Self-cleaning system of air-jet loom

An air-jet loom and self-cleaning technology, applied in the field of self-cleaning systems, can solve problems such as dirtying the workshop, affecting the respiratory health of employees, affecting the efficiency of looms and fabric quality, etc., to ensure cleanliness, reduce suspended flying flowers, and reduce labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

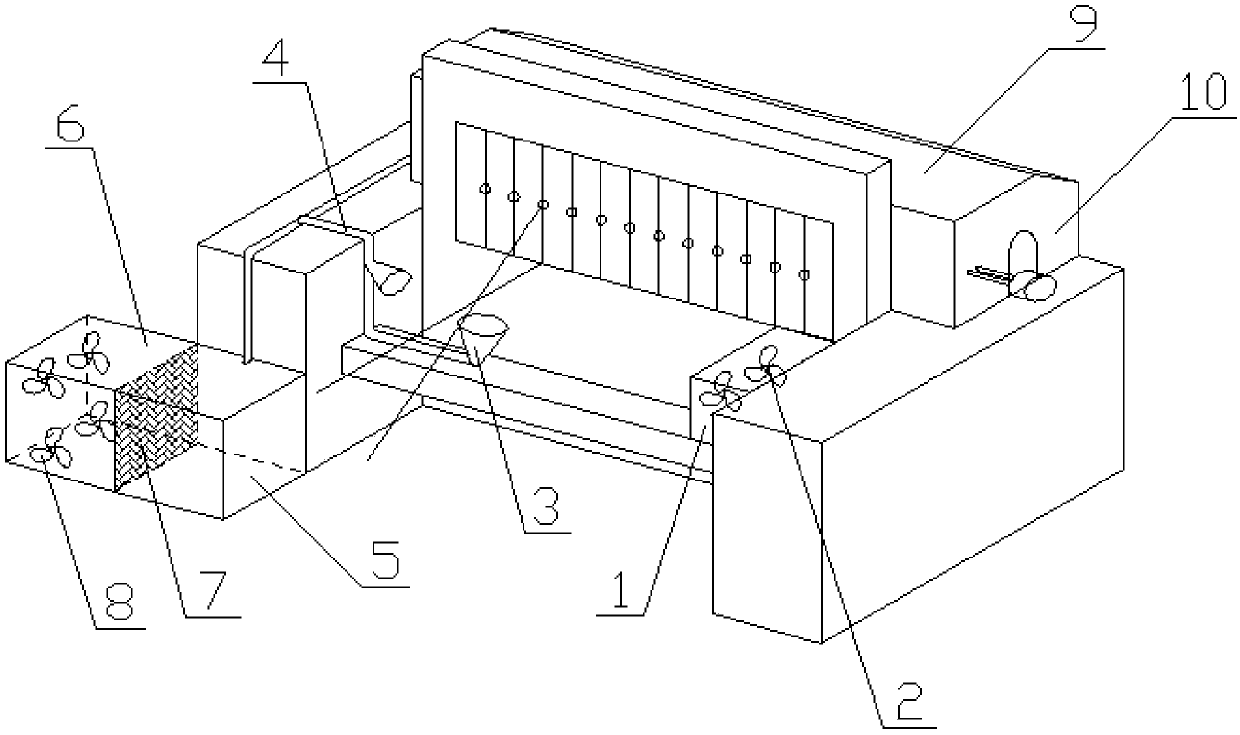

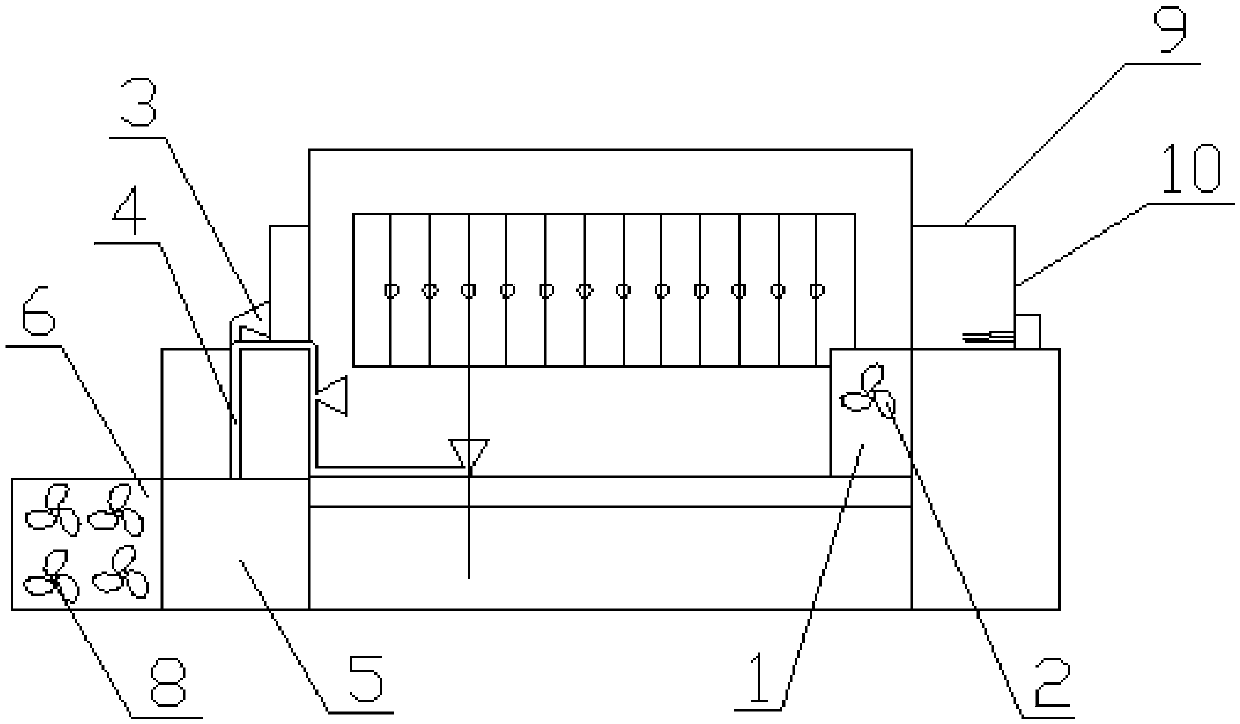

[0025] This embodiment provides a self-cleaning system for an air-jet loom. The system is composed of a blowing device, a collecting device and a protective cover device. The blowing device and the collecting device are correspondingly arranged on the left and right side walls below the rear opening of the heald frame of the air-jet loom On the board, the protective cover device surrounds the main nozzle of the air-jet loom and the front opening of the heald frame; the blowing device is composed of a cuboid-shaped blowing port 1 and a fan, and the air outlet of the fan is arranged on the inside of the edge of the blowing port 1 to blow air. Port 1 opens towards the back of the heald frame; the collection device is composed of five trumpet-shaped collection ports 3, pipes 4, cotton collection box 5 and fan 6, and the pipe 4 connects the collection port 3 with the cotton collection box 5, and the collection of cotton Box 5 and fan 6 are internally connected and separated by filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com