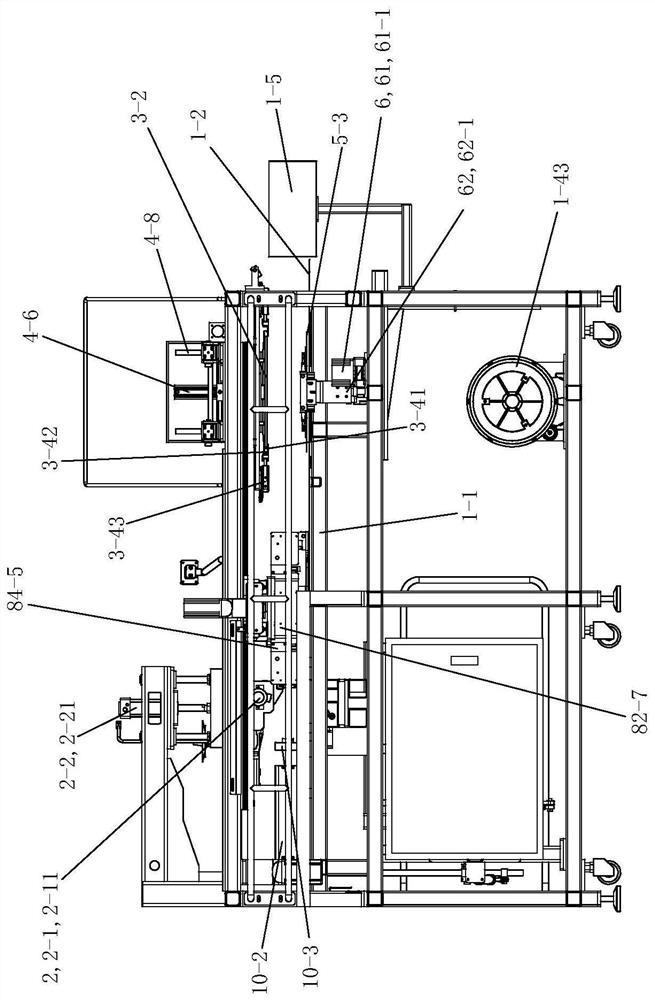

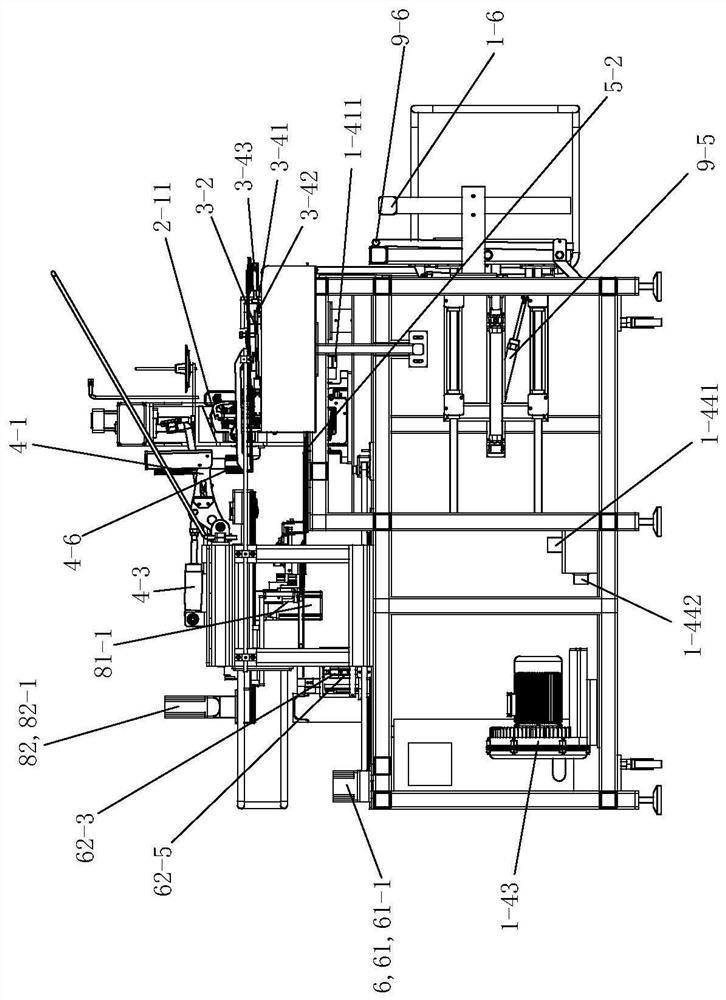

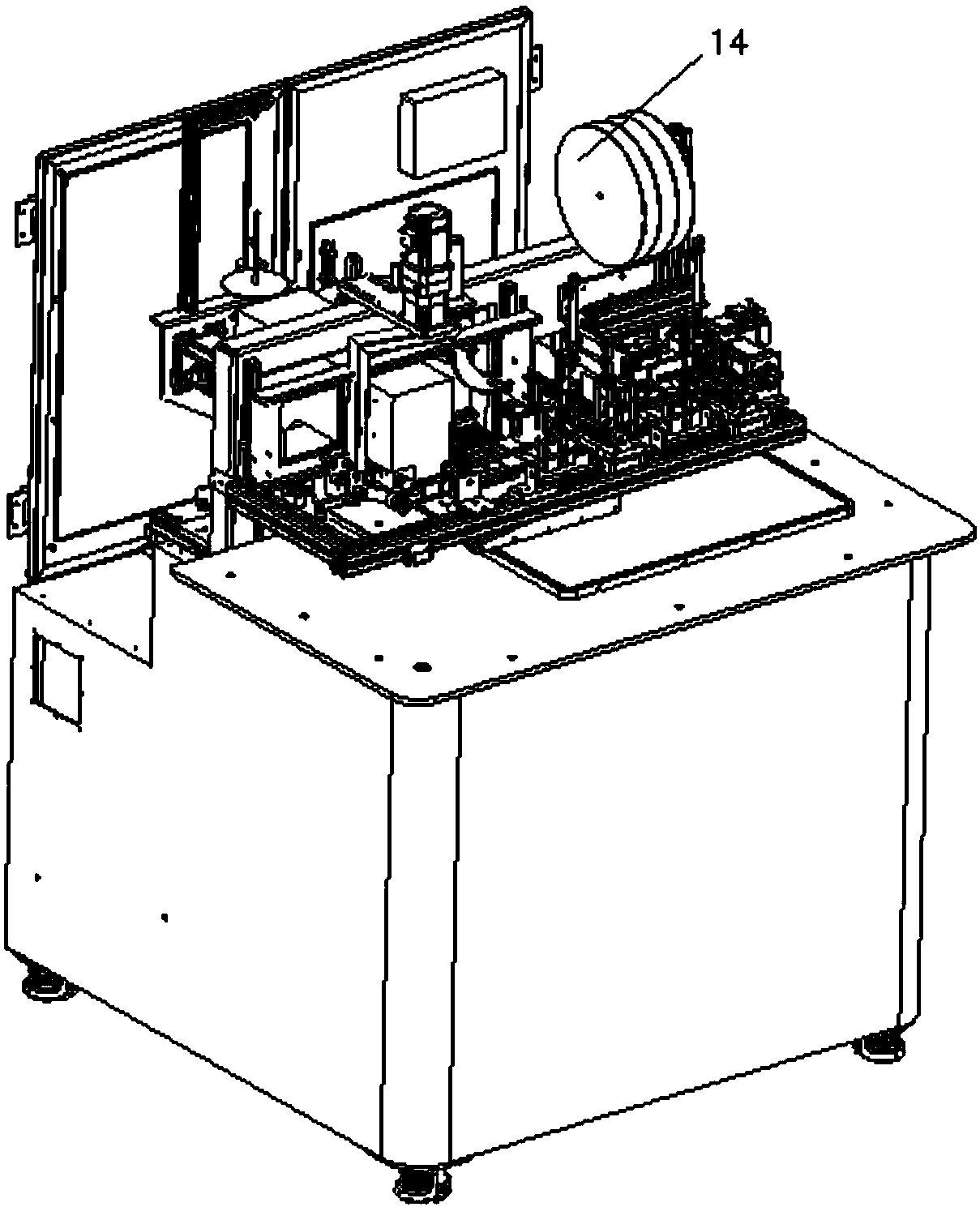

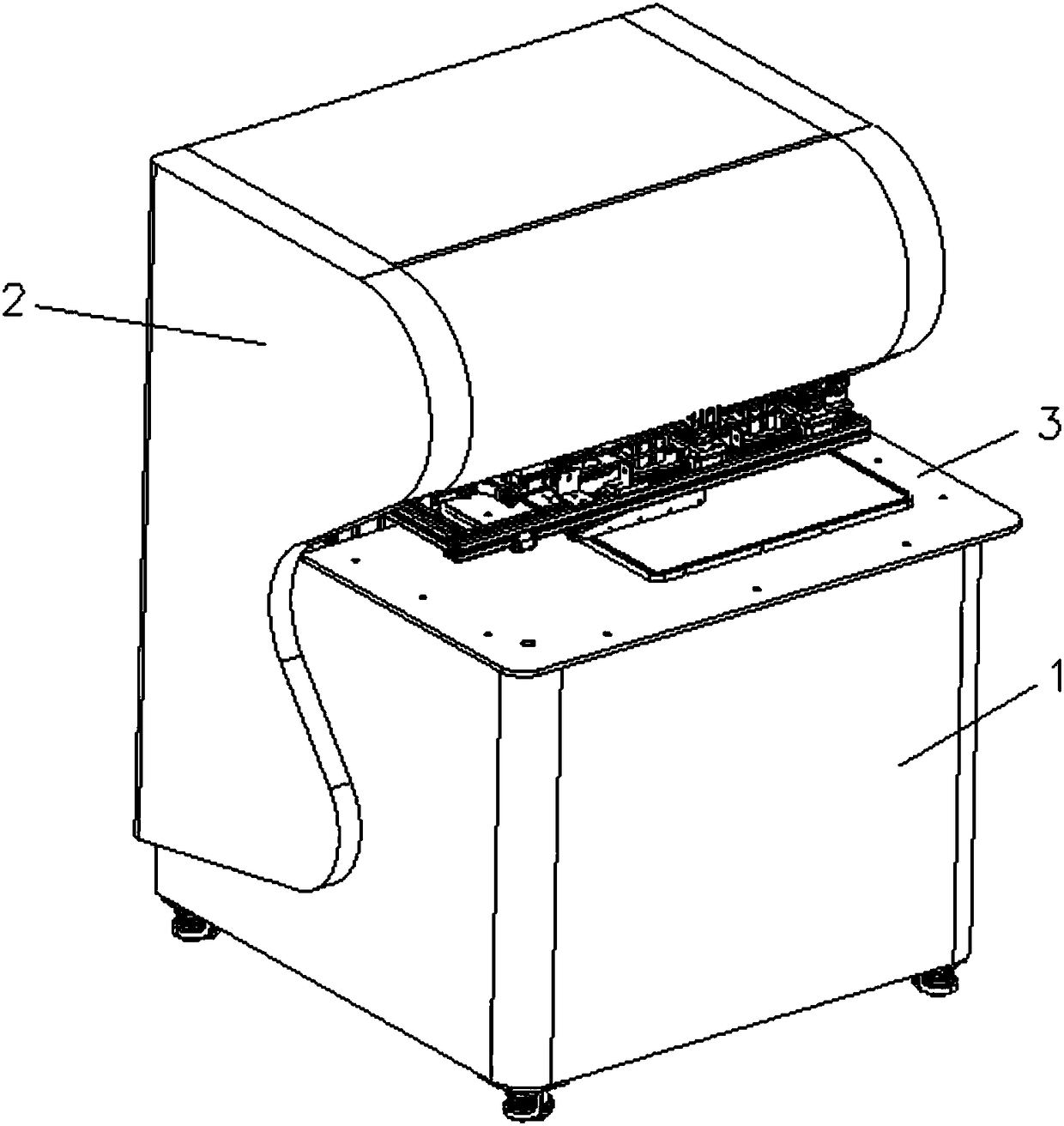

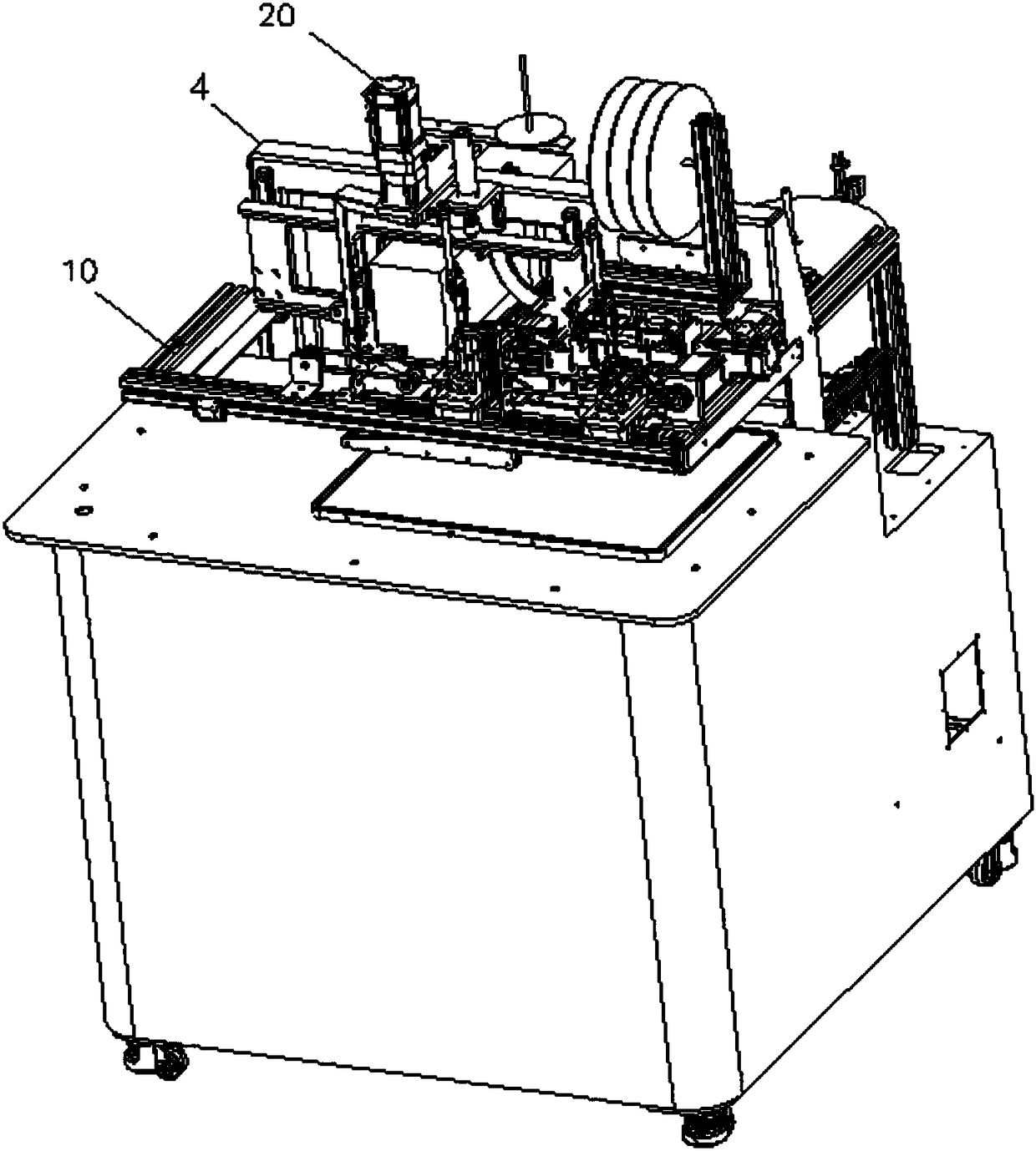

Flanging machine

PendingCN107984733AStrong adsorptionFast deliveryFinal product manufactureElectrolyte accumulators manufactureEngineeringFlanging

The invention discloses a flanging machine. The flanging machine comprises a rack and a base arranged on the rack, wherein a trimming carrying and conveying mechanism, an alignment mechanism, a trimming mechanism and a flanging mechanism are arranged on the base; the trimming carrying and conveying mechanism is used for conveying a battery; the alignment mechanism is positioned on the two sides ofthe trimming carrying and conveying mechanism and is used for seeking the central line of the battery; the trimming mechanism is used for cutting a redundant laminating film; the flanging mechanism is used for bending the residual laminating film; an overturning mechanism used for overturning the battery is arranged in the position, following the flanging mechanism, on the base; a roll folding and carrying mechanism used for carrying the battery, a prepressing locating mechanism which is positioned on the two sides of the roll folding and carrying mechanism and is used for prepressing the laminating film and locating the battery, and a roll folding mechanism used for folding the laminating film through rolling are arranged in the position, following the overturning mechanism, on the base;and a hot pressing shaping mechanism used for leveling the laminating film is arranged in the position, following the roll folding mechanism, on the base. According to the flanging mechanism, trimming, flanging, code scanning, weighing, shaping and overturning can be automatically carried out on the battery, the automation degree is high, product specifications are uniform, the battery is not damaged, manpower is greatly saved, and quality is improved.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

Covering machine for washing machine inner barrel production

ActiveCN104014625AFlexible and secure installationImprove stabilityMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention relates to a covering machine for washing machine inner barrel production. A locating mechanism, a barrel bottom covering mechanism and a barrel edge covering mechanism are respectively arranged on a workbench. The barrel edge of a semi-finished product piece of a washing machine inner barrel is flexibly and firmly arranged and located through a disc rotary locating component and a supporting rolling wheel, a barrel bottom carries out stable pressing and holding through a rotary pressing head, the inner barrel rotates smoothly under the action of the disc rotary locating component, the barrel edge of the inner barrel is bent through a barrel edge folding device to form an inclined folding edge, and the folding edge is bent along a forming groove to form a turned edge in the continuous rotating process under the action of an edge covering press block of a barrel edge rolling device. Meanwhile, a protruding edge at the barrel bottom of the semi-finished product piece of the inner barrel is pressed and bent by the barrel bottom rotary pressing block to form a covered edge in the rotating process. According to the covering machine for washing machine inner barrel production, the semi-finished product piece of the inner barrel is arranged flexibly and firmly, stability is high, machining quality is high, edge covering machining is achieved on the protruding edge of the barrel bottom and the barrel edge of the inner barrel at the same time, production efficiency is high, and adaptability is strong.

