Device for mounting and take-down mould covering device of rotation cutting anvil cylinder

A rotary cutting, cylinder technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as decreased machine productivity, large covering strips, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

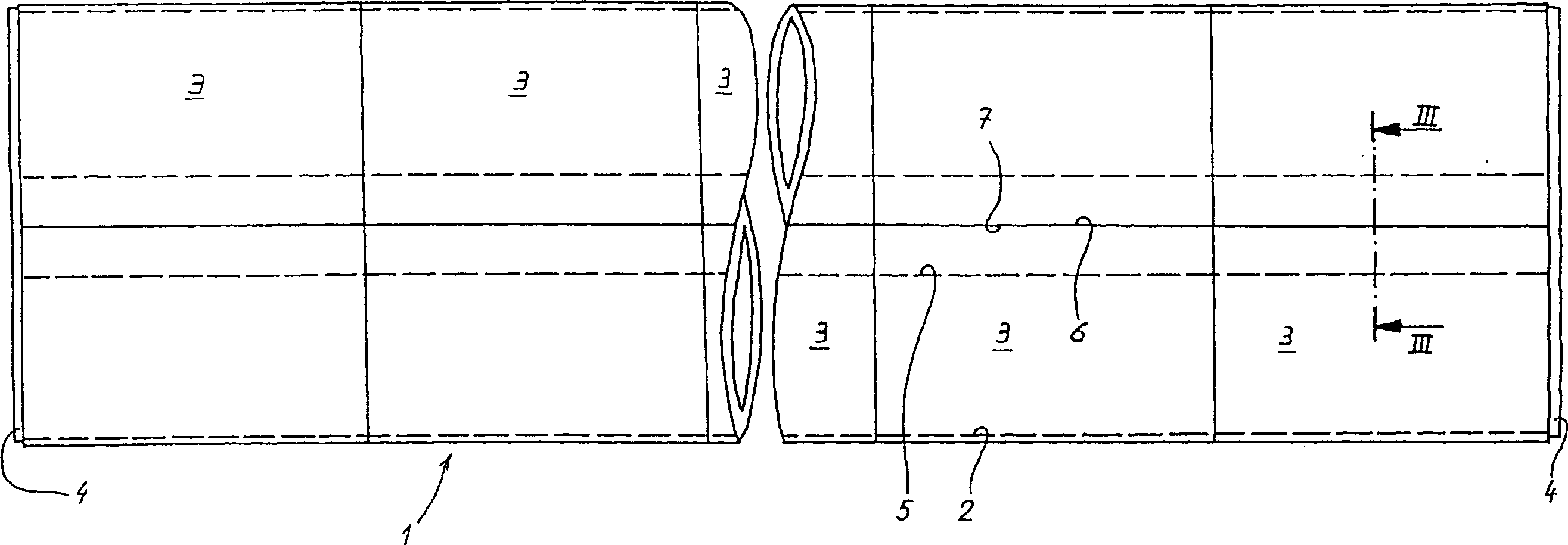

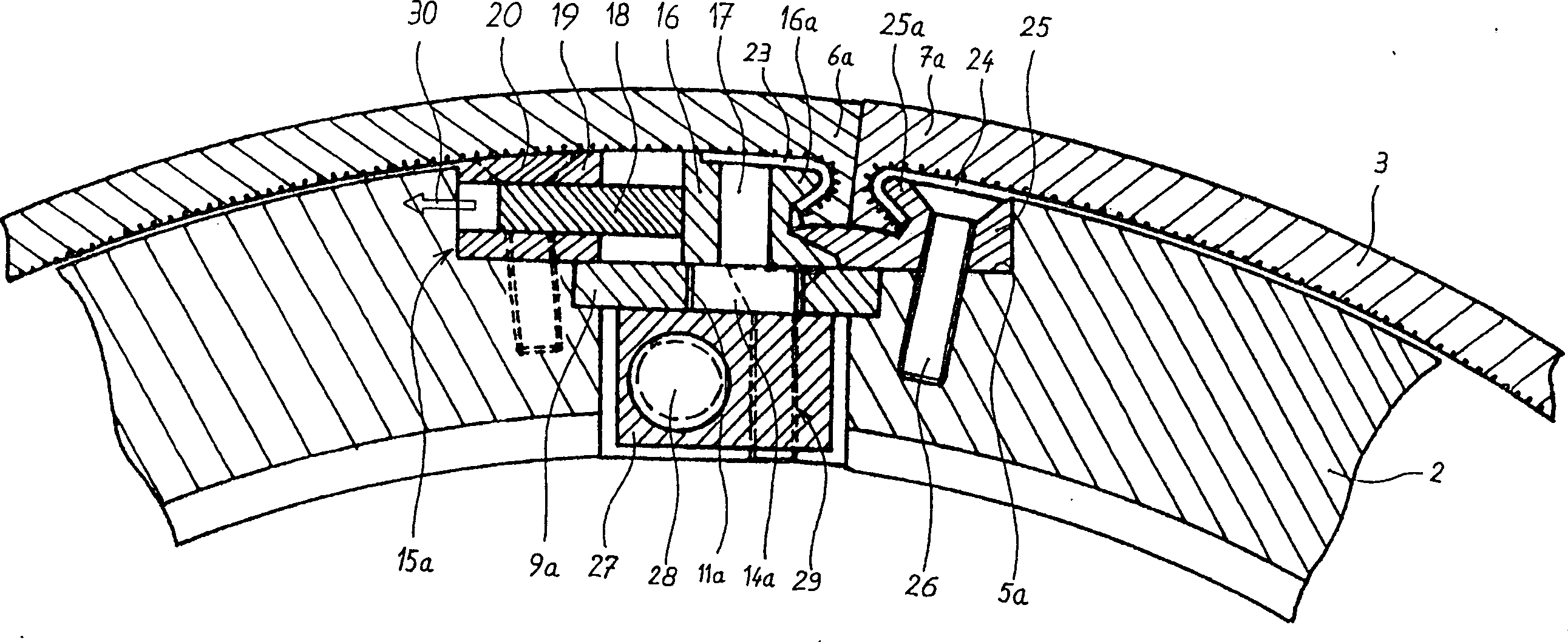

[0022] figure 1 Is a schematic view of a rotary cutting anvil cylinder 1 comprising a cylinder 2 on which covering strips 3 are wound and held at each end by stop discs 4. The cylinder 2 has a groove 5 extending over its entire length. The ends 6, 7 of the covering strip 3 fit into a locking and unlocking device 8 (see image 3 , 4 and 5) within the fastening and loosening device.

