Paperboard edge covering method

A cardboard and edge-wrapping technology, which is applied in the direction of machining/deformation, can solve the problems of low edge-wrapping efficiency, achieve the effects of improving edge-wrapping efficiency, improving equipment utilization efficiency, and improving edge-wrapping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

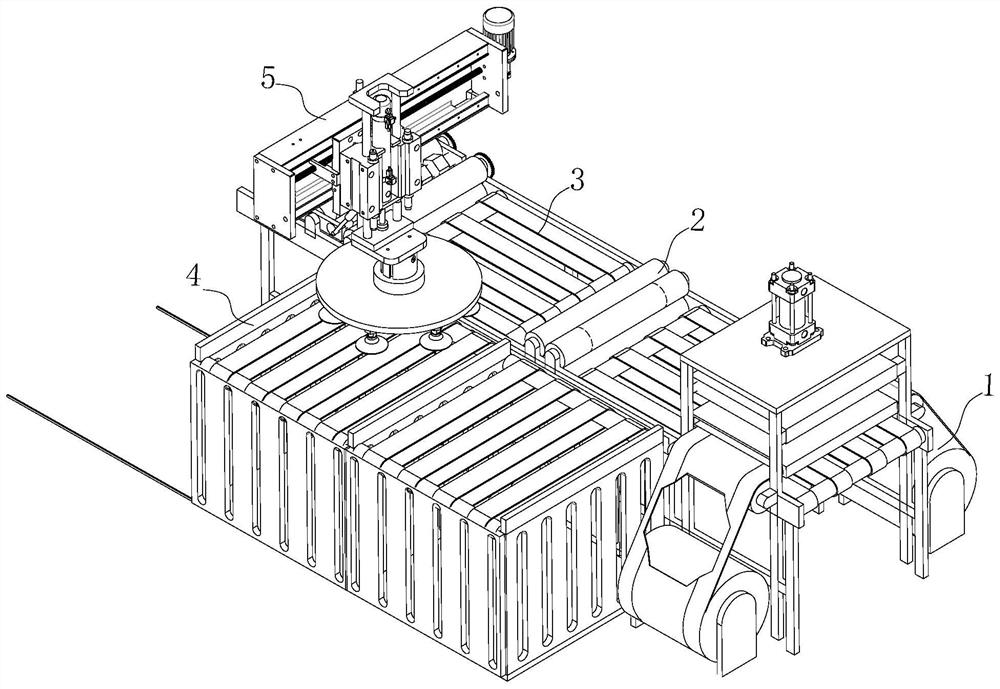

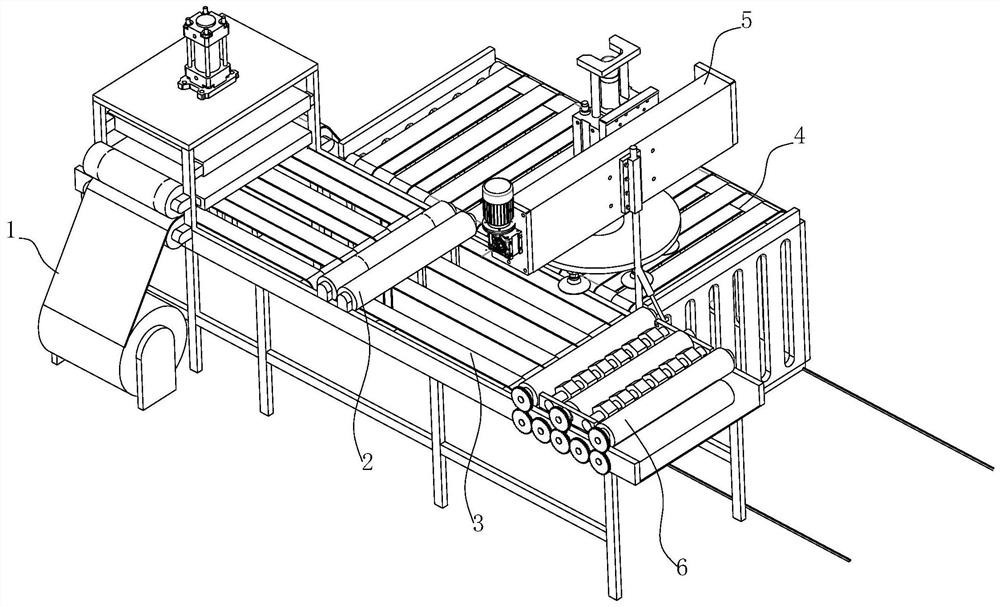

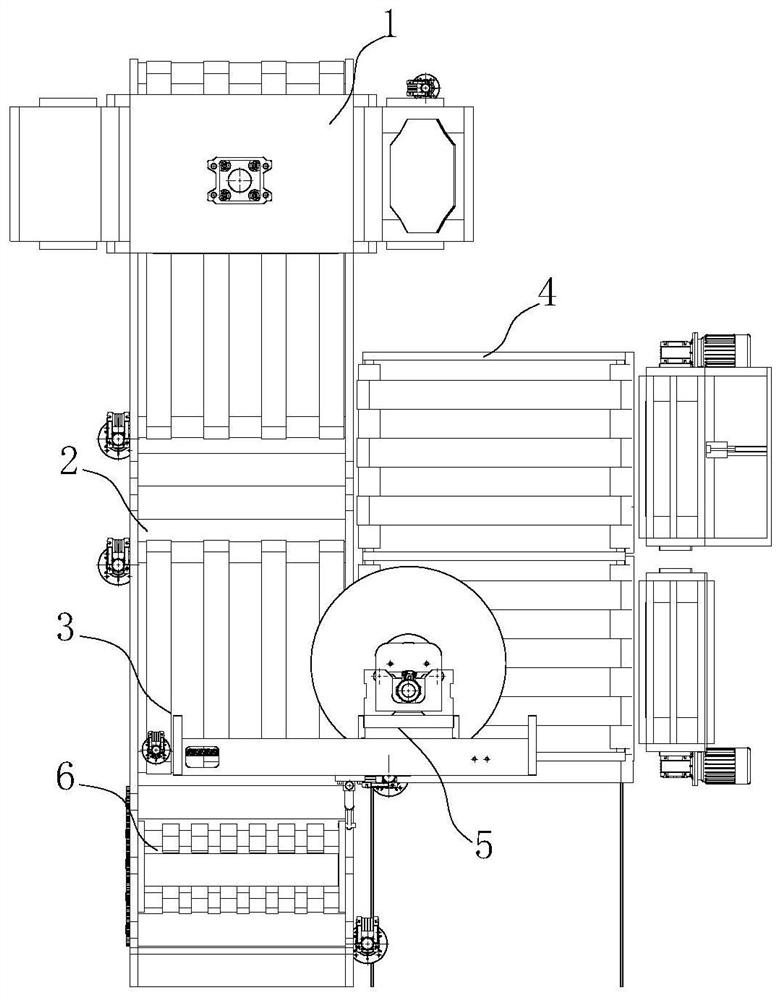

[0046] refer to Figure 1-3 , The present embodiment relates to a cardboard hemming device, the cardboard hemming device includes a paper conveying mechanism 1 , a gluing mechanism 2 , a conveying table 3 , a cardboard conveying mechanism 4 and an hemming mechanism 6 . The paper conveying mechanism 1 is used to convey paper of a predetermined size for edge wrapping on the conveying table 3; the glue applying mechanism 2 is used to apply glue to the upper surface of the paper in the conveying direction of the paper; The cardboard conveying mechanism 4 is used to deliver the predetermined size cardboard to be hemmed on the conveying platform 3, and grabs and conveys the hemmed cardboard on the conveying platform 3; the conveying platform 3 is used to carry paper and cardboard , and convey it to the hemming mechanism 6;

[0047] combine figure 2 and Figure 11 , the conveying table 3 has a first conveying belt 31; for the convenience of describing the positional relationship,...

no. 2 example

[0104] The difference between this embodiment and the first embodiment of the cardboard hemming device is that in this embodiment, the cardboard hemming device also includes an indentation mechanism, see Figure 14 , the creasing mechanism includes two creasing assemblies 