Owner:JIANGSUSNGCHENG PRECISION MOLD TECH

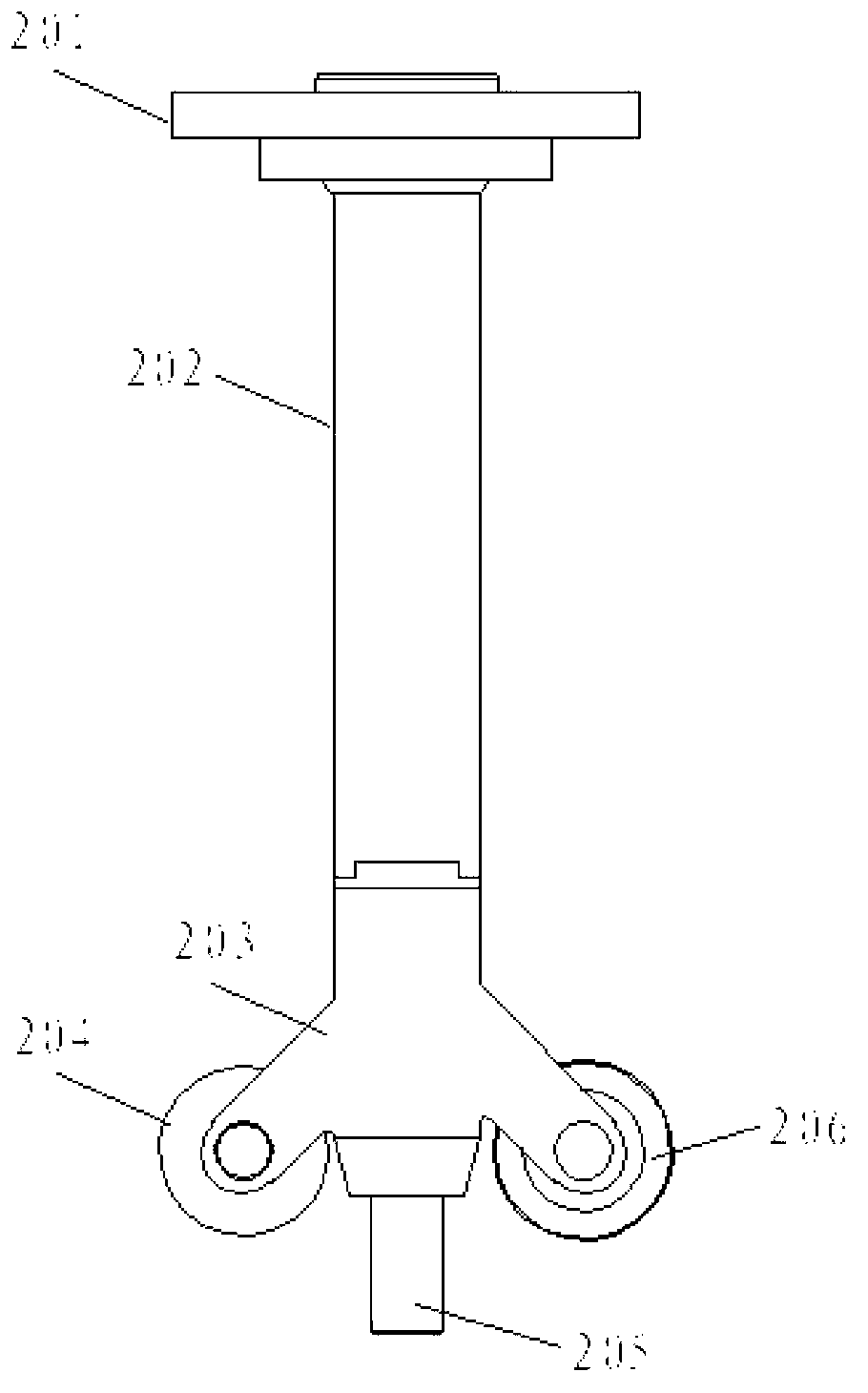

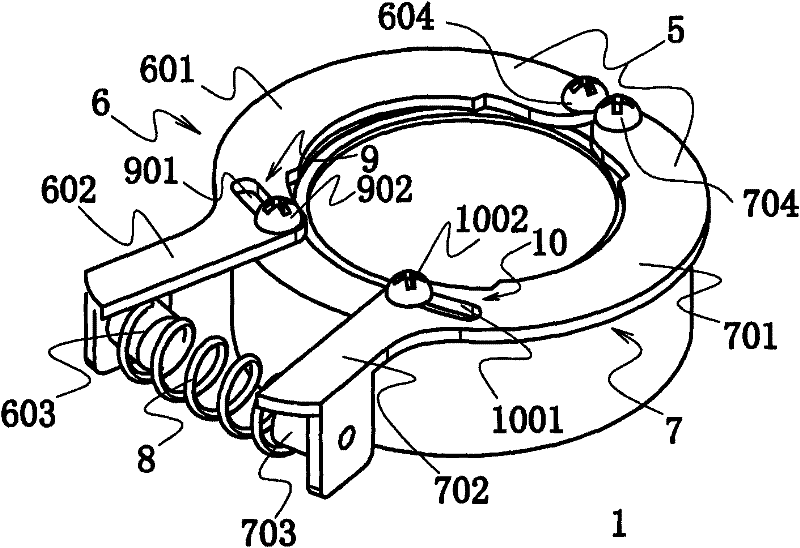

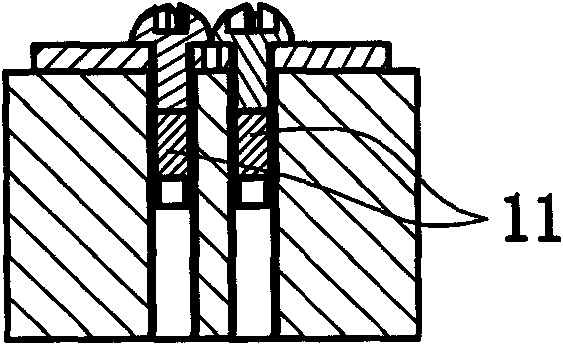

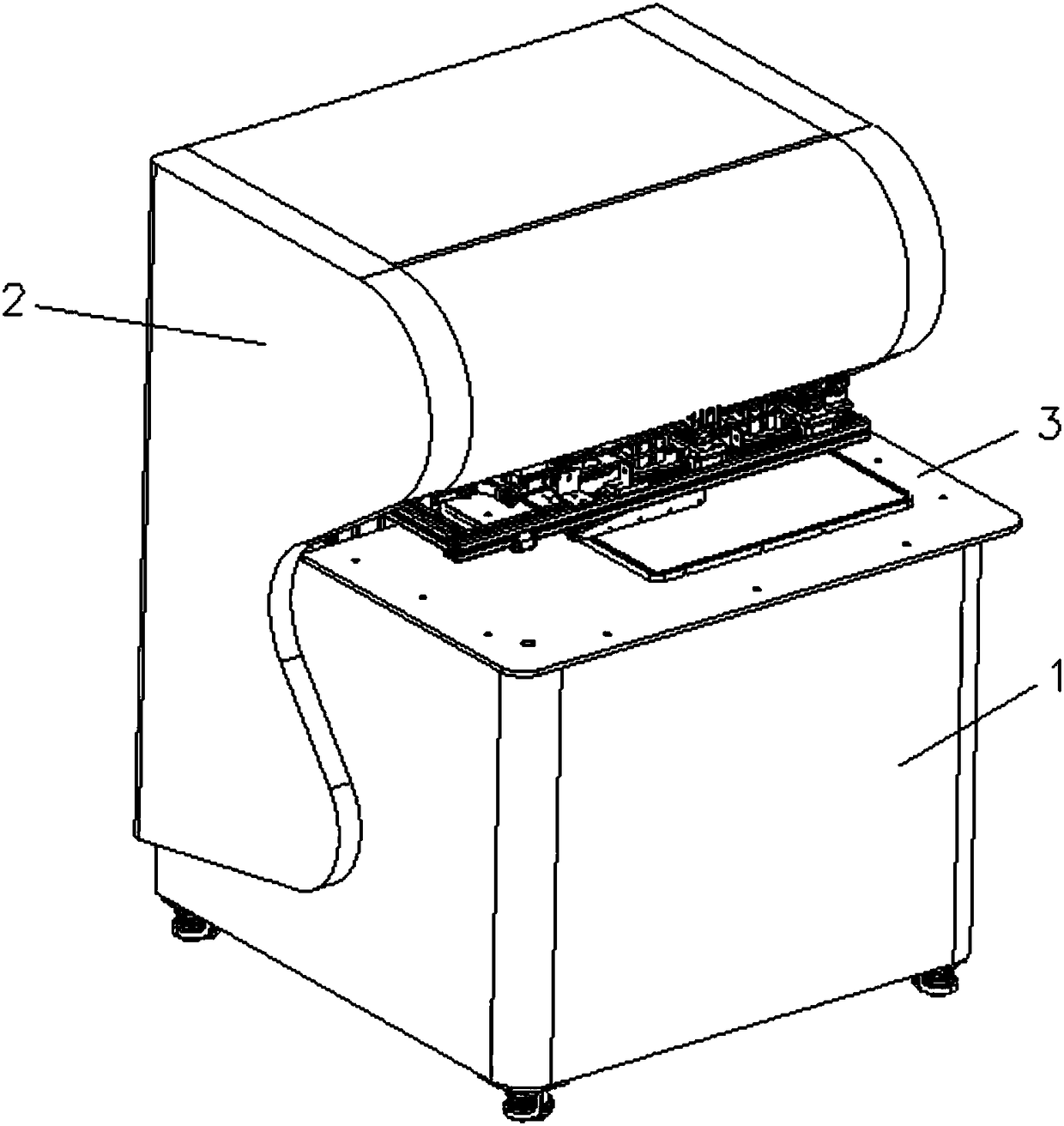

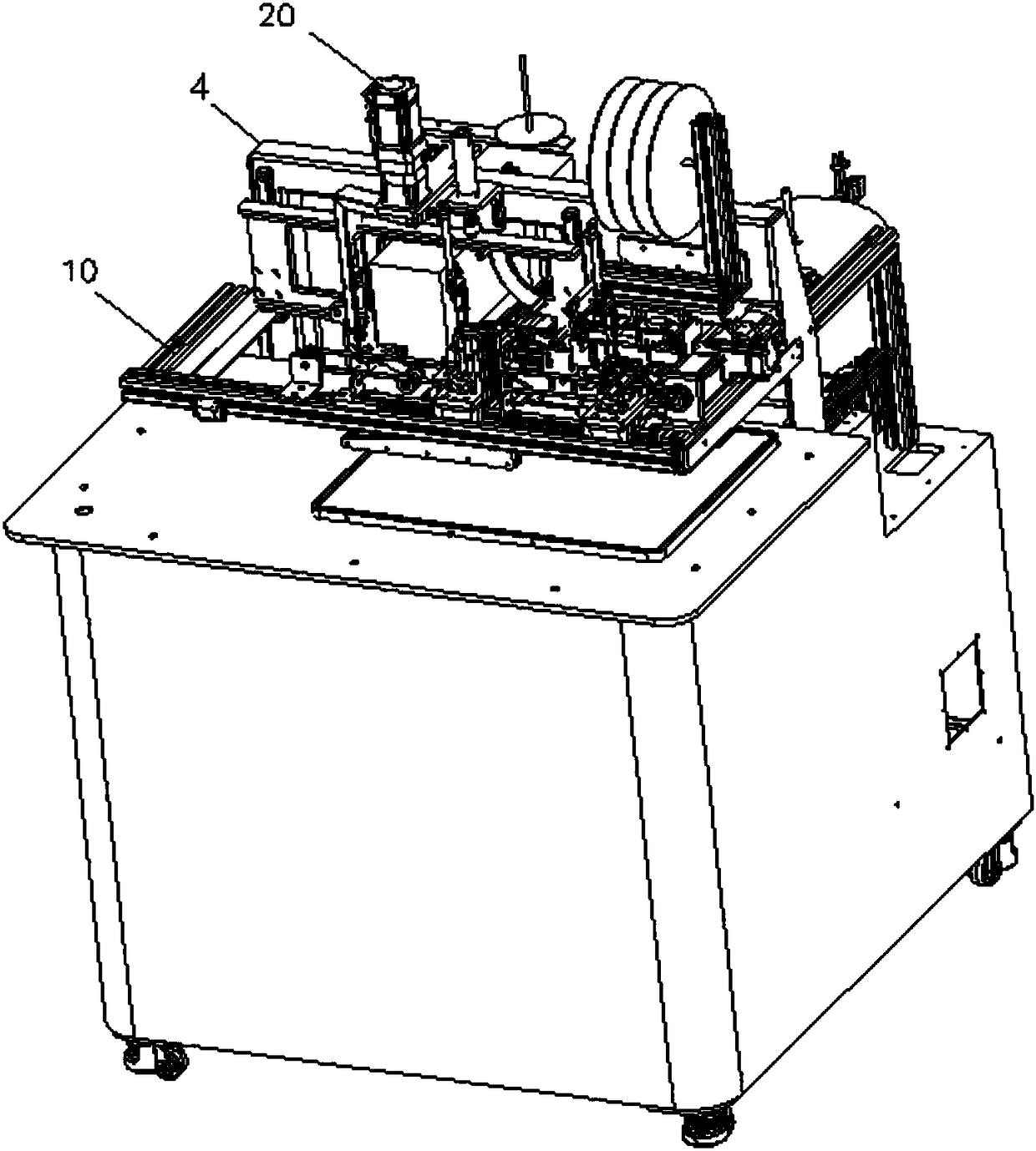

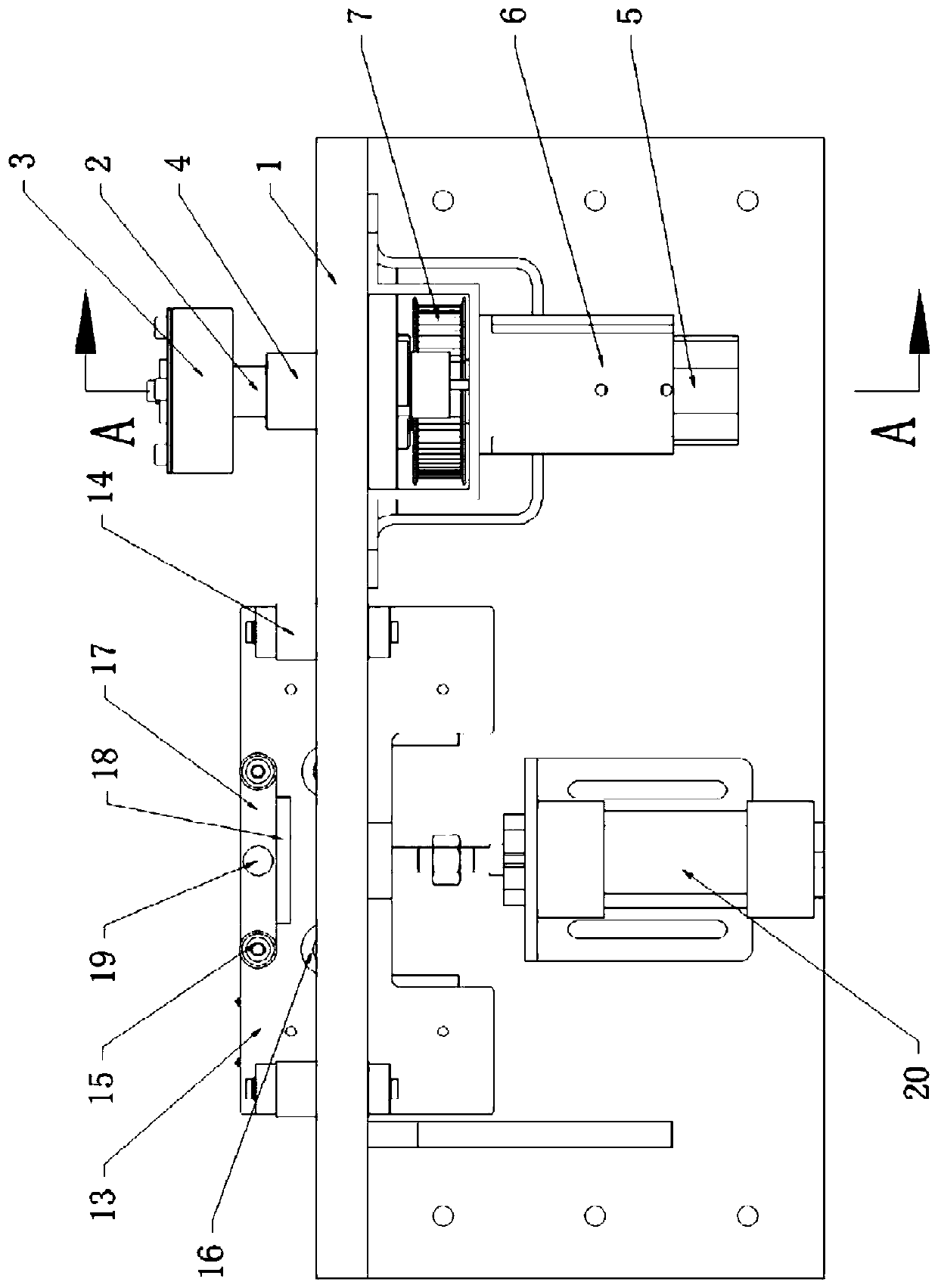

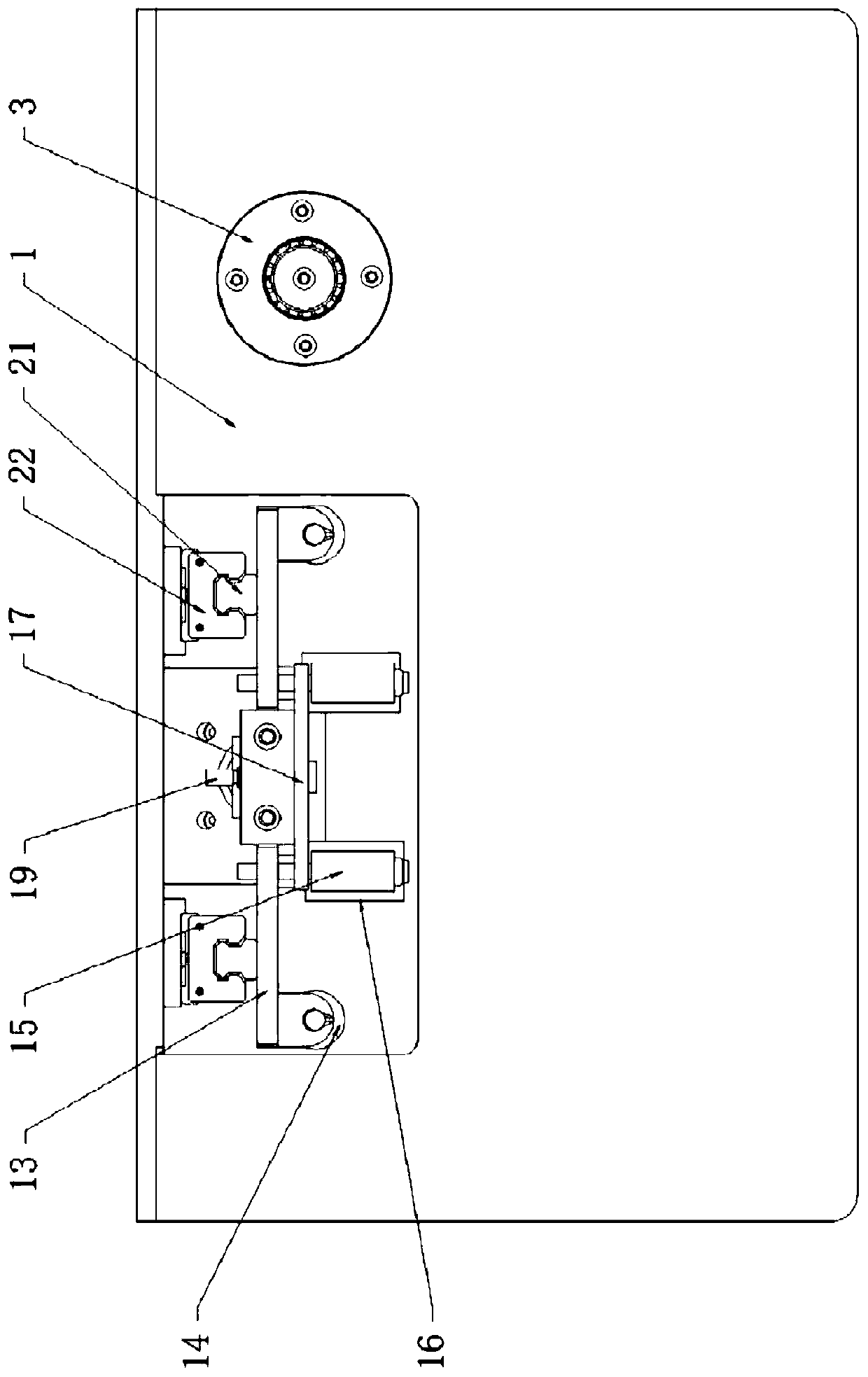

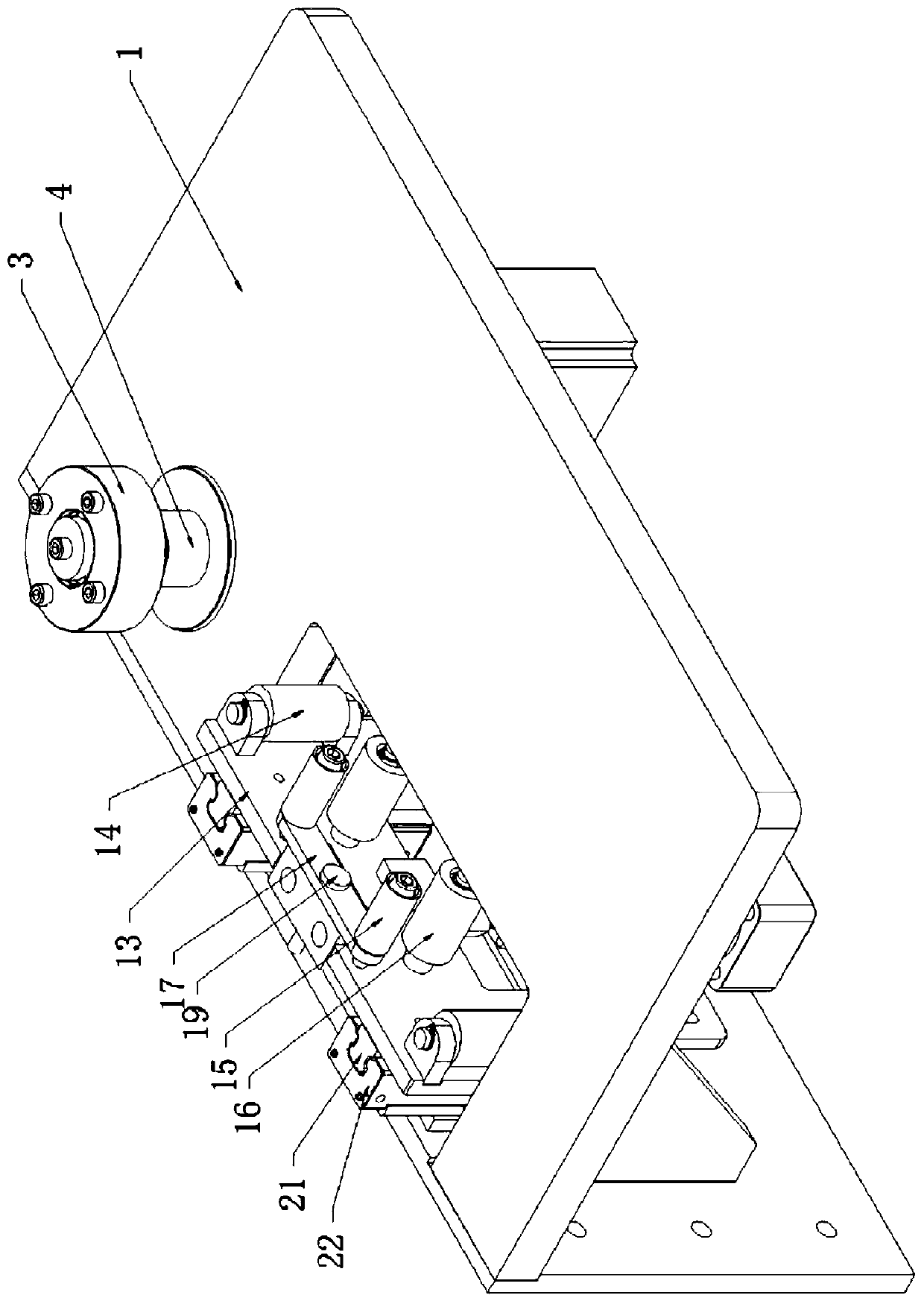

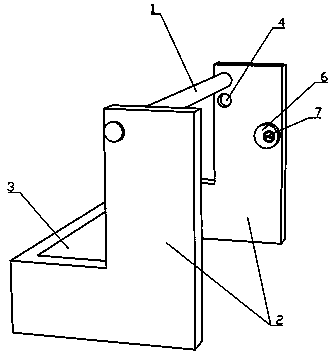

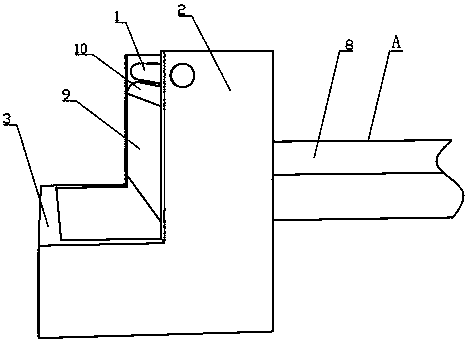

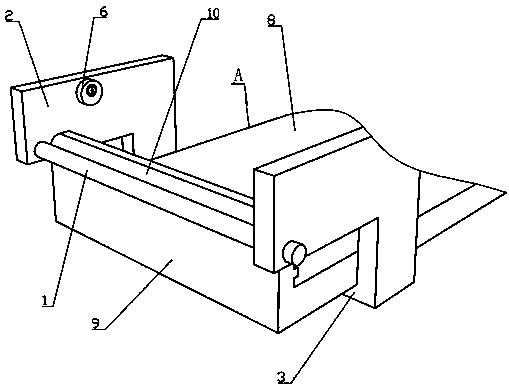

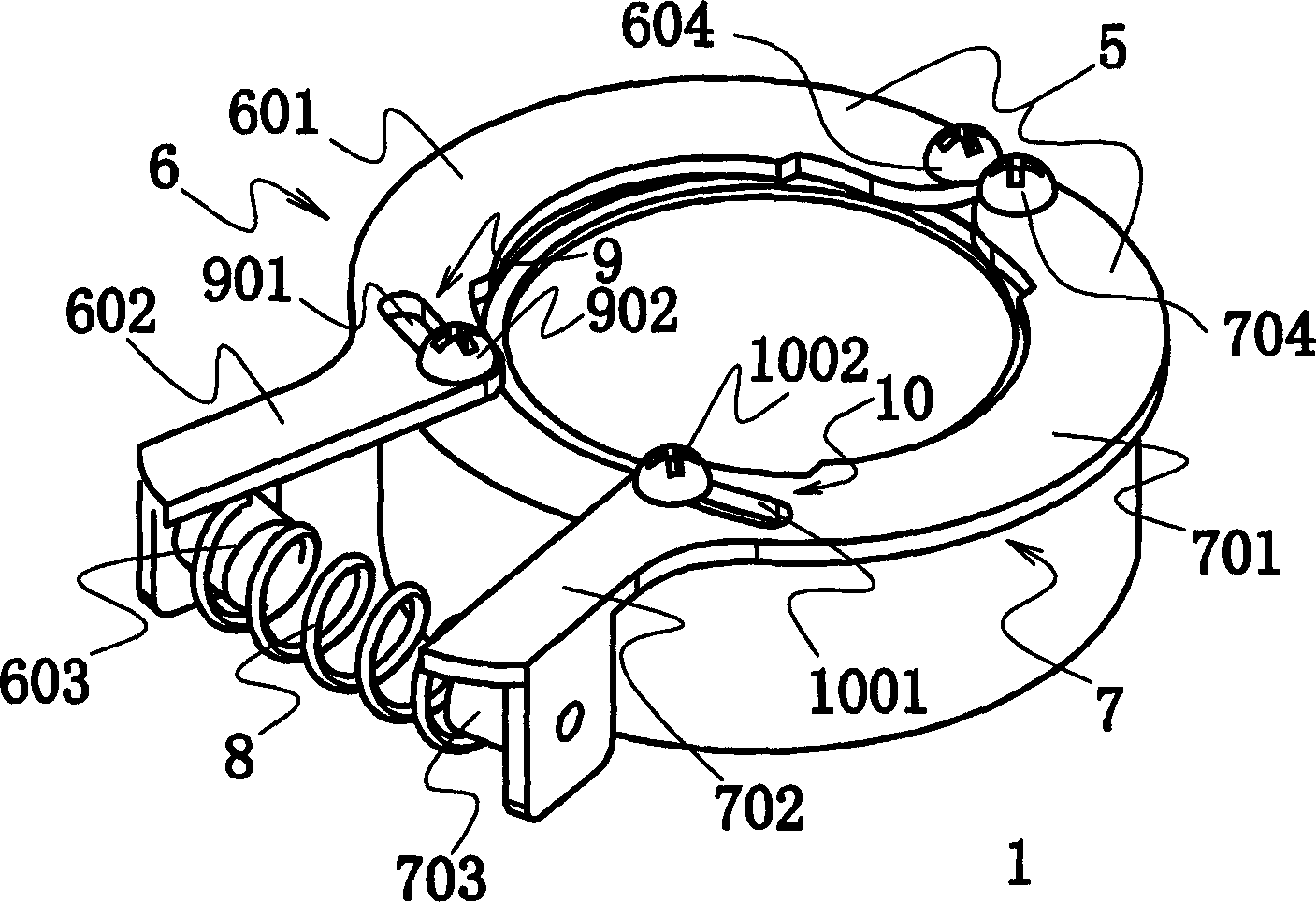

Low-concentration sampling nozzle forceps clip binder

ActiveCN102218658AReasonable designSimple in structure and totally functionalAssembly machinesForcepsMaterials science

The invention relates to a binder, in particular to structural improvement on a low-concentration sampling nozzle forceps clip binder. The low-concentration sampling nozzle forceps clip binder is characterized by comprising a base (1) and a rotation mechanism (4) arranged in the base (1); and a binding mechanism (5) used for binding a low-concentration sampling nozzle is arranged on the base (1). The low-concentration sampling nozzle forceps clip binder has the advantages of reasonable design, simple structure, quite practicality, convenience for operation, high working efficiency, uniform binding and high binding quality.

Owner:WUHAN TIANHONG INSTR

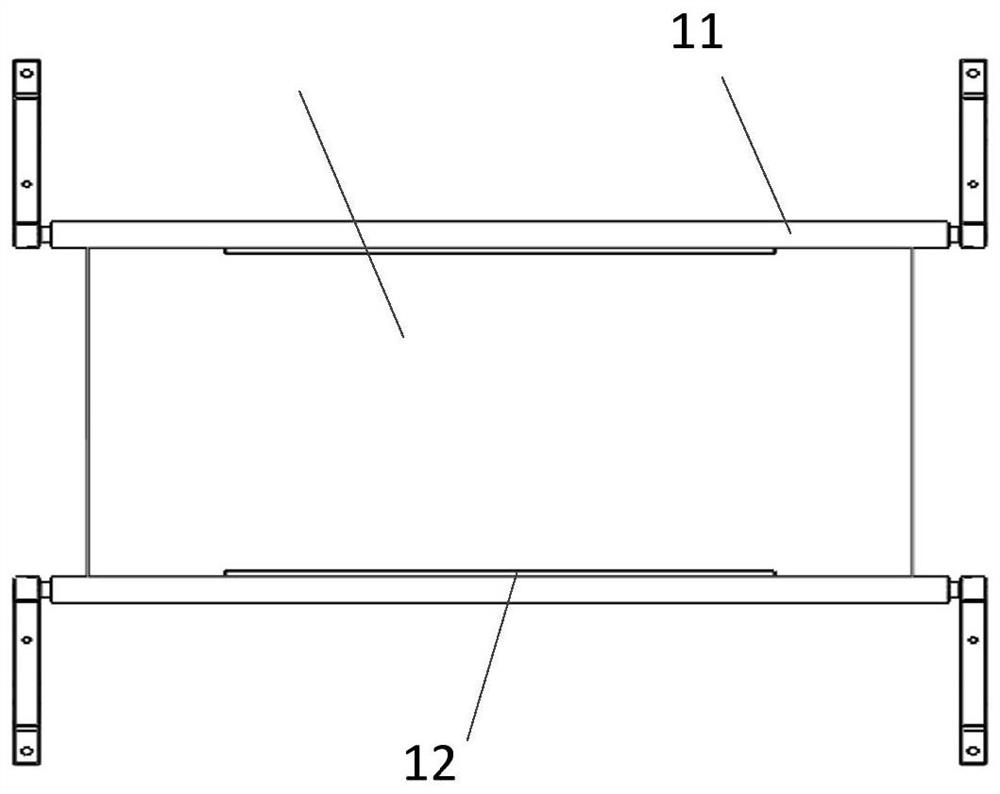

Fabric edge-folding mechanism and fabric edge-folding method

InactiveCN106521826AImprove stabilityAvoid unstable qualityWork-feeding meansInstabilityAerospace engineering

The invention provides a fabric edge-folding mechanism used for edge folding of a fabric. The fabric comprises a fabric body and a fabric edge-folding portion at one end of the fabric body. The fabric edge-folding mechanism comprises an edge-folding fixed plate, an edge-folding moving plate and a driving component, wherein the edge-folding fixed plate is positioned above the fabric body, the edge-folding moving plate is positioned under the fabric edge-folding portion, and driving component is connected with the edge-folding moving plate and is capable of driving the edge-folding moving plate to move vertically and further capable of driving the edge-folding moving plate to move away from and close to the edge-folding fixed plate. The fabric edge-folding mechanism can be used for edge folding of the fabric and is high in edge folding efficiency, edge folding quality and edge-folding quality stability, and quality instability in manual edge folding is avoided. In addition, the fabric edge-folding mechanism is integrally simple in structure and low in production cost.

Owner:JACK SEWING MASCH CO LTD

Cloth edgefold mechanism and edgefold method

The invention discloses a cloth edgefold mechanism using for flanging cloth. The cloth comprises a cloth edgefold part and a cloth double-flanged part on one side of the cloth edgefold part. The cloth edgefold mechanism comprises an edgefold fixed plate arranged below the cloth edgefold part, an edgefold support is fixed on the opposite location of the edgefold fixed plate, a main actuating device arranged on the edgefold support and an edgefold movable plate connected with the output end of the main actuating device. The main actuating device drives the edgefold movable plate to move in the directions of closing to and being away from the cloth edgefold part. According to the cloth edgefold mechanism, the flanging process of the cloth double-flanged part being folded under the cloth edgefold part is realized. The cloth edgefold mechanism has the advantages of auto flanging which replaces traditional manual flanging and higher flanging efficiency and stability of flanging quality, which saves labor force and reduces processing cost of enterprises.

Owner:JACK SEWING MASCH CO LTD

Floor mat covering device

PendingCN108532140ARealize rotary hemmingReasonable structureWorkpiece carriersWork-feeding meansEngineeringManipulator

The invention relates to a floor mat covering device including a feeding mechanism, a label processing mechanism, a stitching machine and a covering band processing mechanism which are arranged on a working table. The feeding mechanism includes a feeding assembly at least having the unidirectional feeding capability; the feeding assembly drives a floor mat to move in the trace direction of the stitching machine; the feeding assembly is matched with a steering mechanism of the floor mat; the steering mechanism pokes the floor mat to rotate with a machine needle of the stitching machine as the circle center, the label processing mechanism is arranged on one upstream side of the stitching machine; the label processing mechanism at least includes a label sending machine for automatically cutting a trade mark; the feeding mechanism is matched with a mechanical hand for pneumatically clamping the trade mark; the mechanical hand clamps the trade mark from the label sending machine and sends the trade mark to the position of the machine needle for synchronous seaming with a covered edge; and the side of the stitching machine is provided with the covering band processing mechanism. The covering band processing mechanism includes a sending and folding assembly, a shear assembly and a pull barrel which cooperate with mechanical transmission feeding in a blowing mode.

Owner:苏州匠博智能科技有限公司

Automatic edge covering equipment

The invention discloses automatic edge covering equipment which comprises a worktable. A primary extruding unit is arranged on the worktable and comprises a guide shaft, a pressing wheel and a sleeve,wherein the pressing wheel is rotatably arranged on the guide shaft in a sleeving manner and the sleeve is rotatably arranged on the guide shaft in a sleeving manner. According to the automatic edgecovering equipment, the side face of a covered edge leans against the sleeve of the primary extruding unit and a guide roller of the secondary extruding unit, and the upper and lower surfaces of the covered edge are extruded by the pressing wheel, the worktable, a first extruding roller and a second extruding roller, so that the side face and the upper and lower surfaces of the covered edge compress the edge of a decorative plate so as to prevent the covered edge from shifting or falling off; the sleeve is driven by a motor to rotate to drive the covered edge leaning against the sleeve to moveforward so as to extrude an aluminum alloy strip to the edge of the decorative plate continuously by pushing the decorative plate forward by matching with an operator.

Owner:JINAN WEIER LASER EQUIP

Veneer bidirectional automatic folding machine

