Covering machine for washing machine inner barrel production

A washing machine and hemming machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low processing quality, reduced production efficiency, low production efficiency, etc., and achieve high processing quality, high production efficiency, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below according to the drawings and embodiments.

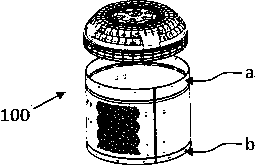

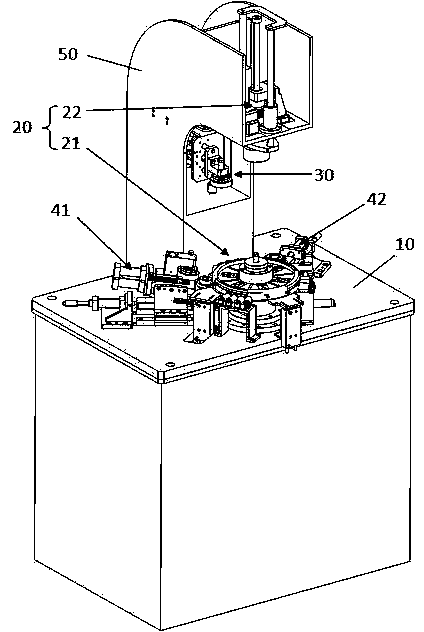

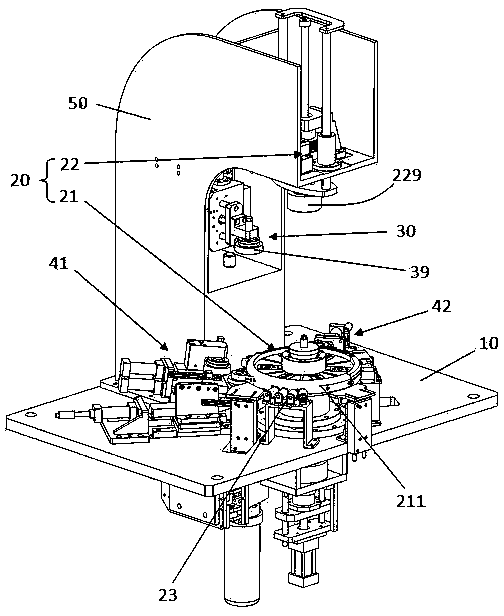

[0039] like figure 2 , image 3 , Figure 4 and Figure 15 , Figure 16 As shown, the hemming machine for washing machine inner cylinder production according to the embodiment of the present invention includes a workbench 10, on which a positioning mechanism 20, a cylinder bottom hemming mechanism 30, a cylinder edge hemming mechanism, and a positioning mechanism are respectively arranged. 20 includes a cylinder edge positioning device 21 and a cylinder bottom positioning device 22. The cylinder edge positioning device 21 includes a radially movable expansion and contraction disc rotation positioning assembly 211, and the outer side of the disk rotation positioning assembly 211 is provided with support rollers that rotate tangentially. 23. The cylinder bottom positioning device 22 includes a rotary pressure head 229 correspondingly arranged above the disc po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com