Tight covering device of flip type packaging container cover

A packaging container and clamshell technology, applied in the field of capping devices, can solve the problems of increased production costs and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

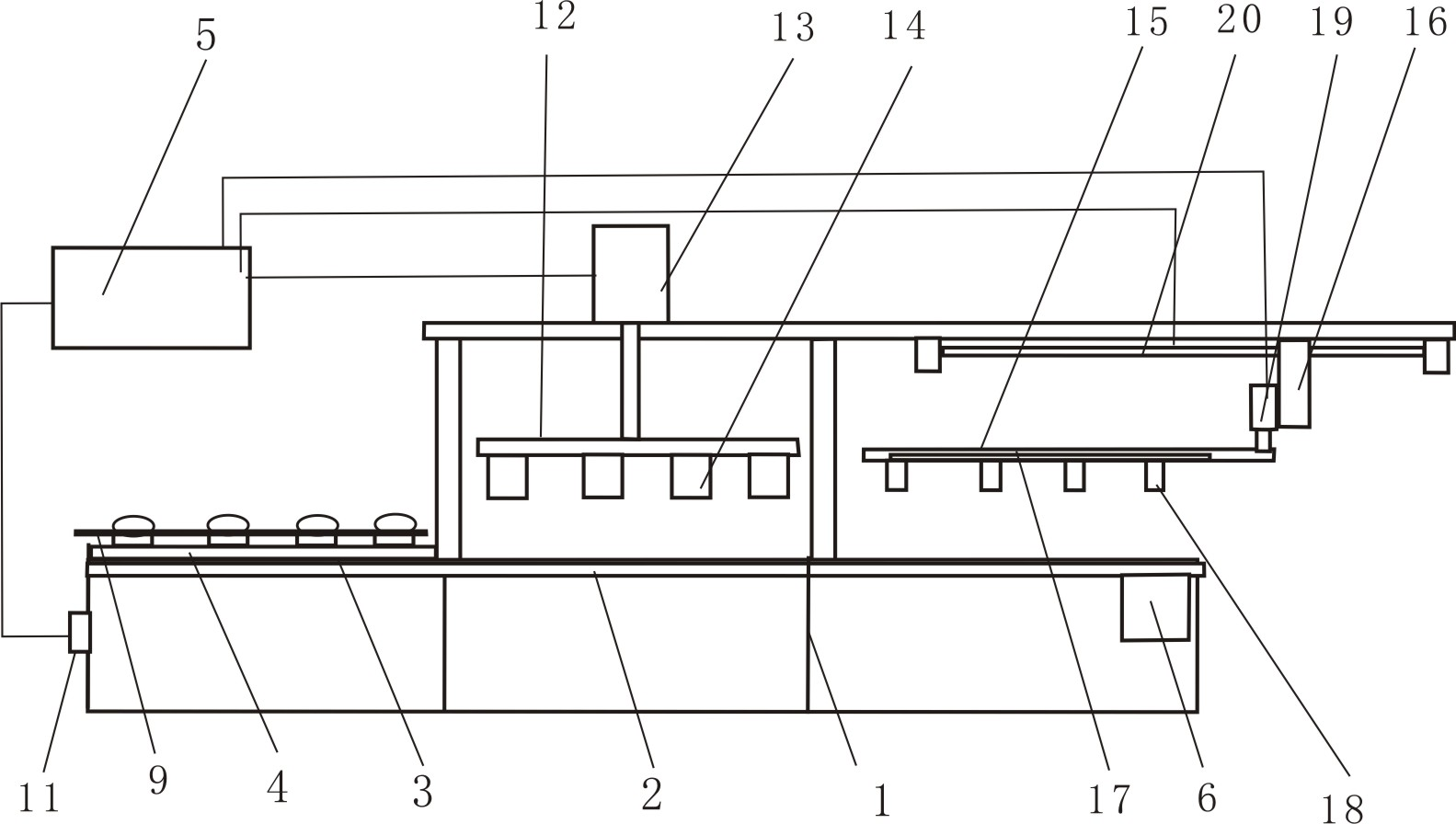

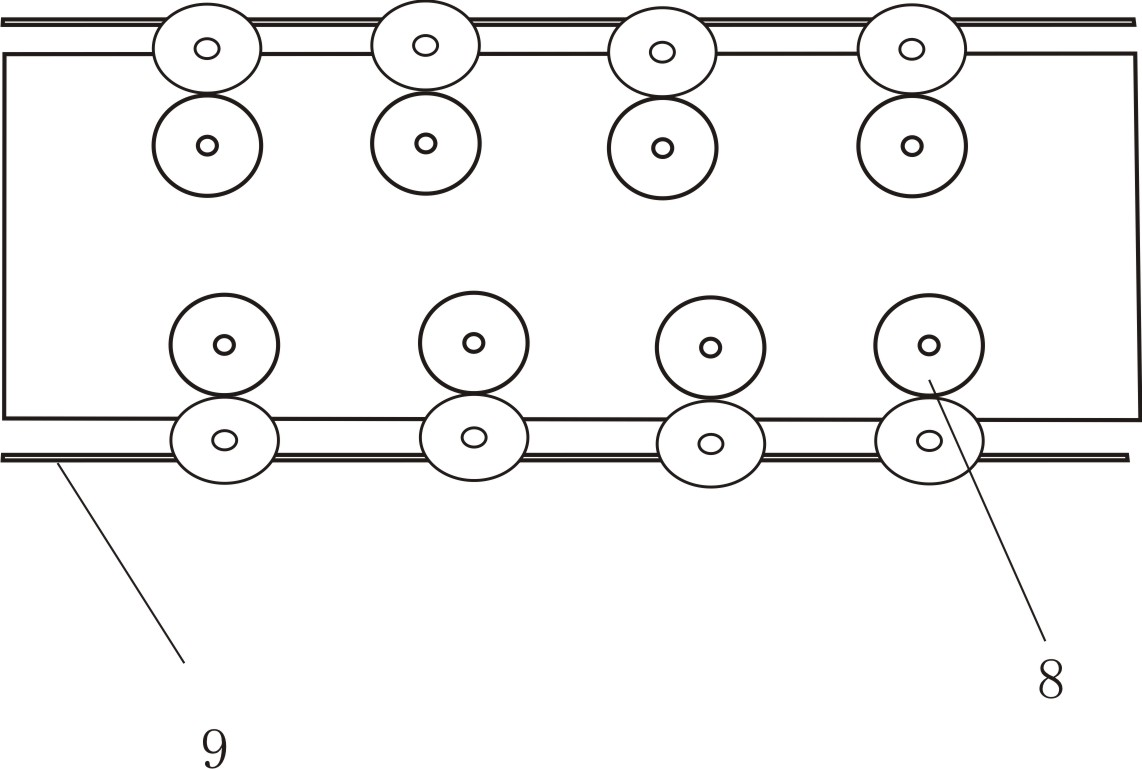

[0020] As shown in the figure, the capping device of the flip-top packaging container lid of the present invention includes a frame 1, a controller 5, and a workbench drive motor 6. Said frame 1 is provided with a drag platform 2 arranged horizontally, said drag platform 2 is provided with a guide rail 3 , said guide rail 3 is provided with a workbench 4 , and said