The invention discloses a veneer bidirectional automatic folding machine, and relates to the technical field of flanging machines. The veneer bidirectional automatic folding machine comprises a machine frame side plate. A lower knife plate is arranged on one side of the top of a lower seat; a rotating seat is fixedly connected to the surface of a rotating shaft of a speed reducer; a folding platepart is fixedly connected to one side of the surface of the rotating seat; a hydraulic oil cylinder is rotatably connected to the position, close to the machine frame side plate, of the side, away from a supporting beam, of the surface of the machine frame side plate; a pulling rotating arm is rotatably connected to the working end of the hydraulic oil cylinder; and a connecting shaft is fixedly connected to the end, away from the hydraulic oil cylinder, of the pulling rotating arm. The end, away from the pulling rotating arm, of the connecting shaft penetrates through the outer wall of the machine frame side plate and extends to the inner part of the machine frame side plate. The end, away from the pulling rotating arm, of the connecting shaft is fixedly connected with a pressing plate part. The veneer bidirectional automatic folding machine achieves the effects of automatic flanging and firm compaction, has simple structure and convenient use, reduces manual labor, saves time and labor, and improves working efficiency.

Owner:湖南固可得建筑科技有限公司

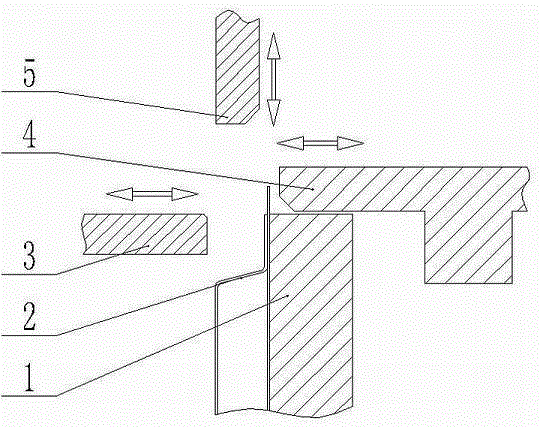

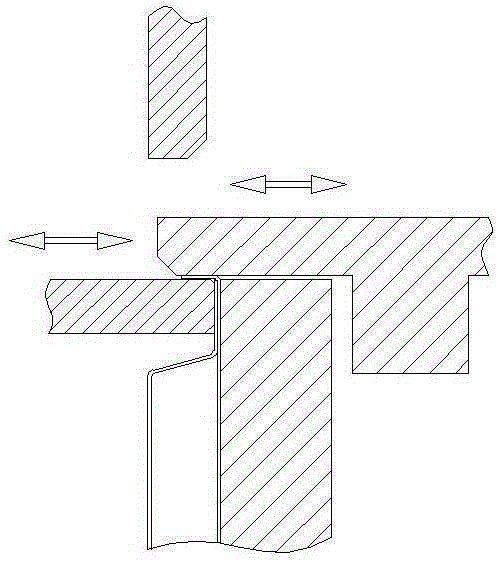

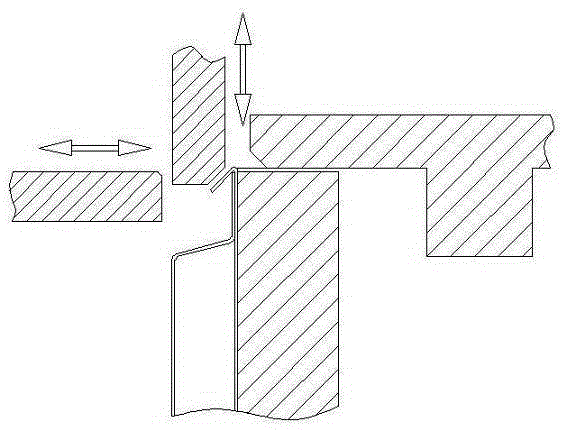

Edge covering method for automobile trunk door

InactiveCN105251841AReduce manufacturing costImprove hemming qualityCar manufacturingStructural engineering

The invention belongs to the field of automobile manufacturing and specifically relates to an edge covering method for an automobile trunk door. The edge covering method comprises the following steps: firstly, a trunk door waiting for edge covering is placed in a lower die of an oil press and clamped by use of a hold-down block; secondly, a final covering module mounted under an upper die of the oil press tightly props against an inner side of the trunk door waiting for edge covering under the action of an oil cylinder, and similarly, an edge reversing module mounted below the upper die of the oil press and located on an outer side of the trunk door waiting for edge covering goes forward toward the trunk door waiting for edge covering under the action of the oil cylinder to carry out edge reversing work, and an edge reversing angle can be adjusted within a certain range according to process requirements; then, the edge reversing module and the final covering module retreat from an edge covering region, respectively; a pre-covering module mounted below the upper die moves downwards under the action of the oil cylinder for pre-covering, and a pre-covering edge can be adjusted within a certain range according to process requirements; finally, after pre-covering is finished, the pre-covering module retreats upwards from the edge covering region, and the final covering module is pushed by the oil cylinder to carry out final covering work.

Owner:ANHUI SYNCHRONOUS AUTOMATION TECH

Kangaroo pocket sewing equipment

PendingCN111826820ASimple structureHigh degree of automationWork-feeding meansSewing-machine control devicesMechanical engineering

The invention discloses kangaroo pocket sewing equipment. The kangaroo pocket sewing equipment comprises a workbench assembly and a sewing assembly. The workbench assembly comprises a rack and a workbench plate. The workbench plate is horizontally and fixedly arranged on the rack. The sewing assembly is arranged on the right portion of the rack. The kangaroo pocket sewing equipment is characterized by further comprising an edge folding assembly, an edge folding driving device, a pocket-shaped plate assembly, a pocket-shaped plate driving device, a frame pressing device and a frame pressing driving device. The edge folding assembly cooperates with the pocket-shaped plate assembly to fold the edge of pocket cloth. The edge folding driving device drives the edge folding assembly to move up and down, and the pocket-shaped plate driving device drives the pocket-shaped plate assembly to move up and down and back and forth. The frame pressing device is used for conveying the folded pocket cloth and bodice cloth to the sewing assembly for sewing, and the frame pressing driving device drives the frame pressing device to move up and down, front and back and left and right.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Baking and welting compound equipment

The invention belongs to the technical field of automobile parts, and provides baking and welting compound equipment which comprises an upper die turnover device, a lower die mounting device, a baking mechanism and a control mechanism. An upper die is used for fixing an automobile interior framework, and a lower die is mounted on the lower die mounting device and fixes a skin. Under the control of the control mechanism, the lower die ascends to attach the skin to the automobile interior framework, and a product to be subjected to edge covering is obtained. The baking mechanism is controlled by the control mechanism to bake the product to be subjected to edge covering, then a clamping mechanism and a side mold tire are matched to clamp a reserved edge, a side driving mechanism drives the side mold tire to ascend relative to a main supporting mold tire, the product to be subjected to edge covering is covered with the reserved edge, and automatic edge covering is achieved. A turnover driving mechanism drives a fixing mechanism to turn over around a rotating shaft relative to a rack, so that a product subjected to edge covering can be conveniently taken down or mounted on the upper die. The whole process integrates edge covering and baking, convenience and rapidness are achieved, and the working efficiency is improved.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

Floor mat covering machine

PendingCN108532142ARealize rotary hemmingReasonable structureWorkpiece carriersWork-feeding meansEngineeringManipulator

The invention relates to a floor mat covering machine. A feeding mechanism drives a floor mat to move in the trace direction of a stitching machine; the feeding mechanism is matched with a steering mechanism of the floor mat; the steering mechanism pokes the floor mat to rotate with a machine needle as the circle center; a label processing mechanism is arranged on one upstream side of the stitching machine; the feeding mechanism is matched with a mechanical hand for pneumatically clamping a label; the mechanical hand clamps a trade mark from the label processing mechanism and sends the trade mark to the position of the machine needle for synchronous seaming with a coverage edge; the side of the stitching machine is provided with a covering band processing mechanism; and the covering band processing mechanism includes a sending and folding assembly, a shear assembly and a pull barrel which cooperate with mechanical transmission feeding in a blowing mode. The shear assembly at least includes a pneumatically pushed push plate and a cutting head with a blade for bisection. The cutting head is divided into a first cutting head and a second cutting head. The first cutting head is an inversely V-shaped outer edge; the second cutting head is an inversely V-shaped inner edge; the first cutting head is embedded in the second cutting head, and the outer edge is matched with the inner edgefor brake cutting. The push plate abuts against the middle portion of a covering band to make the covering band oppositely folded and then inserted between the first cutting head and the second cutting head.

