Vermicelli production process and equipment thereof

A technology of production equipment and production process, which is applied in the field of vermicelli production, can solve problems such as difficult batch production, and achieve the effects of improving product quality and hygiene quality, simple process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of vermicelli production technology, it is characterized in that: concrete steps are as follows:

[0037] (1) Material selection: use high-quality sweet potato starch as raw material;

[0038] (2) Mixing: Weigh the selected sweet potato starch, add water according to the weight ratio of starch to water 1:2.5, stir in the mixing machine to form a slurry, and the speed of mixing is 300 rpm;

[0039] (3) Sizing: adjust the rotation speed of the grouting pump so that the starch slurry is flattened on the conveyor belt without gaps, and the starch slurry obtained in step (2) is sprayed out from the slurry outlet hole of the first slurry coating device to form the powder skin on the second conveyor belt In-mold sizing;

[0040] (4) Shaping: Heat the starch slurry in the powder skin forming mold sized in step (3) to a solid state through a steam calibrating box, and keep the heating temperature at 95°C until it does not flow on the conveyor belt;

[0041] (5) Poaching...

Embodiment 2

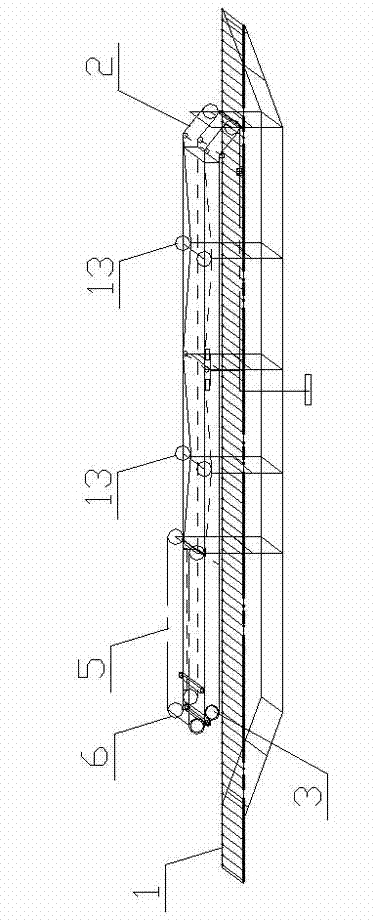

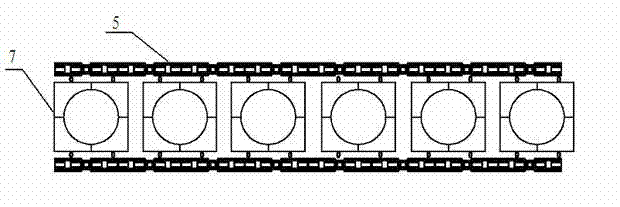

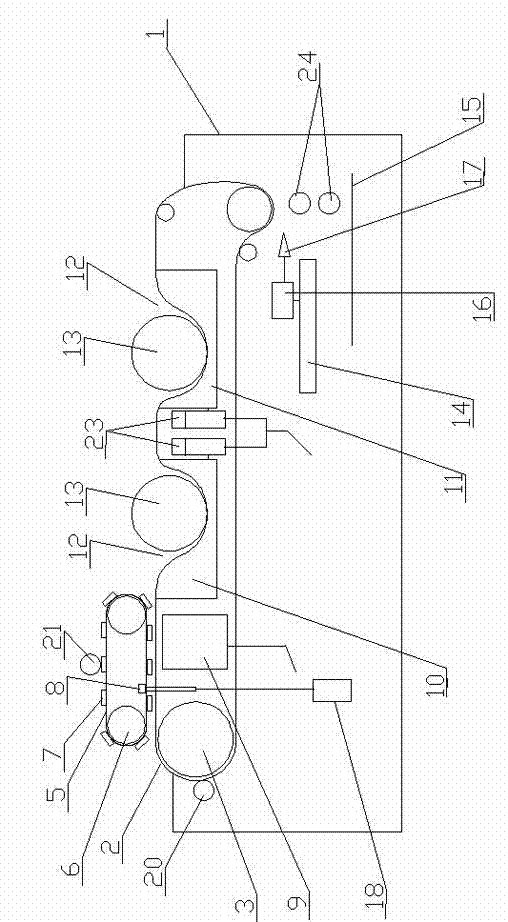

[0045] like Figure 1-3 As shown, a kind of equipment that is used for the vermicelli production process described in embodiment 1 comprises frame 1, and frame 1 is provided with first conveyer belt 2, and first conveyer belt 2 is conveying steel belt, and the two ends of first conveyer belt 2 are fixed A first chain is provided, and the first chain is connected with a first gear 3, and the first gear 3 is connected with the motor; the upper part of the frame 1 is provided with a second conveyor belt 5, and the two ends of the second conveyor belt 5 are fixedly provided with a second chain. The second chain is connected with a second gear 6, and the second gear 6 is connected with the motor; the second conveyor belt 5 is pressed with a powder skin forming mold 7; the transmission direction of the first conveyor belt 2 and the second conveyor belt 5 is opposite, and the first conveyor belt 2 is in the direction Clockwise transmission, the second conveyor belt 5 is counterclockw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com