Edge covering machine for spare tire cover plate and machining process thereof

A technology of spare tire cover and processing technology, which is applied in the directions of lamination auxiliary operations, chemical instruments and methods, lamination, etc. problem, to achieve the effect of improving the quality of the hemming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

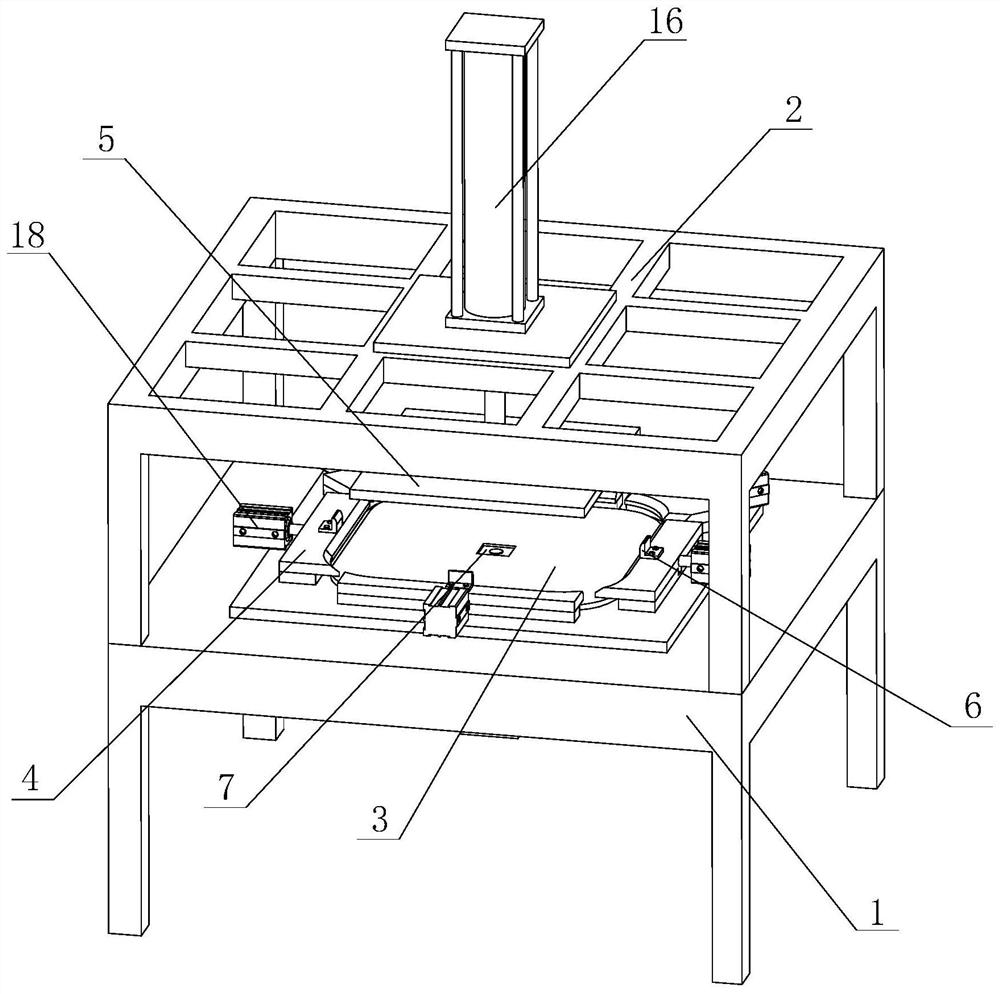

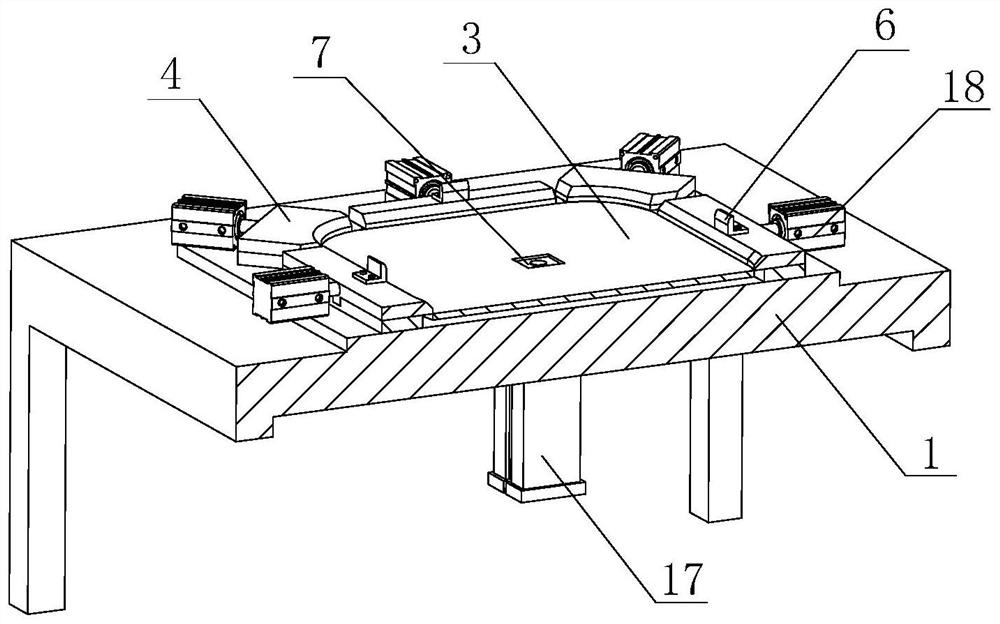

[0050] refer to figure 1 and figure 2 , the embodiment of the present application discloses a spare tire cover hemming machine, including a machine 1 and a frame 2, and the frame 2 is fixed on the upper side of the machine 1. The upper side middle part of machine platform 1 is provided with the lower pressing plate 3 that slides up and down, is provided with the lower pressing member that is used to drive lower pressing plate 3 to slide up and down between machine platform 1 and lower pressing plate 3, and lower pressing member is pressing down cylinder 17. Pressing down cylinder 17 is fixed on the machine platform 1 lower side, and the piston rod of pressing down cylinder 17 passes to the upper side of machine platform 1 and is fixed with the lower side of lower pressing plate 3 . Press down cylinder 17 to facilitate down pressing plate 3 to slide up and down.