Owner:苏州匠博智能科技有限公司

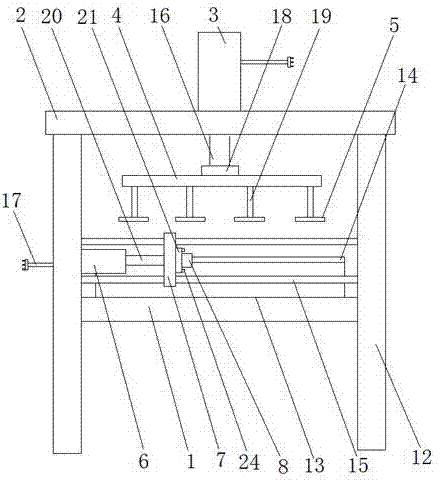

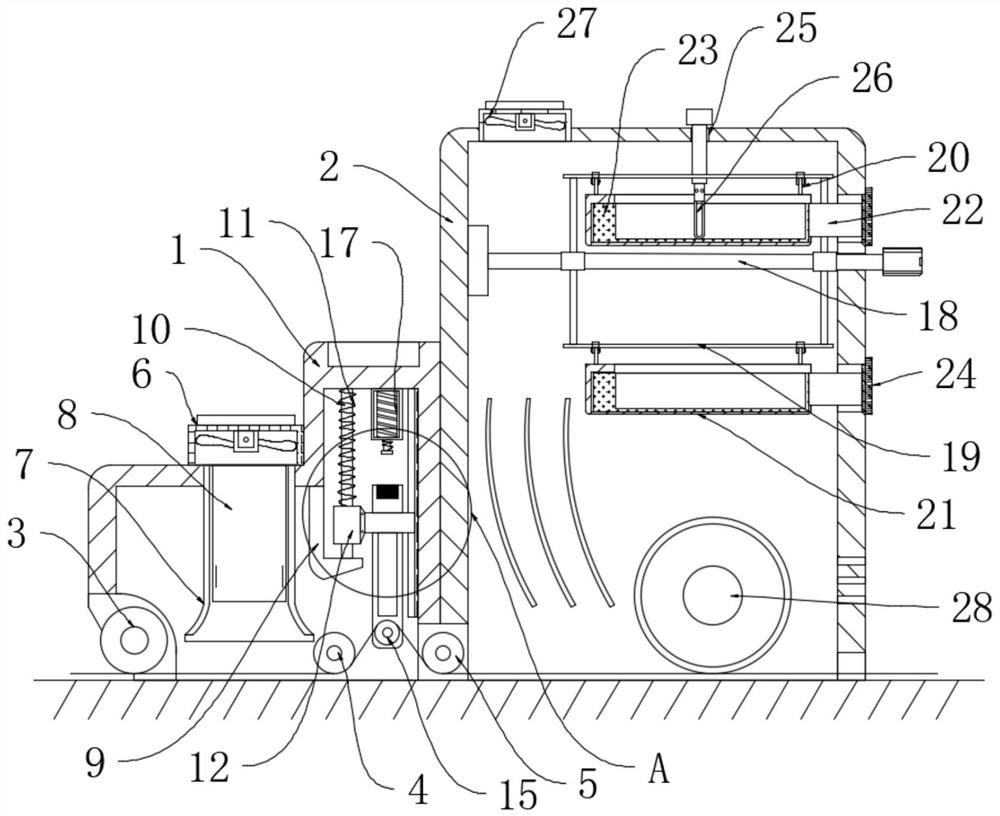

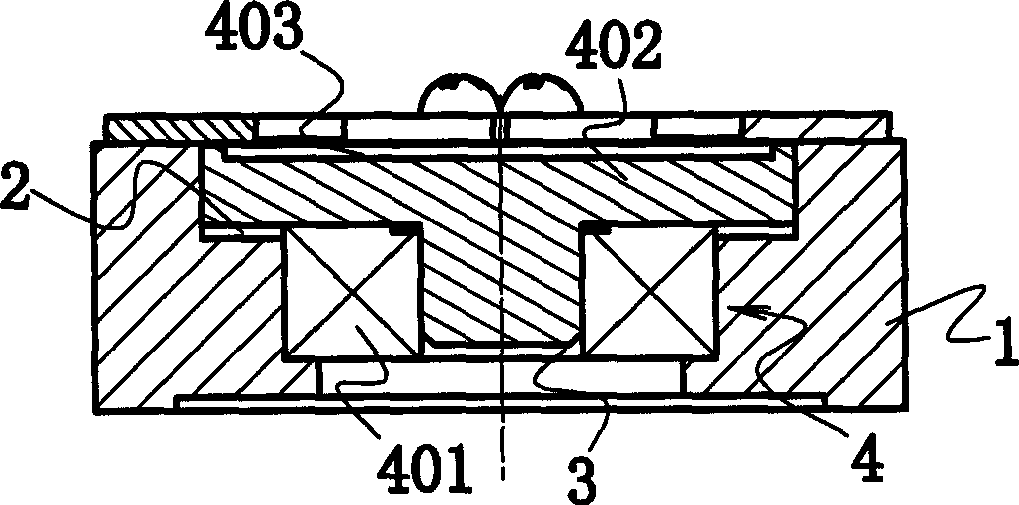

Device used for edge folding of lithium battery and application method thereof

PendingCN107785619AImprove hemming qualityIncreased hemming securityFinal product manufactureCell sealing materialsEngineeringPlastic film

The invention relates to a lithium battery processing device and a processing method, in particular to a device used for edge folding of a lithium battery and an application method thereof. The devicecomprises a horizontal base station and a vertical base station, wherein the vertical base station is arranged above the horizontal base station and at the left side of the horizontal base station, and two location bosses are arranged at the right side of the vertical base station; and a limiting base station is arranged above the right side of the horizontal base station. The method comprises the following steps: placing the lithium battery on the horizontal base station, and tightly pushing the end part of the lithium battery against the location bosses by the limiting base station, so thata to-be-buckled aluminum-plastic film extends out from the upward side of the vertical base station; maintaining the state that the to-be-buckled aluminum-plastic film extends out from the upward side of the vertical base station, heating the extended aluminum-plastic film by adopting a sealing head of heat sealing equipment and softening the aluminum-plastic film, then turning over the horizontal base station with the lithium battery for 90 degrees together, and buckling the extended aluminum-plastic film until the aluminum-plastic film fits with a panel at the right side of the vertical base station, so that edge folding of the lithium battery is completed. The device provided by the invention has the advantages that edge folding quality is improved, and edge folding safety is improved.

Owner:SICHUAN JIENENG NEW ENERGY TECH

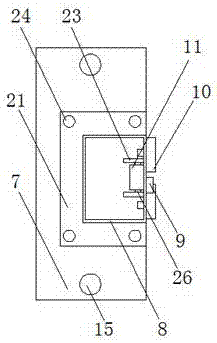

Plate workpiece folding device

InactiveCN107377715AImprove firmnessImprove stabilityMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a hemming device for a plate-shaped workpiece, which comprises an operating table, a top plate, a cylinder one, an adjustment plate, a pressure plate, a cylinder two, a push block, a fixed block, a hemming wheel, an auxiliary wheel and a transmission wheel, and is characterized in that : the operating table is arranged between the vertical plate and the vertical plate, a cross bar is arranged between the vertical plate and the vertical plate, the top plate is arranged on the vertical plate, and the cylinder one is arranged on the top plate , the adjustment plate is connected to the piston rod, the auxiliary wheel is arranged on the fixed block through the connecting shaft, and the two ends of the transmission wheel are arranged between the fixed plate and the fixed plate through the connecting rod. In the present invention, the fixing block provided with the flanging wheel and the auxiliary wheel is arranged on the pushing block through the mounting plate, and the pushing block is arranged on the piston rod 2 of the cylinder 2, so that the pushing block can move back and forth on the cross bar, driving and fixing The hemming wheel and the auxiliary wheel on the block and the fixed block move back and forth to hem the edge of the plate-shaped workpiece, which improves the work efficiency of the hemming of the plate-shaped workpiece.

