Patents

Literature

42results about How to "Minimize warpage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

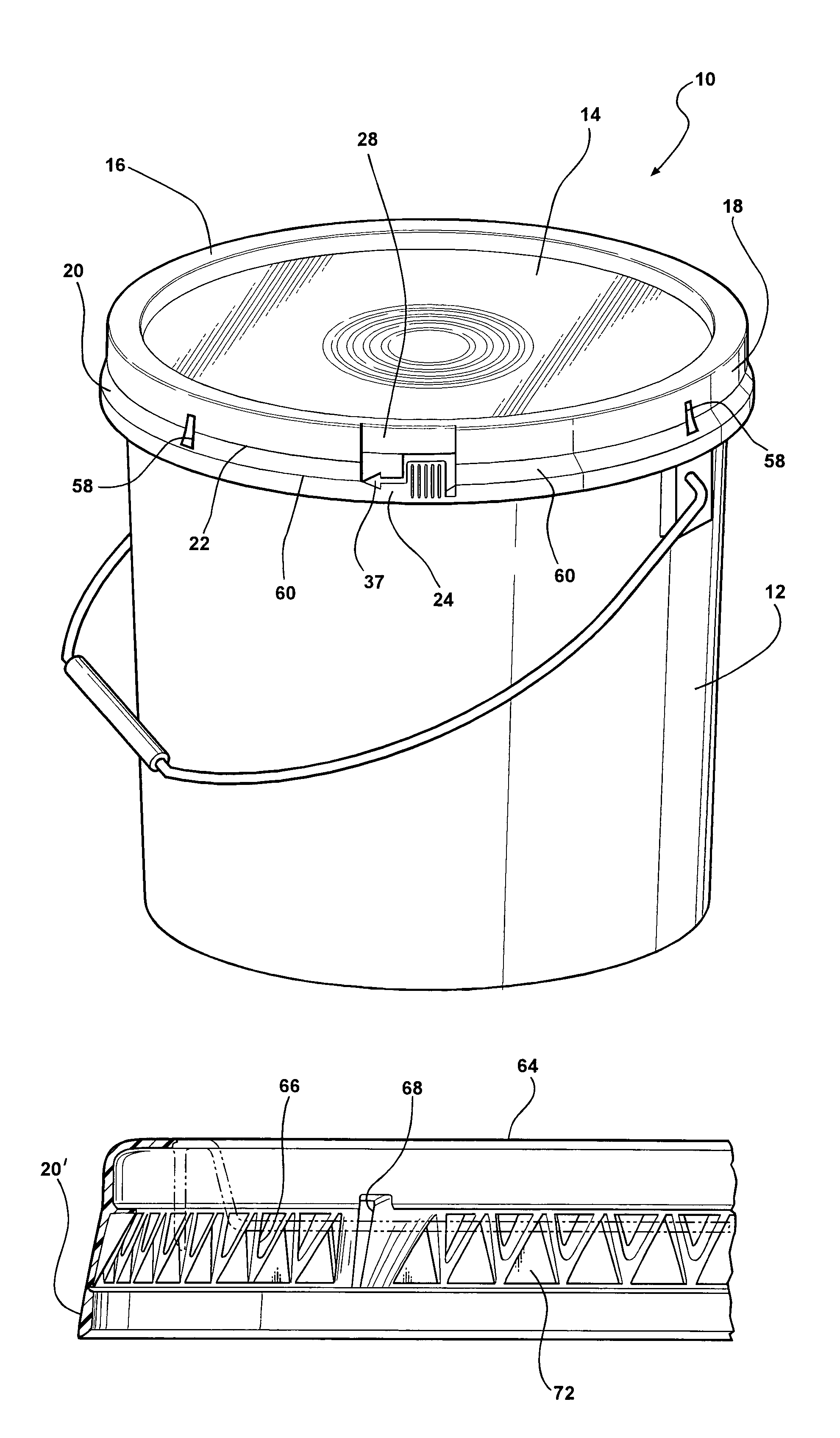

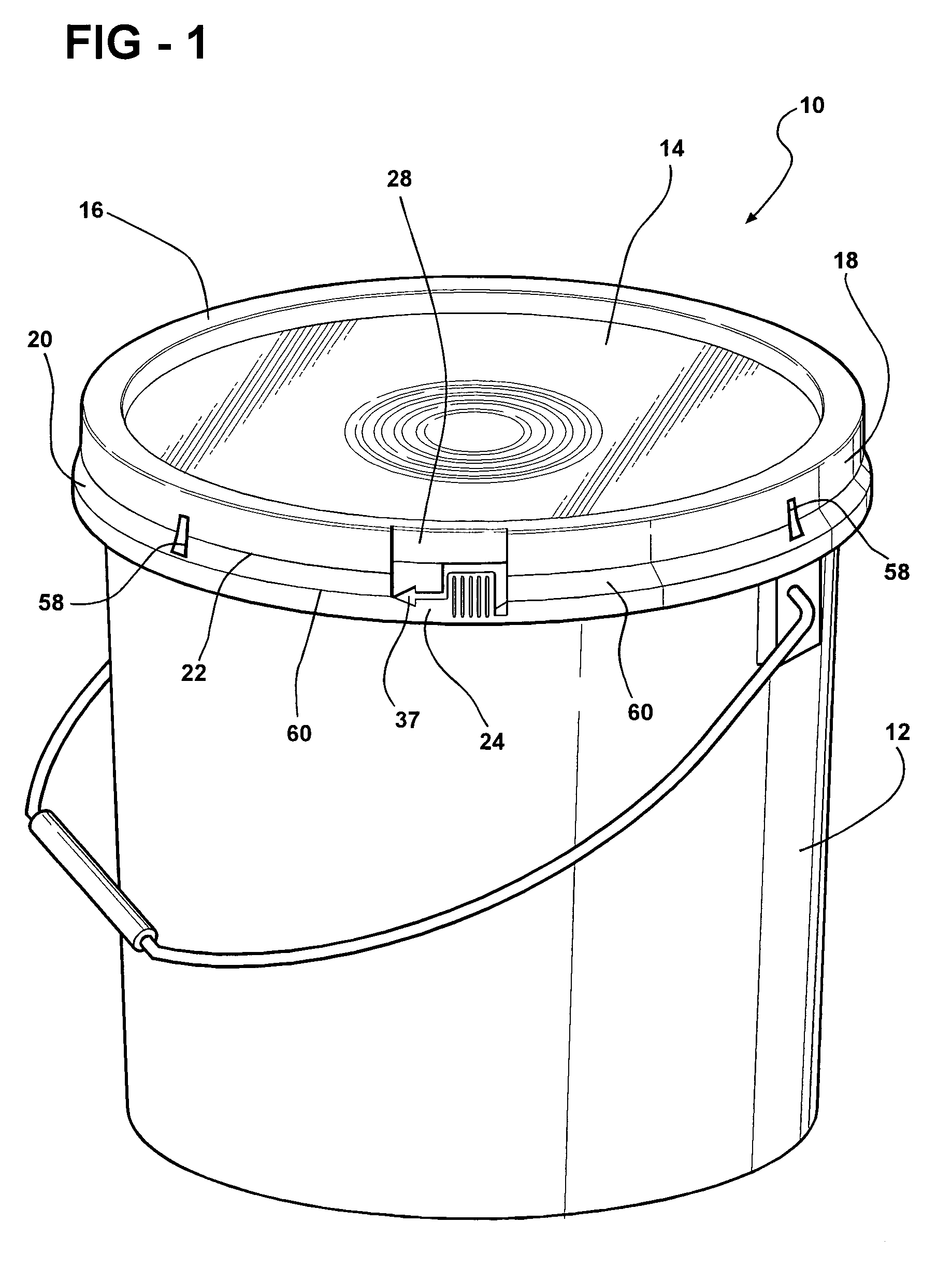

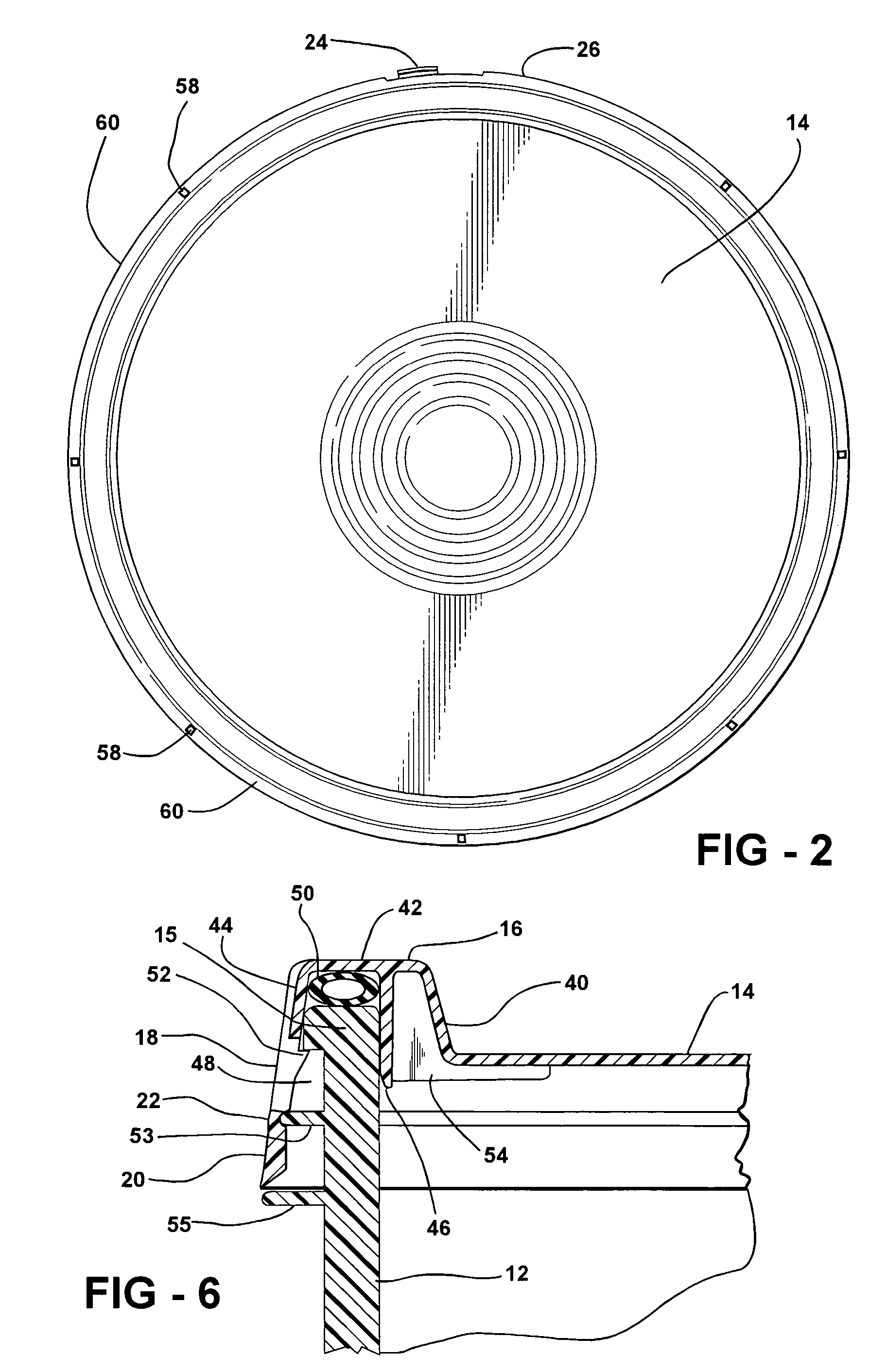

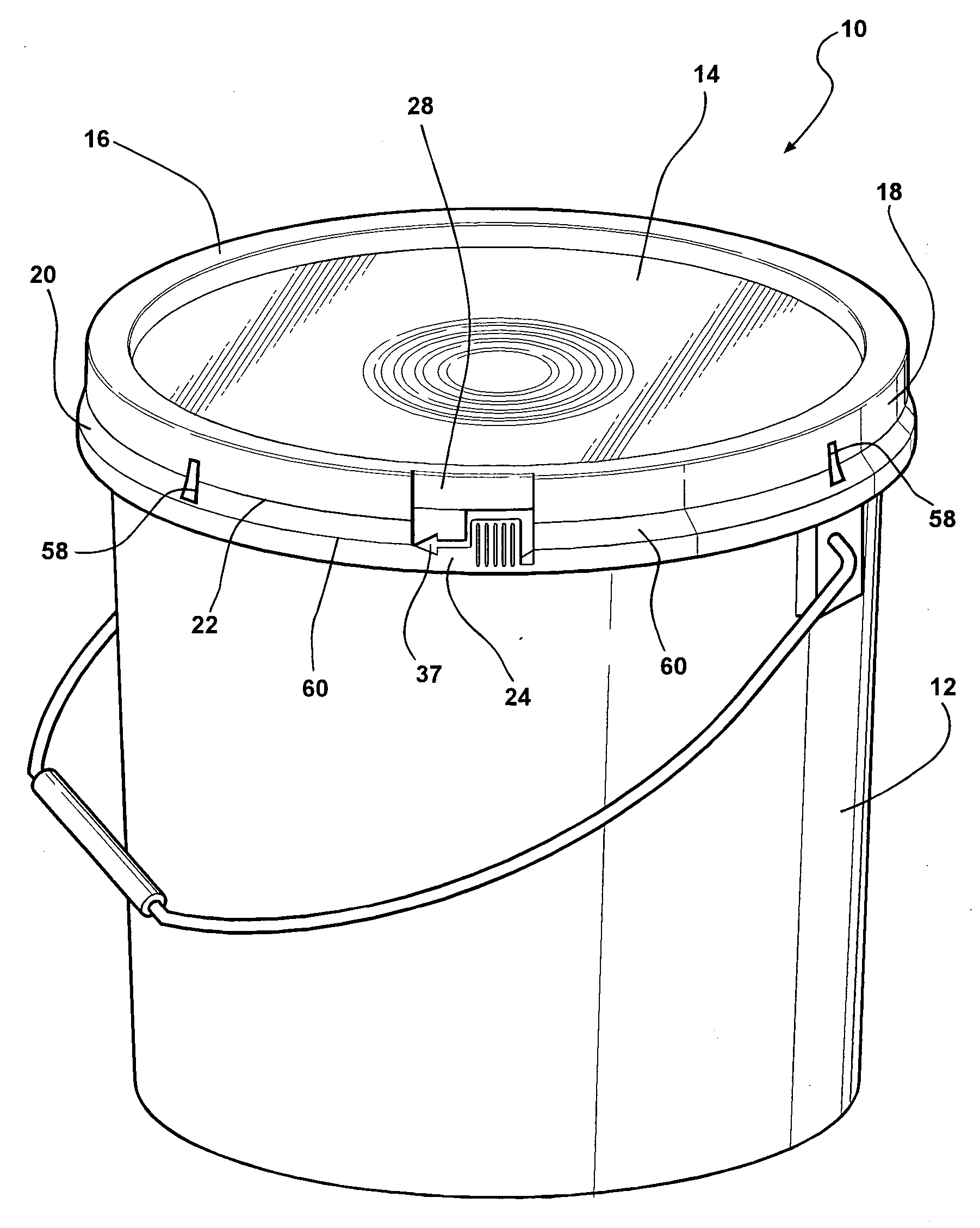

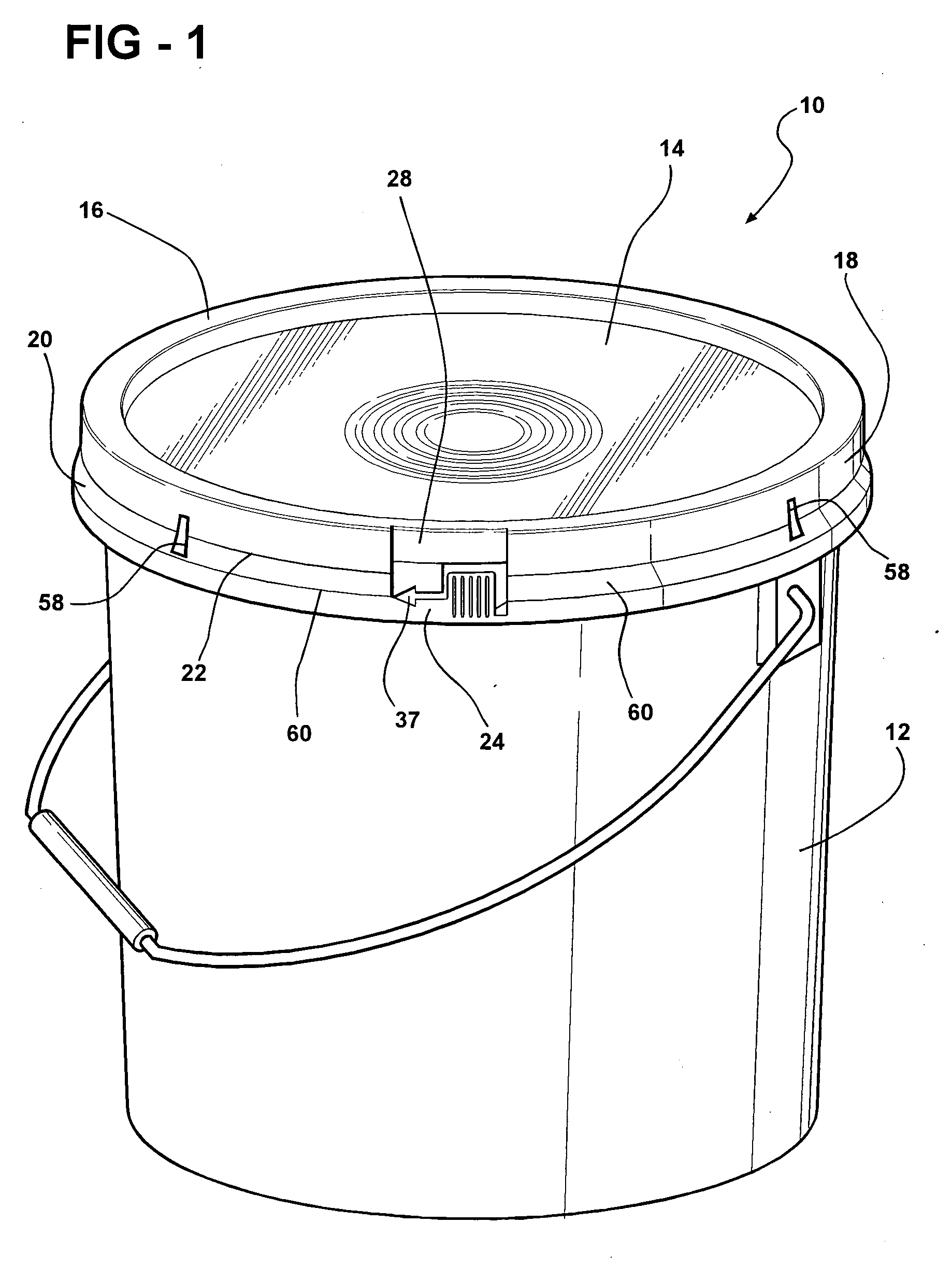

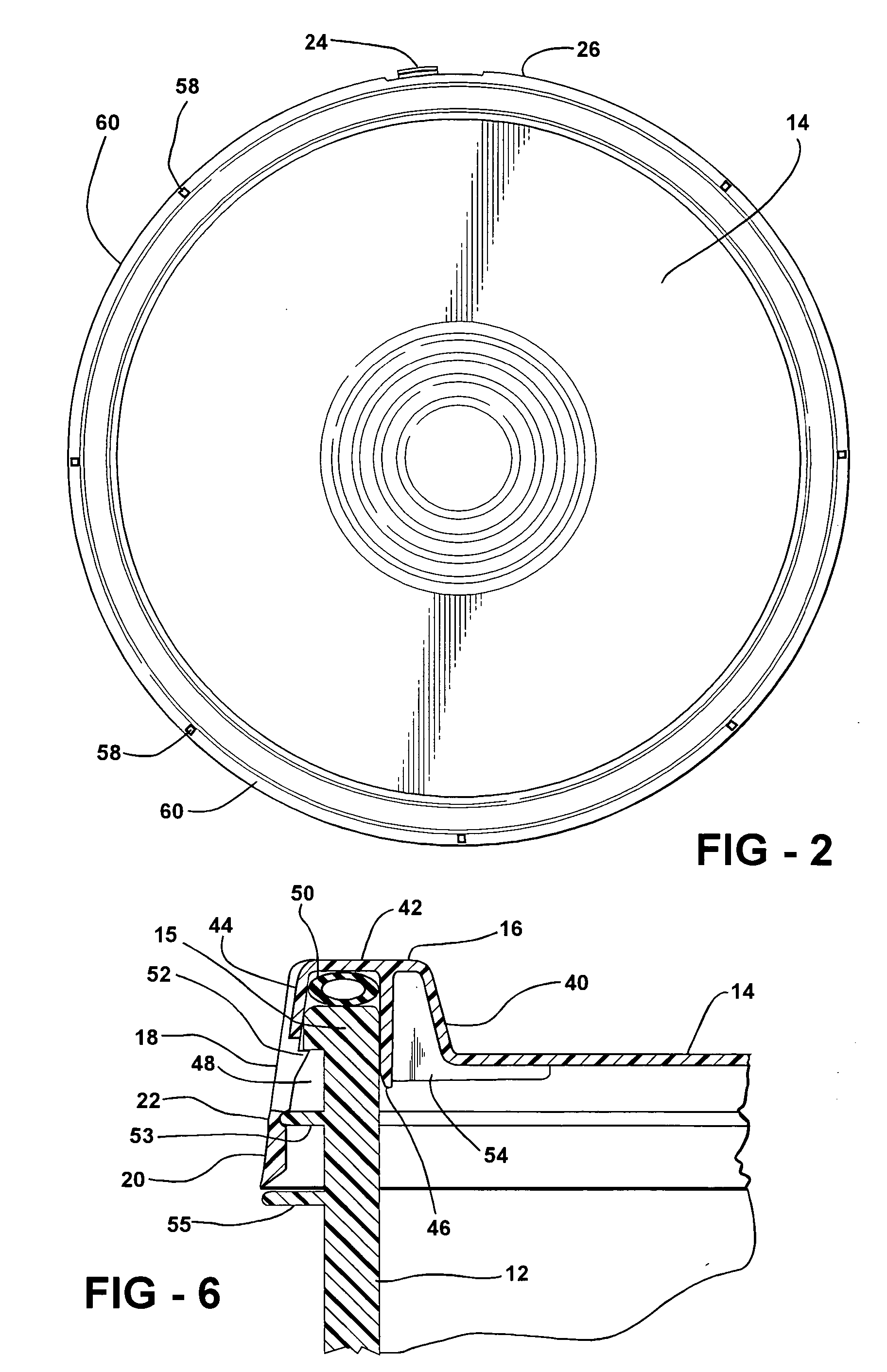

Closure with tear strip

InactiveUS7207457B2Improve effectivenessEasy to disassembleCapsClosure capsMechanical engineeringInverted u

