Solar battery double glass component tape first positioning automatic edge device and its edge process

A technology for solar cells and double-glass modules, which is applied in the direction of electrical components, circuits, and sending objects, which can solve the problems of tape sticking, cumbersome edge sealing process, and edge sealing wrinkles, so as to achieve accurate relative positions, improve the quality of edge wrapping, Controllable relative position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

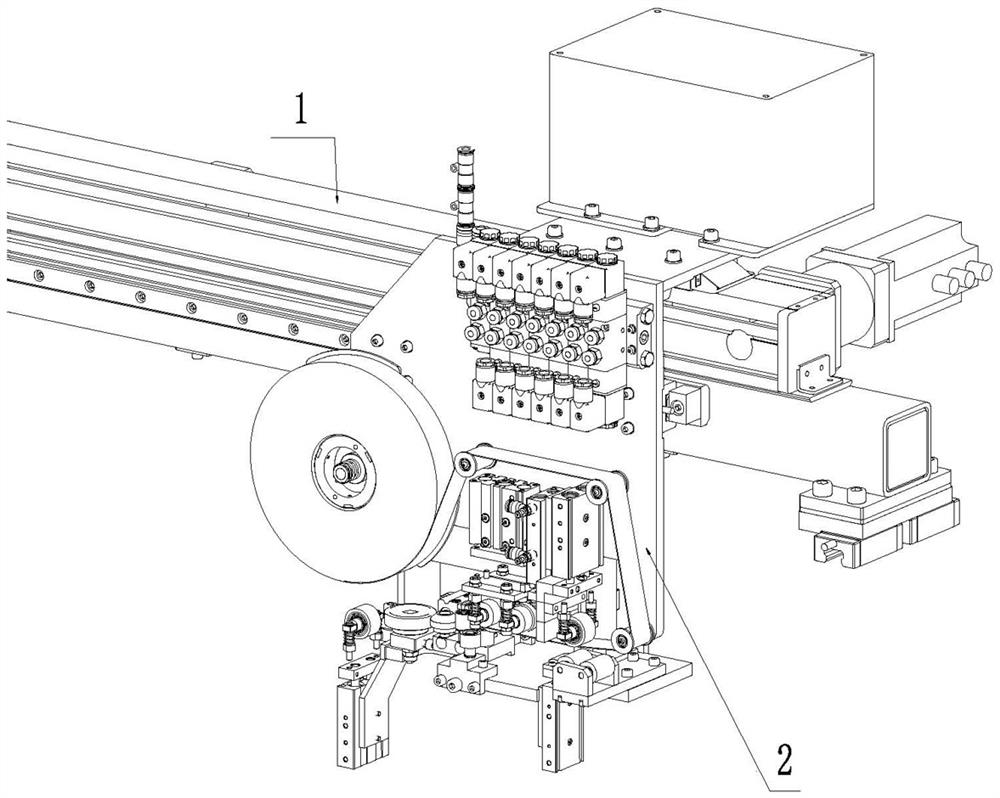

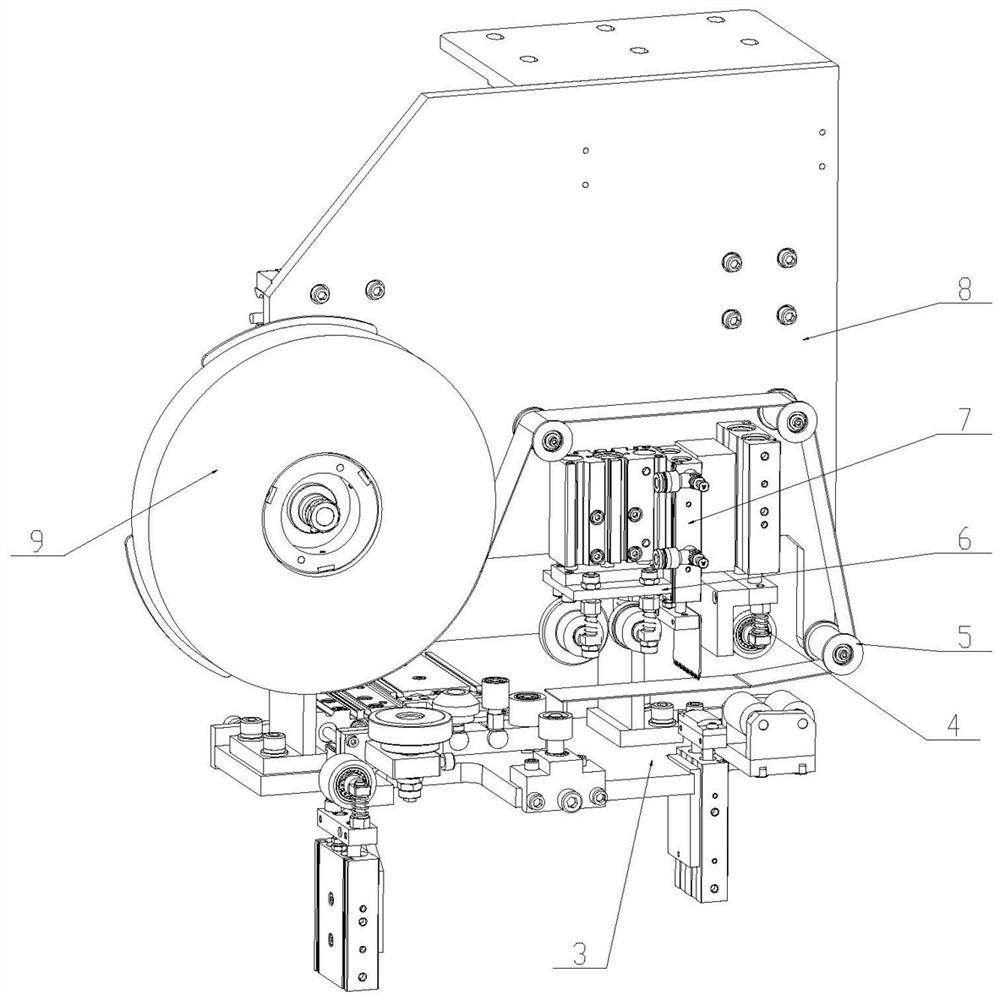

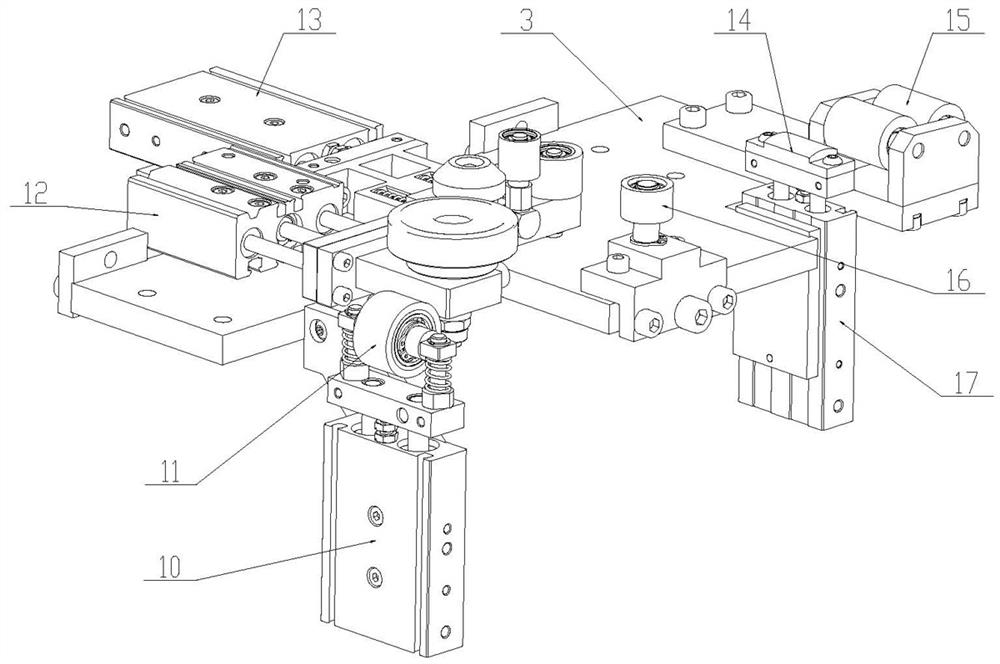

[0059] The solar battery double-glass module tape-positioning automatic edge-sealing device of the present invention includes an edge-sealing head 2, and is characterized in that: the edge-sealing head 2 includes a support 8, and the tape material roll 9 and the tape material are arranged on the support 8. The set of guide pulleys corresponding to the volume 9, the guide pulley corresponding to the end on the support 8 is provided with an upper compacting roller assembly 4, a folding roller assembly 6, a shaping roller assembly, an edge wrapping roller assembly and a lower compacting roller 11 assembly in sequence; The rotation axes of the tape stock roll 9 and the upper compacting roller 26 of the upper compacting roller assembly 4 combined with the guide pulley are parallel to each other.

[0060] As a preferred solution of the present invention, the upper compaction roller assembly 4 includes a lower pressure cylinder 25 arranged on the support 8, the lower end of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com