Owner:WUHU QIANKAI MATERIAL TECH CO LTD

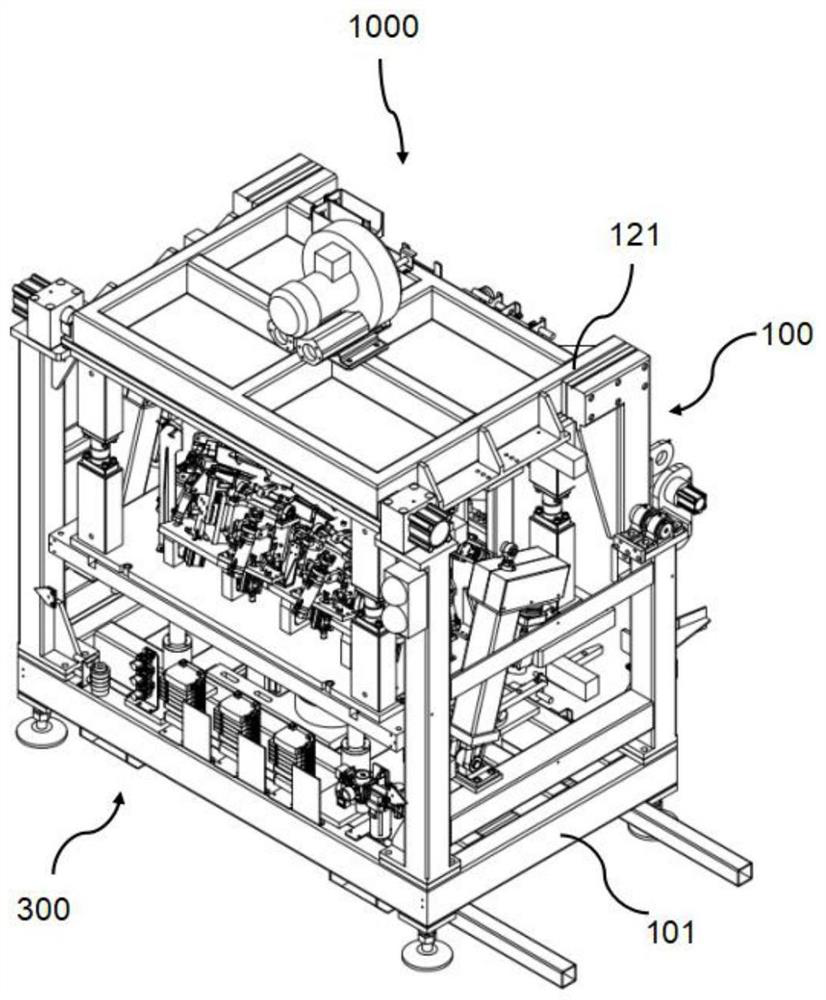

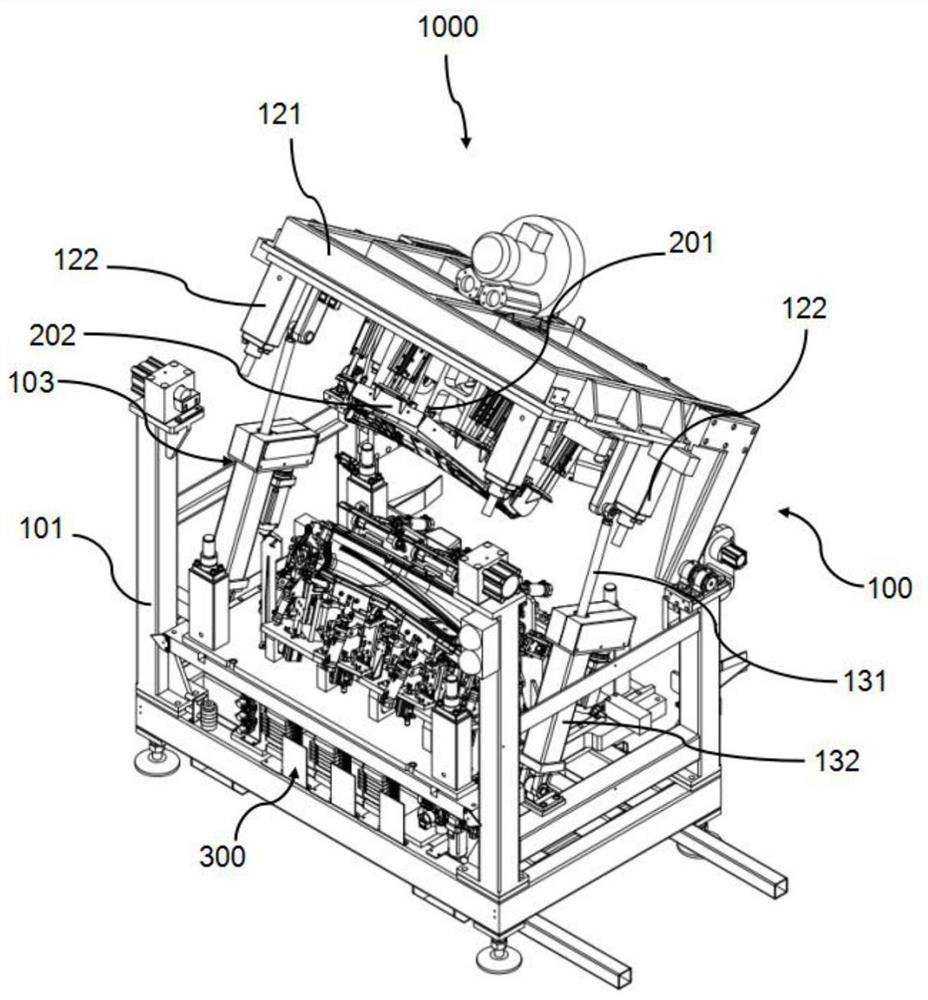

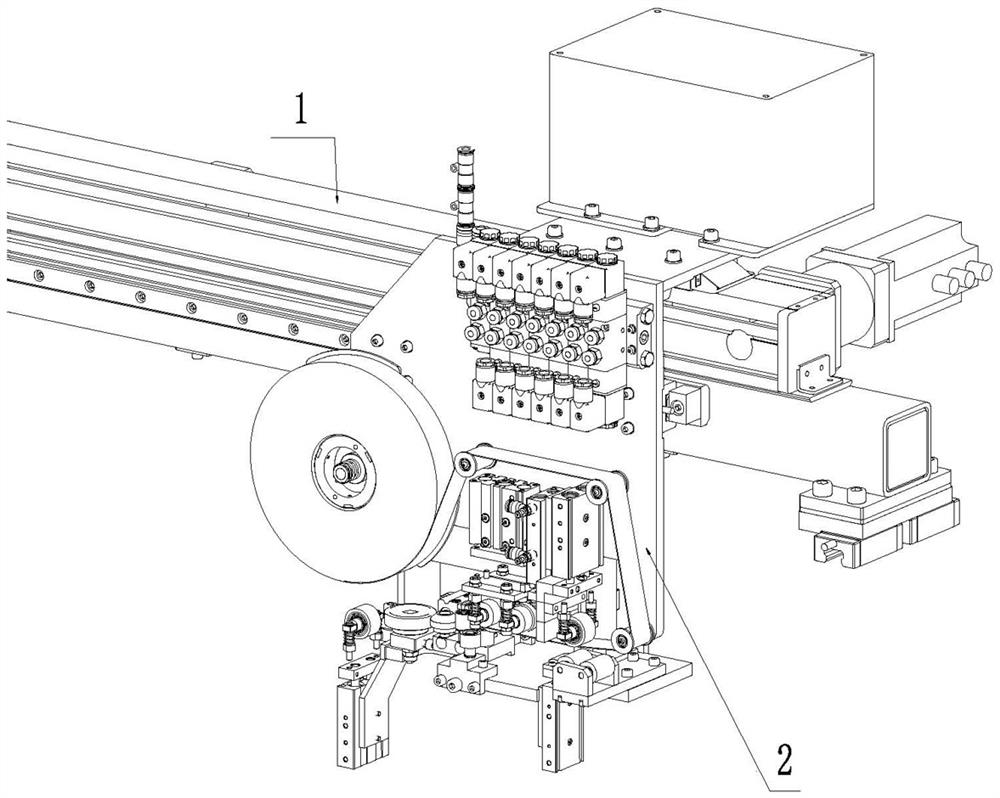

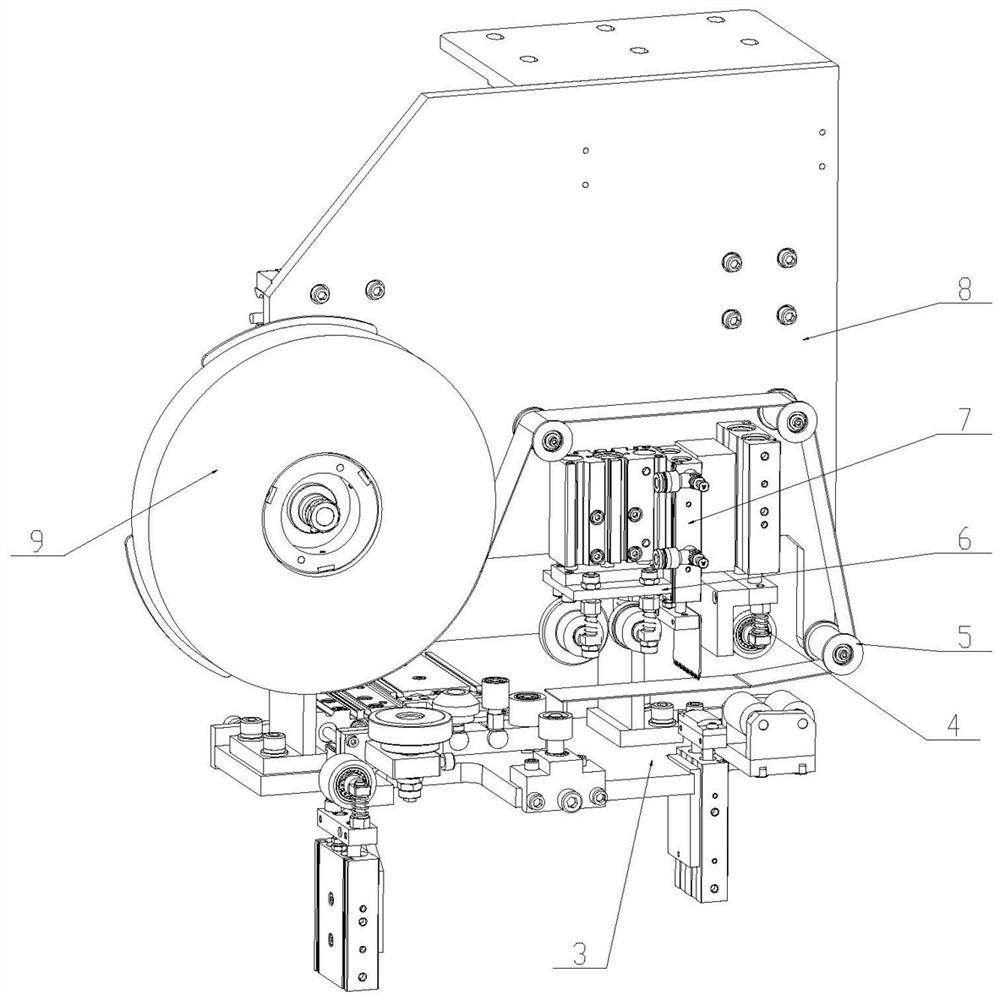

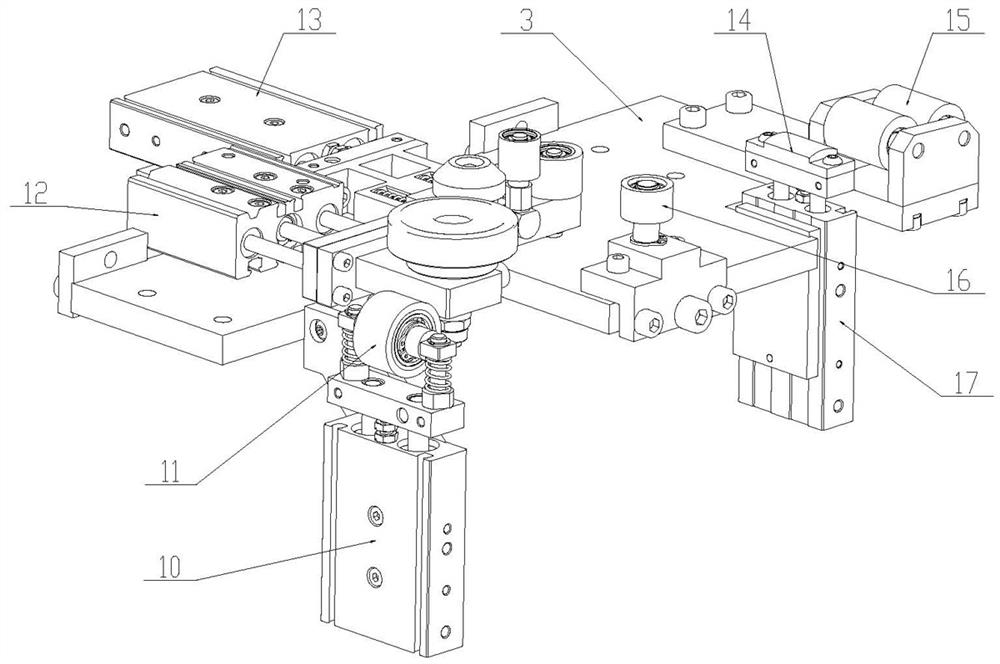

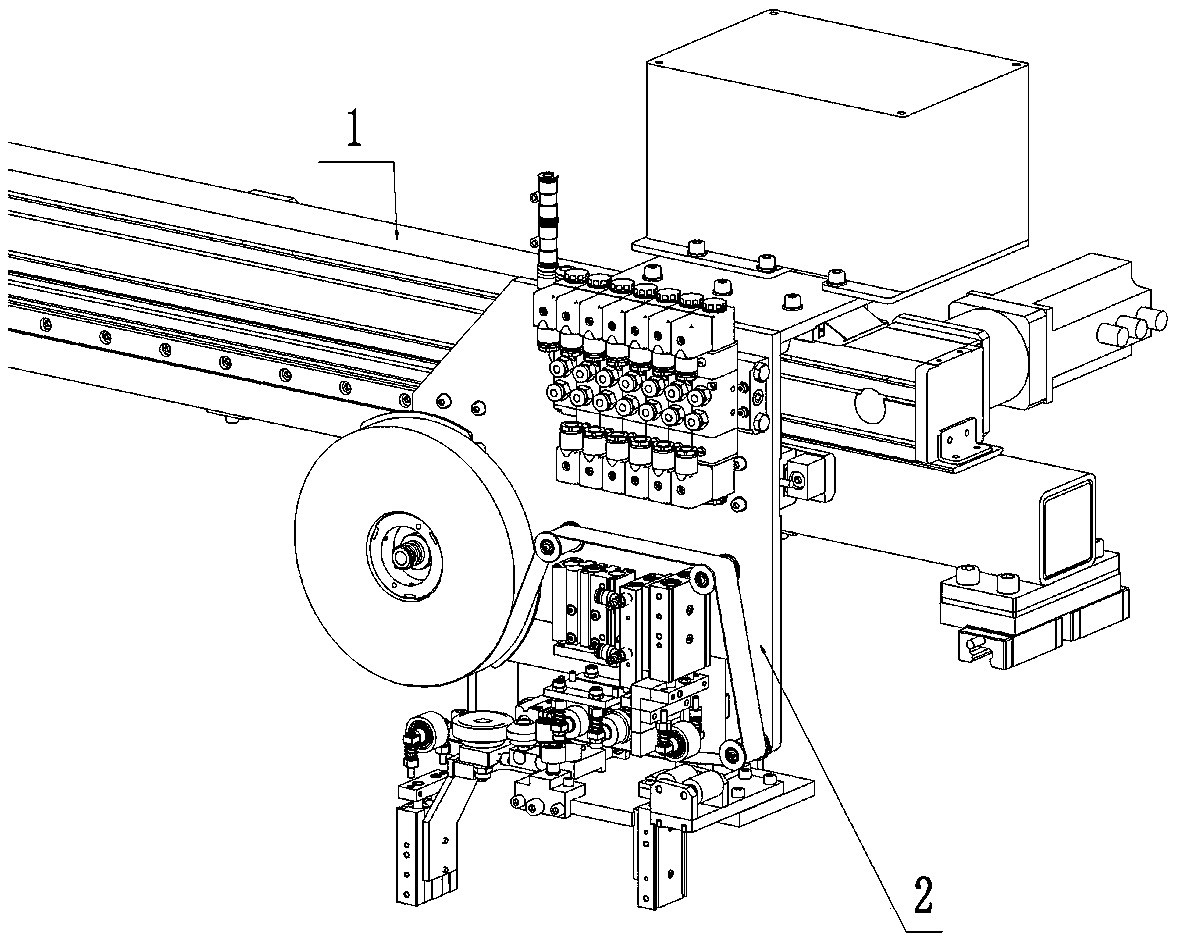

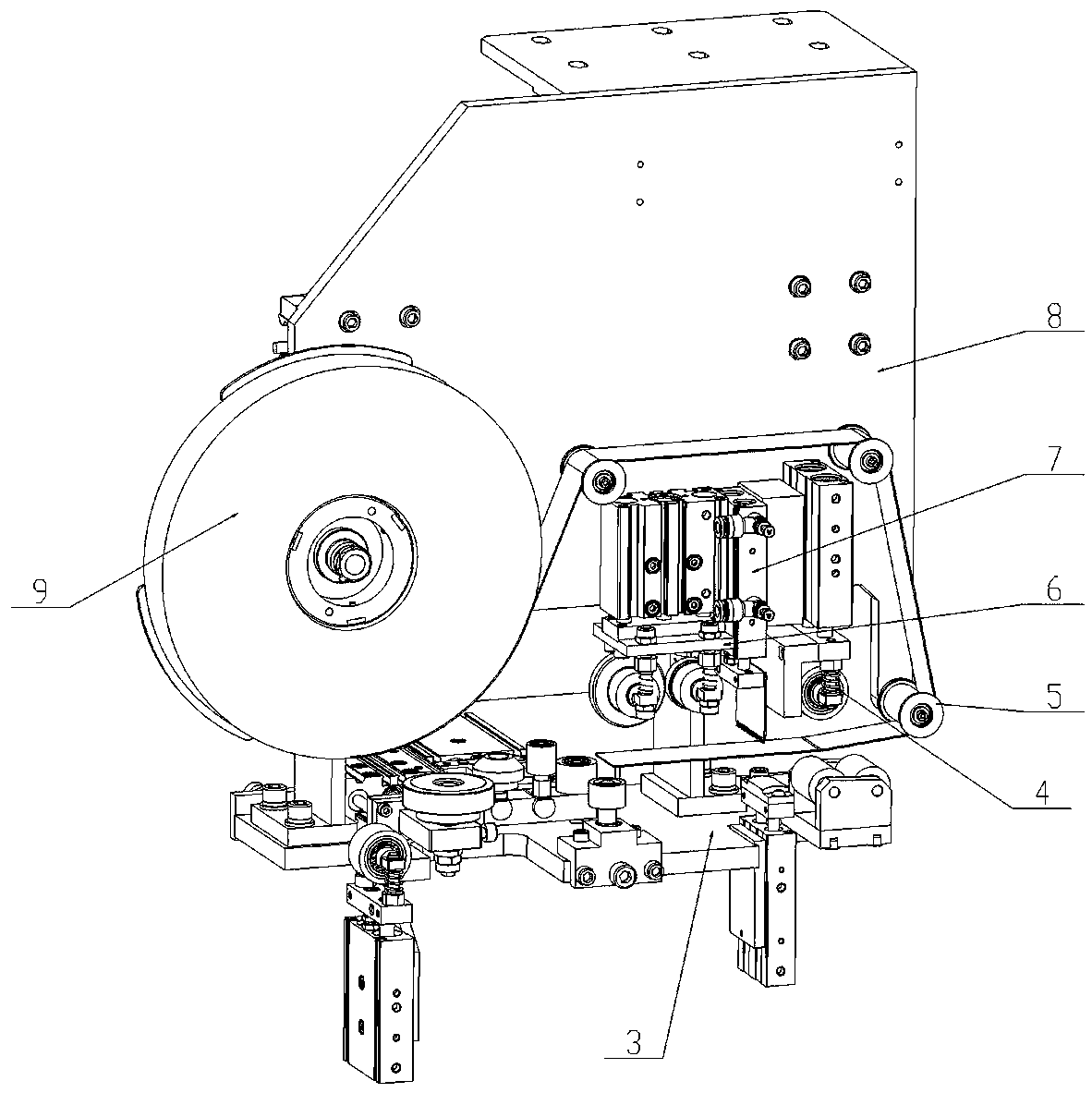

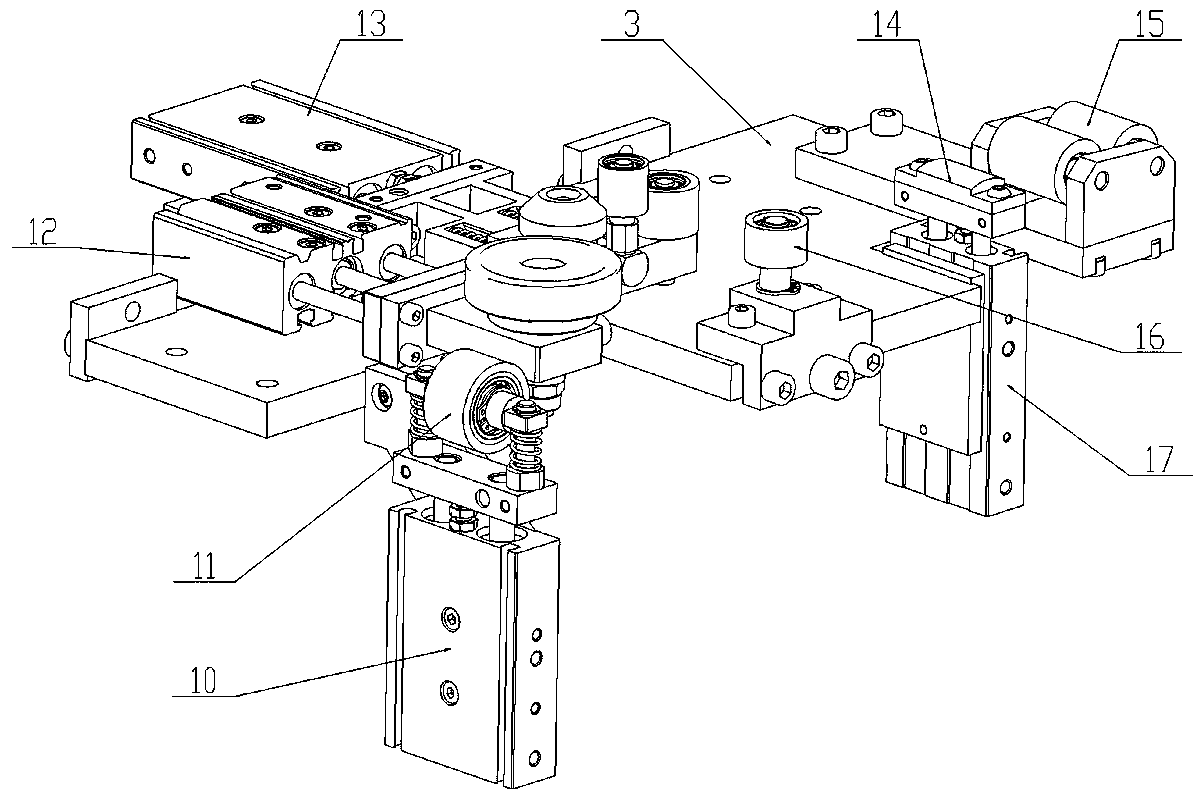

Solar battery double glass component tape first positioning automatic edge device and its edge process

ActiveCN111362043BPaste width controllablePosition is easy to controlFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The solar cell double-glass module tape first positioning type automatic edge banding device and its edge banding process belong to the technical field of solar cell module automatic production equipment, and specifically relate to a solar cell double glass module tape first positioning type automatic edge banding device and its edge banding process . The invention provides a high-efficiency solar cell double-glass component tape-positioning automatic edge-sealing device and its edge-sealing process with simple structure, high degree of automation, simple process and labor-saving. The adhesive tape first positioning type automatic edge banding device for solar cell double-glass modules of the present invention includes an edge banding head, which is characterized in that: the edge banding head includes a bracket, and a tape material roll and a guide belt corresponding to the tape material roll are arranged on the bracket The wheel set, corresponding to the guide pulley at the end, is provided with an upper compacting roller assembly, a folding roller assembly, a shaping roller assembly, an edge wrapping roller assembly and a lower compacting roller assembly in sequence; The rotating shafts of the upper compacting rollers of the upper compacting roller assembly are parallel to each other.