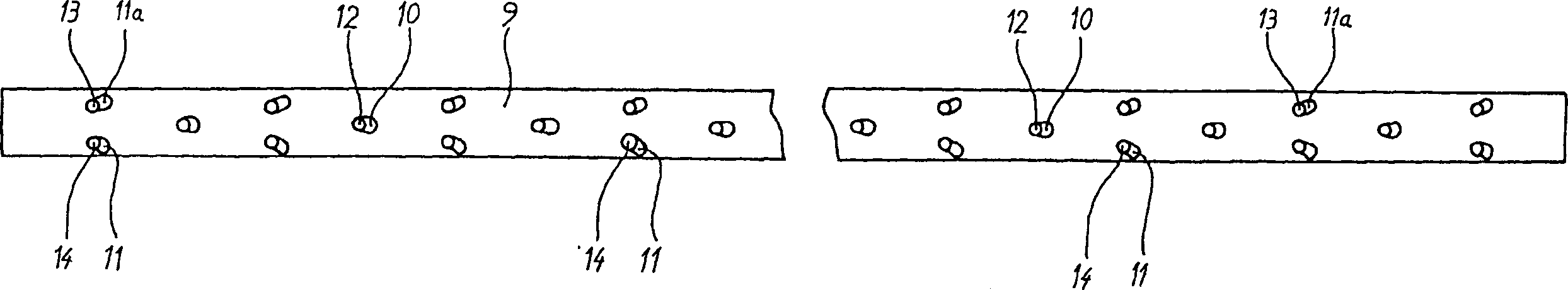

[0023] figure 2 is a plan view of a removable slide 9 used in the locking and unlocking device 8 . The removable slide 9 comprises a guide groove 10 and a groove 11 in the shape of a linear cam in which rollers 12, 13 and 14 fit (see Figures 3 to 6 ).

[0024] image 3 is along figure 1 Partially cutaway view taken along the line III-III, which shows a locking and unlocking device 15a in which only one pawl 16 is in the fastening position of the covering strip 3. The locking and unlocking device 15a comprises a removable slide 9a comprising grooves 11a in the shape of linear cams in which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com