A closure for covering an opening of a container. The closure includes an inverted U-shaped peripheral channel for receiving the rim of a container therein. A tear strip is formed with the skirt of the closure via a tear line that circumscribes the skirt. A breakaway pull tab having an inner surface with U-shaped ribs, the combination of the surface and ribs being such as to provide a concavity which assists in gripping the tab to pull the strip away. Linear vertical ribs may be provided on the outer surface to provide further assistance in the gripping function. The skirt includes a recessed area underlying the pull tab for providing access to the pull tab. An alternative embodiment uses a zig-zag structure of strengthening ribs in the skirt to reduce the amount of material necessary to provide the undercut. This reduces the probability of warpage in the closure structure.

Owner:LETICA

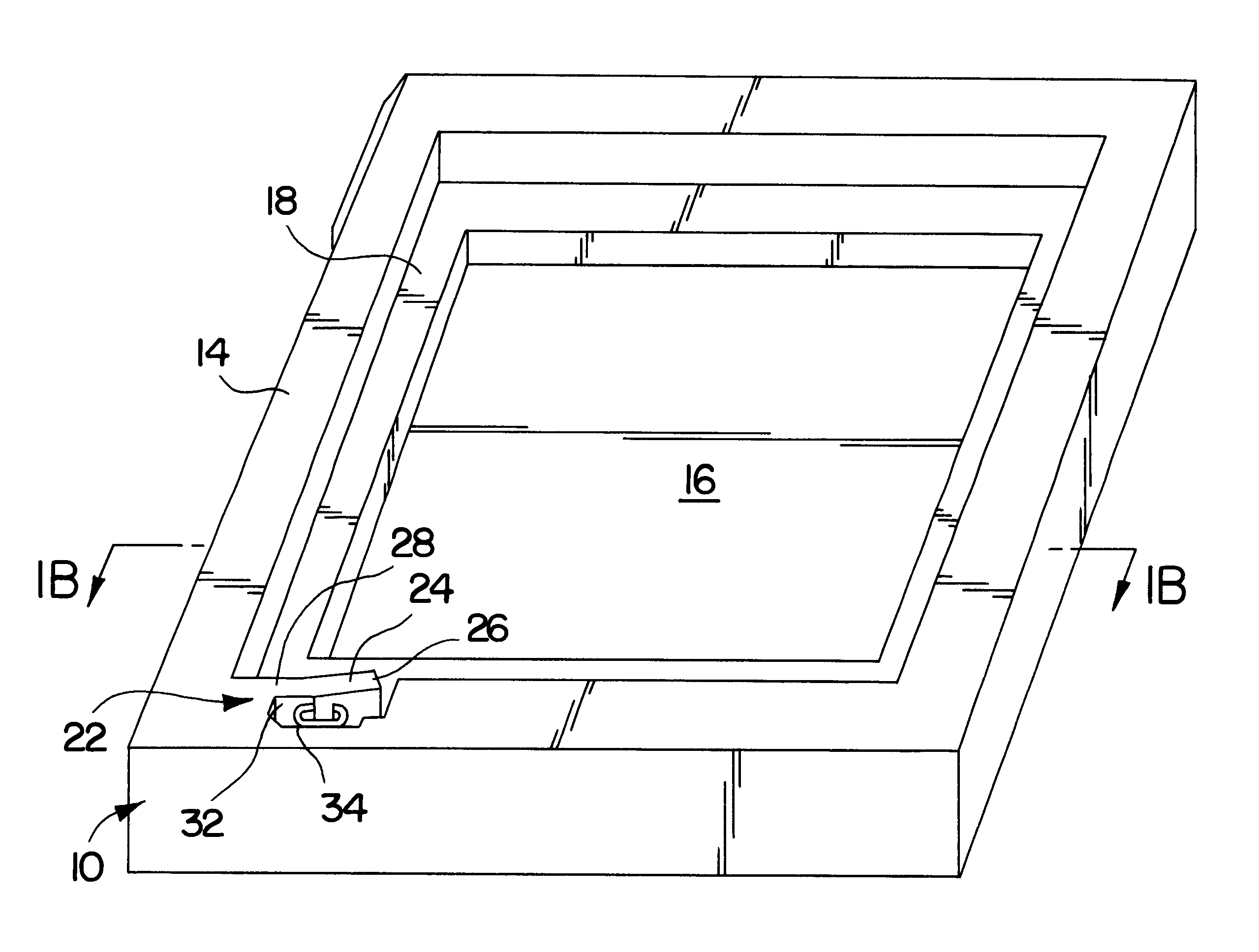

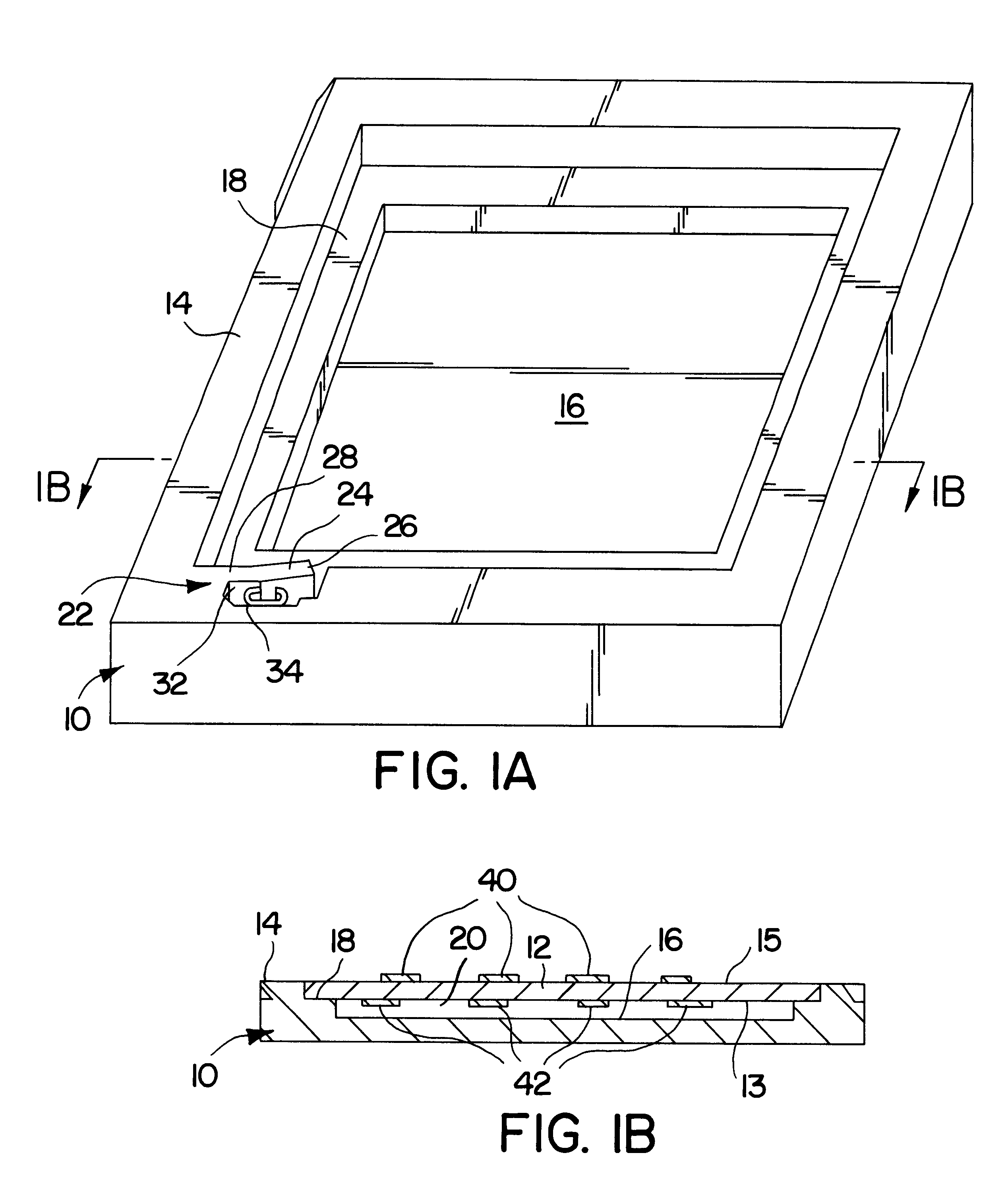

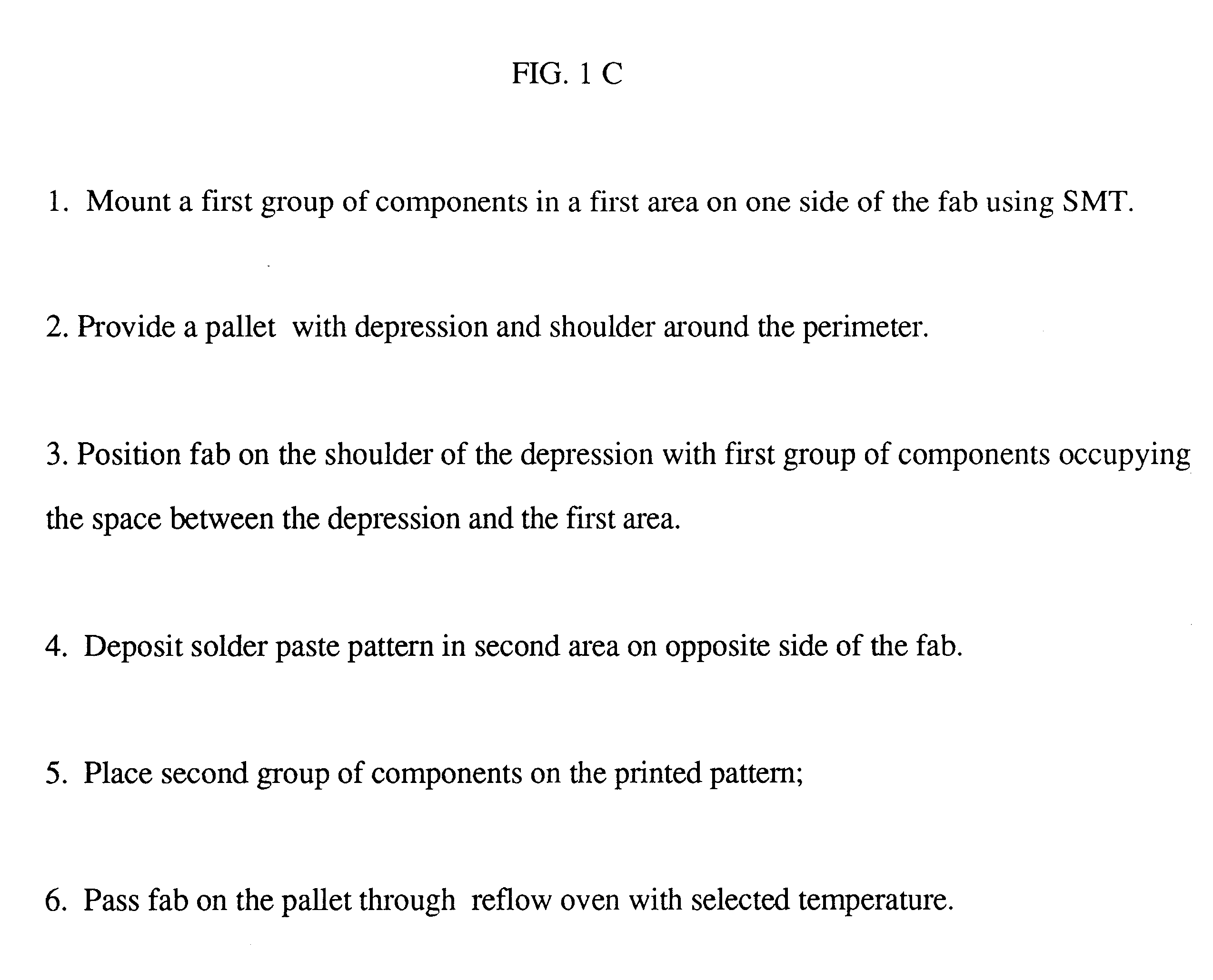

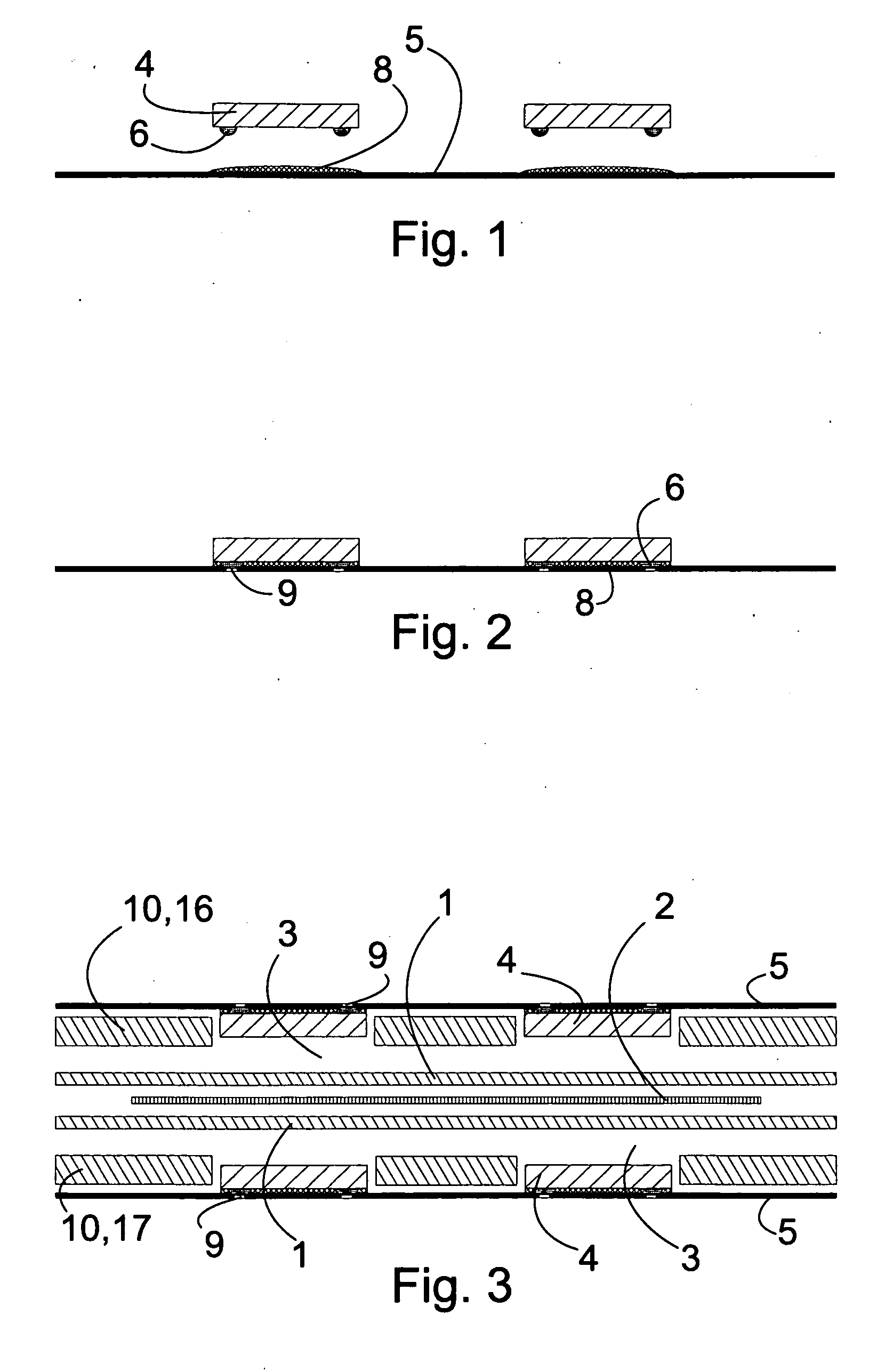

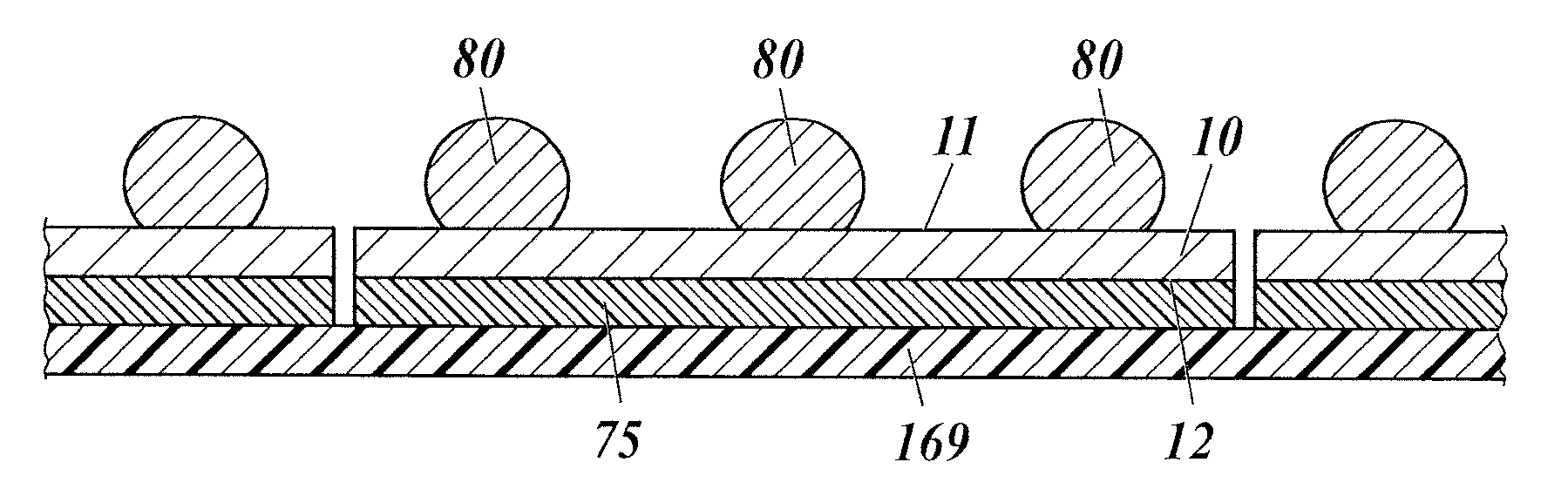

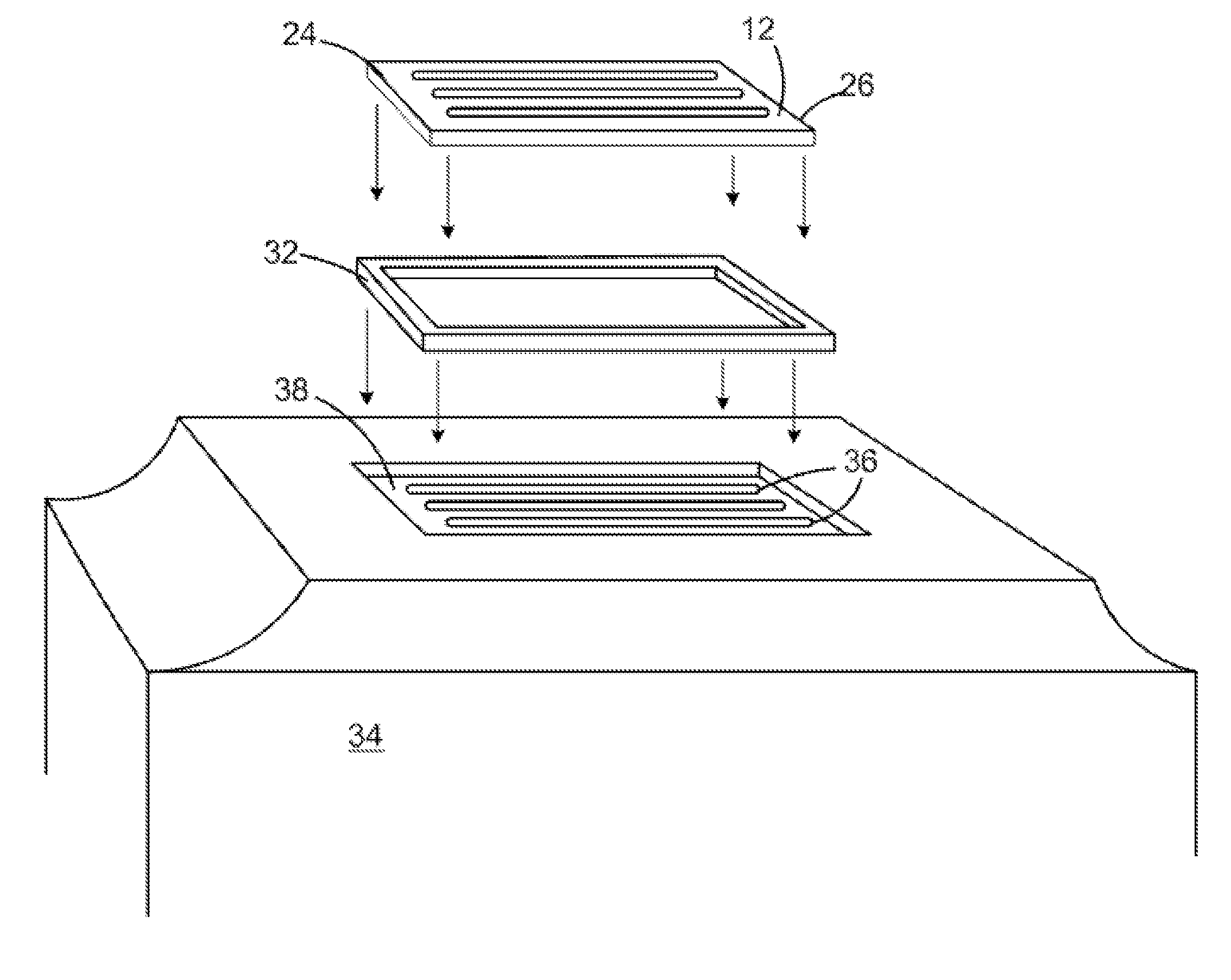

Pallet for combined surface mount and wave solder manufacture of printed ciruits

InactiveUS6267288B1Even heat distributionMinimize warpagePrinted circuit assemblingFinal product manufactureSurface mountingEngineering

A pallet for mounting components on a double sided PCB including a fab (panel) having a frame area surrounding a depression. A shoulder around the depression is dimensioned to support the fab. The fab is laid on the shoulder with the a group of components mounted in a previous reflow operation in the space between the depression and a first area of the fab. The print, pick and place and reflow operations are performed to mount a second group of components on the opposite side of the fab. The first area of the fab is shielded from the heat of the oven so that the first components do not separate from the fab during the second reflow step. Standoffs in the depression prevent sagging of the board. Another area of the pallet has a recessed area with cutouts for wave soldering components located on the third area of the fab.