Owner:YINGKOU JINCHEN MACHINERY

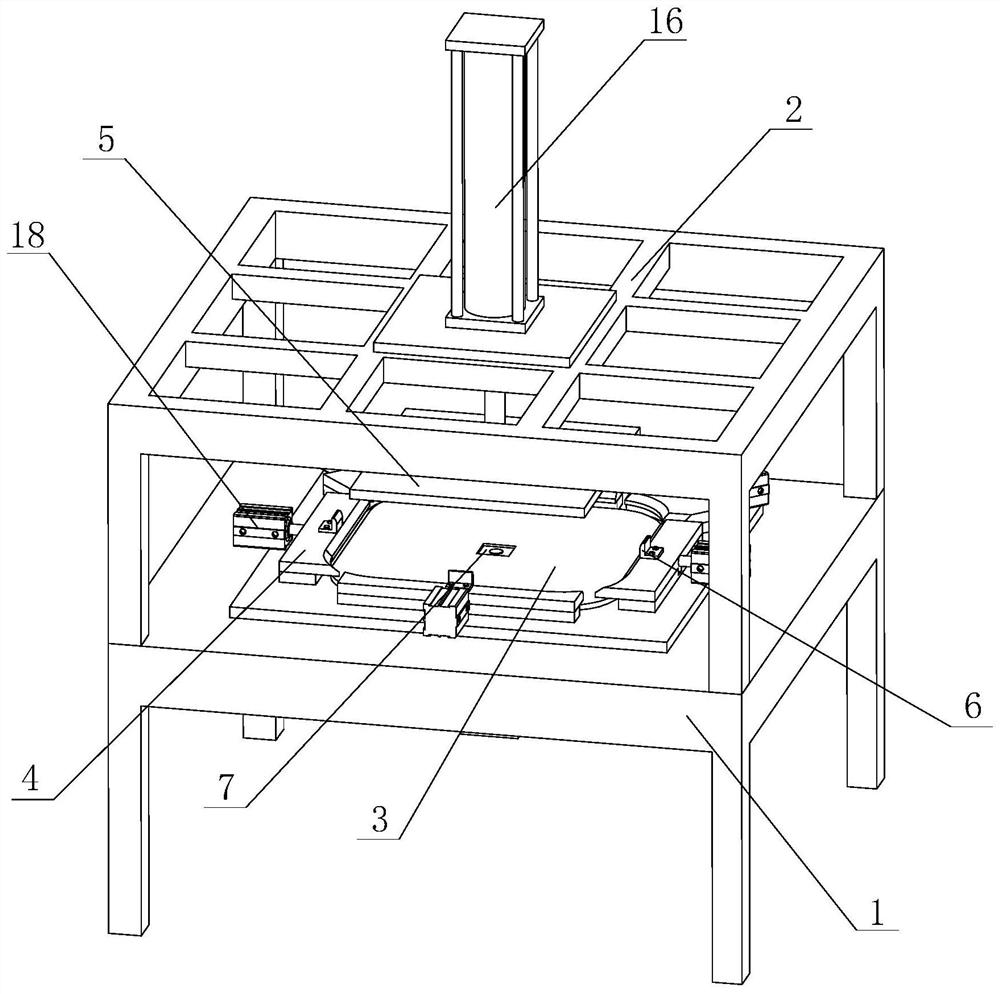

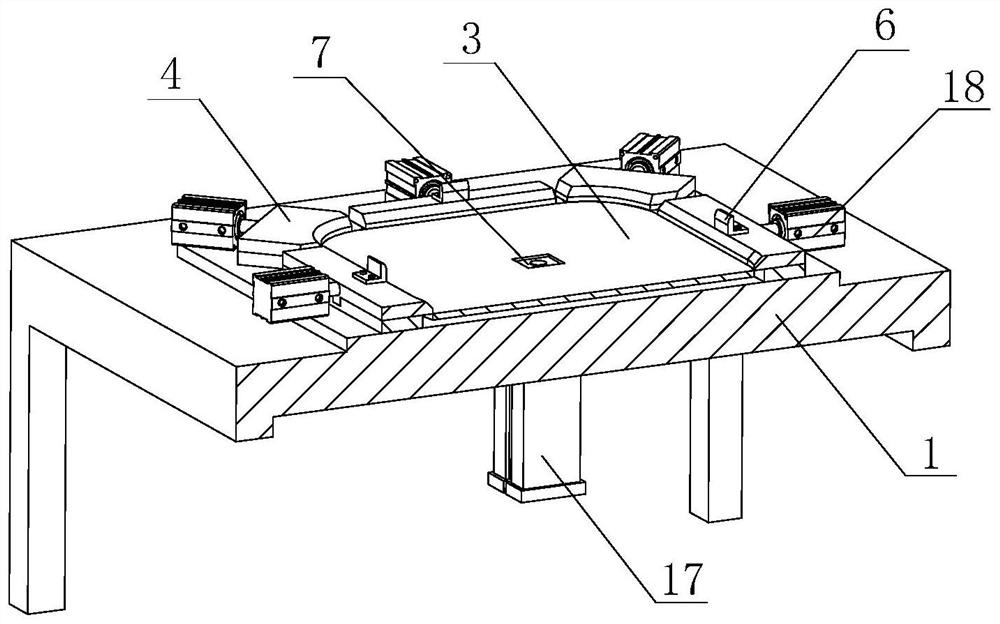

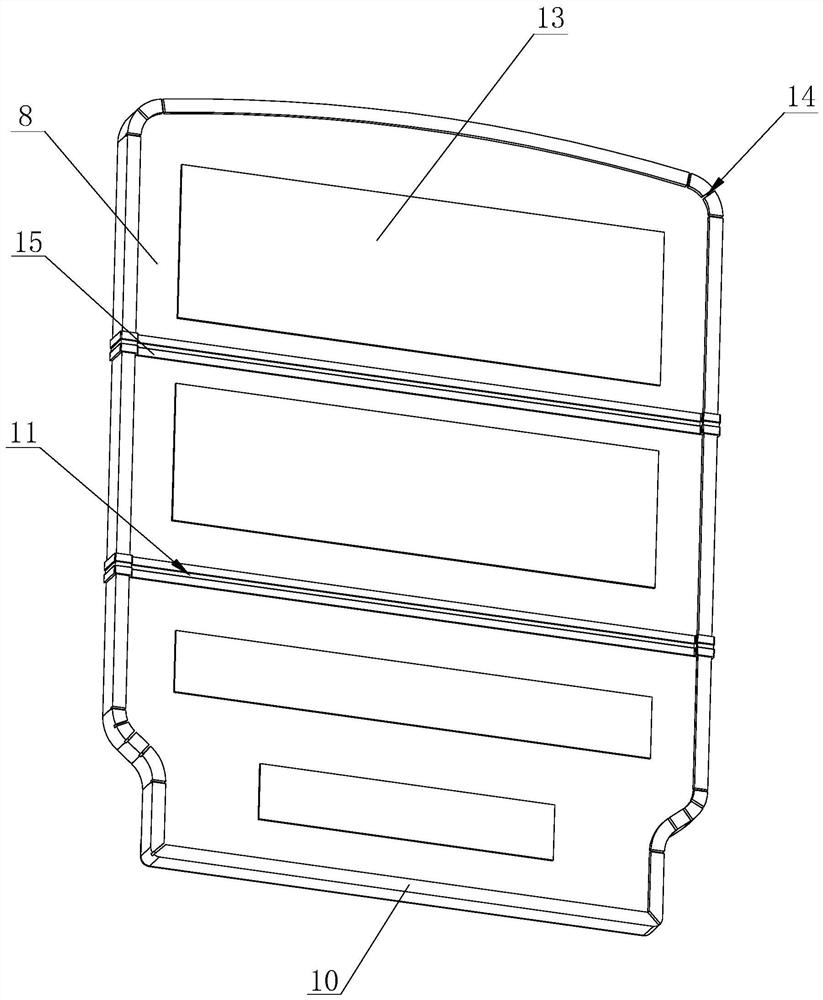

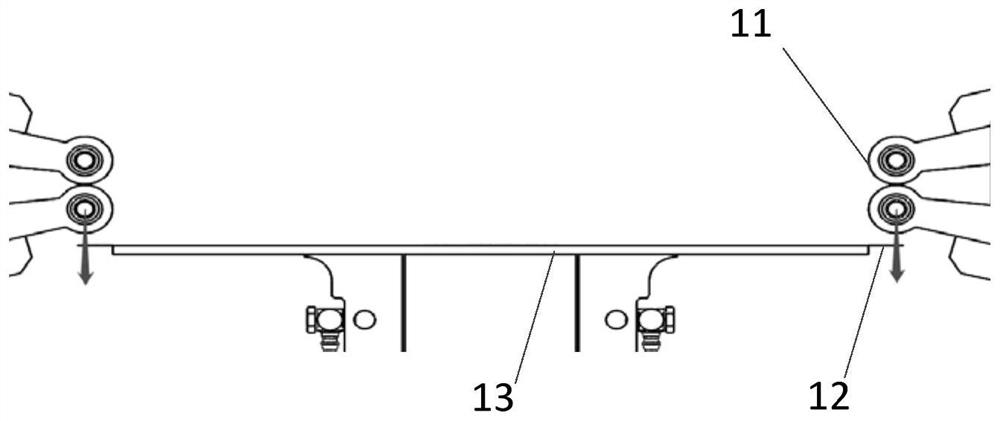

Edge covering machine for spare tire cover plate and machining process thereof

ActiveCN111716868AConvenient ascentImprove hemming qualityLamination ancillary operationsLaminationMachineMachining process

The invention relates to the field of automobile part machining, in particular to a spare tire cover plate edge covering machine and a machining process thereof. The spare tire cover plate edge covering machine comprises a machine table and a frame, wherein a lower pressing plate sliding up and down is arranged on the upper side of the machine table, and a lower pressing piece used for driving thelower pressing plate to slide up and down is arranged between the machine table and the lower pressing plate; a plurality of edge covering blocks are arranged on the peripheral side of the lower pressing plate on the upper side of the machine table, the lower sides of the edge covering blocks are higher than the upper side of the lower pressing plate, and a plurality of driving pieces used for driving the edge covering blocks to slide close to or away from the lower pressing plate are arranged on the upper side of the machine table; the frame is arranged on the upper side of the machine table; an upper pressing plate sliding up and down is arranged above the machine table; and an upper pressing piece used for driving the upper pressing plate to slide up and down is arranged between the upper pressing plate and the frame. The edge covering device has the effect of improving the edge covering quality of the spare tire cover plate.

