Baking and welting compound equipment

A composite equipment and welt technology, applied in the field of auto parts, can solve the problems of reduced glue viscosity, affecting the quality and efficiency of hemming, and inconvenience, and achieve the effect of improving work efficiency, realizing automation, and improving the quality of hemming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following combined with the embodiments and accompanying drawings will describe the baking and welting composite equipment of the present invention in detail.

[0035]

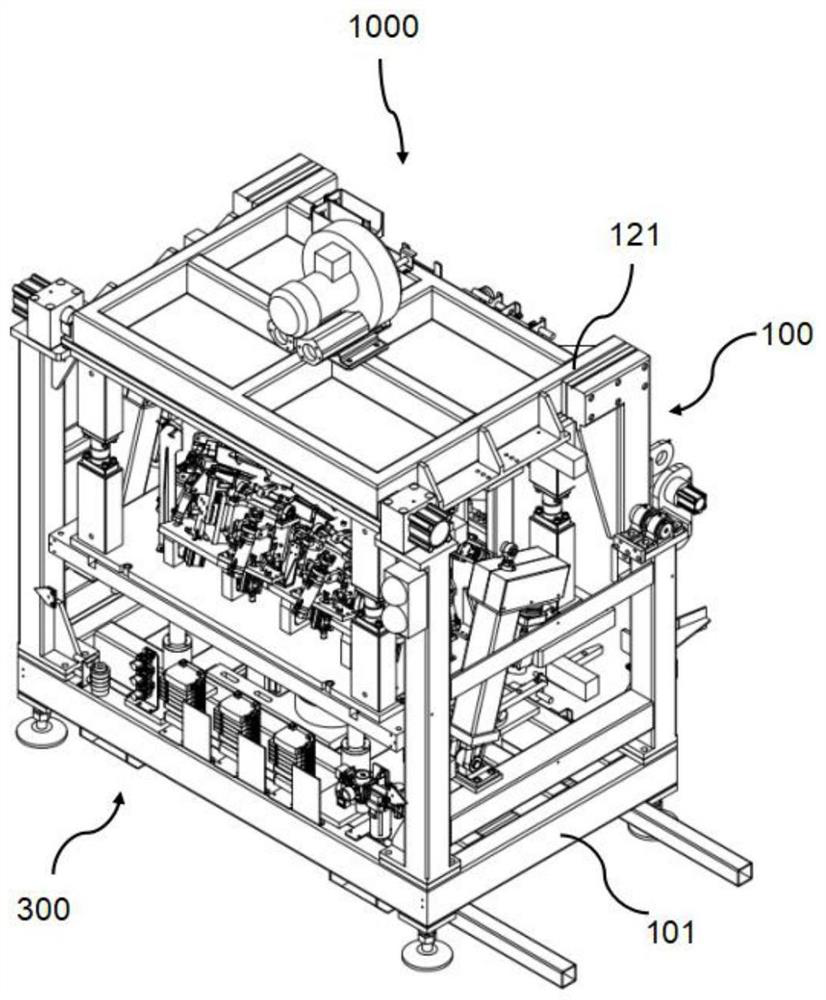

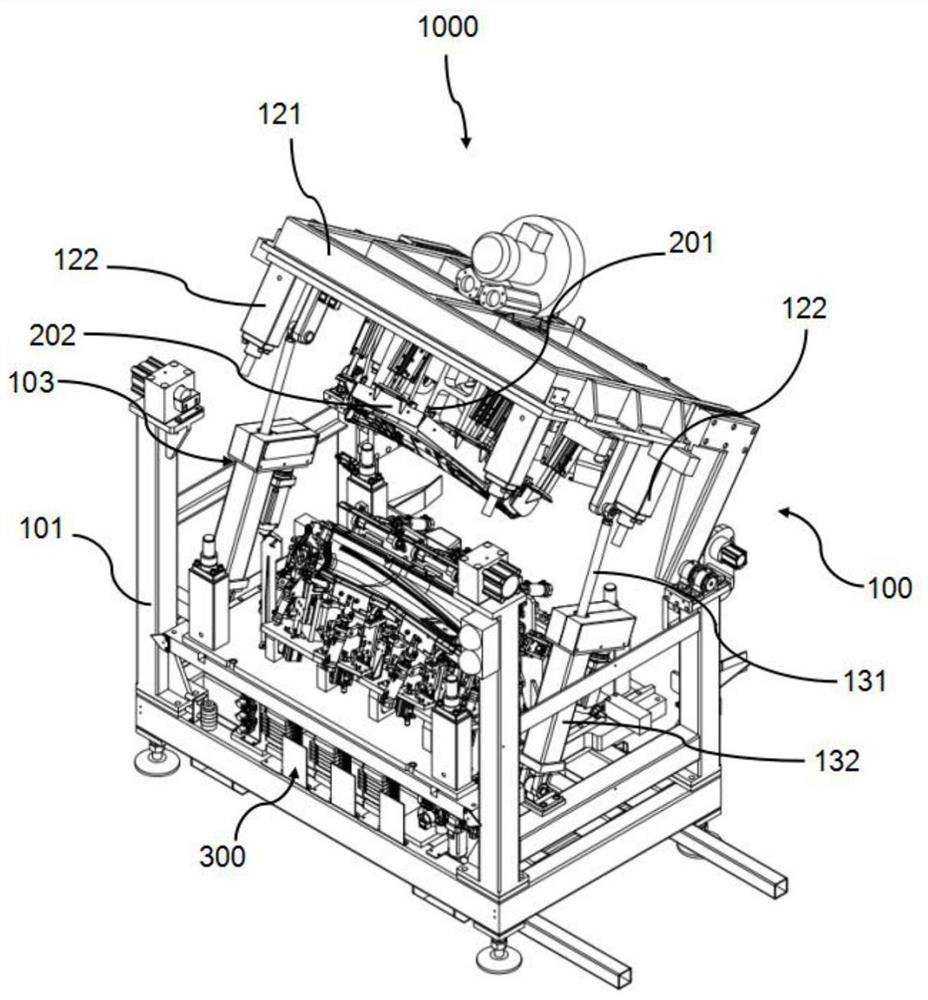