Owner:CHUNG HENRY

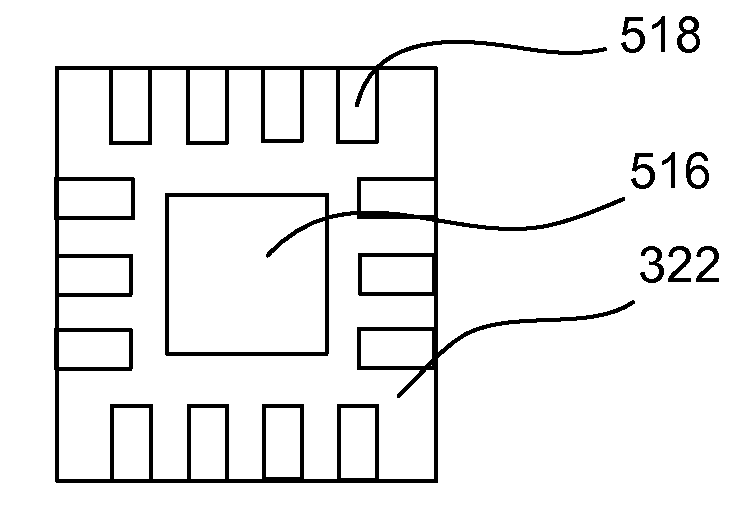

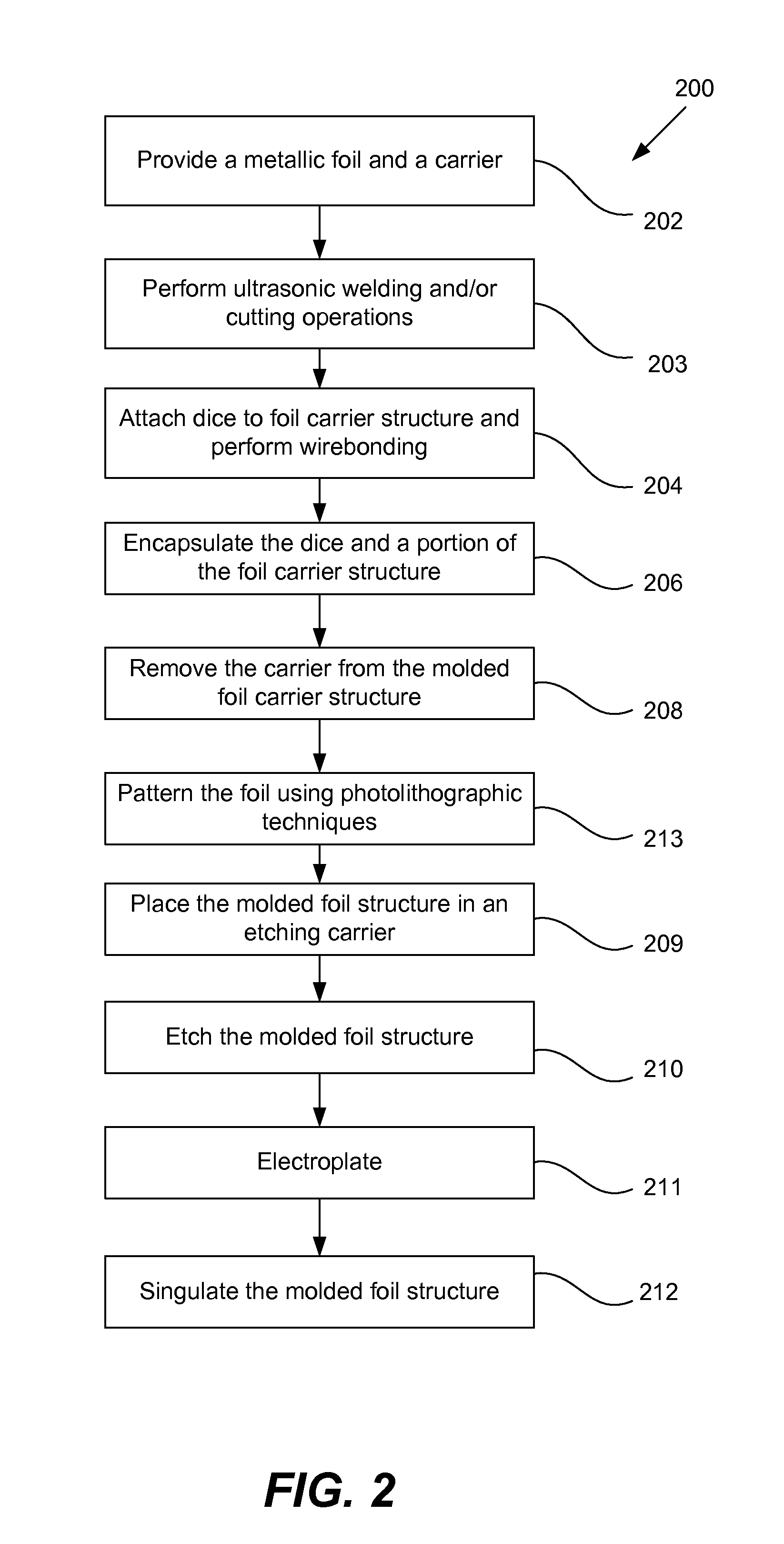

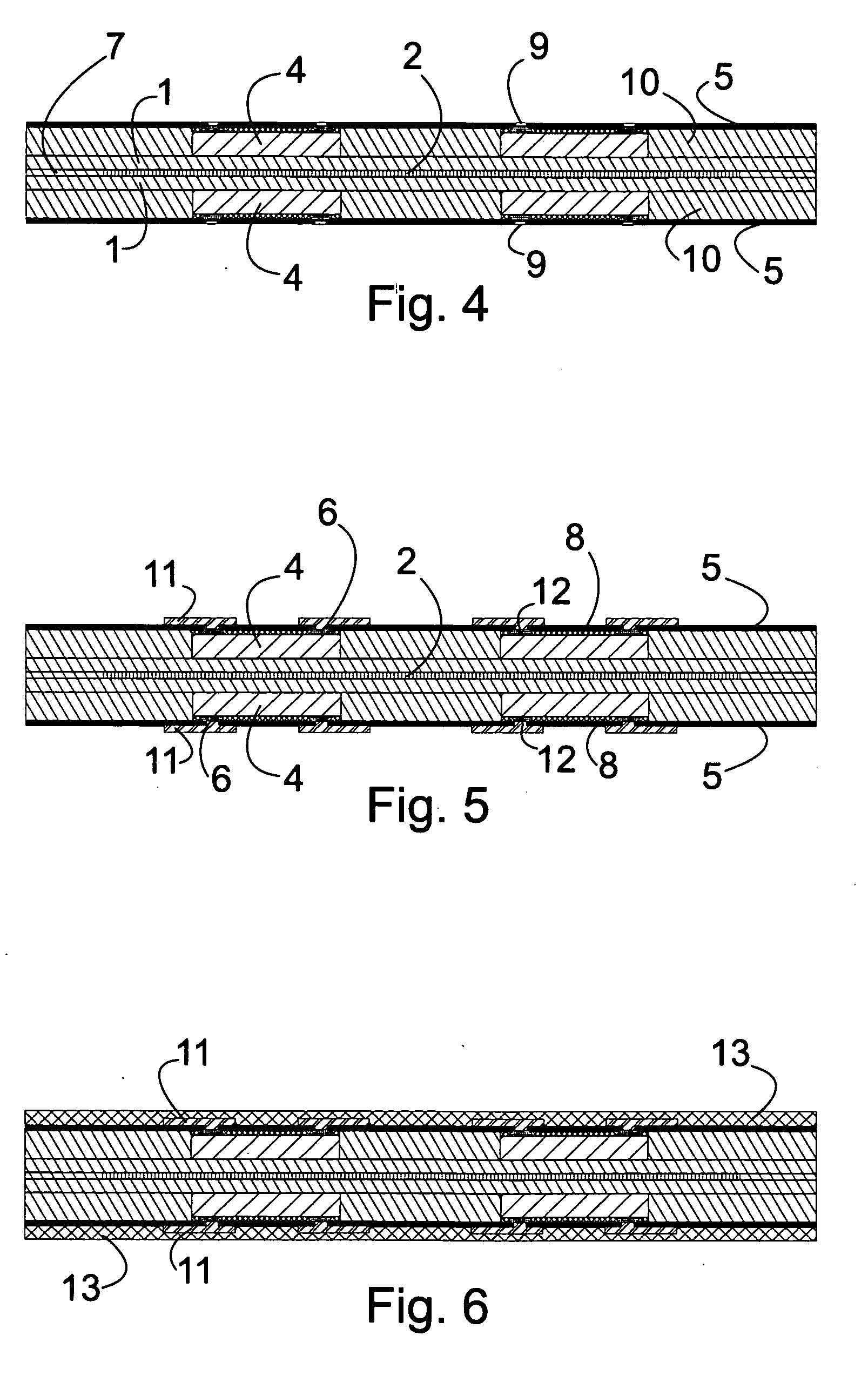

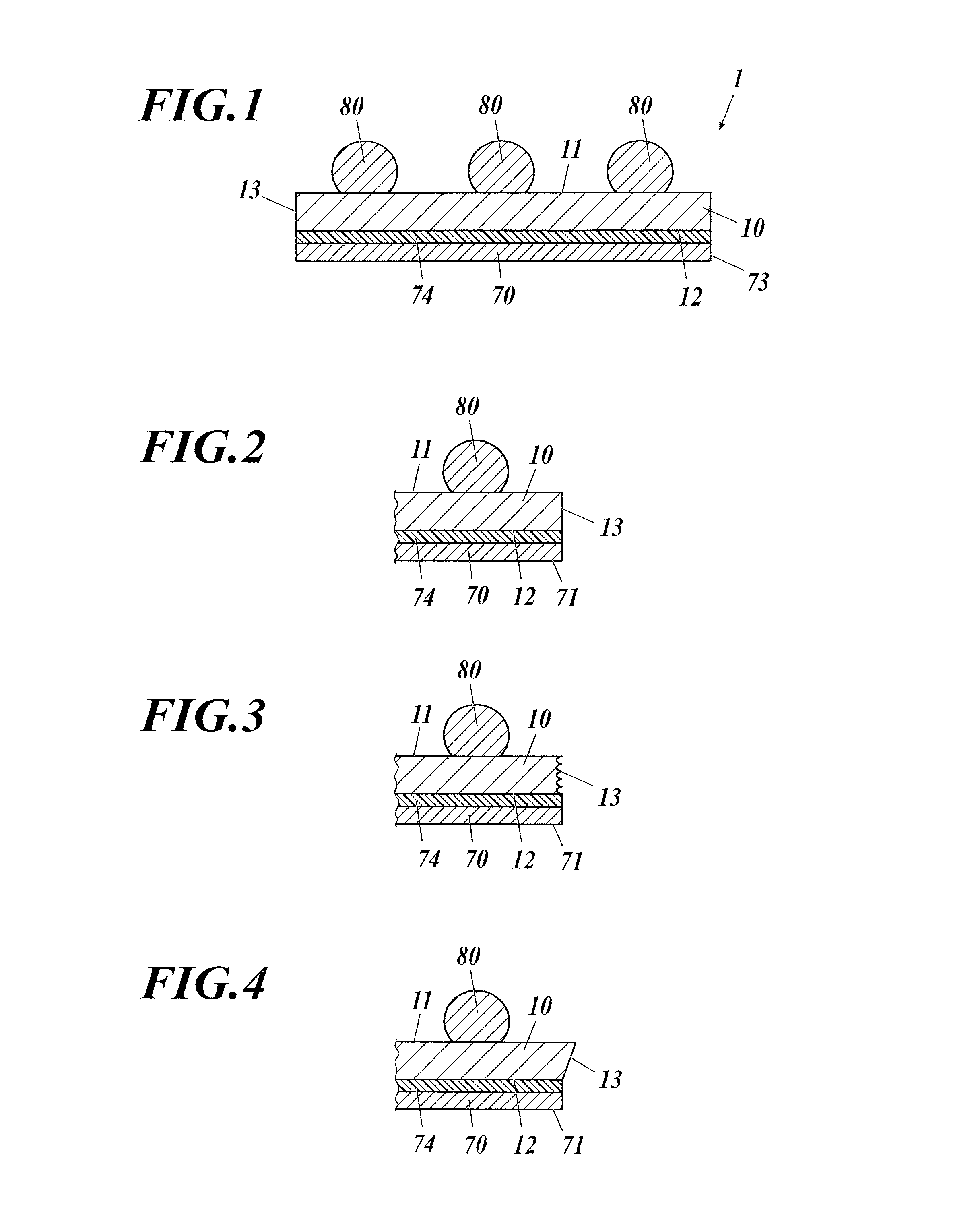

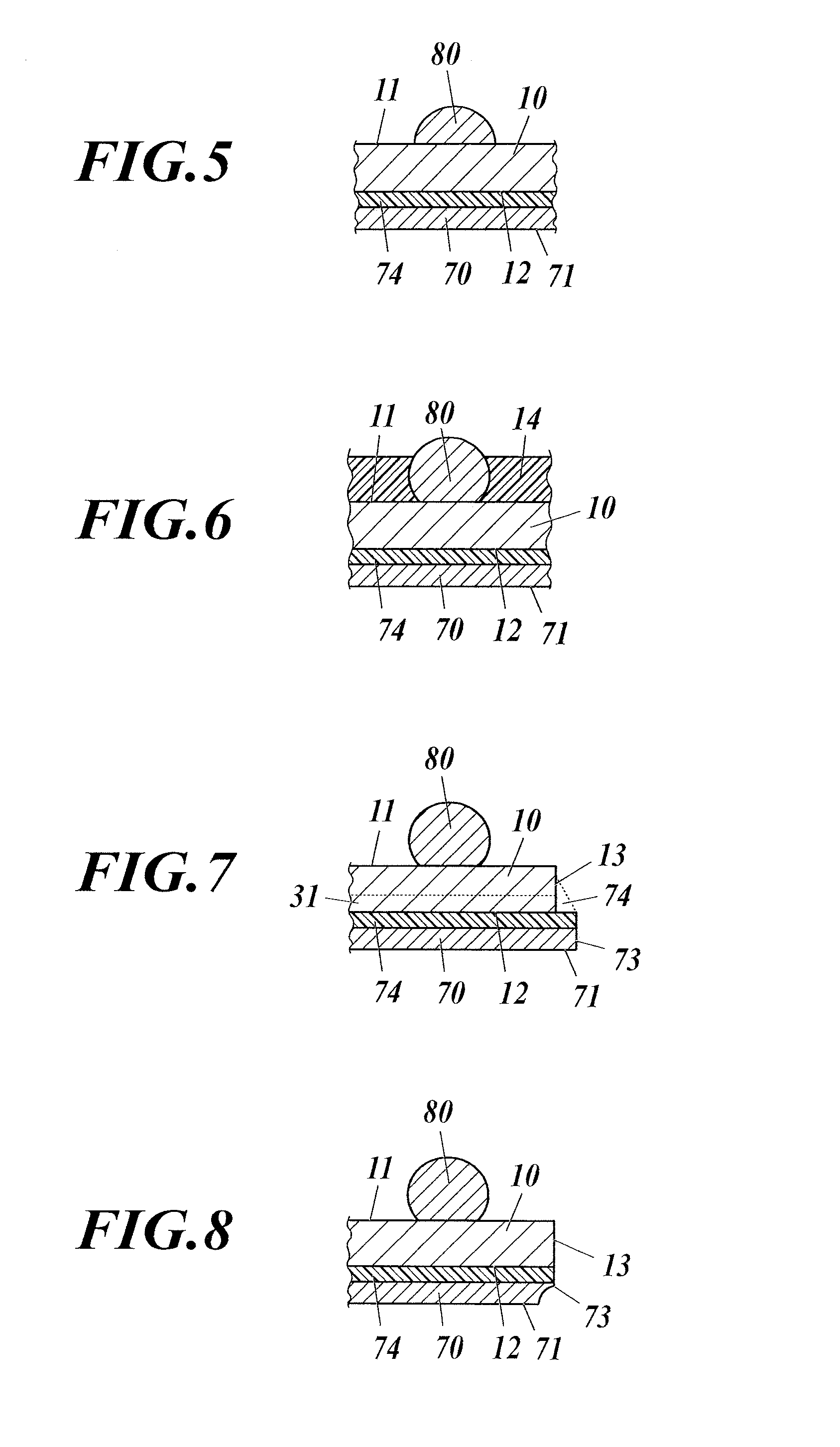

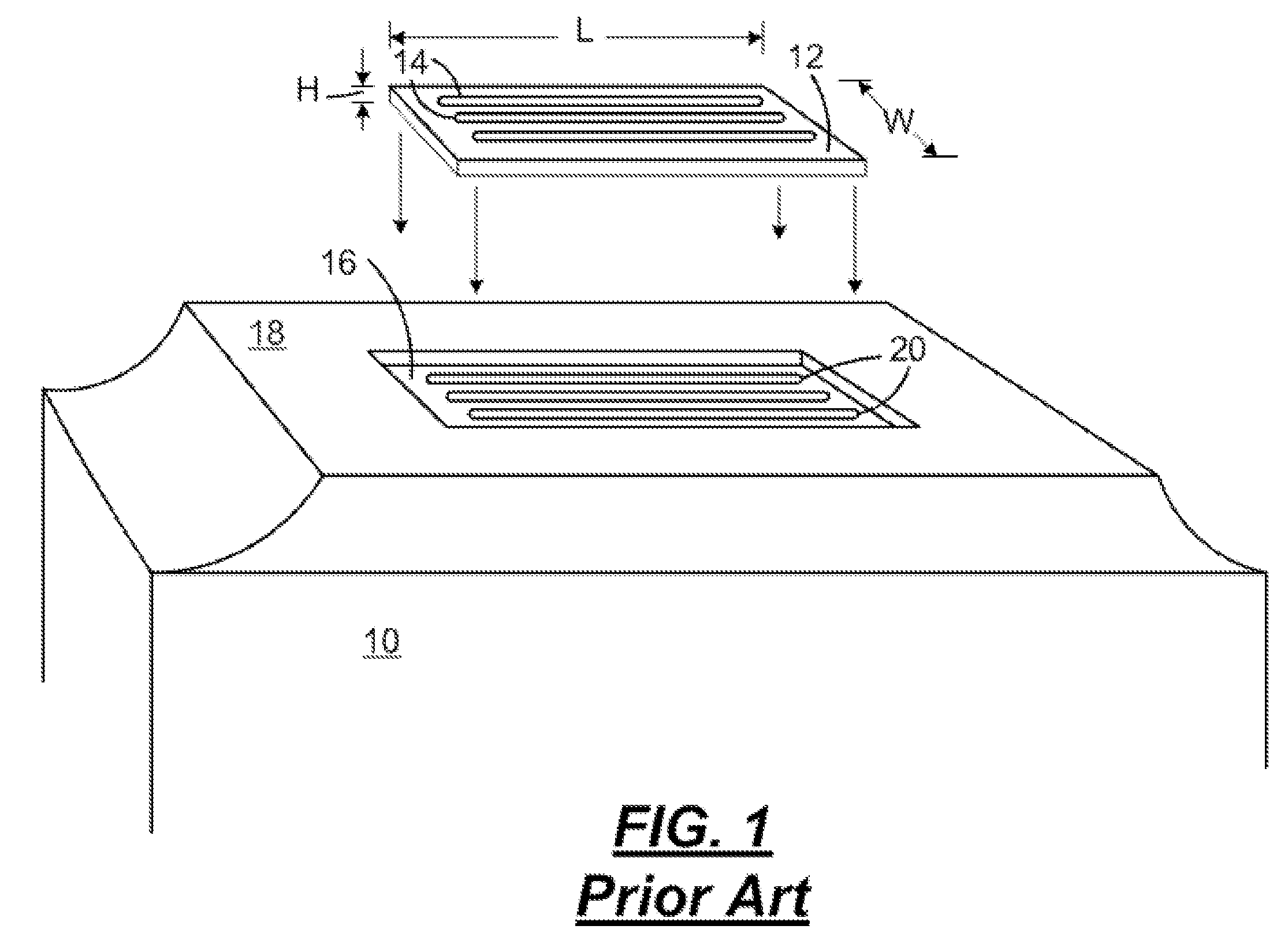

Thin foil for use in packaging integrated circuits

InactiveUS20100084748A1Minimize warpageReduce heat-induced warpageSemiconductor/solid-state device detailsSolid-state devicesMetallic foilUltrasonic welding

Methods for minimizing warpage of a welded foil carrier structure used in the packaging of integrated circuits are described. Portions of a metallic foil are ultrasonically welded to a carrier to form a foil carrier structure. The ultrasonic welding helps define a panel in the metallic foil that is suitable for packaging integrated circuits. Warpage of the thin foil can be limited in various ways. By way of example, an intermittent welding pattern that extends along the edges of the panel may be formed. Slots may be cut to define sections in the foil carrier structure. Materials for the metallic foil and the carrier may be selected to have similar coefficients of thermal expansion. An appropriate thickness for the metallic foil and the carrier may be selected, such that the warpage of the welded foil carrier structure is limited when the foil carrier structure is subjected to large increases in temperature. Foil carrier structures for use in the above methods are also described.

Owner:NAT SEMICON CORP

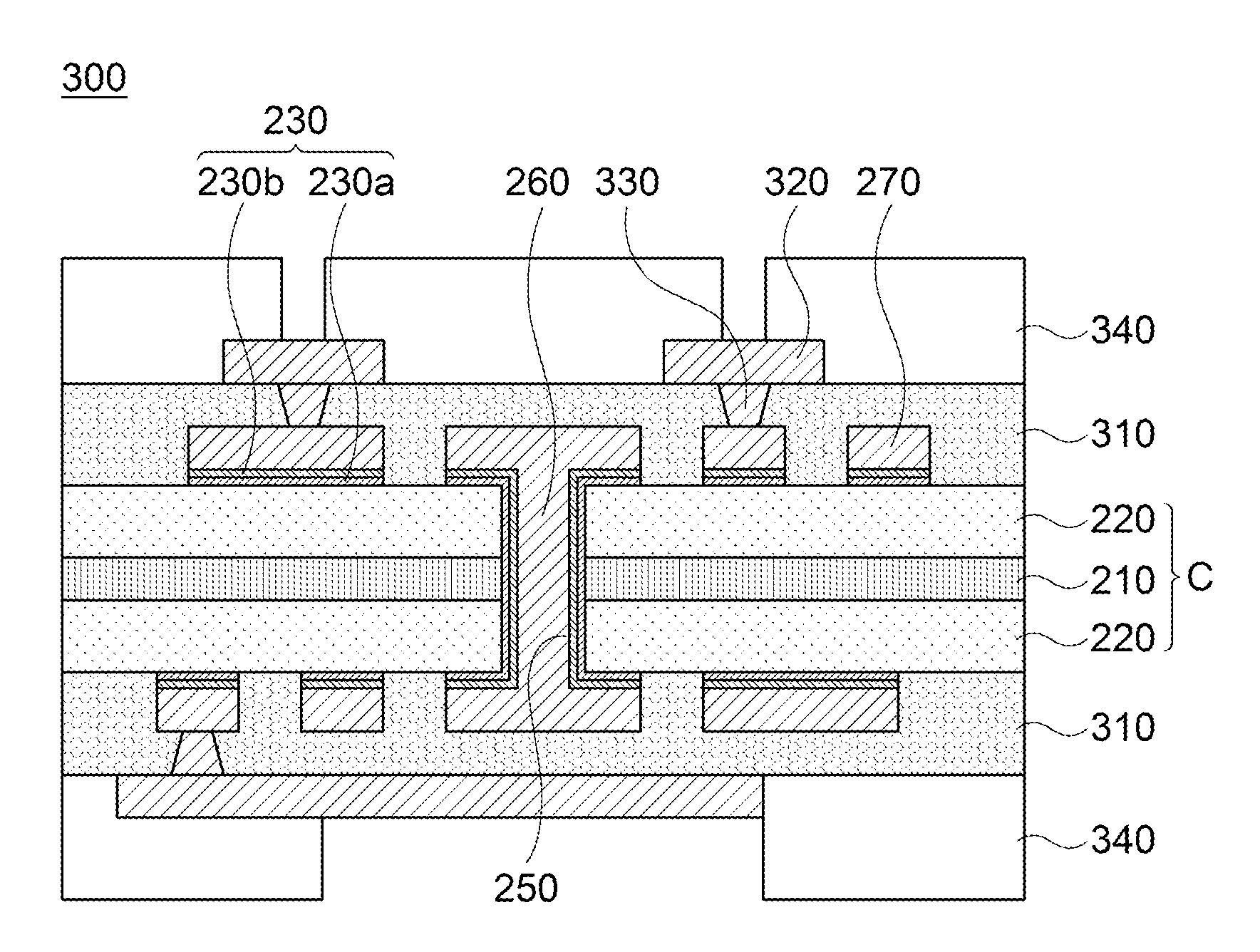

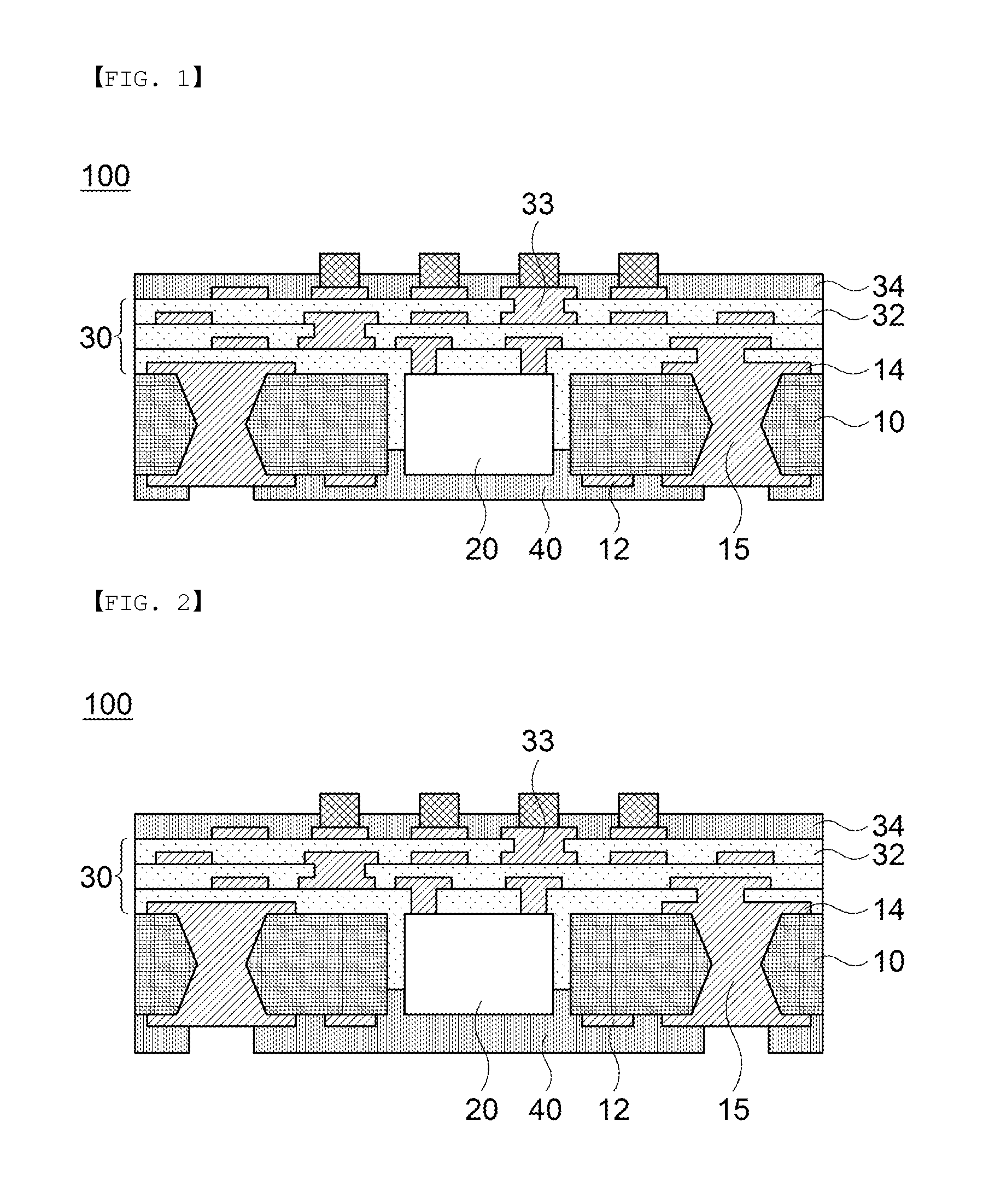

Printed circuit board and method for manufacturing the same

InactiveUS20140027163A1Avoid warpingMinimize warpageElectrical connection printed elementsSurface layering apparatusInter layerEngineering

Disclosed herein are a printed circuit board and a method for manufacturing the same. The printed circuit board includes: a core reinforcement having stiffness; insulating layers formed on both surfaces of the core reinforcement; a through hole formed by penetrating through the insulating layer and the core reinforcement; and a circuit layer formed on the insulating layer and a plating layer formed in the through hole for implementing inter-layer connection of the circuit layers.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method of manufacturing a semiconductor device including electrodes on main and reverse sides of a semiconductor chip

