Lithium battery processing equipment and using method thereof

A technology for processing equipment and lithium batteries, which is used in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc. It can solve problems such as uneven thickness, workers prone to burns, and hidden safety hazards, and improve the quality of hemming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and embodiments:

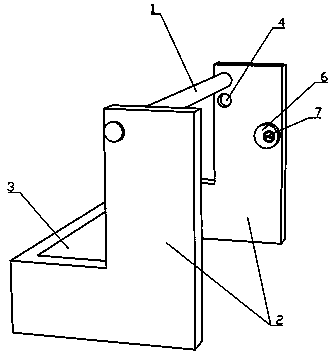

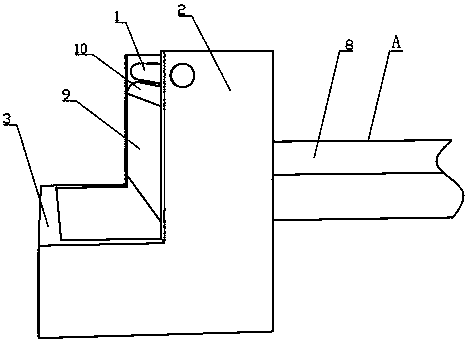

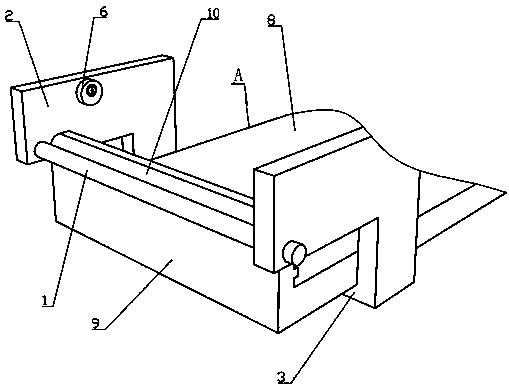

[0023] See attached Figure 1 to 3 , The lithium battery processing equipment in the figure is characterized in that it includes a roller 1 and two fixed blocks 2. The two ends of the roller 1 are rotatably connected to the two fixed blocks 2, and the roller 1 is located in a circular arc. Right above the round chamfer 10, there is a gap between the drum 1 and the arc-shaped chamfer 10 for the passage of aluminum plastic film; the fixing block 2 is provided with a fixing hole 4, and the fixing hole 4 is located on the drum Directly below 1, the two fixing blocks 2 are respectively rotatably connected to both sides of the lithium battery hemming device A, and the center of the fixing hole 4 coincides with the center of the arc-shaped chamfer 10. It is found through experiments that an important reason why the quality of the hemming does not meet expectations is that it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com