[0036] figure 1 It is a structural schematic diagram of the baked welt compounding equipment in the embodiment of the present invention.

[0037] Such as figure 1 As shown, the baking and welting composite equipment 1000 is used for baking and welting the car interior frame. The working environment of the baked and welted composite equipment 1000 is a constant temperature workshop at 25°C.

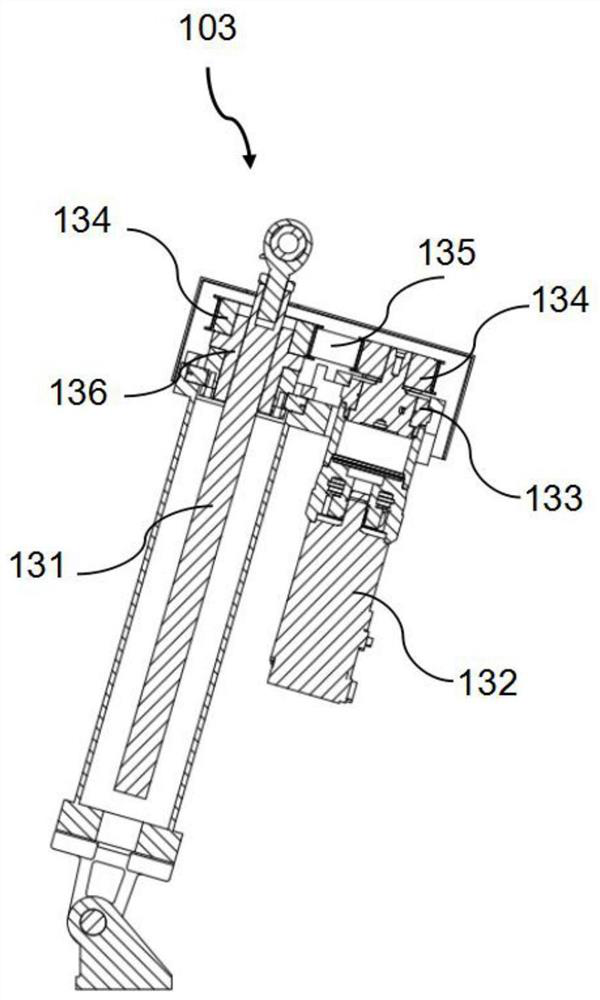

[0038] The baking and welting composite equipment 1000 includes an upper mold turning device 100, a baking mechanism, a lower mold installation device 300 and a control mechanism (not shown in the drawings). In this embodiment, an upper decorative panel, which is a kind of vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com