InactiveUS20050170555A1Prevent penetrationWarpage of the semiconductor wafer can be minimizedSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A method for manufacturing a semiconductor chip includes preparing a semiconductor wafer to be oriented so that a main side and reverse side of the semiconductor wafer is oriented similar to a main side and reverse side of the semiconductor chip intended to be cut from the semiconductor wafer. An electrode is formed on a reverse side of the semiconductor wafer. Another electrode is formed on the main side of the semiconductor wafer while the reverse side of the wafer is fixed to a supporting substrate. The semiconductor wafer is cut later to form the semiconductor chip.

Owner:DENSO CORP

Wiring board and method for manufacturing the same

ActiveUS20090260866A1Structure miniaturizationSimplify the manufacturing processPrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

Owner:IMBERATEK LLC

Closure with tear strip

InactiveUS20050145628A1Improve effectivenessEasy to disassembleCapsClosure capsEngineeringMechanical engineering

A closure for covering an opening of a container. The closure includes an inverted U-shaped peripheral channel for receiving the rim of a container therein. A tear strip is formed with the skirt of the closure via a tear line that circumscribes the skirt. A breakaway pull tab having an inner surface with U-shaped ribs, the combination of the surface and ribs being such as to provide a concavity which assists in gripping the tab to pull the strip away. Linear vertical ribs may be provided on the outer surface to provide further assistance in the gripping function. The skirt includes a recessed area underlying the pull tab for providing access to the pull tab. An alternative embodiment uses a zig-zag structure of strengthening ribs in the skirt to reduce the amount of material necessary to provide the undercut. This reduces the probability of warpage in the closure structure.

