Parallel robot edge-coating system with a rotary table

A rotary table and robot technology, applied to metal processing machinery parts, manipulators, manufacturing tools, etc., can solve problems such as difficult to guarantee the quality of hemming, increased hemming force, excessive requirements on mechanical and dynamic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

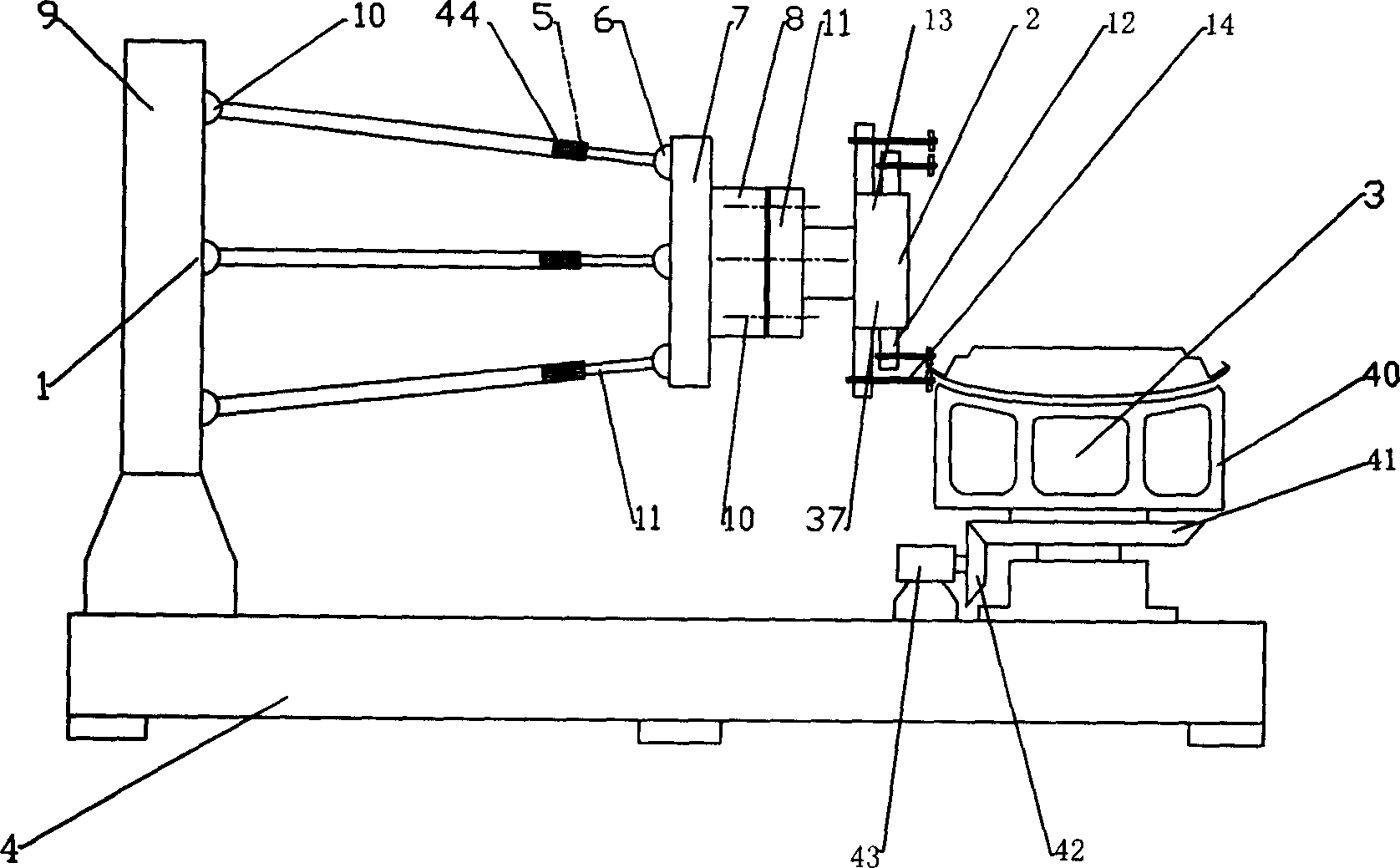

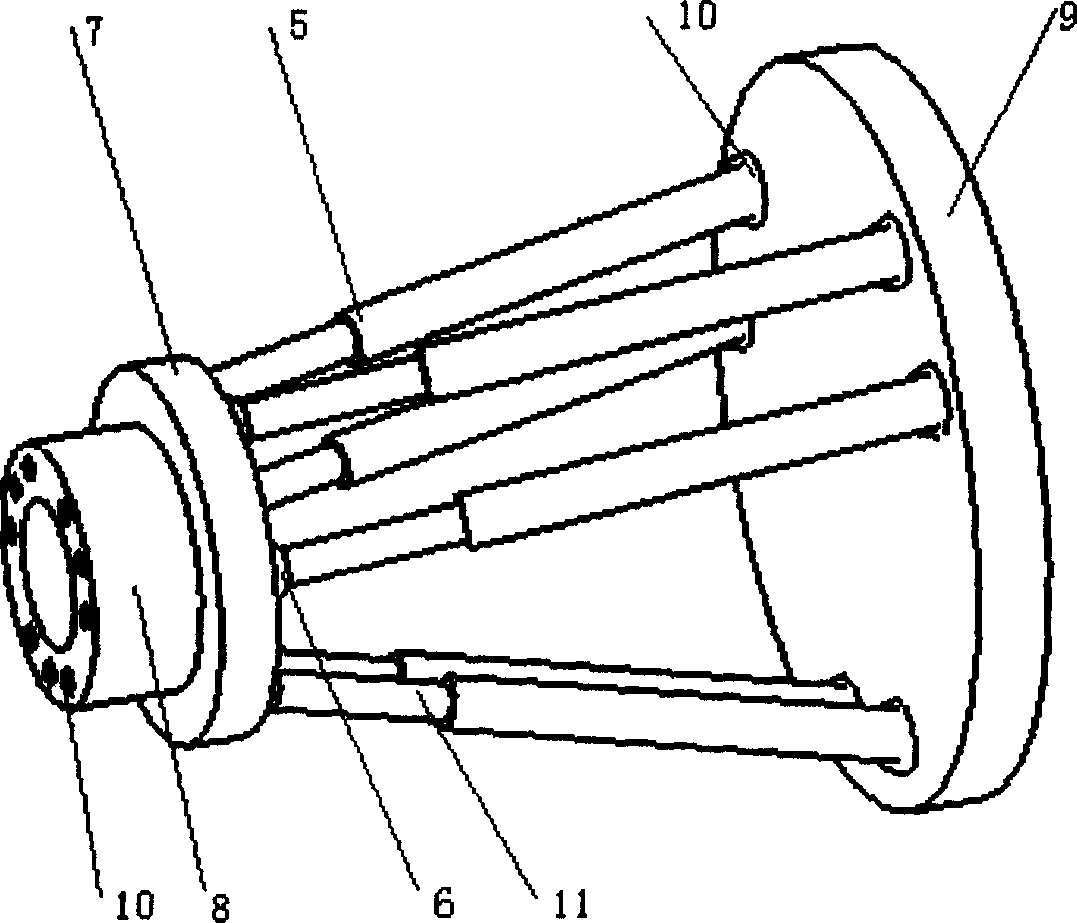

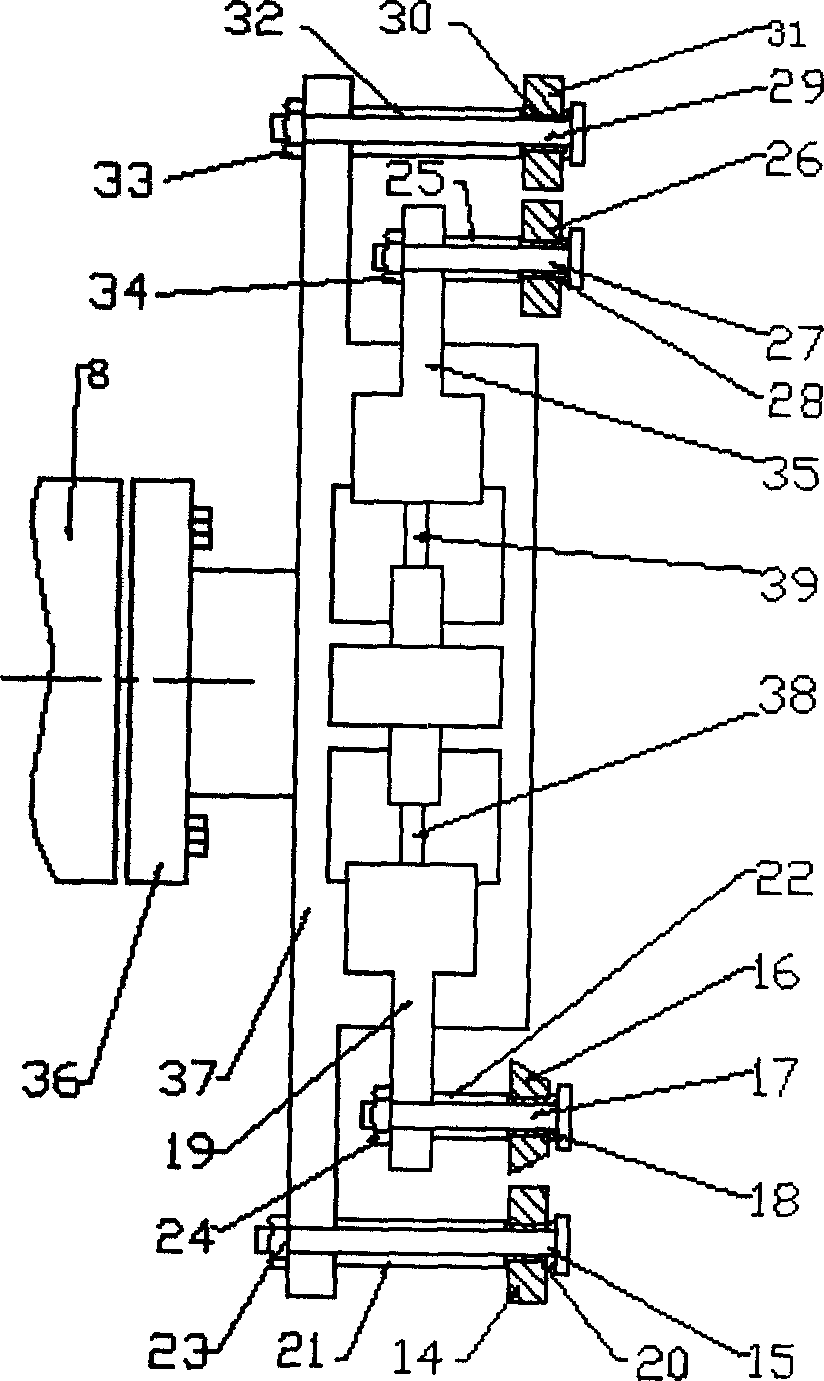

[0014] Such as Figure 1~4 As shown, the present invention includes: a six-degree-of-freedom parallel robot 1 , a rolling mechanism 2 , a rotary table 3 and a base 4 . The six-degree-of-freedom parallel robot 1 is fixed on the base 4 and connected with the rolling mechanism 2 through a flange, and the rotary table 3 is placed above the base 4 .

[0015] The six-degree-of-freedom parallel robot 1 is a platform mechanism with six degrees of freedom. The six-degree-of-freedom parallel robot consists of six independently free telescopic rods. The six-degree-of-freedom parallel robot 1 is placed on the base 4 through the fixed platform of the robot, and the robot's The movable platform is connected with the rolling mechanism 2 through a flange, the rotary table 3 is placed on the base 4, and the base 4 is placed at the bottom of the whole device, and a six-degree-of-freedom parallel robot 1 and a rotary robot are placed on both ends of the base 4. The workbench 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com