71, wherein one creasing assembly 71 is located at the inlet end of the paper input passage 142, and is used for creasing the paper in the longitudinal direction, and the creasing assembly 71 includes two A creasing roller, a first creasing passage for paper to pass is formed between the two creasing rollers, the axis of the creasing roller extends transversely, and the creasing rollers are connected with Crease knife. Another creasing assembly is located at the inlet end of the gluing mechanism 2, that is, between the first conveyor belt 31 and the second conveyor belt 18, for creasing the paper in the transverse direction, and the creasing assembly also includes two creasing assemblies. A creasing roller, ...

no. 3 example

[0107] The difference between this embodiment and the first embodiment of the cardboard hemming device is that in this embodiment, the cardboard hemming device includes a stacking mechanism for vertically stacking the cardboards. refer to Figure 9 , the stacking mechanism is located on the side of the trolley 42 away from the transfer table 3, and the stacking mechanism includes a stacking frame 451, a stacking platform 452 and a first lifting drive mechanism.

[0108] The stacking platform 452 is mounted on the stacking frame 451 so as to slide up and down, and the first lifting drive mechanism 45 is connected to the stacking platform 452 for driving the stacking platform 452 in the vertical direction. Lifting movement.

[0109]Specifically, the first lifting drive mechanism 45 includes a lifting drive motor 453 and a transmission assembly, and the transmission assembly includes a lower sprocket, an upper sprocket 454 and a transmission chain 456, and the lifting drive moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com