Owner:LETICA

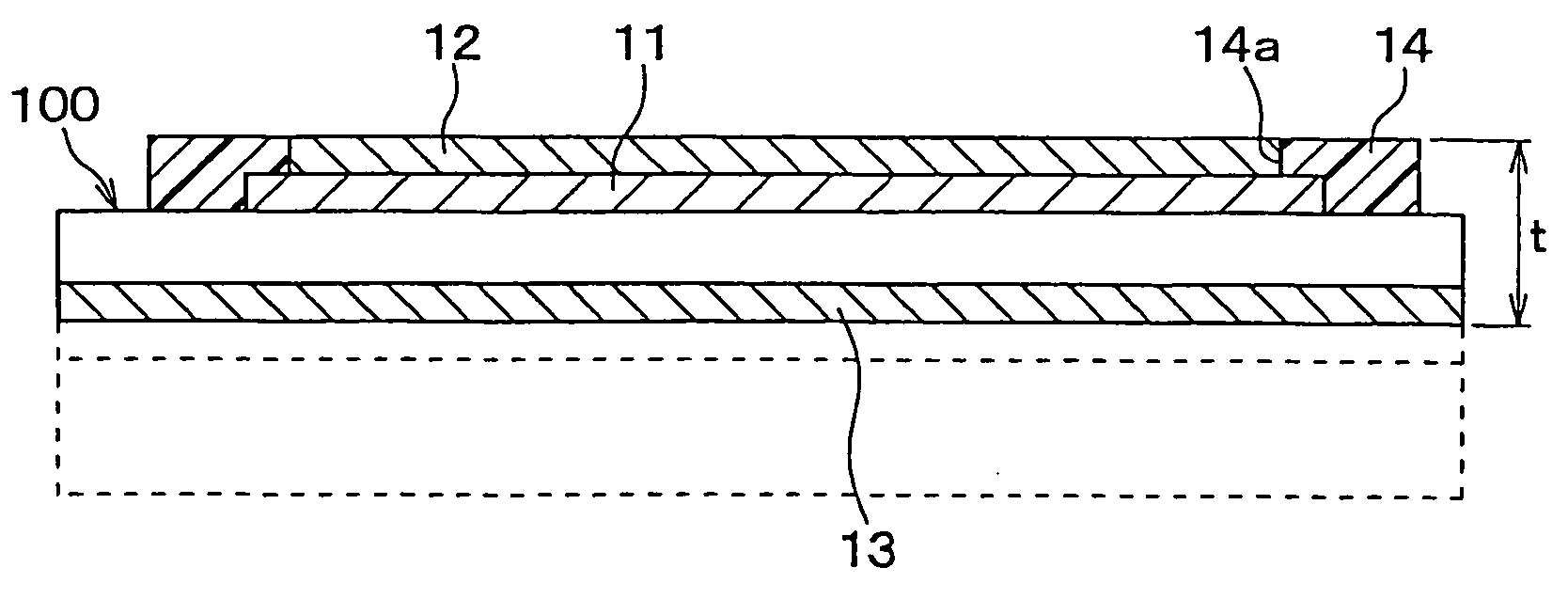

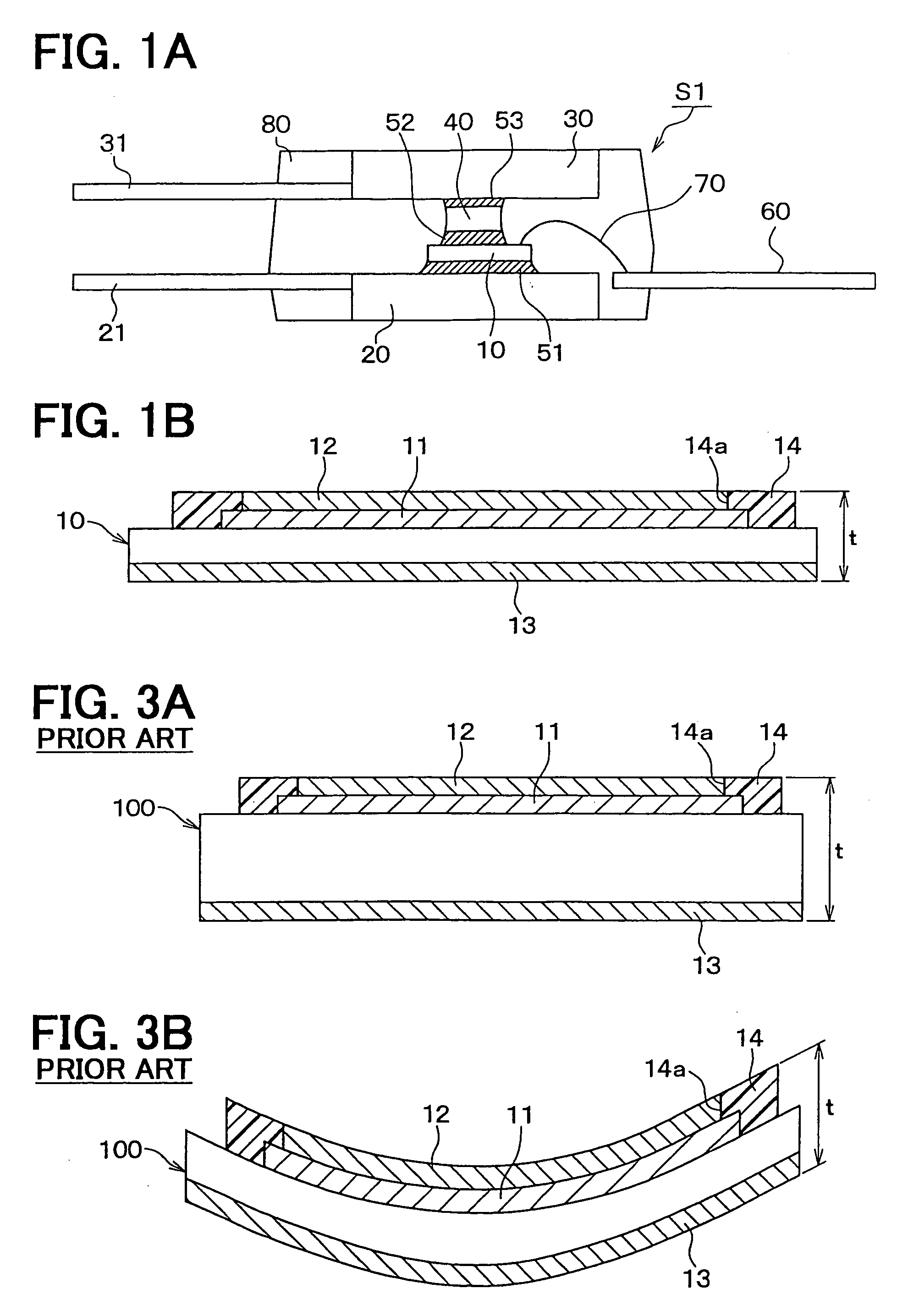

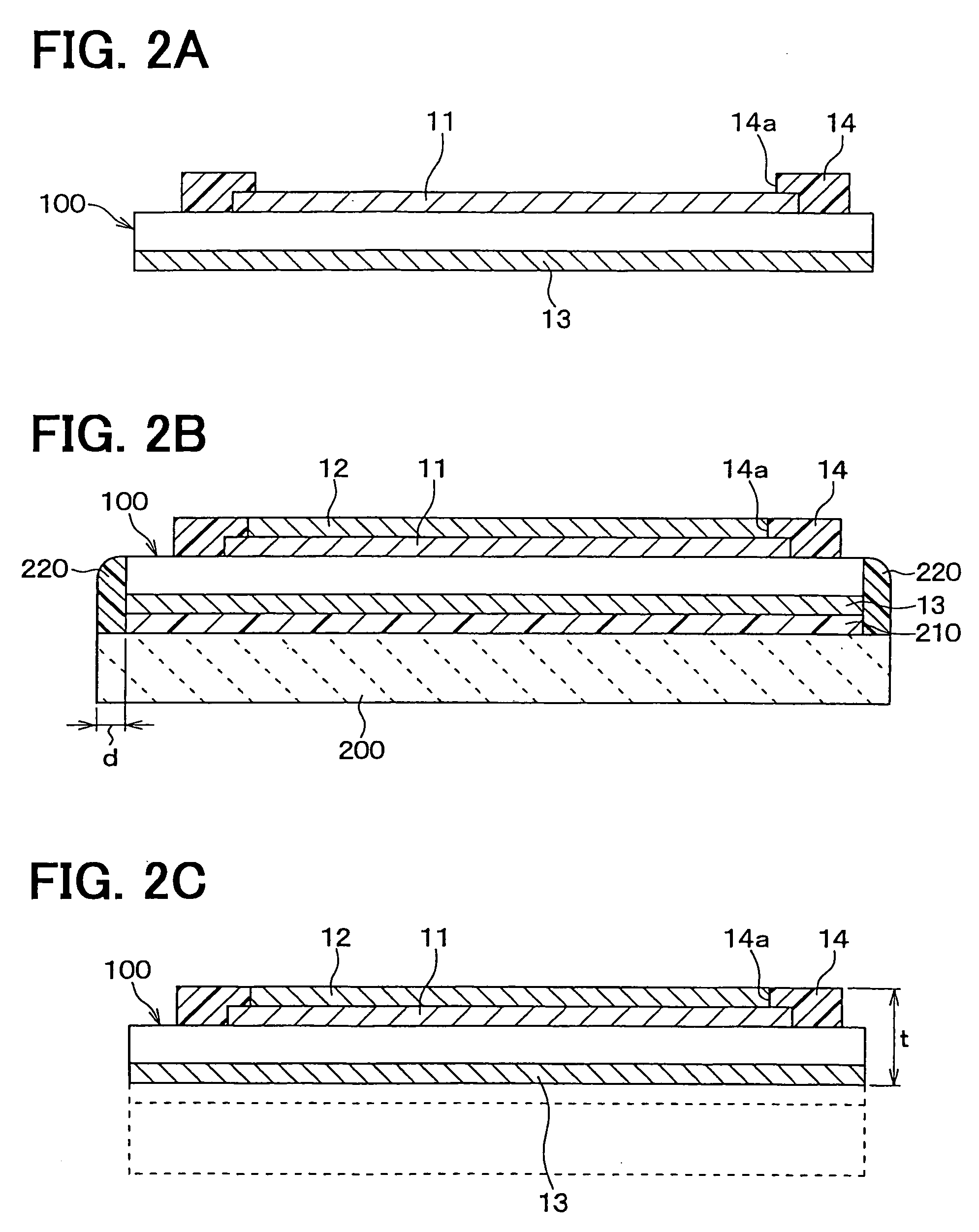

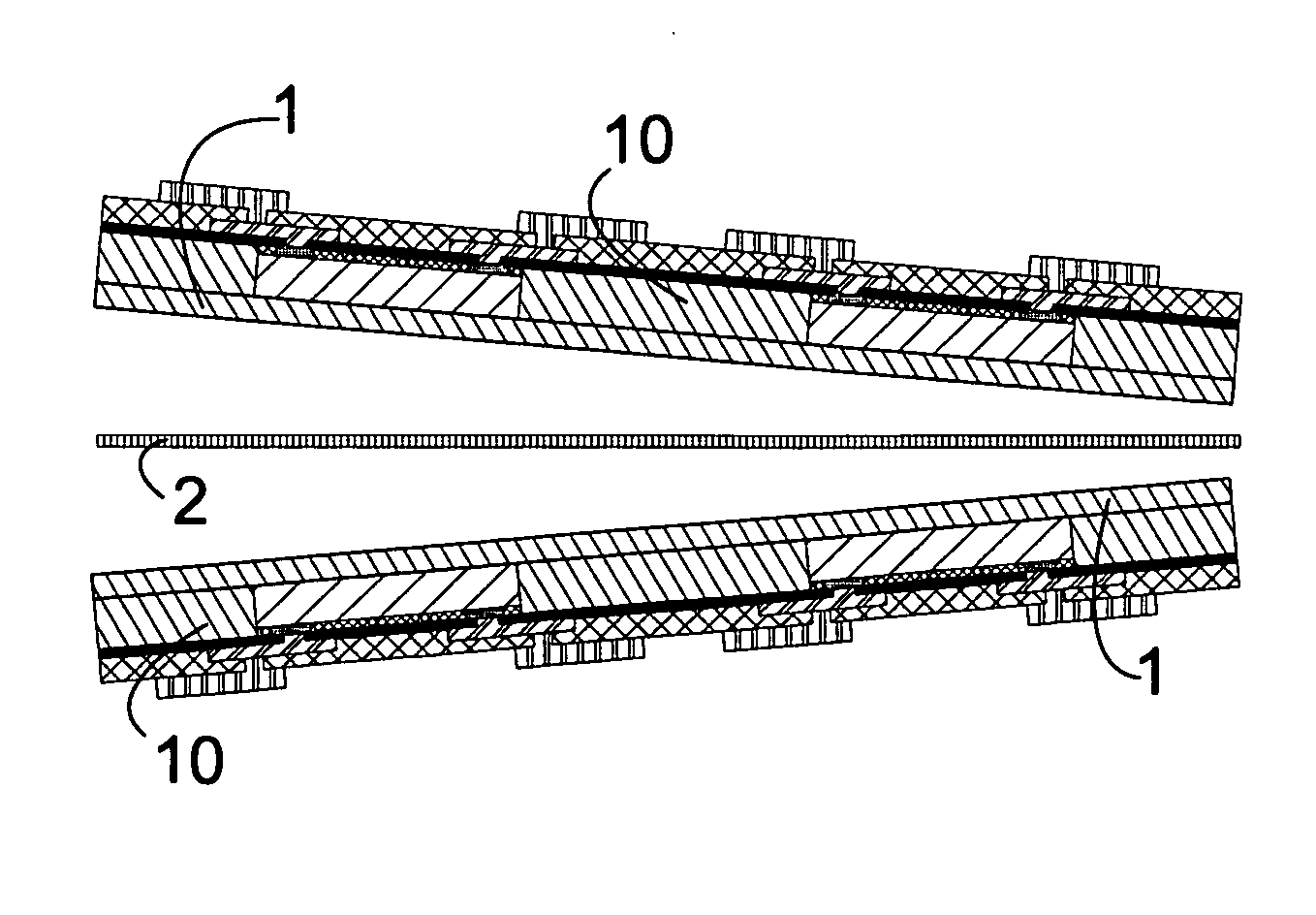

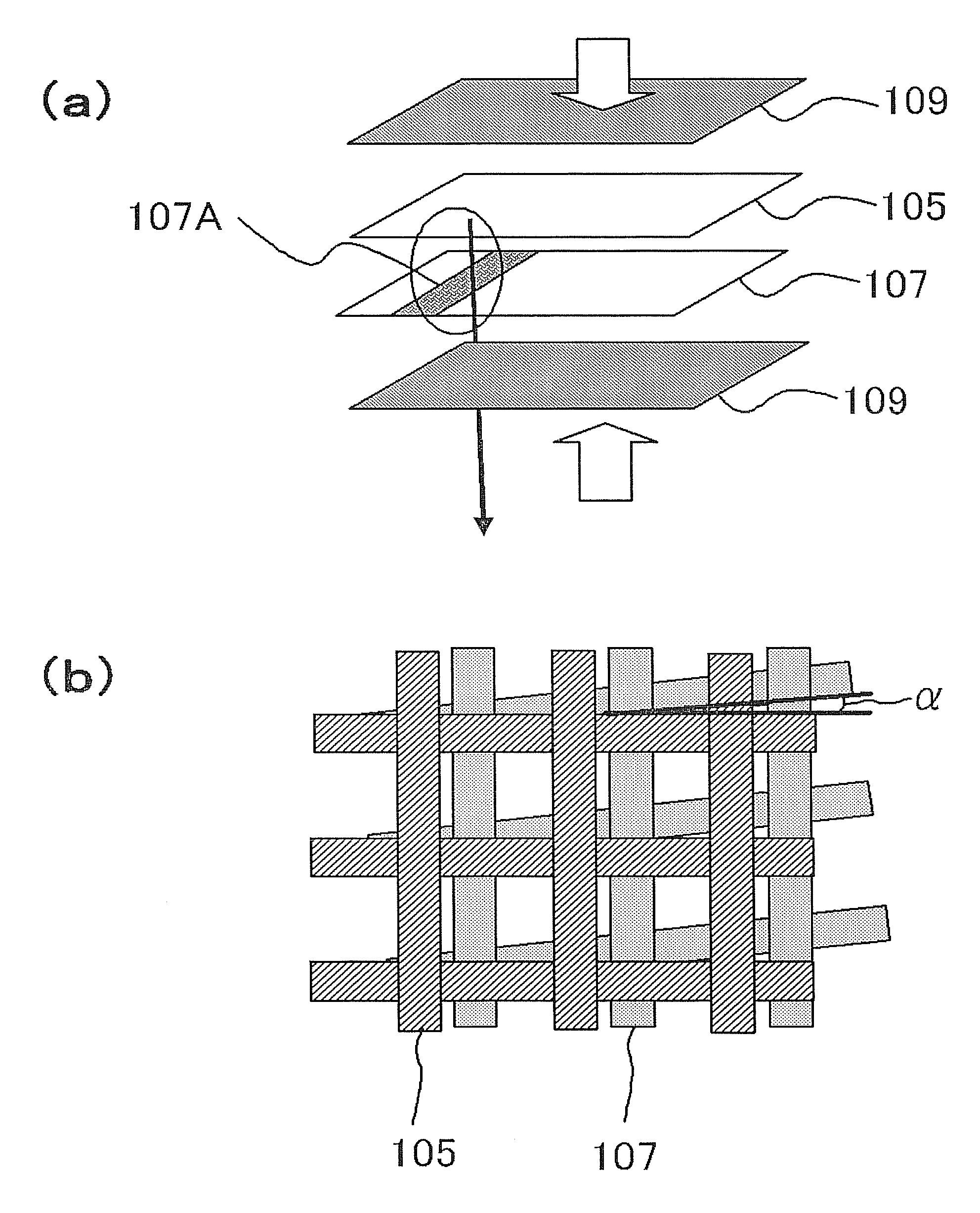

Organic el element sealing member

InactiveUS20120207991A1Prevent degradationEnhance durabilityElectroluminescent light sourcesSynthetic resin layered productsChemistryPlastic film

The present invention provides a sealing member for organic EL elements that enables organic EL elements, in particular, organic EL elements for illumination devices to maintain stable luminescence over a long period and that can be fabricated at reduced cost. The sealing member for organic EL elements of the present invention includes a barrier film including a plastic film and at least one thin metal layer, and a curable resin composition layer on the barrier film. The curable resin composition layer has a thickness of 5 to 100 μm and the curable resin composition exhibits nonfluidity at 25° C. in an uncured state and gains fluidity at an elevated temperature in the range of 40 to 80° C.

Owner:THREE BOND CO LTD

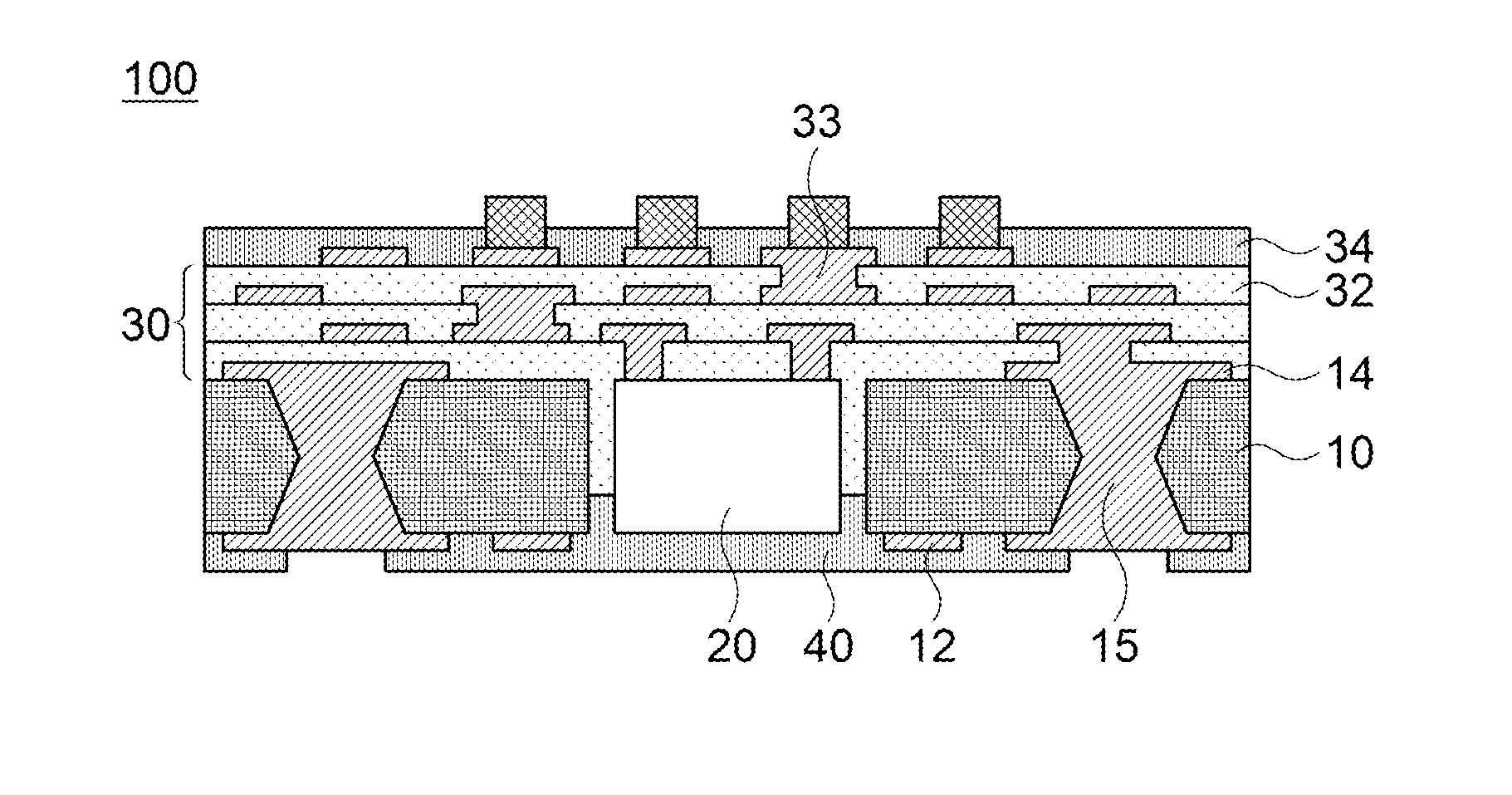

Semiconductor device and method of manufacturing the same

ActiveUS20160233111A1Minimize warpageAvoid bendingSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A method of manufacturing a semiconductor device, including steps of: (a) bonding a support plate to a first main face of a wafer, the first main face having an integrated circuit disposed thereon; (b) thinning the wafer by polishing or grinding a second main face after step (a), the second main face being opposite to the first main face; (c) dividing the wafer into multiple chip bodies concurrently with or after step (b); (d) bonding multiple reinforcing layers to second main faces of the respective chip bodies after step (c); and (e) removing the support plate after step (d).

Owner:AOI ELECTRONICS CO LTD

Curable hot melt adhesive for casemaking

InactiveUS6858695B2Minimize warpageFast and efficientBookbinding casesSynthetic resin layered productsMoistureHot-melt adhesive

A curable casemaking adhesive, books and related articles bound thereby. In one embodiment, a UV curable hot melt adhesive is used to form the case, which is preferably also embossed. In another embodiment, a moisture curable hot melt adhesive is used to form the case, which is preferably also embossed.