Owner:武汉华迎汽车零部件有限公司

Shading adhesive tape flexible edge covering device and method

PendingCN112631000AEasy to debugImprove compatibilityNon-linear opticsAdhesive beltStructural engineering

The invention discloses a shading adhesive tape flexible edge covering device and method. The device comprises a device platform, the device platform is provided with a guide plate and a plurality of rollers which are sequentially arranged in the product feeding direction, and the rollers have different inclination angles respectively; the guide plate is used for downwards pressing the suspended part of the shading adhesive tape for an angle when the product with the shading adhesive tape attached to the front surface is fed; the rollers comprise a plurality of guide rollers and a pair of edge covering rollers which are sequentially arranged in the product feeding direction, the guide rollers are used for guiding the suspended part of the shading adhesive tape to be bent downwards step by step, and the edge covering rollers are used for tightly pressing the shading adhesive tape to the side face and the back face of the product; and in the plurality of rollers, at least the edge covering rollers are provided with elastic surfaces. According to the device, the shading adhesive tape is guided and bent through the multiple rollers with different inclination angles, the edge covering quality is guaranteed by arranging at least the elastic surfaces on the edge covering rollers, and the production efficiency and the yield of shading adhesive tape edge covering are improved.

Owner:SHENZHEN EAGLE EYE ONLINE ELECTRONICS TECH

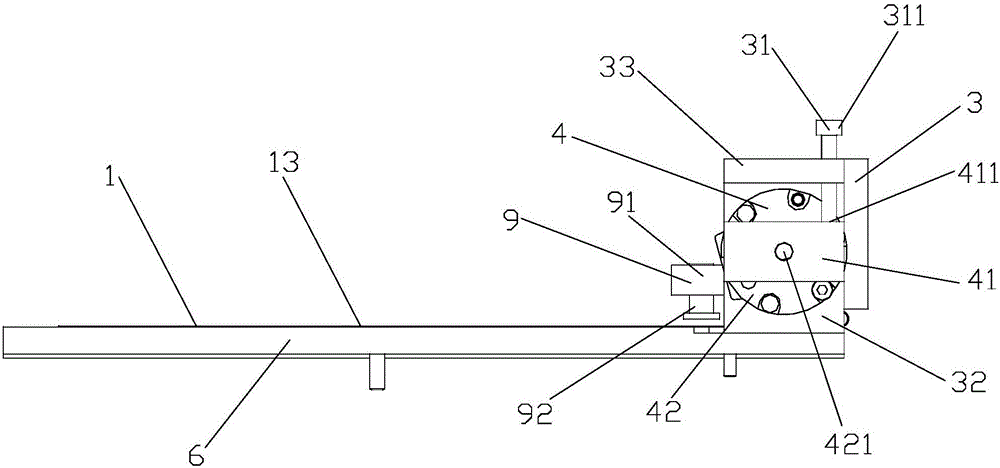

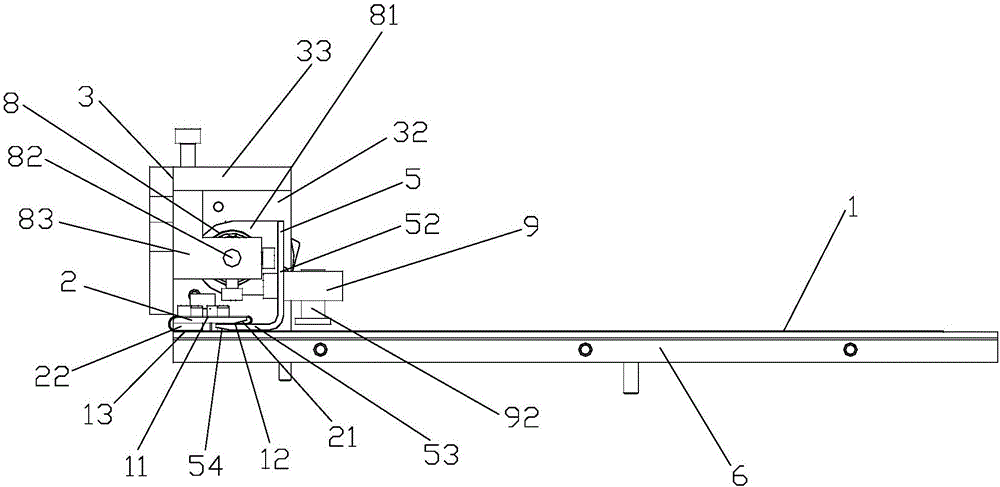

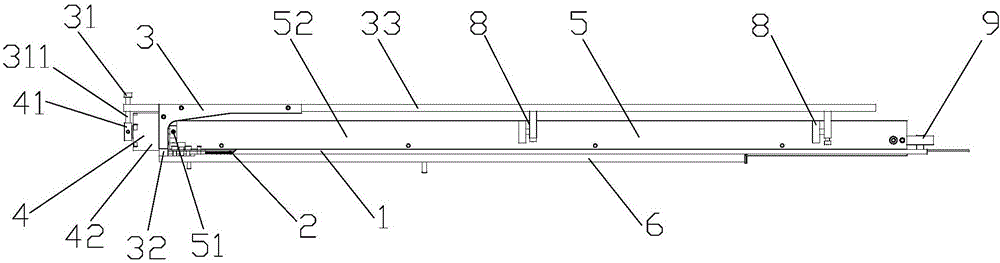

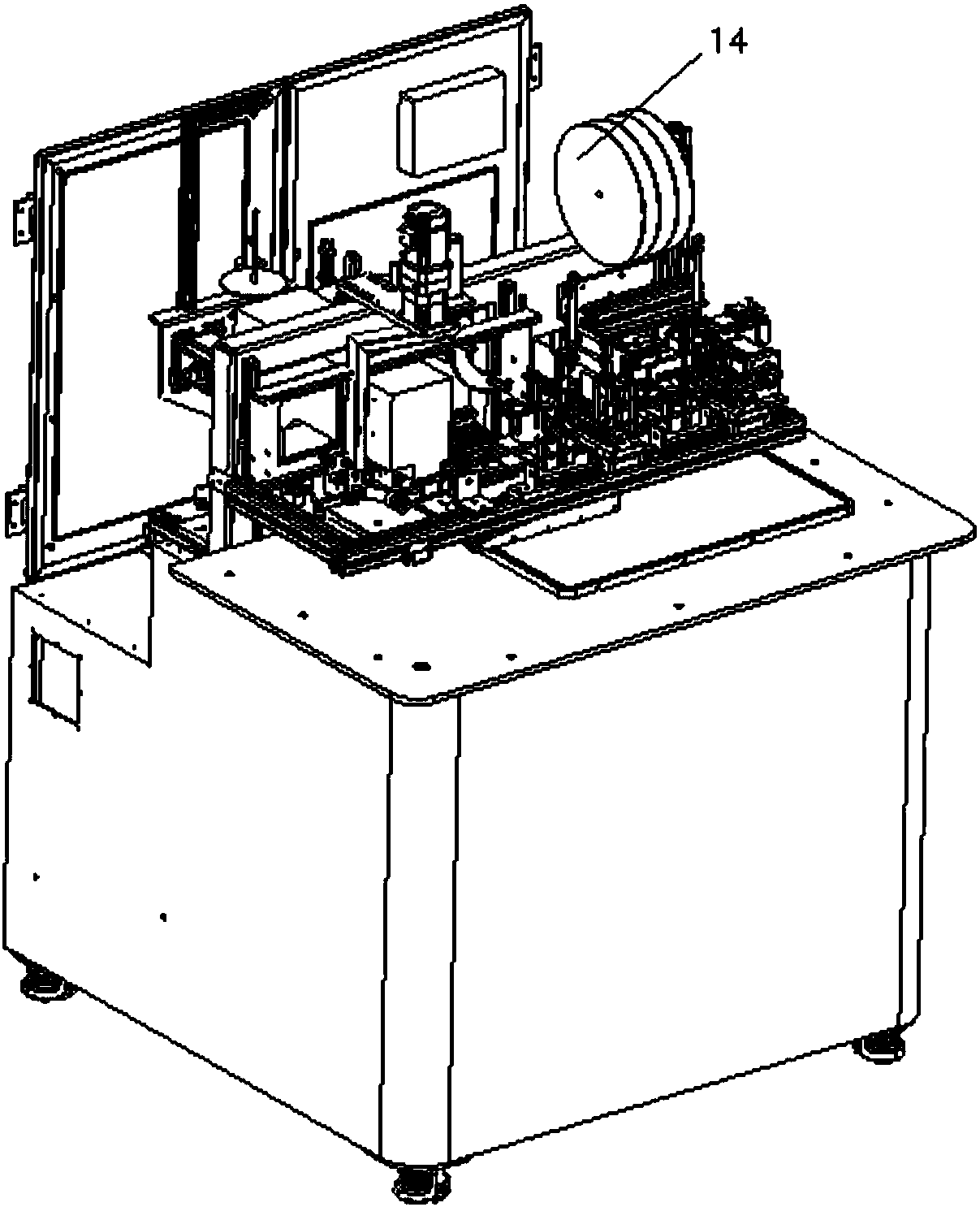

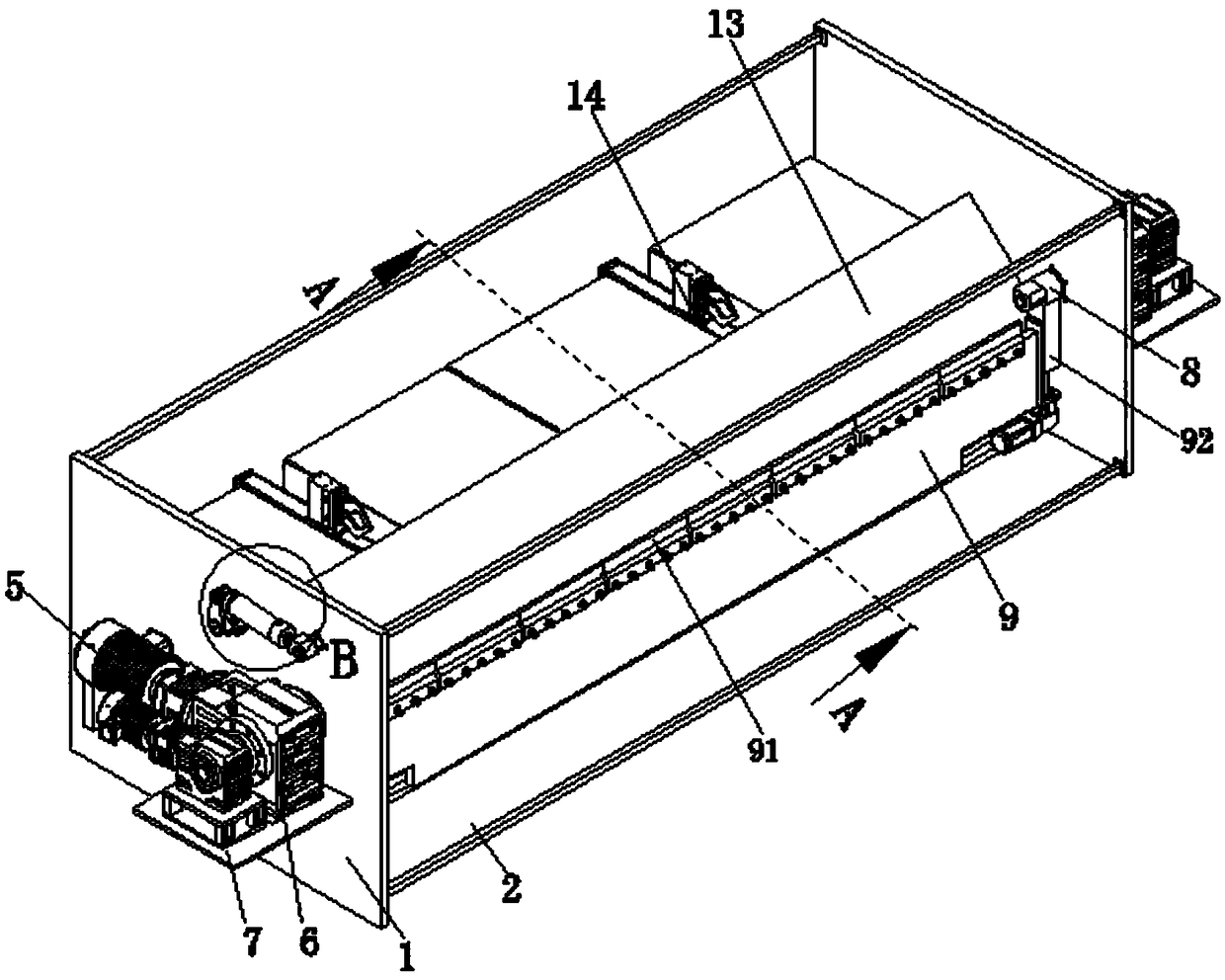

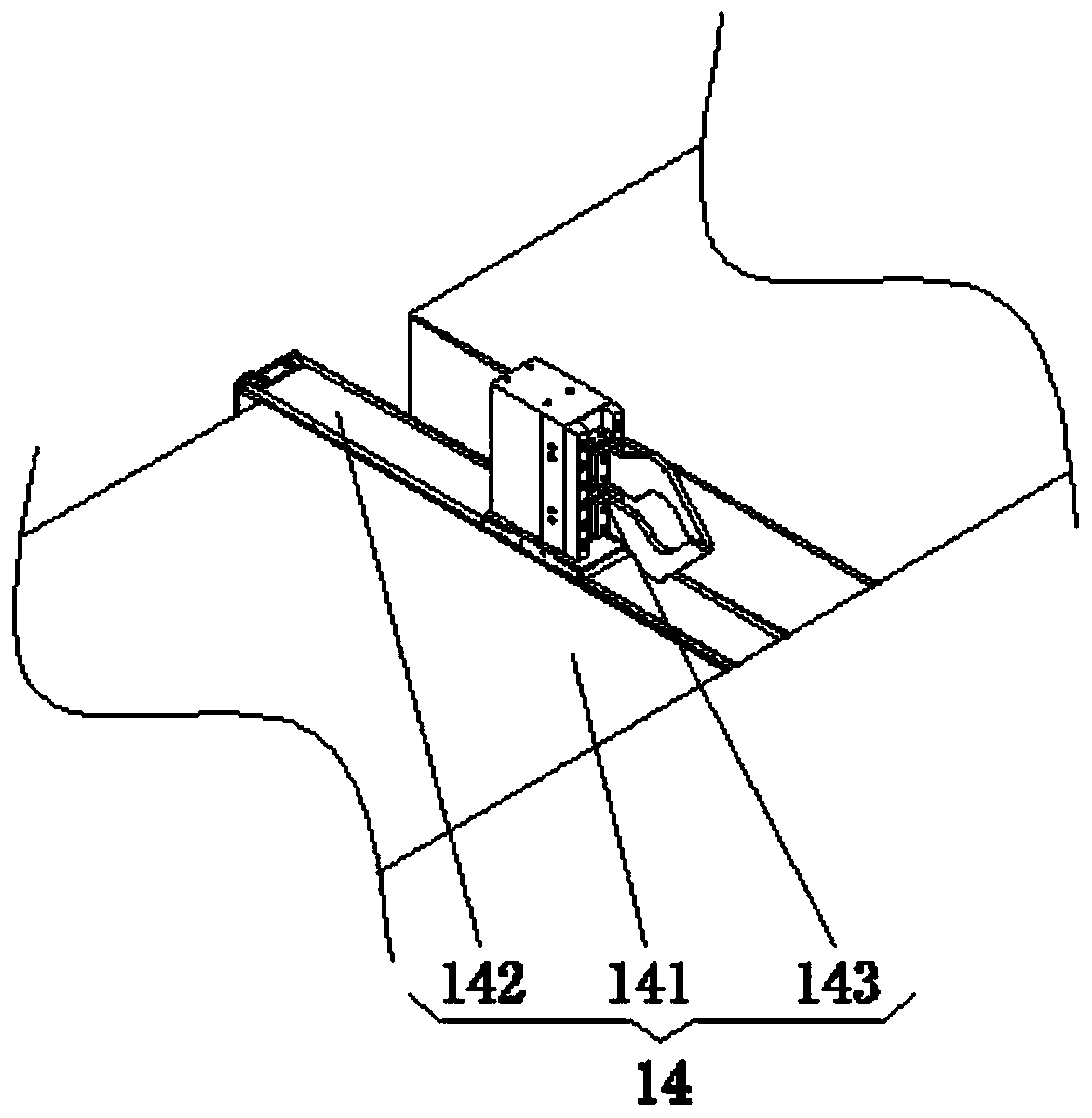

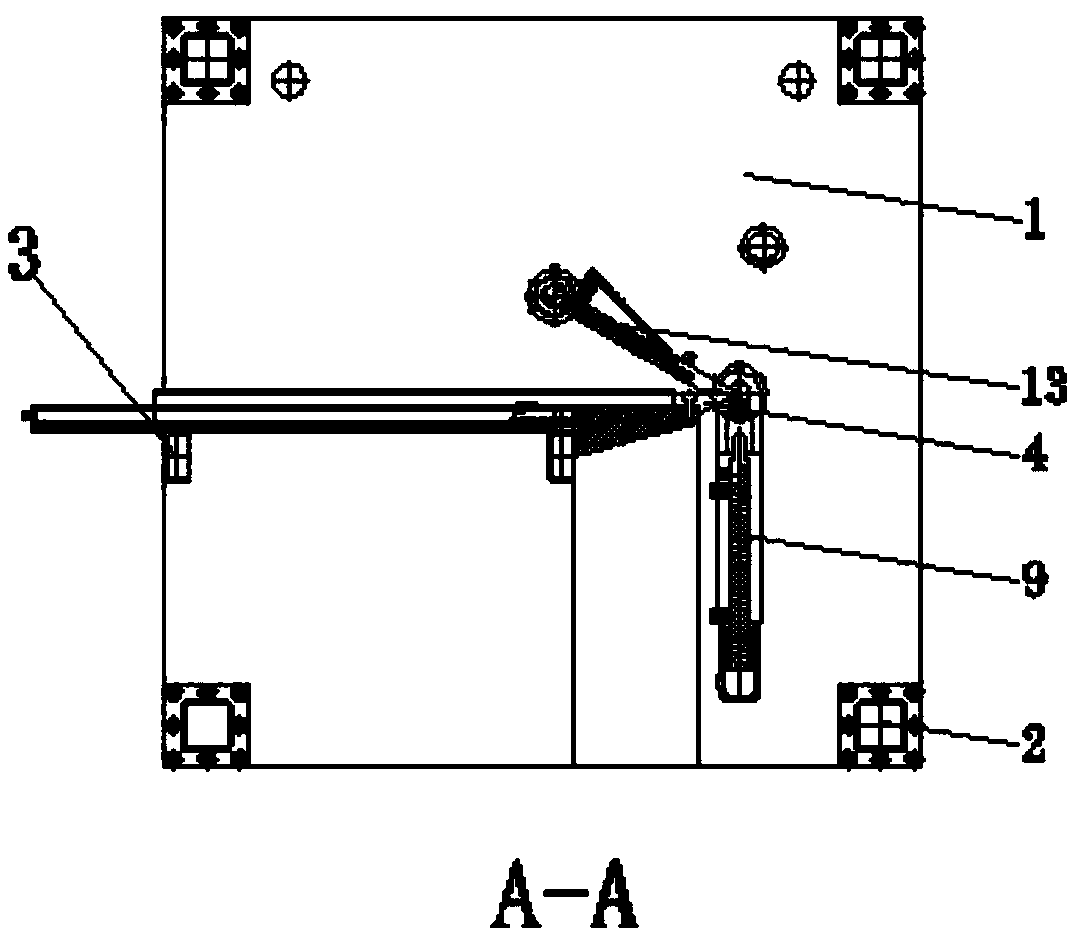

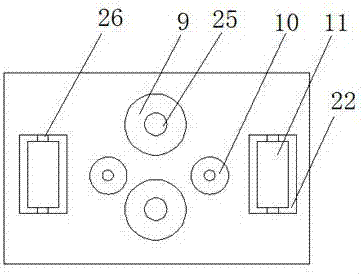

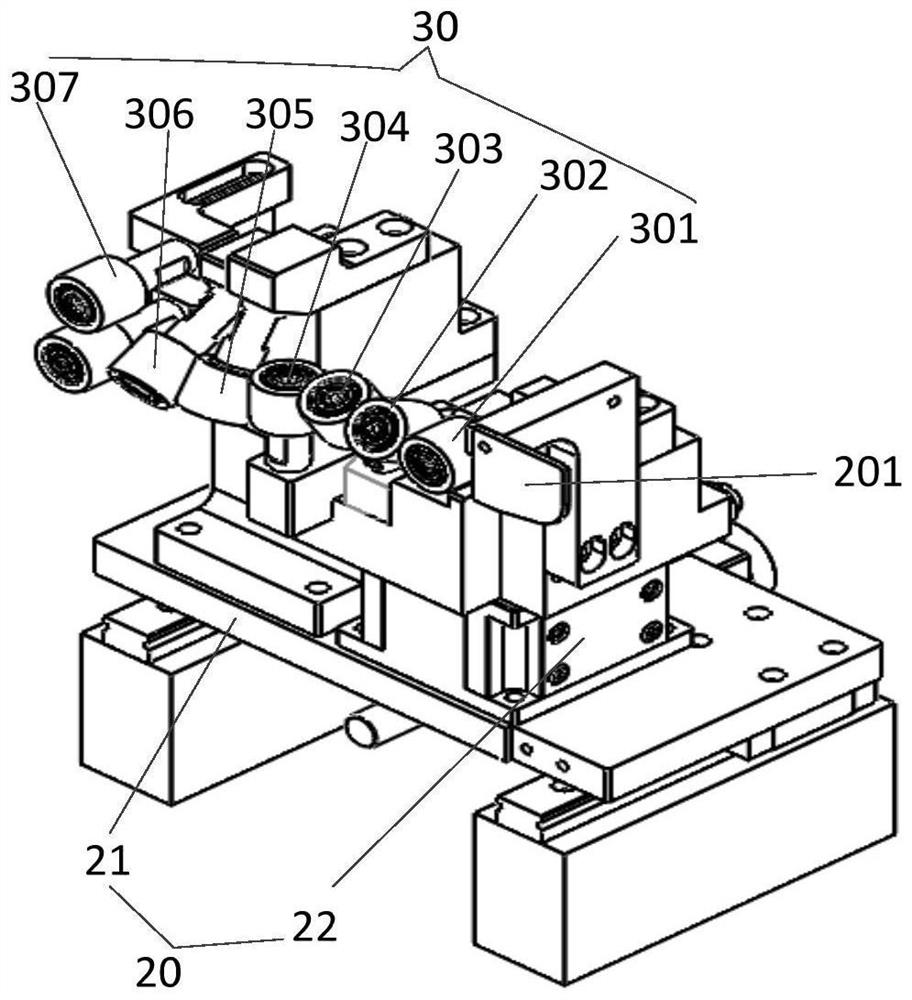

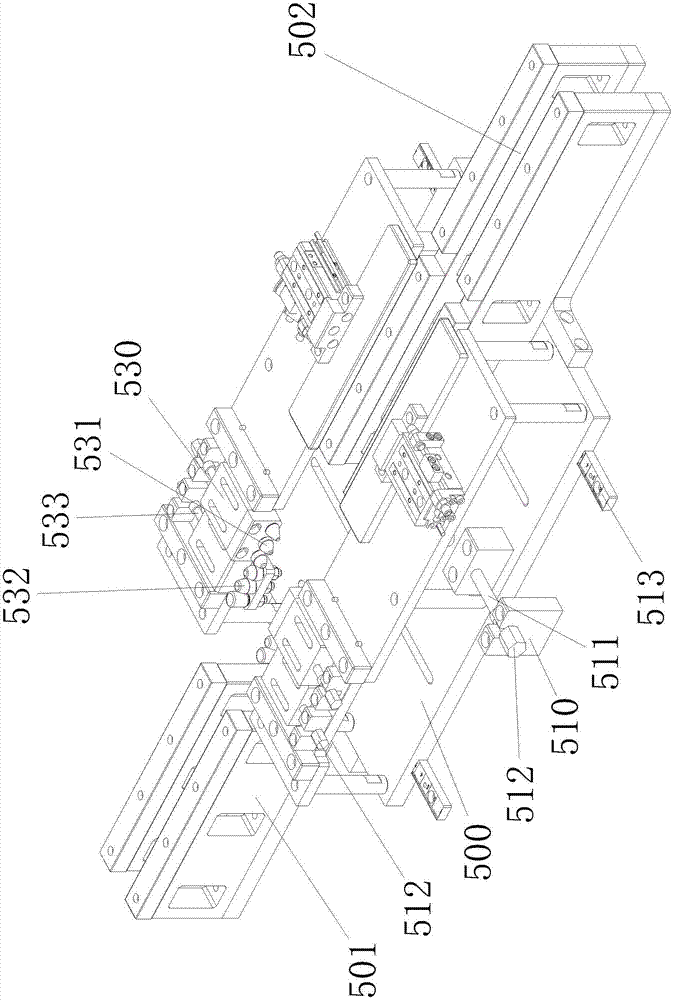

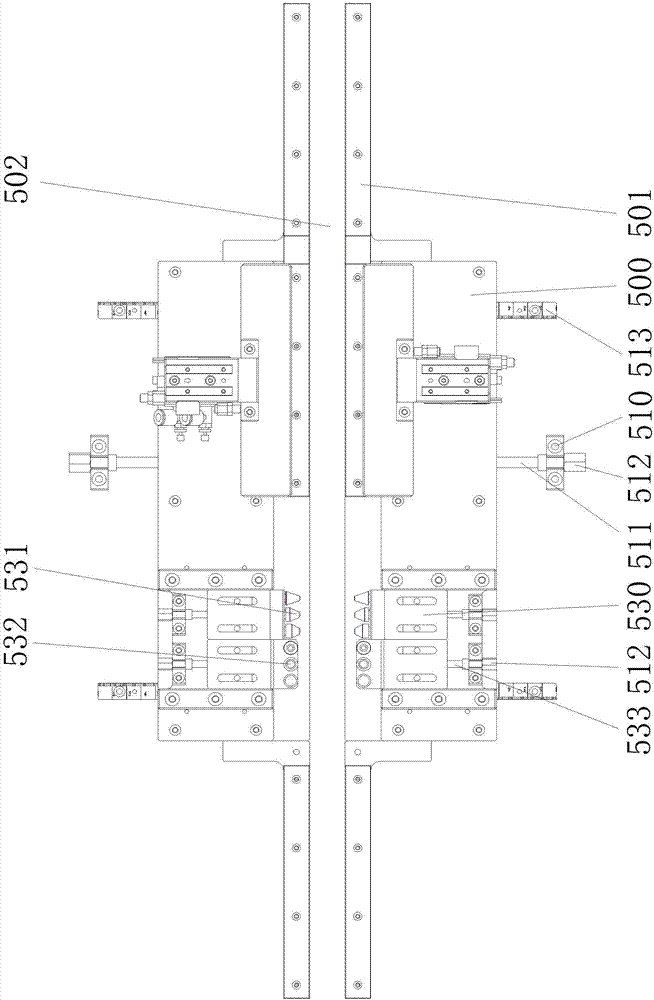

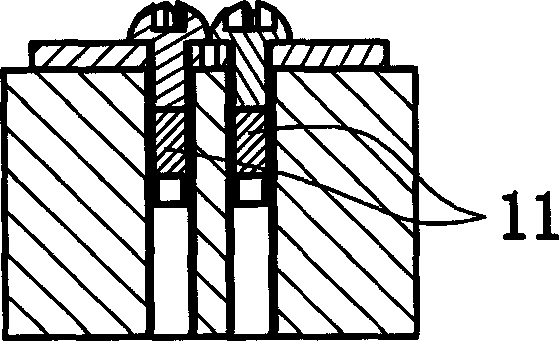

Rolling folding mechanism

PendingCN108011131AImprove hemming qualityGood bending propertiesAssembling battery machinesFinal product manufacturePlastic packagingEngineering

The invention discloses a rolling folding mechanism, which comprises a rolling folding base and a rolling folding bracket arranged on the rolling folding base, wherein the other rolling folding bracket is arranged in a mirror image of the rolling folding bracket; rolling folding pallets are arranged on the opposite side surfaces of the two rolling folding brackets; a rolling folding channel is formed between the two rolling folding pallets; each rolling folding bracket is provided with a horizontal first roller group and a vertical second roller group along the direction of the corresponding rolling folding pallet; and each first roller group and second roller group are arranged in a plane in which the corresponding rolling folding pallet is located in a semisubmersible manner. A battery plastic packaging film can be quickly folded from two horizontal sides to two vertical sides, so that the rolling folding mechanism is good in bending effect, consistent in specification and high in quality.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

Self-adaptive binding tool

The invention discloses a self-adaptive binding tool. The self-adaptive binding tool comprises a connecting base plate, a group of edge covering cylindrical wheels, a group of auxiliary cylindrical wheels, an auxiliary wheel sliding table and an edge covering wheel sliding table, and the auxiliary wheel sliding table and the edge covering wheel sliding table are arranged at the lower end of the connecting base plate; and the auxiliary cylindrical wheels are connected with a first sliding block on the auxiliary wheel sliding table through a first connecting assembly, and the edge covering cylindrical wheels are connected with a second sliding block on the edge covering wheel sliding table through a second connecting assembly, so that the gaps between the auxiliary cylindrical wheels and the edge covering cylindrical wheels can be adjusted to adapt to forming dies and plates of different thicknesses. According to the self-adaptive binding tool, two groups of roller sets are connected to a connecting disc, the two groups of roller sets can axially move by means of sliding rails and sliding blocks, a gap between the two groups of roller sets can be conveniently changed, edge covering of the forming dies and the plates between the two groups of roller sets can be conveniently completed in three steps after the two groups of roller sets are oppositely clamped, and the edge covering quality is improved; and meanwhile, a proportional valve capable of controlling output pressure of an air cylinder is additionally arranged, the proportional valve is operated, different edge covering forces for pre-edge covering and final edge covering can be provided, and the edge covering effect is improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

