An Extrusion Forming Mechanism Used in a Passive Honeycomb Paperboard Hemming Machine

A honeycomb paperboard, extrusion molding technology, applied in the direction of mechanical processing/deformation, can solve the problems of inconsistency, affecting the quality and efficiency of hemming, easy to scratch the board surface, etc., to avoid scratches and improve the efficiency of hemming , Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

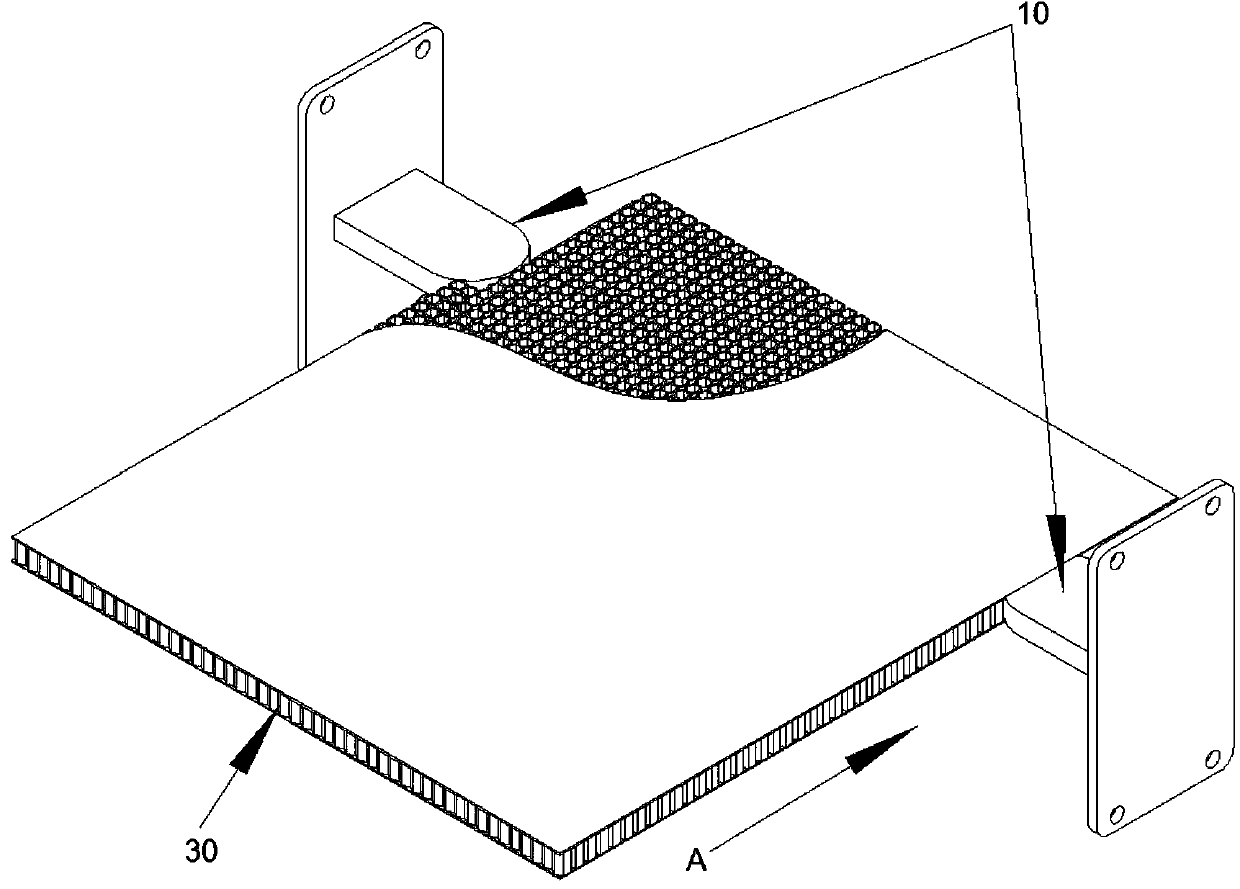

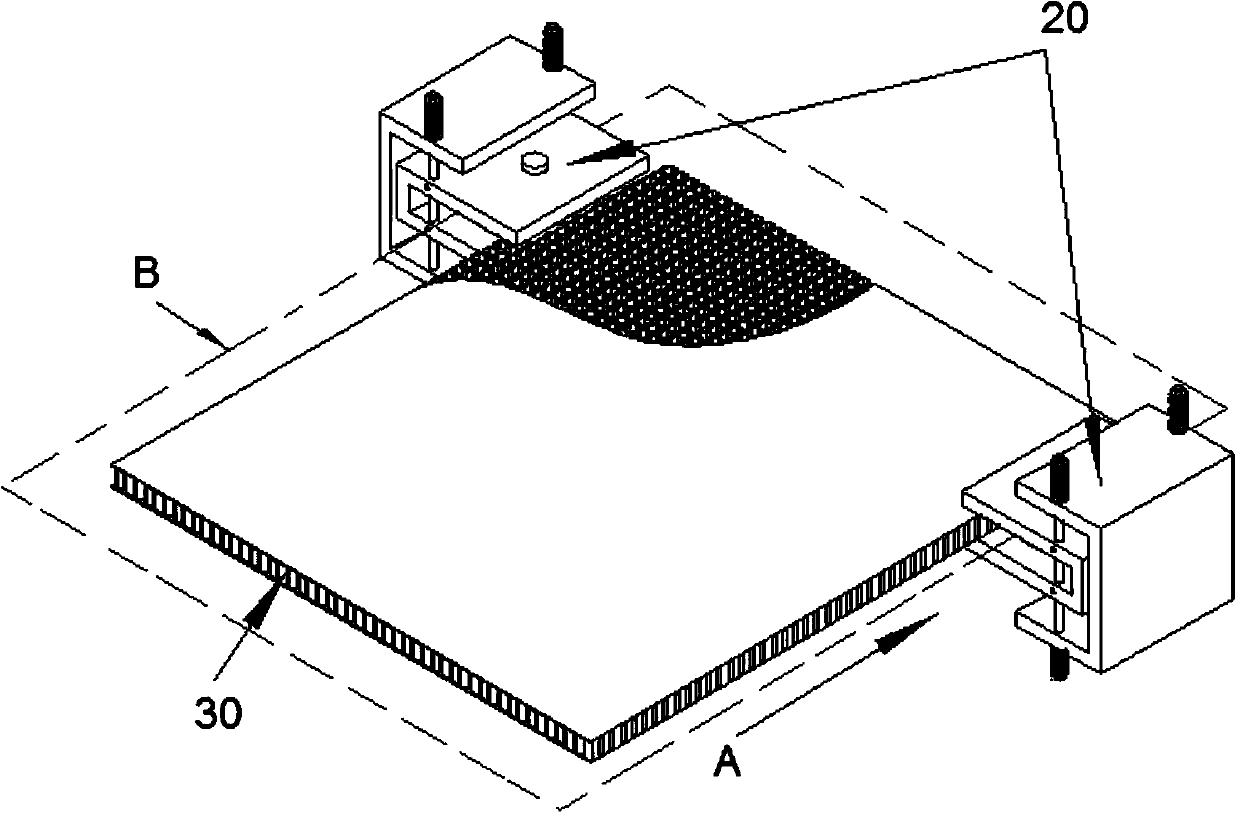

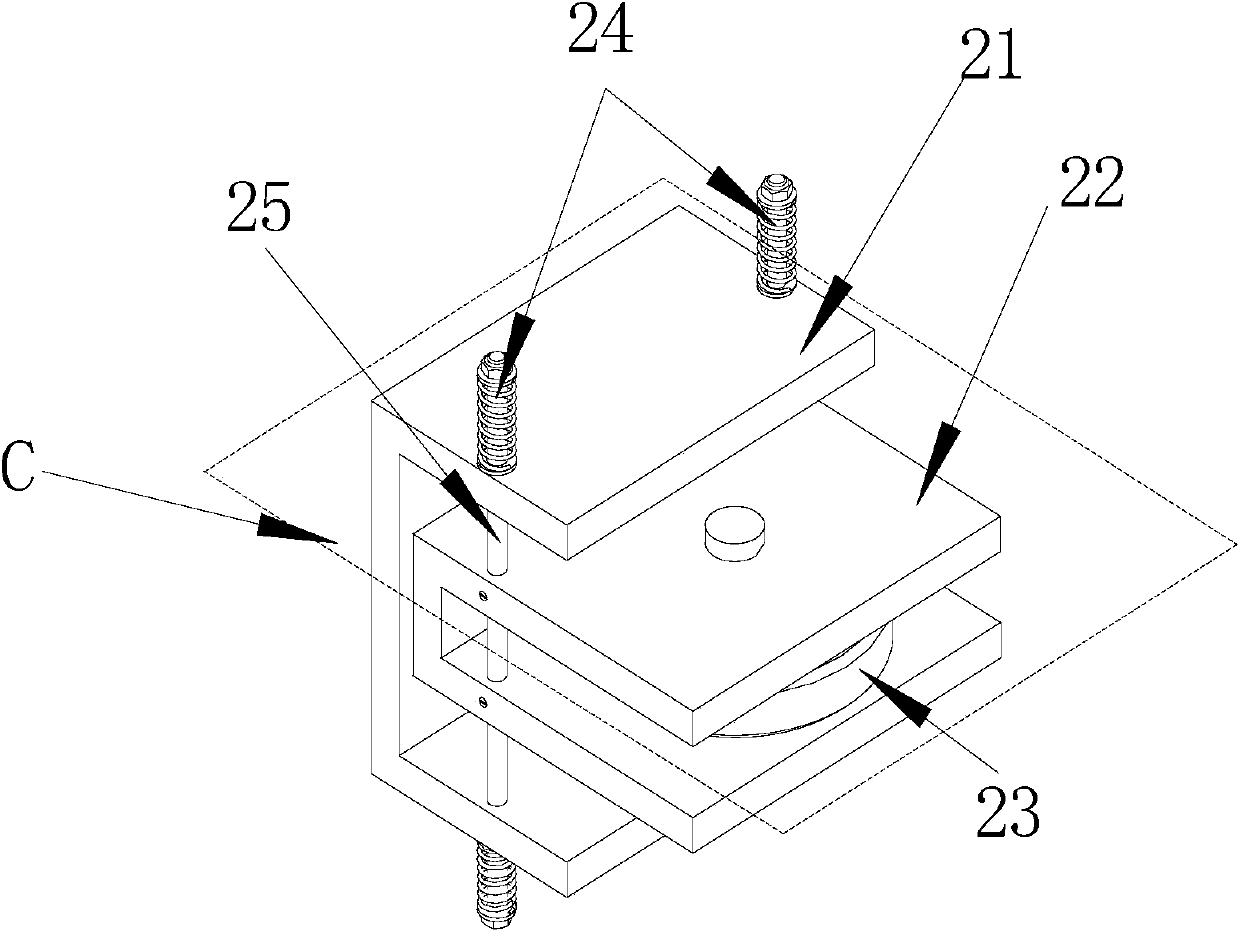

[0020] Such as Figure 2-Figure 3 As shown, a kind of extruding mechanism that is used for passive honeycomb paperboard edge wrapping machine, honeycomb paperboard 30 comprises upper epidermis, lower epidermis and the honeycomb paper core that is arranged between upper and lower epidermis, extruding forming mechanism 20 is provided with two Two extrusion molding mechanisms 20 are symmetrically arranged on both sides of the honeycomb paperboard 30, and each extrusion molding mechanism 20 includes a fixed block 21, a movable block 22, an extrusion block 23, a spring 24 and a slide bar 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com