Owner:HENKEL IP & HOLDING GMBH

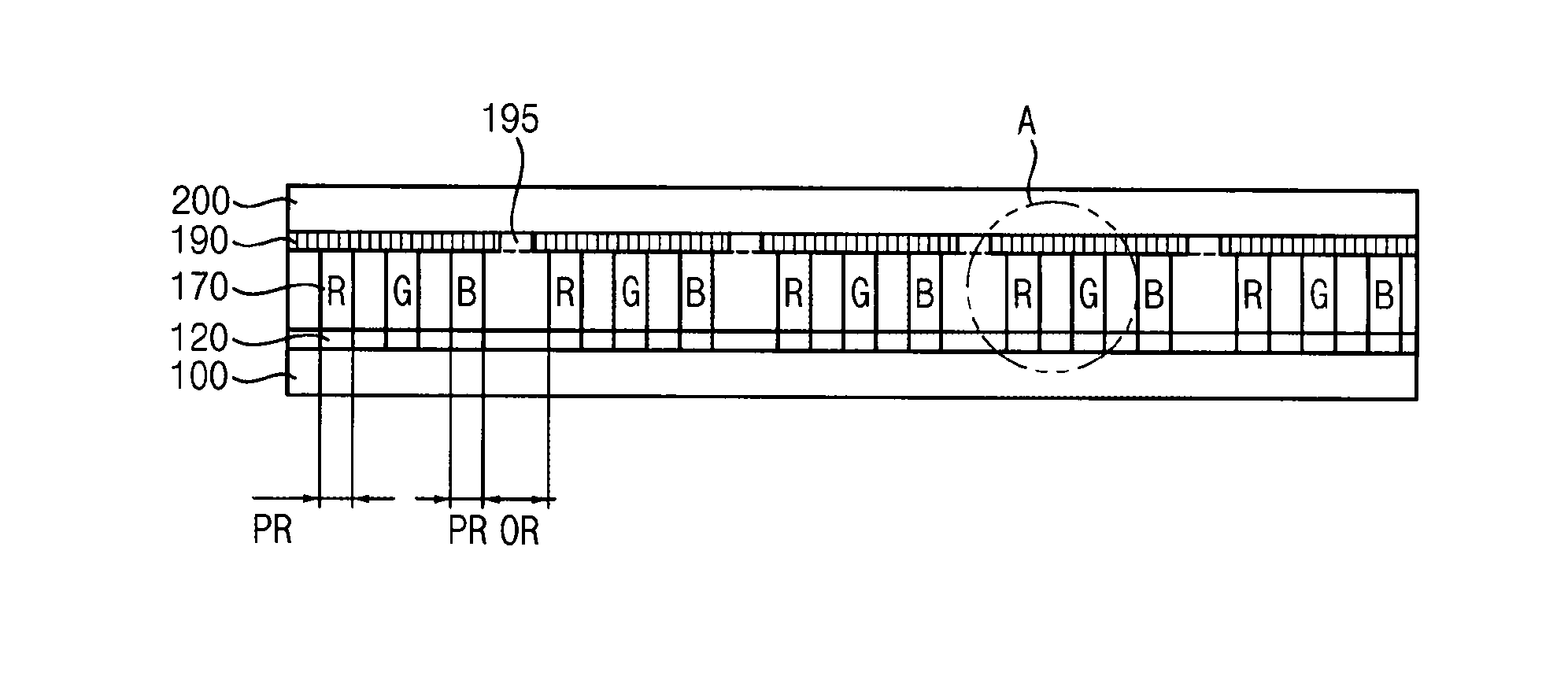

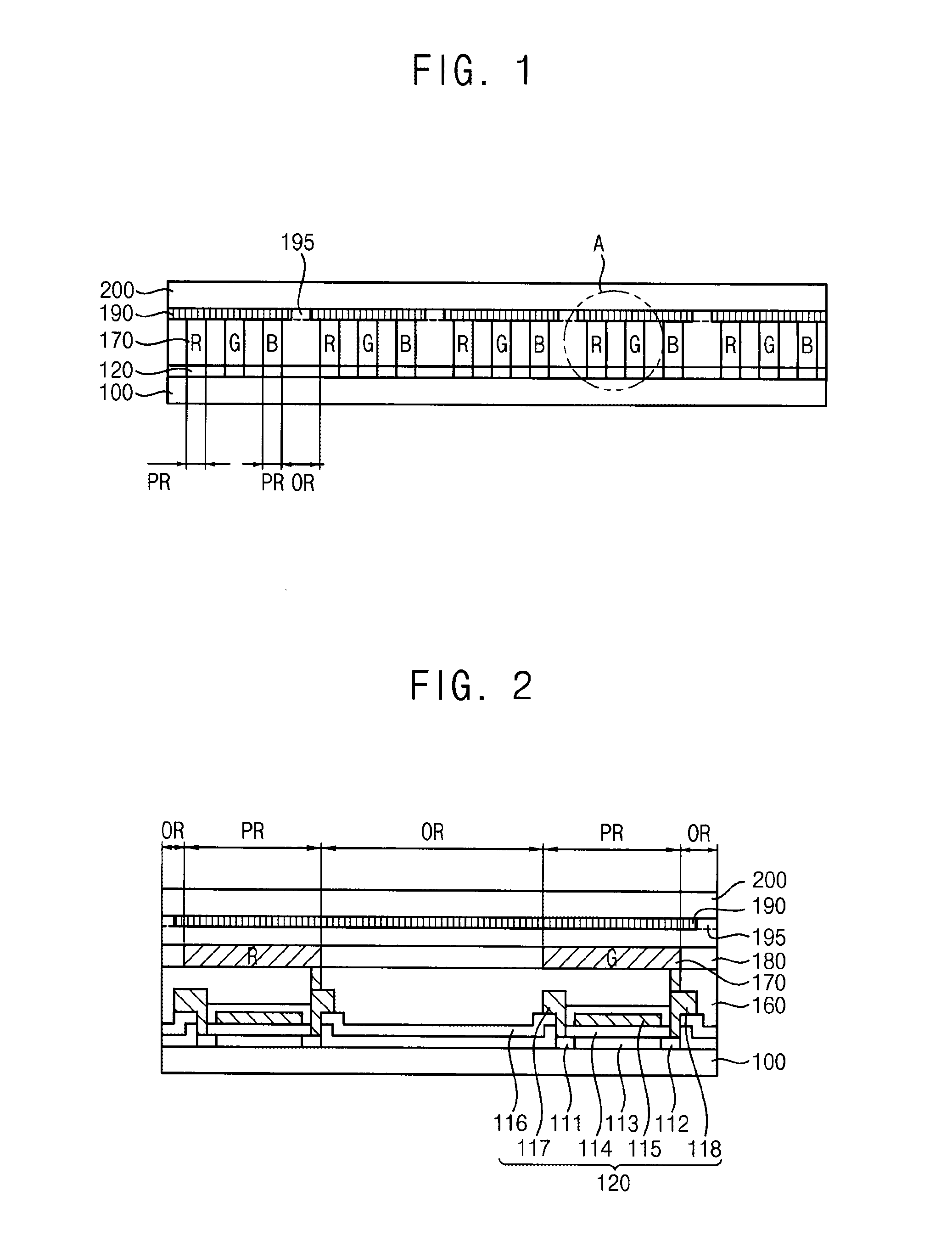

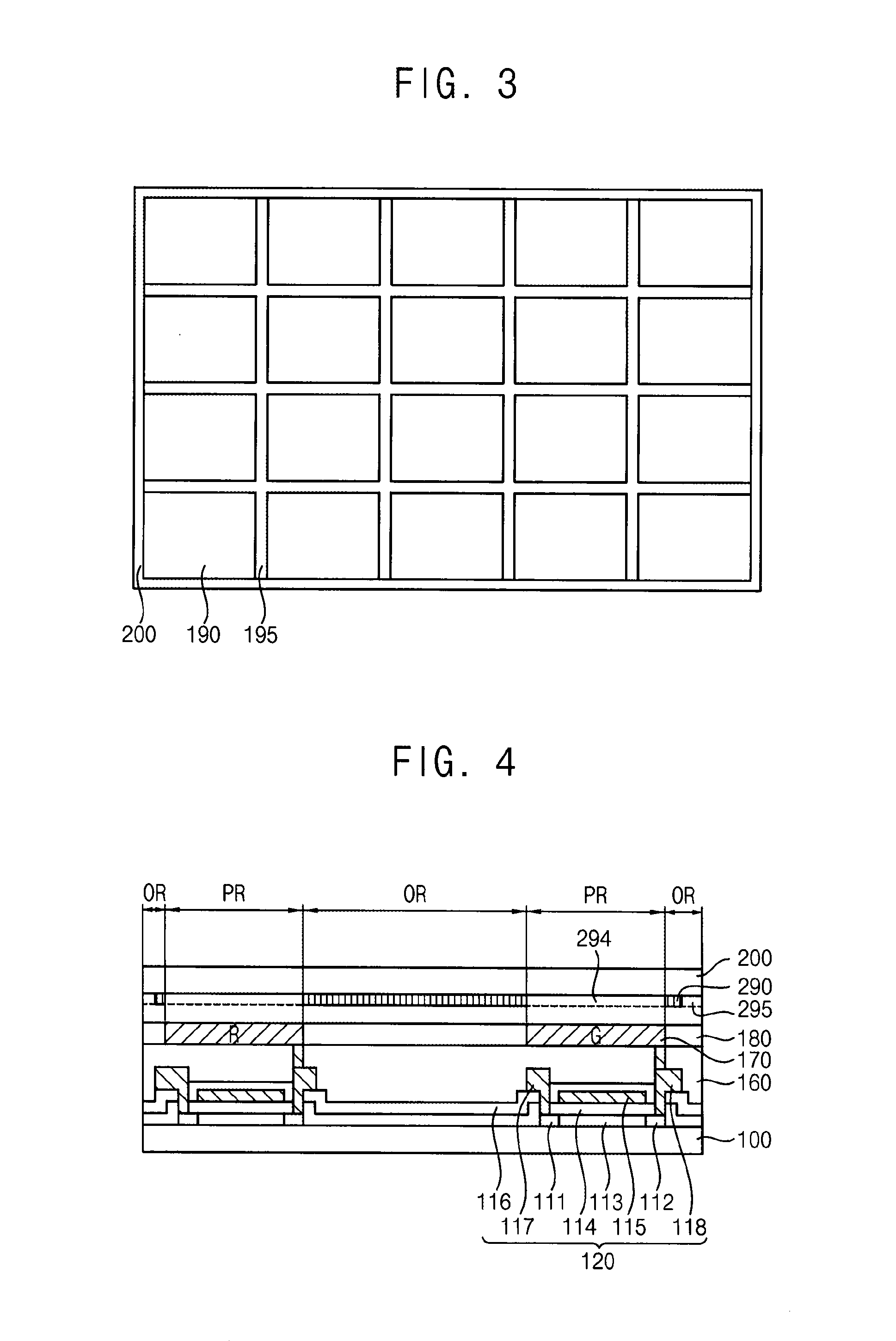

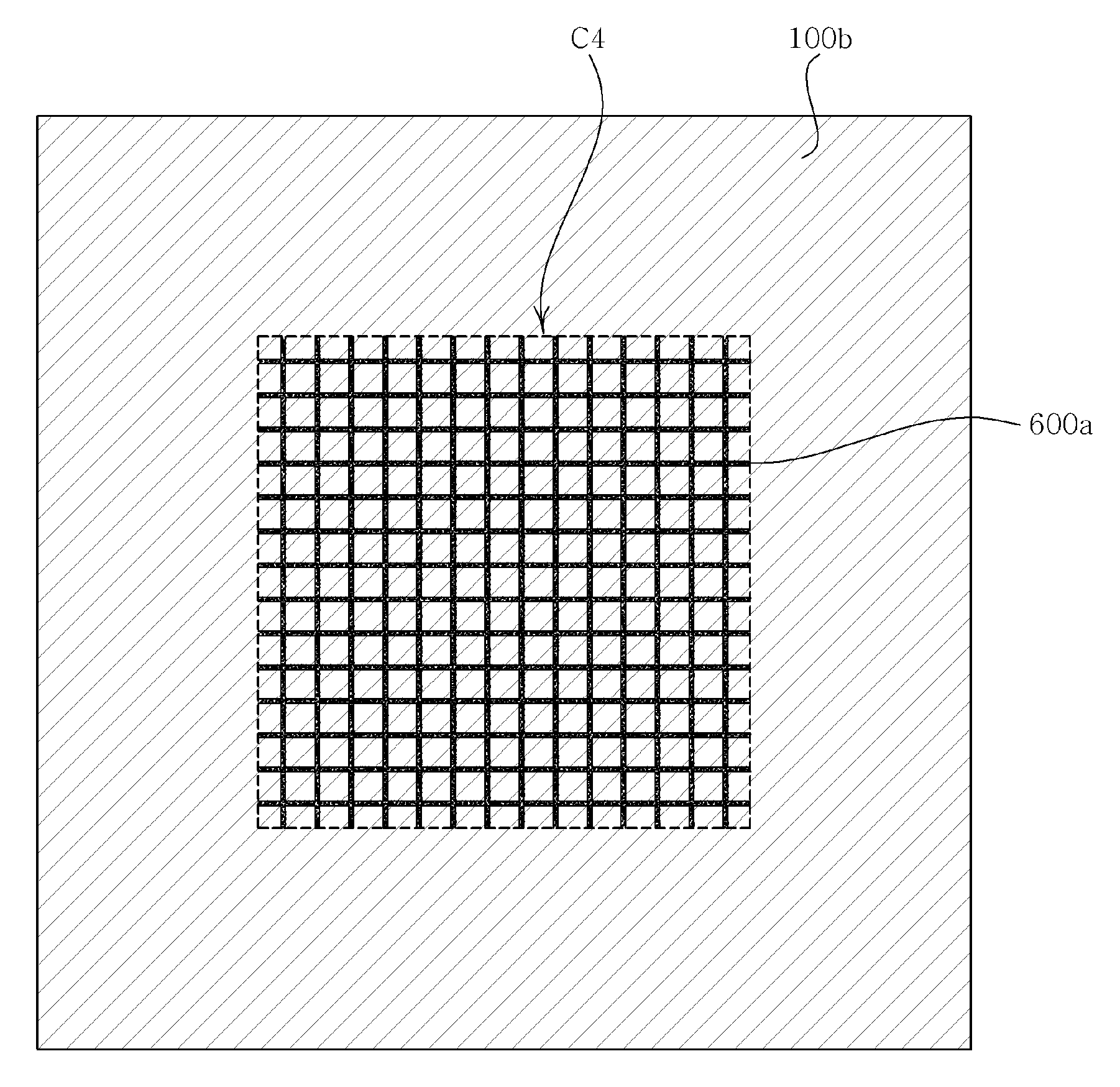

Mirror type display apparatus and method of manufacturing the same

InactiveUS20150002953A1Minimize warpageImprove luminanceMirrorsSolid-state devicesDisplay deviceOptoelectronics

A mirror type display apparatus comprises a base substrate having a pixel region and a non-pixel region surrounding the pixel region, a driving device, a display device, a protective substrate and an island-shaped reflective layer disposed on a surface of the protective substrate. The island-shaped reflective layer including the island-shaped reflective layers separated by furrows formed on the protective substrate. The island-shaped reflective layer can minimize a warpage caused by a mismatch of coefficient of thermal expansion (CTE) between the protective substrate and the reflective layer.

Owner:SAMSUNG DISPLAY CO LTD

Methods of manufacturing photomask blank and photomask

ActiveUS7195846B2Minimize warpageGood chemical resistancePhotomechanical apparatusSemiconductor/solid-state device manufacturingResistPhotolithography

A photomask blank having a film of at least one layer formed on a substrate is manufactured by forming a film on a substrate and irradiating the film with light from a flash lamp. A photomask is manufactured from the thus manufactured photomask blank by forming a patterned resist on the film on the blank by photolithography, etching away those portions of the film which are not covered with the resist, and removing the resist. The photomask blank and photomask have minimized warpage and improved chemical resistance.

Owner:SHIN ETSU CHEM IND CO LTD

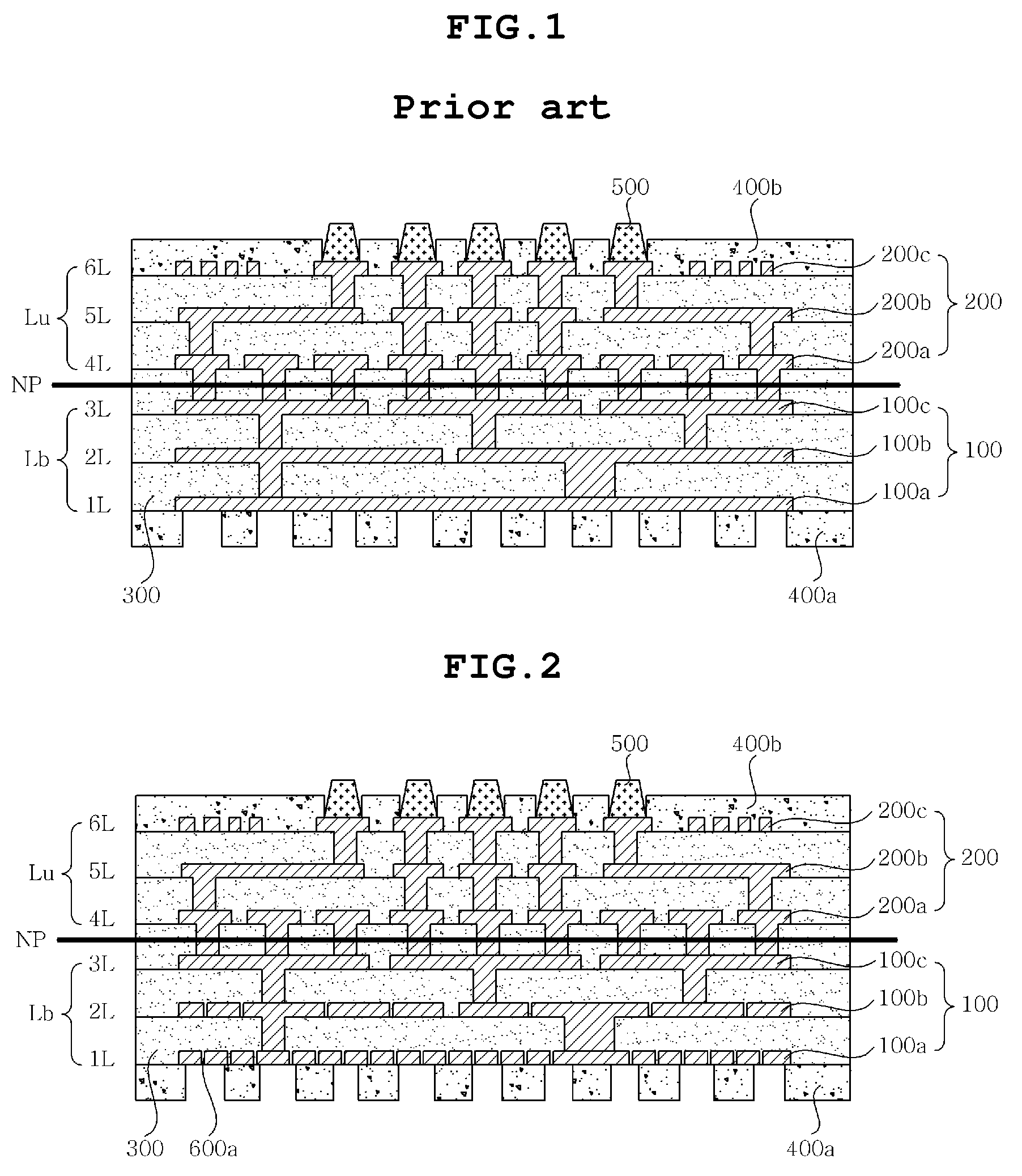

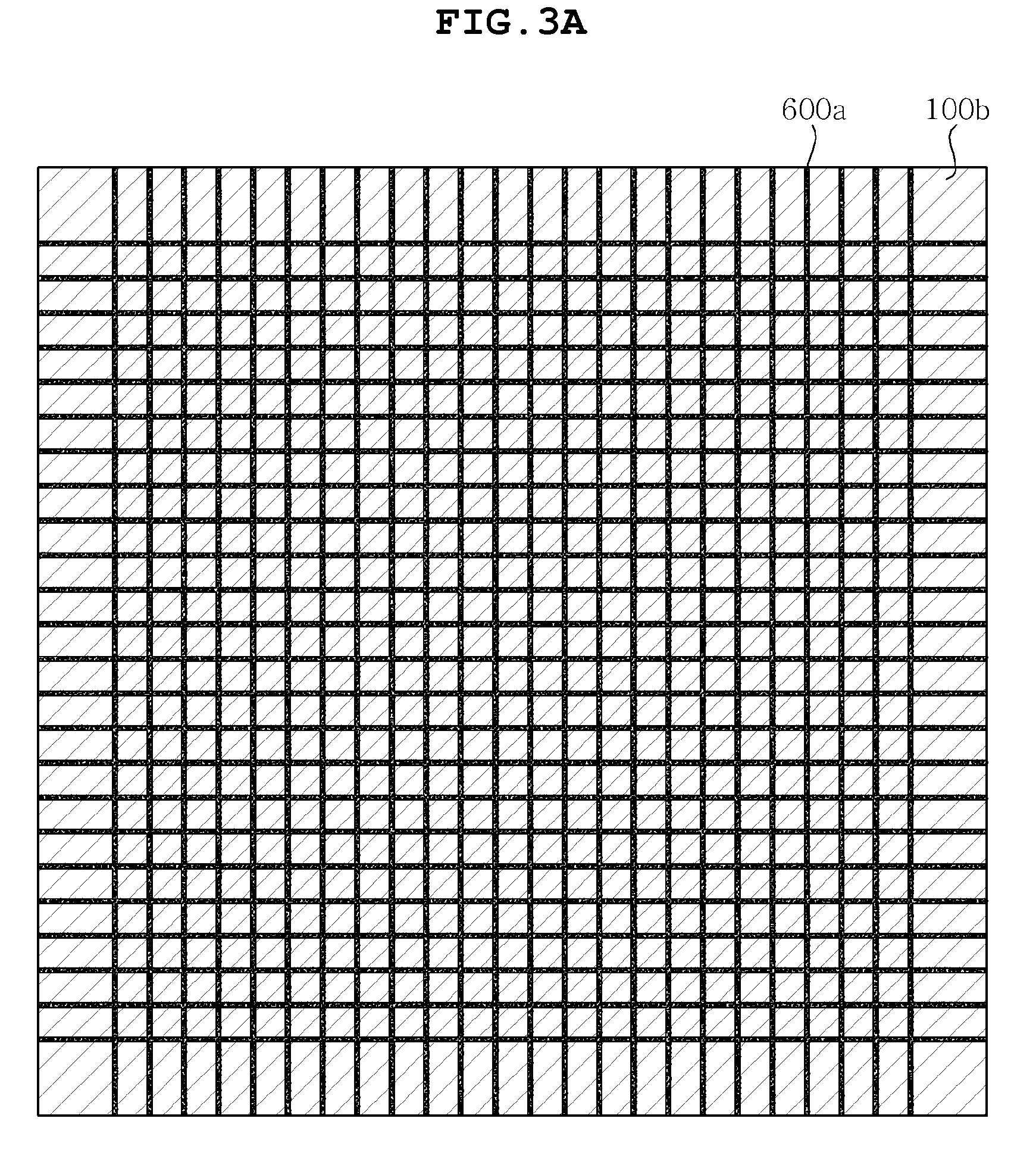

Printed circuit board and manufacture method thereof

InactiveUS20150021074A1Minimize warpagePrinted circuit assemblingPrinted circuit aspectsResistEngineering