[0051] refer to figure 1 and figure 2 , The upper side of the machine table 1 is provided with a plurality ...

Embodiment 2

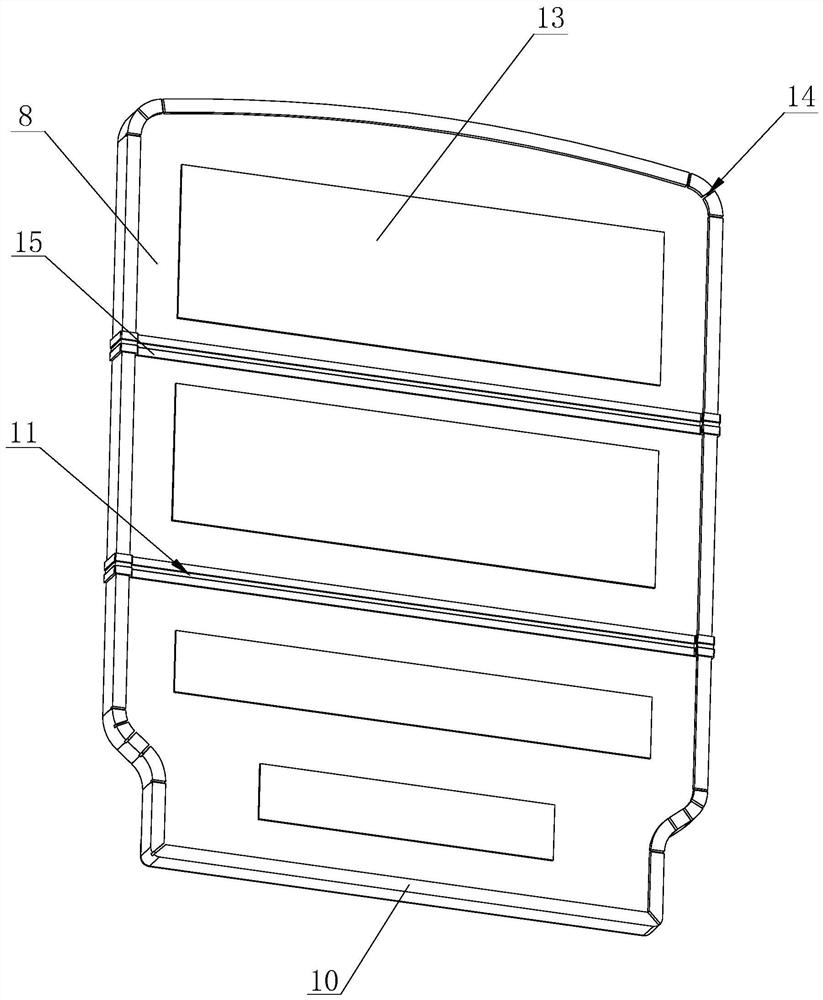

[0057] refer to image 3 and Figure 4 , a processing technology for a spare tire cover, based on a hemming machine for a spare tire cover as described in Embodiment 1, characterized in that it includes the following steps:

[0058] refer to image 3 and Figure 4 , S1, glue spray composite: spray glue on one side of the PP honeycomb panel 8, then adhere the blanket surface 9 to the glue sprayed side of the PP honeycomb panel 8, then press the PP honeycomb panel 8 and the blanket surface 9 together, and the blanket surface 9 The position beyond the PP honeycomb panel 8 is the edge strip 10.

[0059] refer to image 3 and Figure 4 , S2, glue spraying and wrapping: spray glue on the side of the wrapping strip 10 facing the PP honeycomb panel 8, then leave the glue-sprayed wrapping strip 10 at rest, and finally use a method as described in Example 1 The hemming machine for the spare tire cover is hemmed.

[0060] refer to image 3 and Figure 4 , S3, hot-press cutting: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com