Low-concentration sampling nozzle forceps clip binder

A sampling nozzle, low-concentration technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of complex operation process, uneven edging, labor and time-consuming, etc., to achieve uniform edging and high edging quality. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

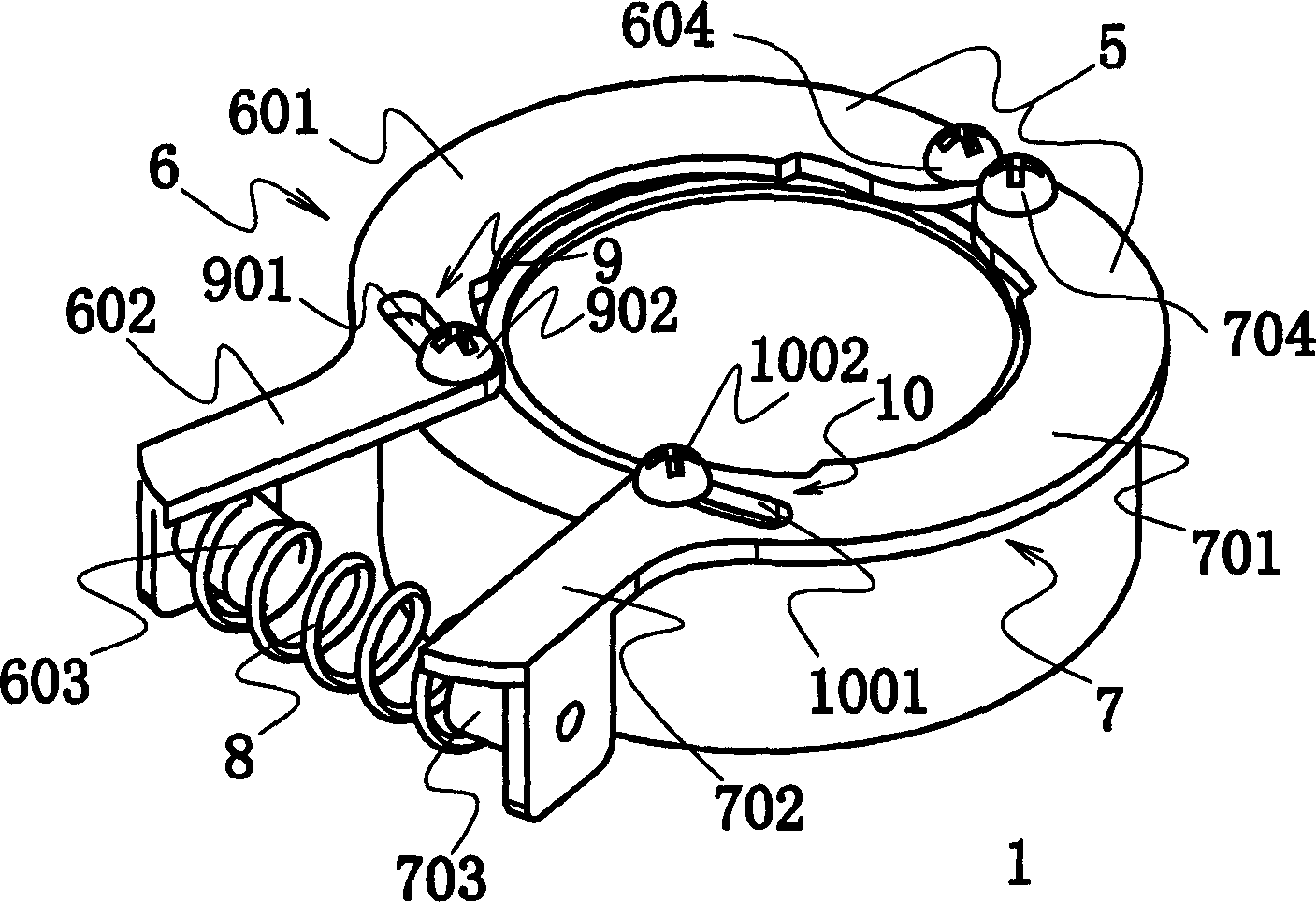

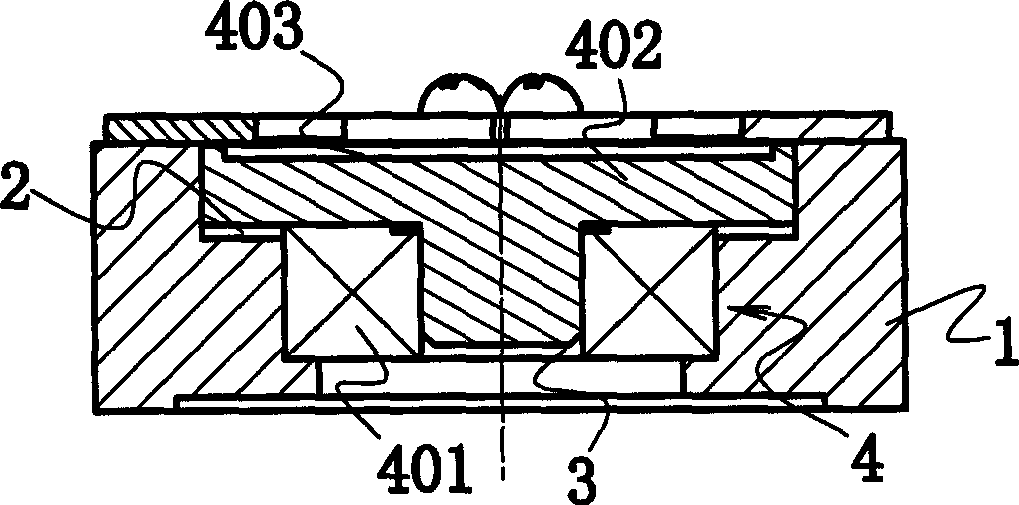

[0027] The low-concentration sampling nozzle clamp-type hemming device includes a base 1 and a rotating mechanism 4 arranged in the base 1, and the base 1 is also provided with a hemming mechanism 5 for hemming the low-concentration sampling nozzle.

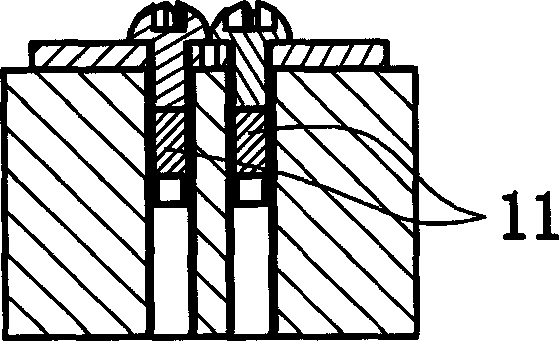

[0028] The base 1 is provided with a placement groove, and the rotation mechanism 4 is arranged in the placement groove. The placement groove is a first inner groove 2 and a second inner groove 3 which are stacked up and down and whose central axes coincide. The rotation mechanism 4 includes a bearing 401 and is sleeved on the The central axis 402 on the bearing 401, the bearing 401 is arranged in the first inner groove 2, the central axis 402 is T-shaped, one end is sleeved in the bearing 401 and arranged in the first inner groove 2, and the other end is arranged in the first inner groove 2. In two inner grooves 3.

[0029] The hemming mechanism 5 includes two first clamping devices 6 and a second clamping device 7 symmetrically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com