Disclosed herein is a printed circuit board capable of implementing slimness by decreasing the number of entire layers through an asymmetrical build-up structure in which an electric device is embedded, the printed circuit board including: a core layer including a cavity formed therein so that an electric device is embedded and a circuit pattern and a pad formed on upper and lower surfaces thereof; a through via formed in the core layer so as to connect the upper and the lower pads of the core layer to each other; a plurality of insulating layers built-up on the core layer and including a plurality of vias so as to be electrically connected to the through via; and a solder resist layer applied onto a lower portion of the core layer so that a lower surface of the through via is partially exposed.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

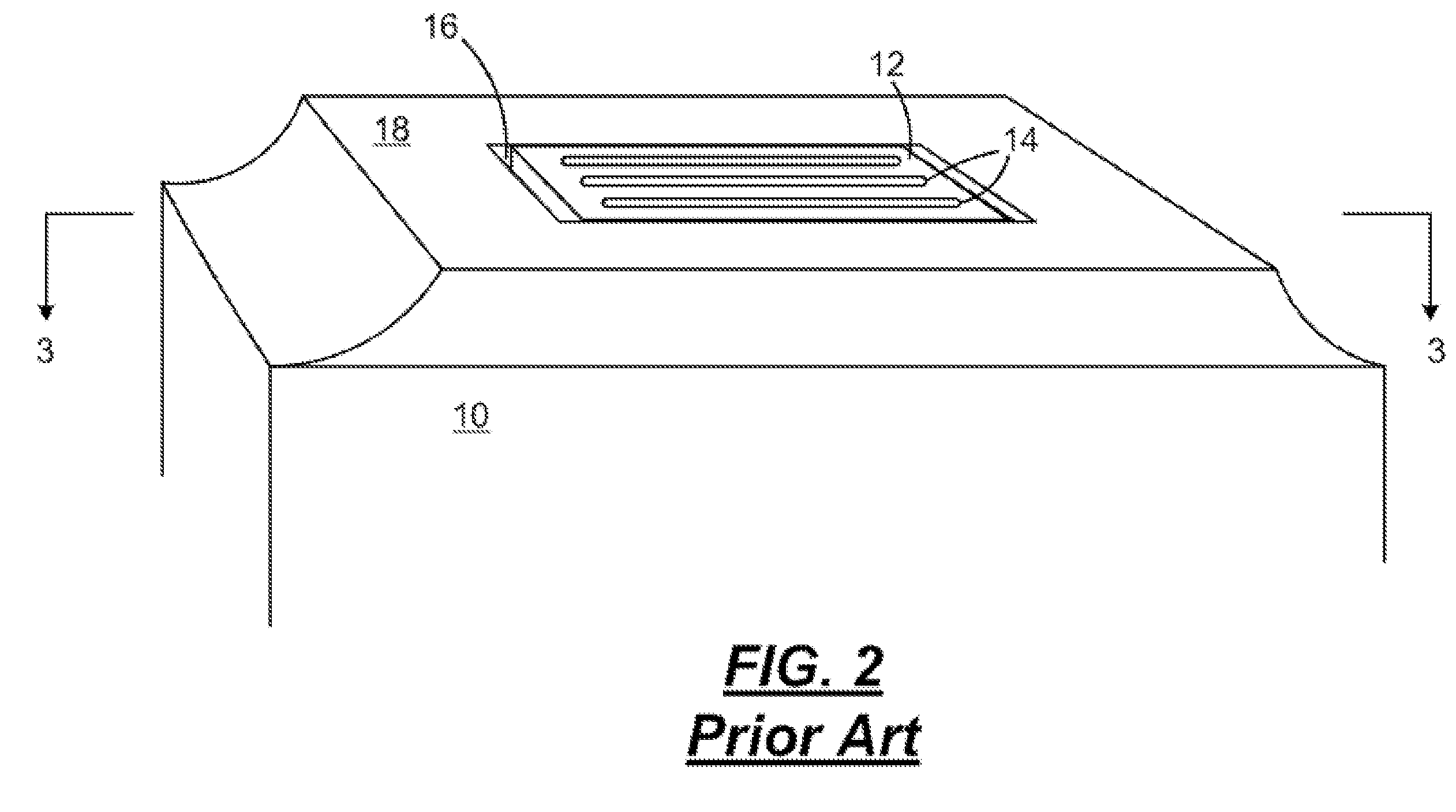

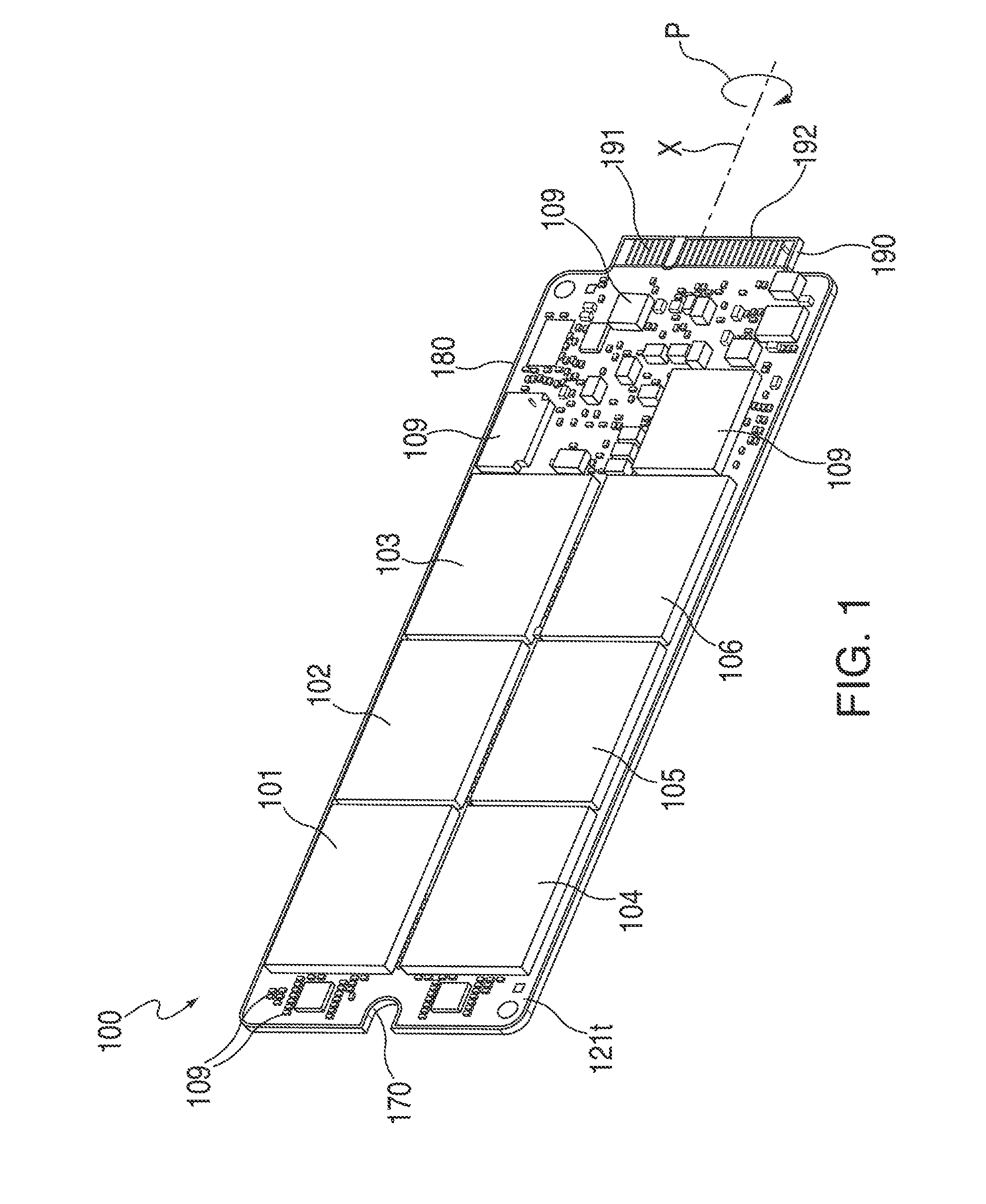

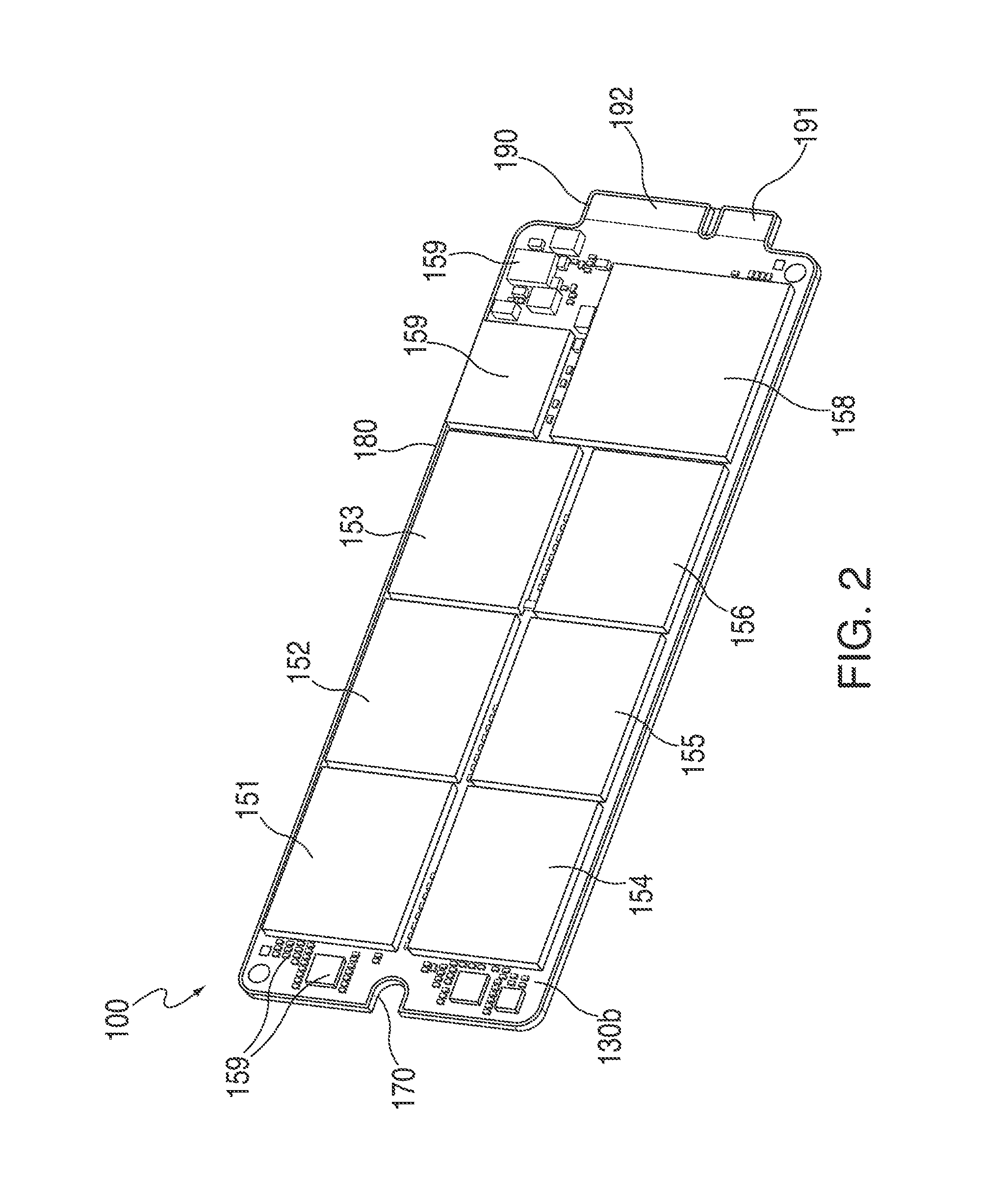

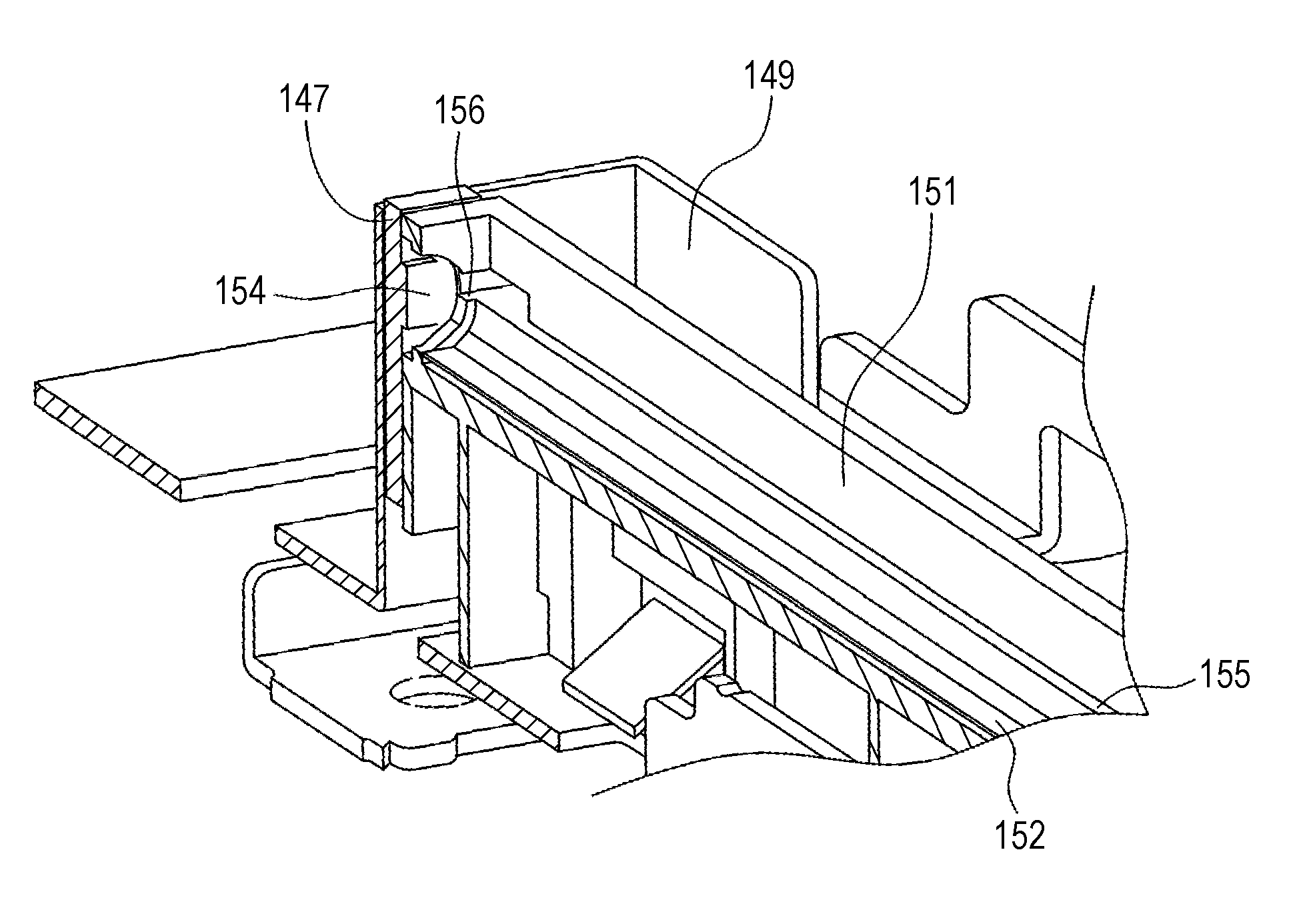

Methods and apparatus for improved ejection head planarity and reduced ejection head damage

A micro-fluid ejection head assembly having improved assembly characteristics and methods of manufacturing a micro-fluid ejection head assembly. The micro-fluid ejection head includes a fluid supply body having at least one fluid supply port in a recessed area therein. A reinforcing member circumscribes the fluid supply port. A micro-fluid ejection head is attached with an adhesive to the supply body in the recessed area so that cracking of the ejection head during adhesive curing is substantially reduced.