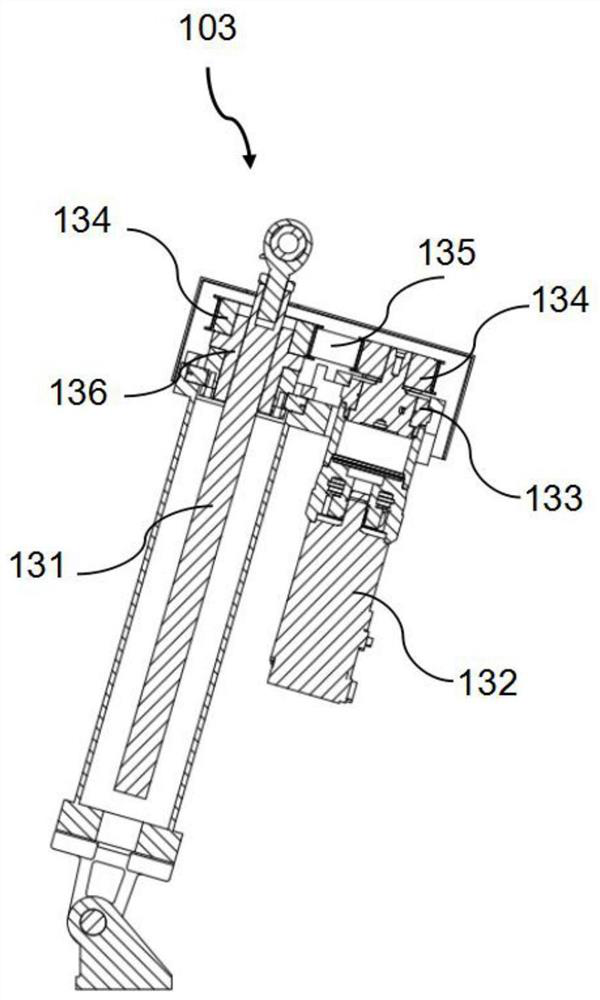

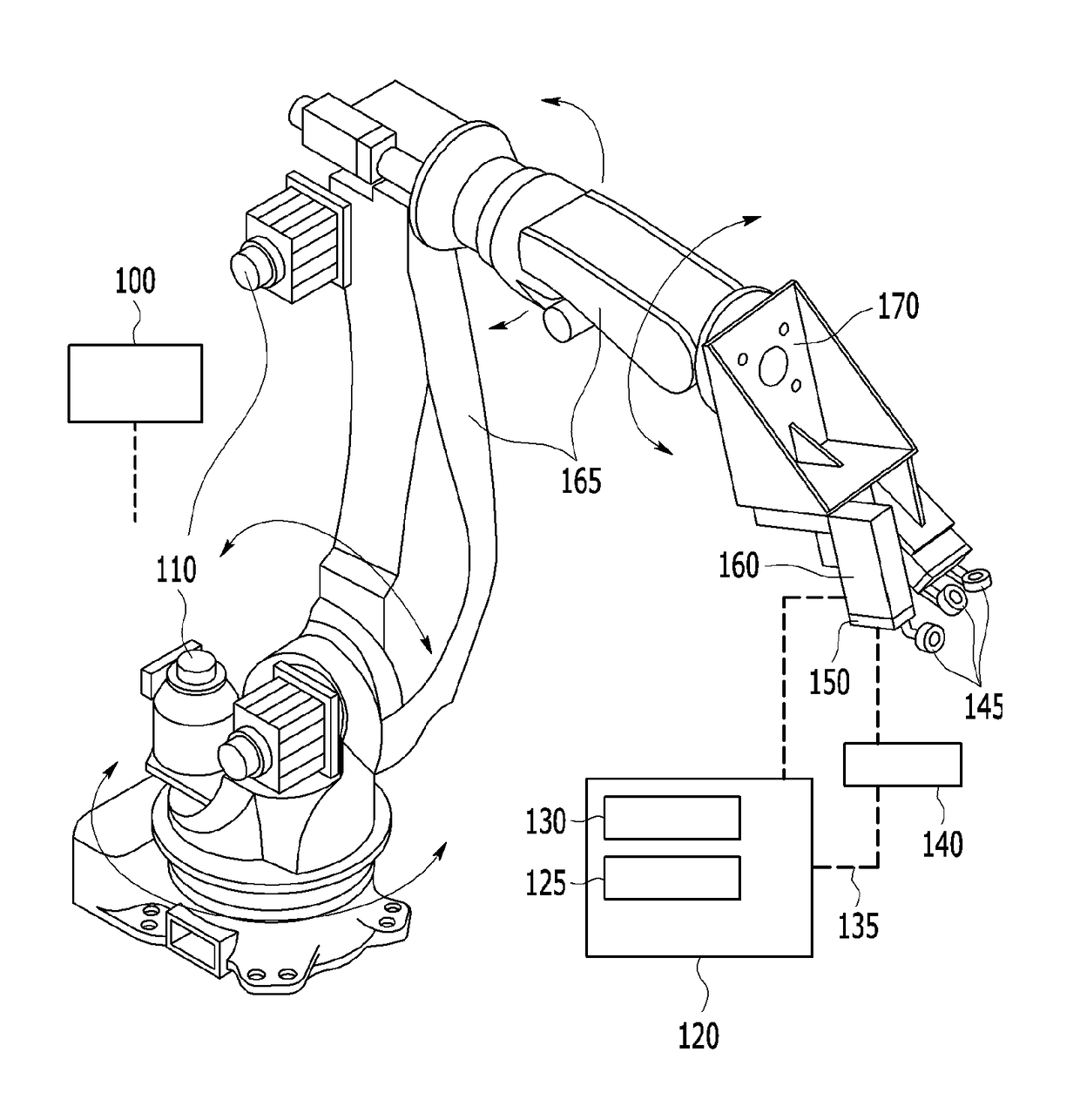

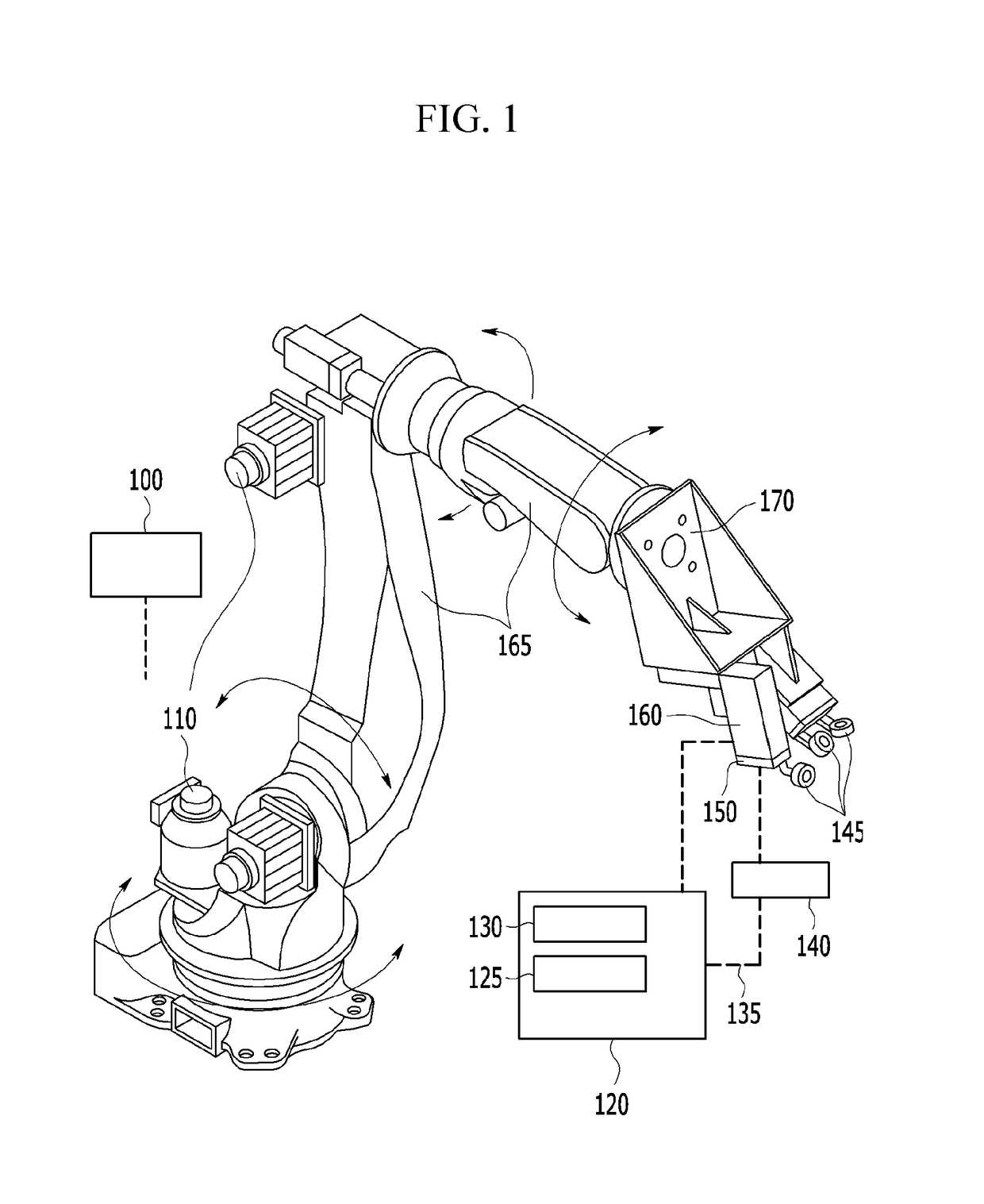

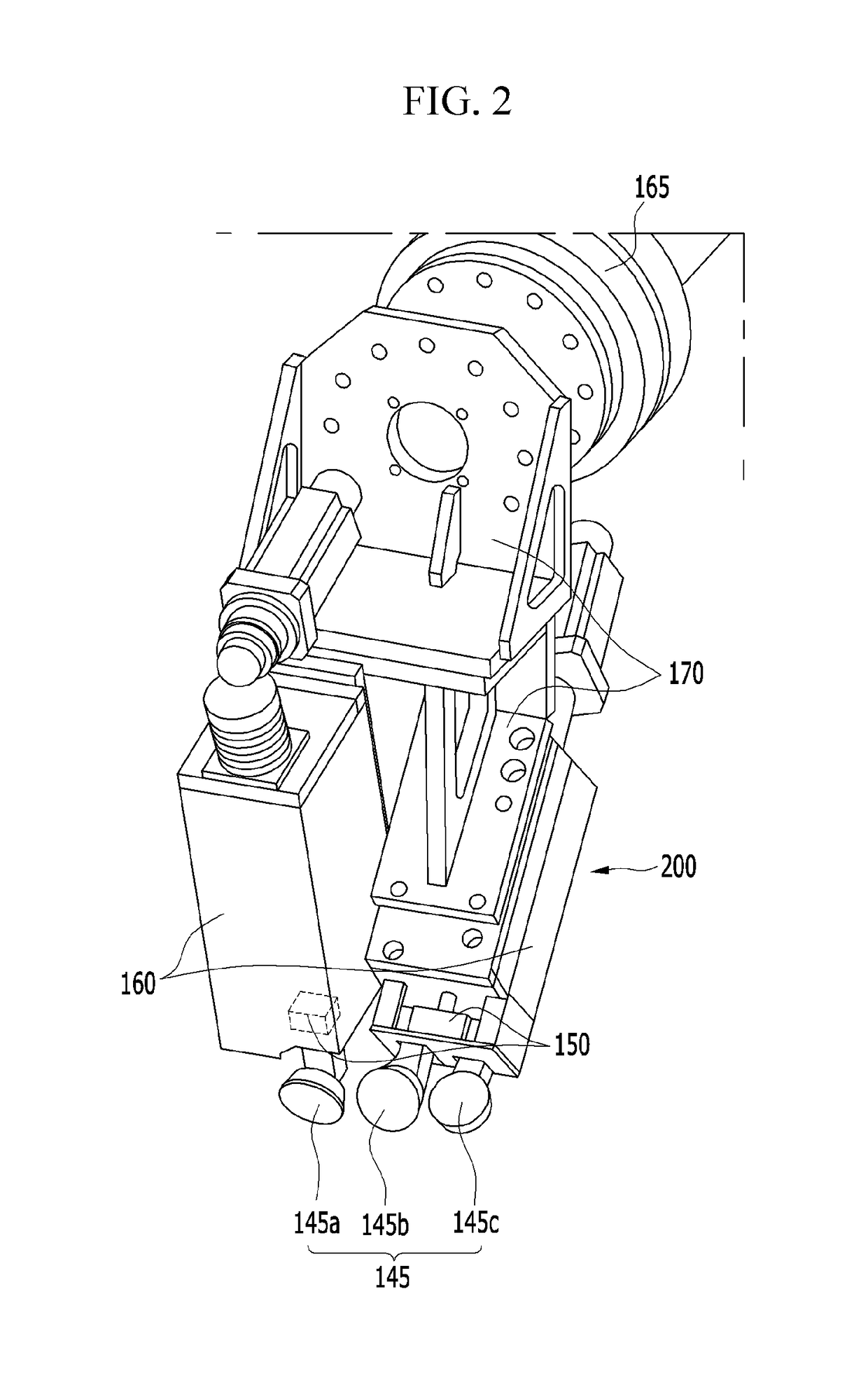

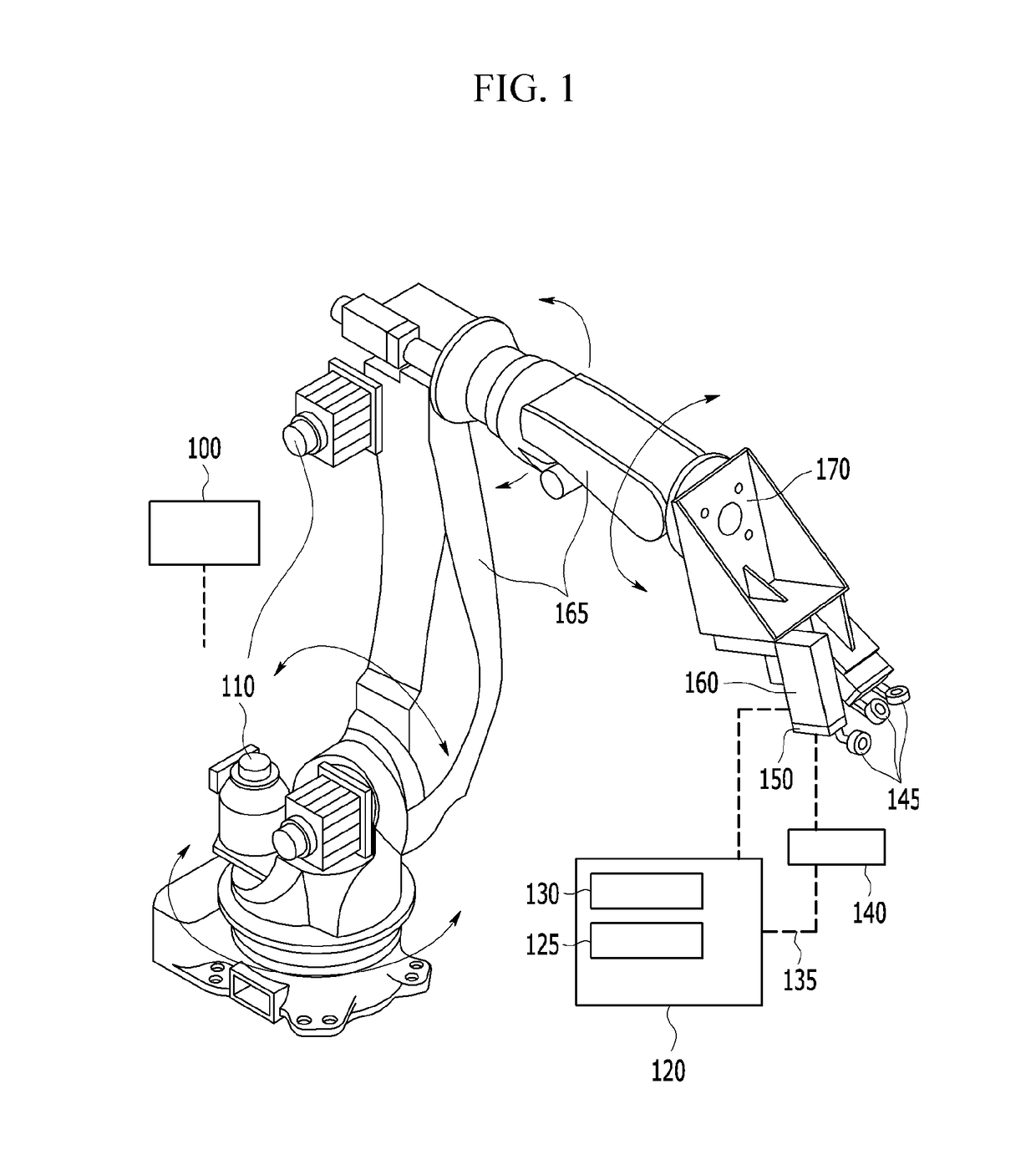

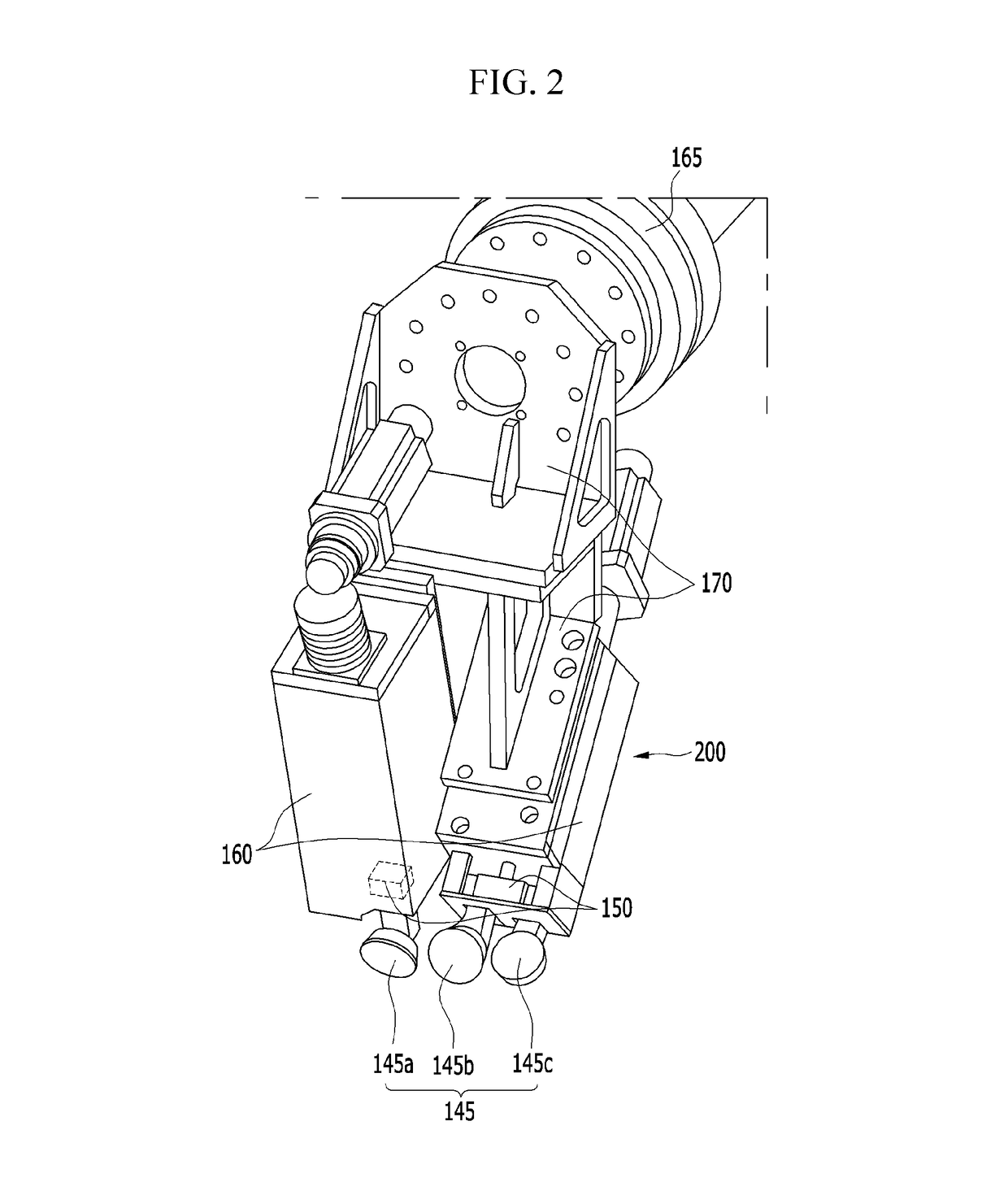

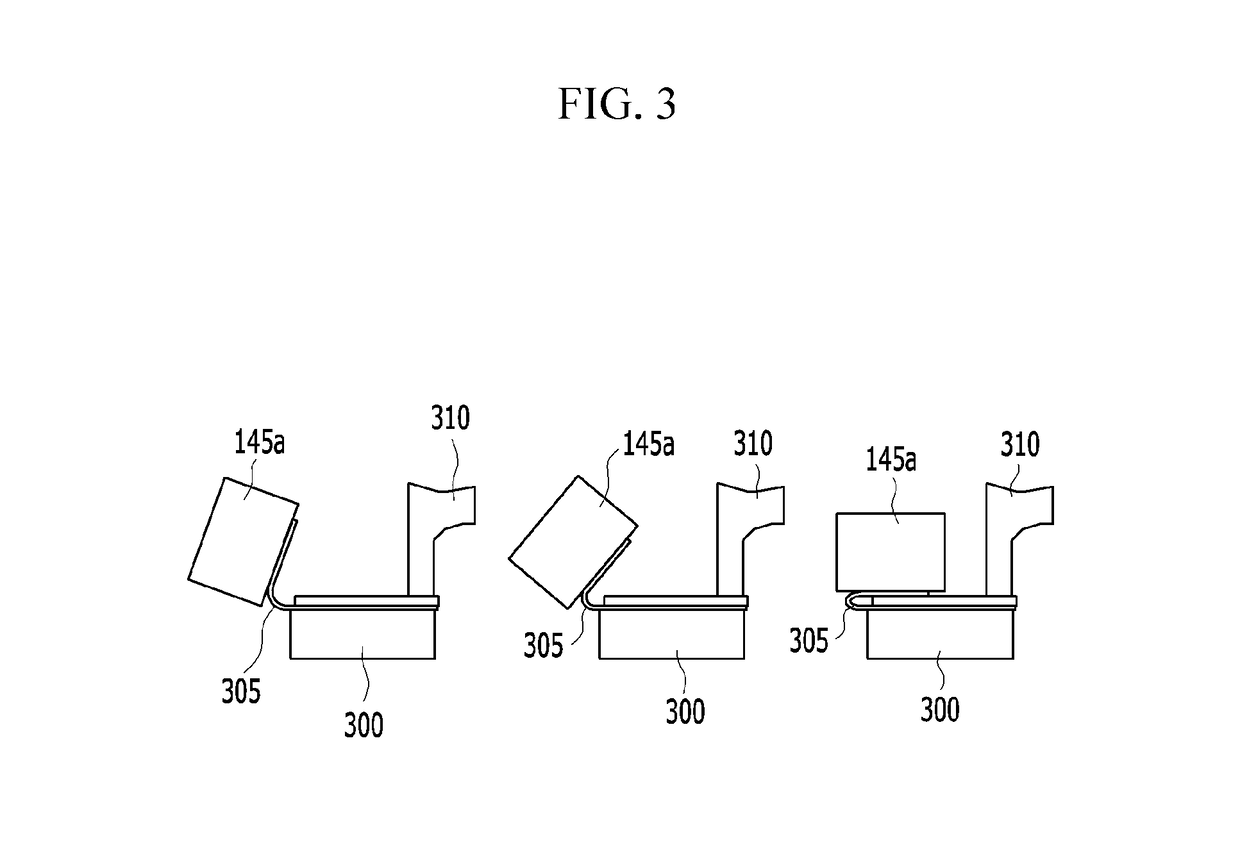

Smart active control roller hemming device and system

ActiveUS20180050377A1MaintenanceQuality andProgramme-controlled manipulatorMetal-working feeding devicesEngineeringPressure detection

A smart active control hemming device is provided. The device includes a robot arm and a hemming roller unit that is disposed at a front end portion of the robot arm. The hemming roller unit includes a plurality of hemming rollers, a control motor that is driven with an electric motor to adjust a hemming pressure or position of at least one of the hemming rollers, and a pressure detection sensor that detects a hemming pressure of the hemming roller in which a hemming pressure is adjusted by the control motor.

Owner:KIA MOTORS CORP +1

Gauze edge covering device

ActiveCN110774603AImprove hemming qualityPrevent tamperingStructural engineeringMechanical engineering

The invention discloses a gauze edge covering device, and relates to the technical field of spinning equipment. The gauze edge covering device comprises an edge covering mechanism and a conveying mechanism used for driving edge cloth to pass through the edge covering mechanism, and the edge covering mechanism comprises a rotatable edge covering roller and a supporting plate located below the edgecovering roller; a pressing part is arranged on one side of the edge covering roller and used for pressing the edge cloth between two adjacent magnetic strips so as to prevent the magnetic strips frommoving; the pressing part is an arc-shaped plate; the center line of a circular ring corresponding to the arc-shaped plate and the center line of the edge covering roller are located on a same straight line, and the diameter of the outer circle of the circular ring corresponding to the arc-shaped plate is the same as that of the edge covering roller; a plurality of first pressing teeth are arranged on the outer side face of the arc-shaped plate; the first pressing teeth are connected with a heat supply assembly. According to the gauze edge covering device, the pressing part is arranged on theedge covering roller, so that the edge cloth between the adjacent magnetic strips can be pressed in the edge covering process, a channel between the adjacent magnetic strips is blocked to prevent movement of the magnetic strips, and the edge covering quality is effectively improved.

Owner:LIXIN FUYA GAUZE CO LTD

Smart active control roller hemming device and system

ActiveUS10166587B2MaintenanceQuality andProgramme-controlled manipulatorMetal-working feeding devicesPressure detectionElectric motor

A smart active control hemming device is provided. The device includes a robot arm and a hemming roller unit that is disposed at a front end portion of the robot arm. The hemming roller unit includes a plurality of hemming rollers, a control motor that is driven with an electric motor to adjust a hemming pressure or position of at least one of the hemming rollers, and a pressure detection sensor that detects a hemming pressure of the hemming roller in which a hemming pressure is adjusted by the control motor.

Owner:KIA MOTORS CORP +1

Automatic edge sealing device and technology capable of primarily positioning adhesive tape for solar cell double-glazed module

ActiveCN111362043APaste width controllableOvercome the disadvantages of edge banding perpendicular to the component planeFinal product manufacturePhotovoltaic energy generationAdhesive beltEngineering

The invention belongs to the technical field of automatic production equipment of solar cell modules and particularly relates to an automatic edge sealing device and technology capable of primarily positioning an adhesive tape for a solar cell double-glazed module. According to the automatic edge sealing device and technology capable of primarily positioning the adhesive tape for the solar cell double-glazed module, the structure is simple, the degree of automation is high, the technology is simple and manpower is saved. The automatic edge sealing device capable of primarily positioning the adhesive tape for the solar cell double-glazed module comprises an edge sealing head and is characterized in that the edge sealing head comprises a bracket, wherein an adhesive tape roll and a tape guide wheel set corresponding to the adhesive tape roll are arranged on the bracket, and an upper compressing roller assembly, a folding roller assembly, a shaping roller assembly, an edge covering rollerassembly and a lower compressing roller assembly are sequentially arranged on the bracket in a mode of corresponding to the tape guide wheel at the tail end; and the adhesive tape roll is parallel toa rotating shaft of an upper compressing roller of the upper compressing roller assembly of the tape guide wheel set.

Owner:YINGKOU JINCHEN MACHINERY

Lithium battery processing equipment and using method thereof

ActiveCN108054437AImprove hemming qualityAssembling battery machinesFinal product manufactureBiochemical engineeringPlastic film

The present invention relates to a lithium battery processing equipment and a using method thereof, pertaining to the technical field of lithium battery production. The equipment comprises a roller and two fixing blocks. Both ends of the roller are rotatably connected on the two fixing blocks separately, the roller is located right above a circular-arc-shaped chamfer, and a pace used for passing through an aluminum-plastic film is arranged between the roller and the circular-arc-shaped chamfer. The method comprises the following steps: a lithium battery is placed on a horizontal base platformof a lithium battery edge-folding device; the horizontal base platform is rotated to the position of contacting with a chock block exactly, the roller is exactly located above the circular-arc-shapedchamfer at the moment, and the aluminum-plastic film passes through the space between the roller and the circular-arc-shaped chamfer of a vertical base platform; the protruding aluminum-plastic film is heated and softened by using the head of a heat sealing equipment; the fixing blocks and the edge-folding device are allowed to rotate relatively after the heating and the softening are completed, and the roller rotates along a circular-arc surface of the chamfer to press the aluminum-plastic film towards the circular-arc surface and allow the aluminum-plastic film to bend. The equipment and themethod can improve the edge-folding quality and the edge-folding safety.

Owner:SICHUAN JIENENG NEW ENERGY TECH

Cloth edge folding mechanism with shaping and pressing functions

ActiveCN112411032AReduce wrinklesImprove hemming qualityMechanical cleaningPressure cleaningStructural engineeringDry box

The invention relates to the technical field of cloth processing, in particular to a cloth edge folding mechanism with shaping and pressing functions. The cloth edge folding mechanism comprises a drying box and a wetting box, wherein a cloth feeding roller is rotatably mounted in the drying box, a guide roller and a transition roller are rotatably mounted in the drying box, a leveling fan and a guide pipe are fixedly mounted on the drying box, a partition plate is fixedly installed in the guide pipe, a base is fixedly installed in the drying box, a sliding rod is fixedly installed on the base,the sliding rod is sleeved with a spring, a sliding sleeve is slidably installed on the sliding rod, a movable frame is fixedly installed on the sliding sleeve, the movable frame is slidably connected into a limiting rail, and a tension roller is rotatably installed on the movable frame. Edge-folded cloth is pre-fixed through the drying box and the wetting box which are connected, a leveling andimpurity removing mechanism and a tension adjusting mechanism are arranged in the drying box, thread residues adhering to the surface of the cloth can be removed, the tension borne by the cloth is changed, creases on the cloth are reduced, and the edge folding quality is improved.

Owner:杭州罗龙科技实业有限公司

Low-concentration sampling nozzle forceps clip binder

ActiveCN102218658BReasonable designSimple in structure and totally functionalAssembly machinesForcepsMaterials science

The invention relates to a binder, in particular to structural improvement on a low-concentration sampling nozzle forceps clip binder. The low-concentration sampling nozzle forceps clip binder is characterized by comprising a base (1) and a rotation mechanism (4) arranged in the base (1); and a binding mechanism (5) used for binding a low-concentration sampling nozzle is arranged on the base (1). The low-concentration sampling nozzle forceps clip binder has the advantages of reasonable design, simple structure, quite practicality, convenience for operation, high working efficiency, uniform binding and high binding quality.

Owner:WUHAN TIANHONG INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com