workbench 4 can move along the guide rail 3 . The drive motor 6 of the workbench is connected with the drive of the workbench 4, so that the workbench 4 can be moved on the guide rail 3 by the rotation of the drive motor 6 of the workbench. Since this transmission mode is relatively common in the mechanical field, it will not be described in detail here.

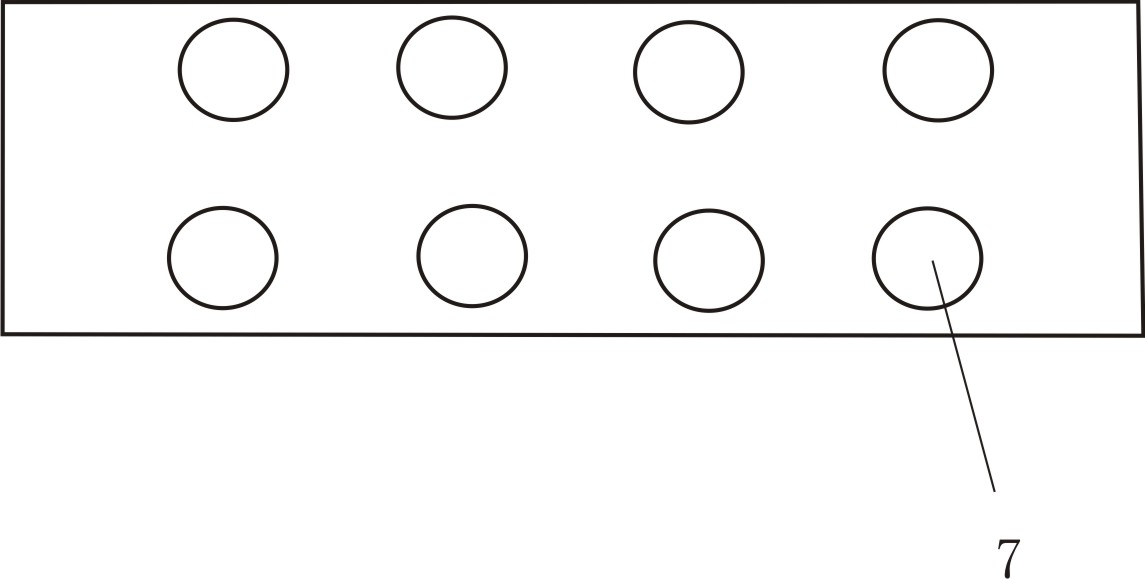

[0021] see figure 2 , the lid tightening device of the flip-top packaging container lid of the present invention, said workbench 4 is provided with more than one row of several container lid holes 7 arranged along the direction of guide rail 3, this implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com