Owner:FUNAI ELECTRIC CO LTD

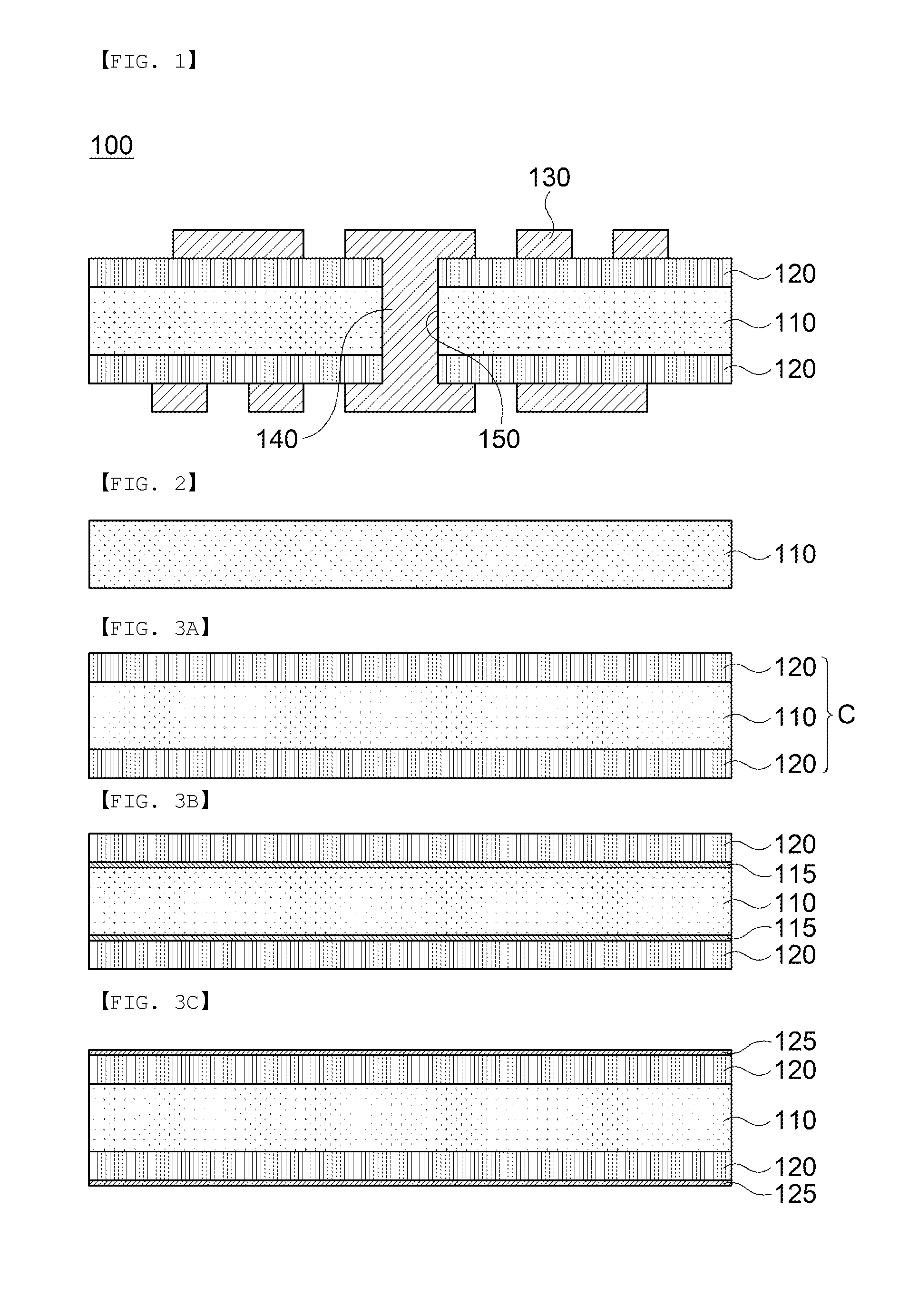

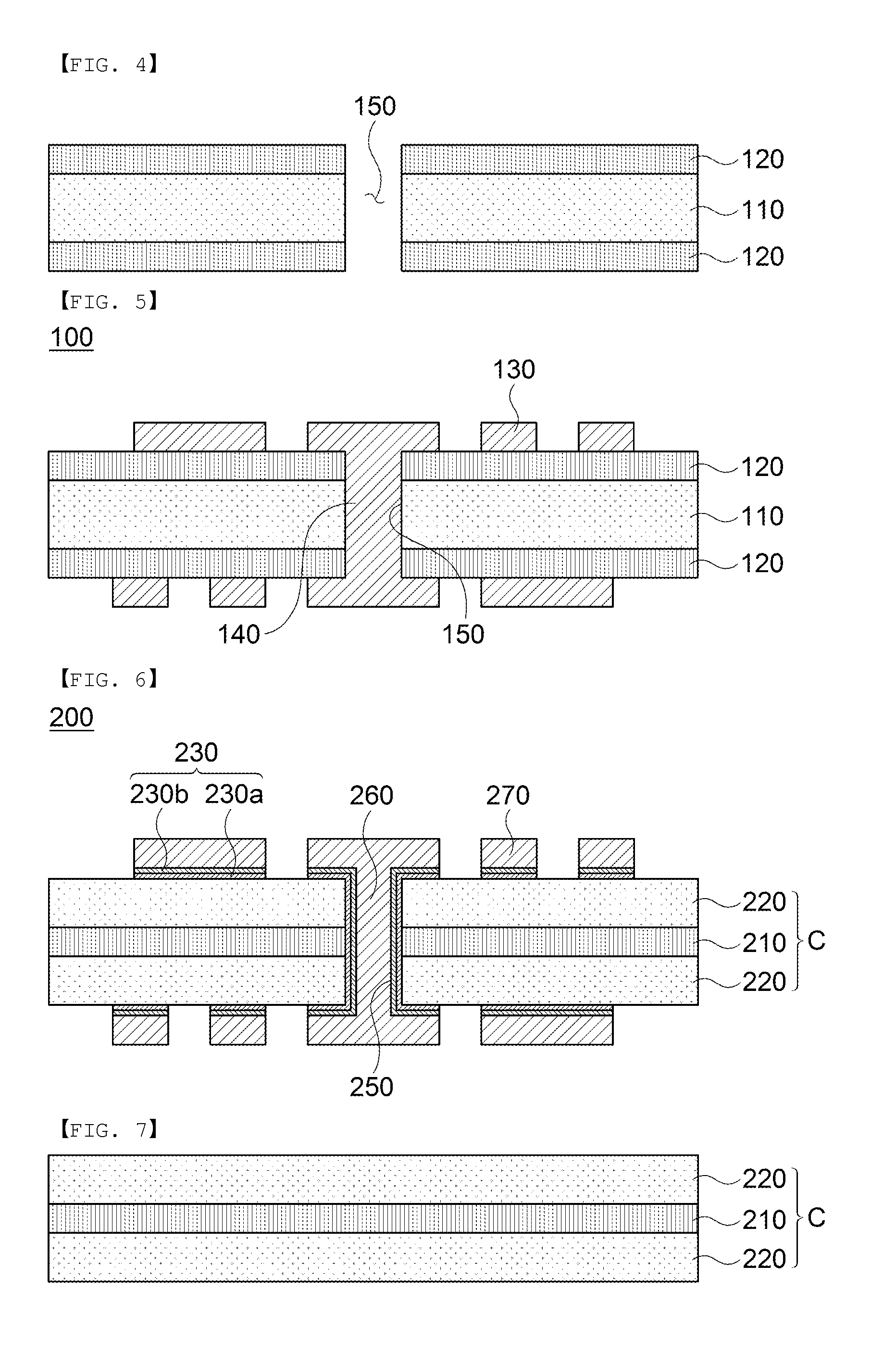

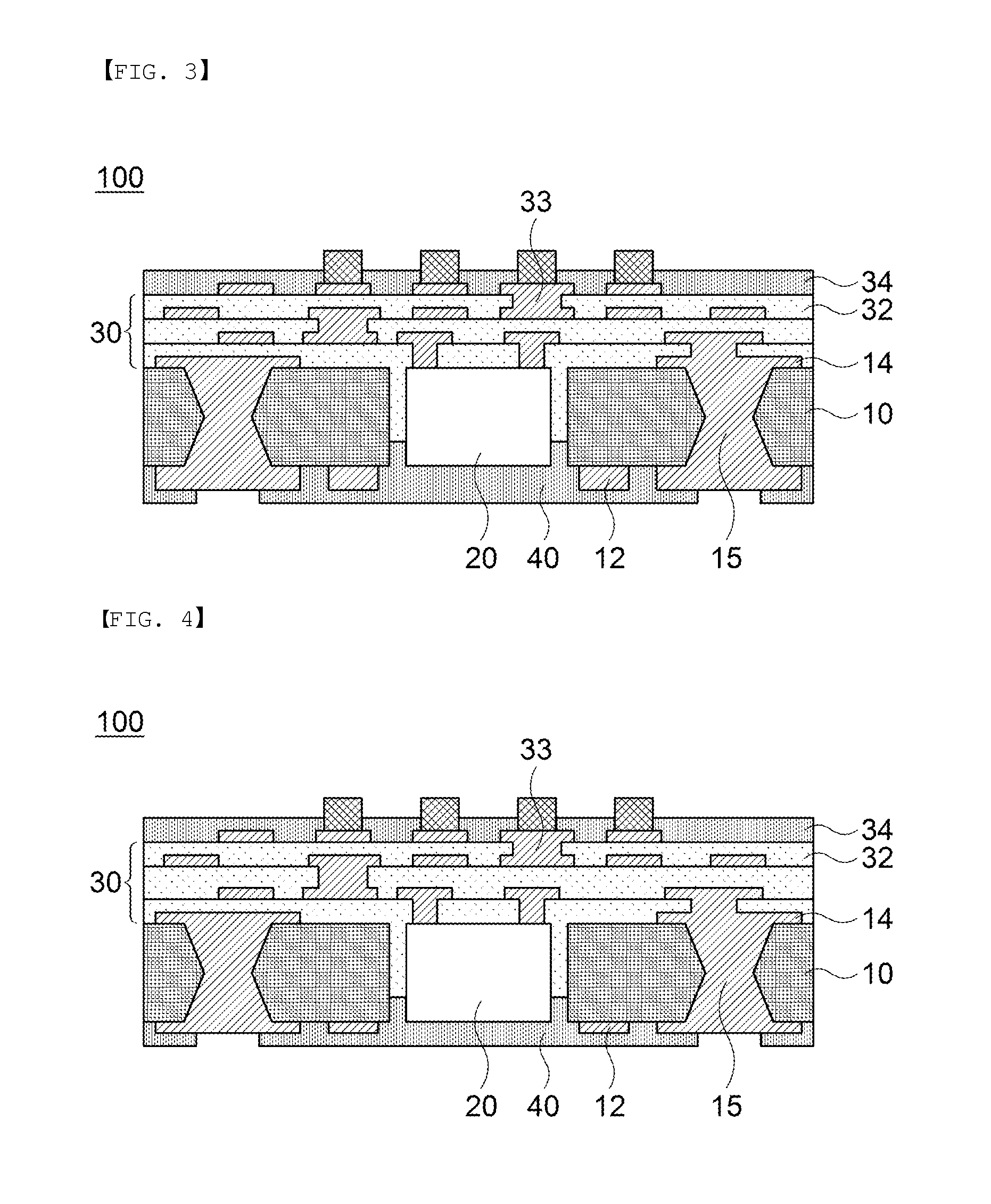

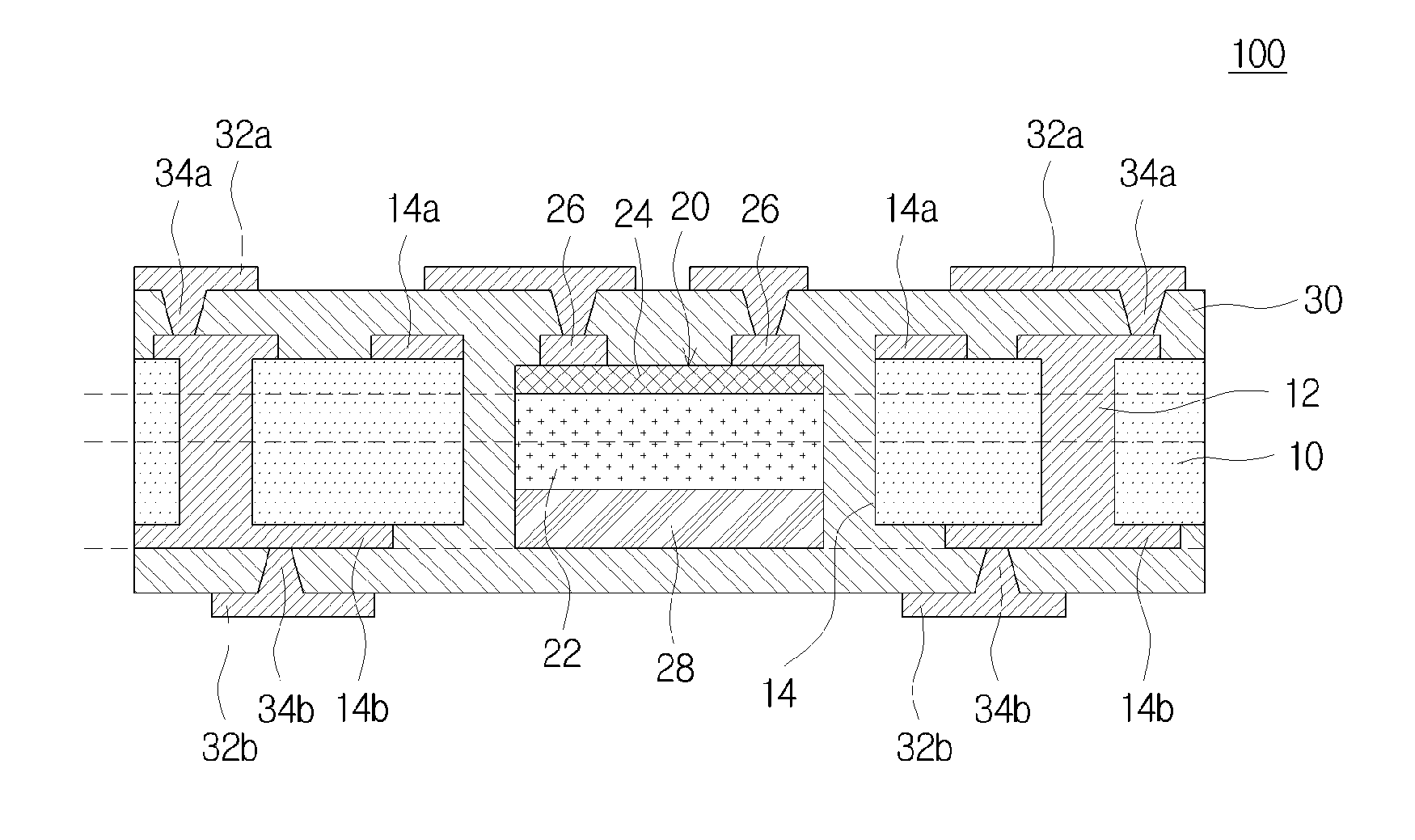

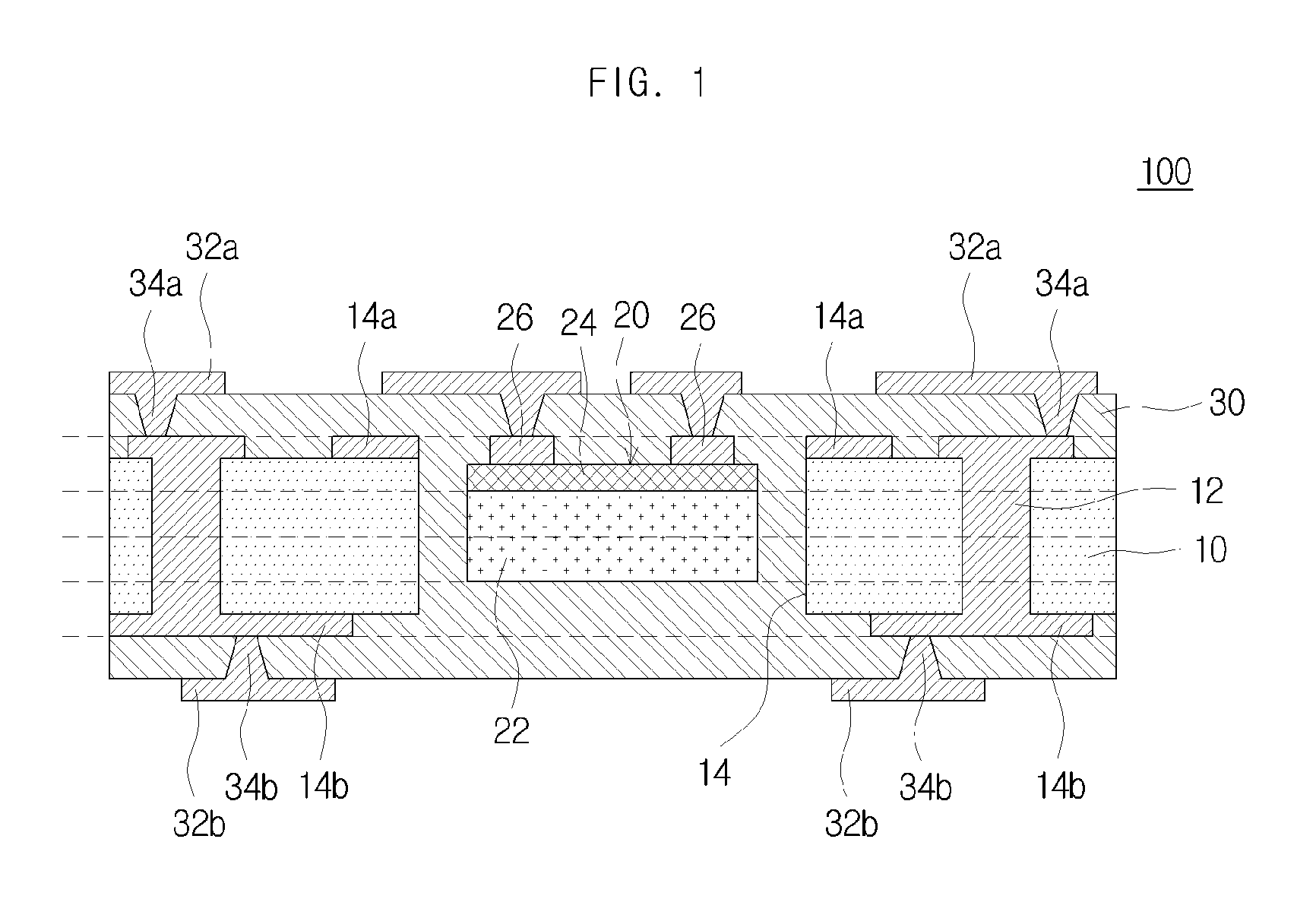

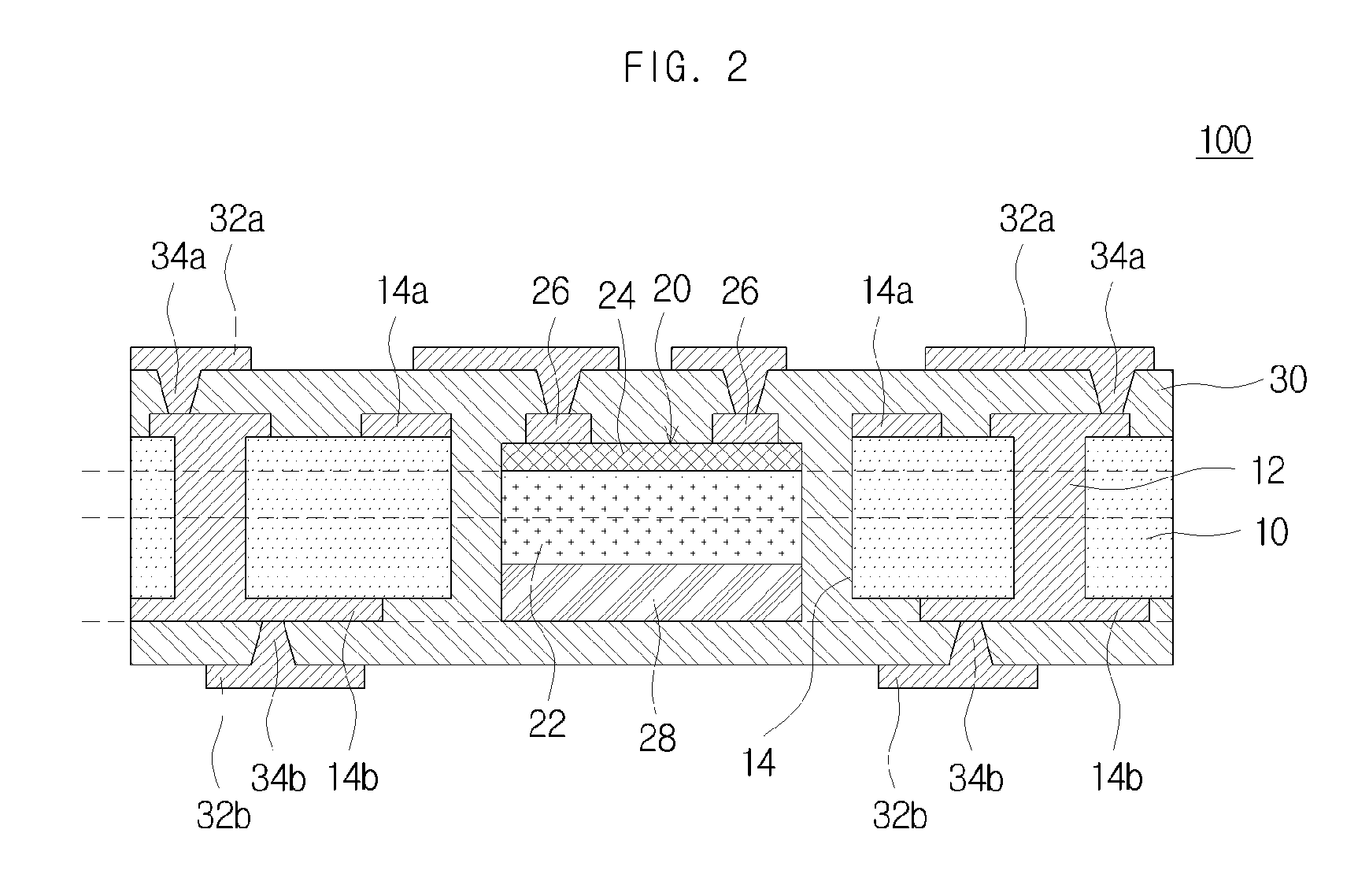

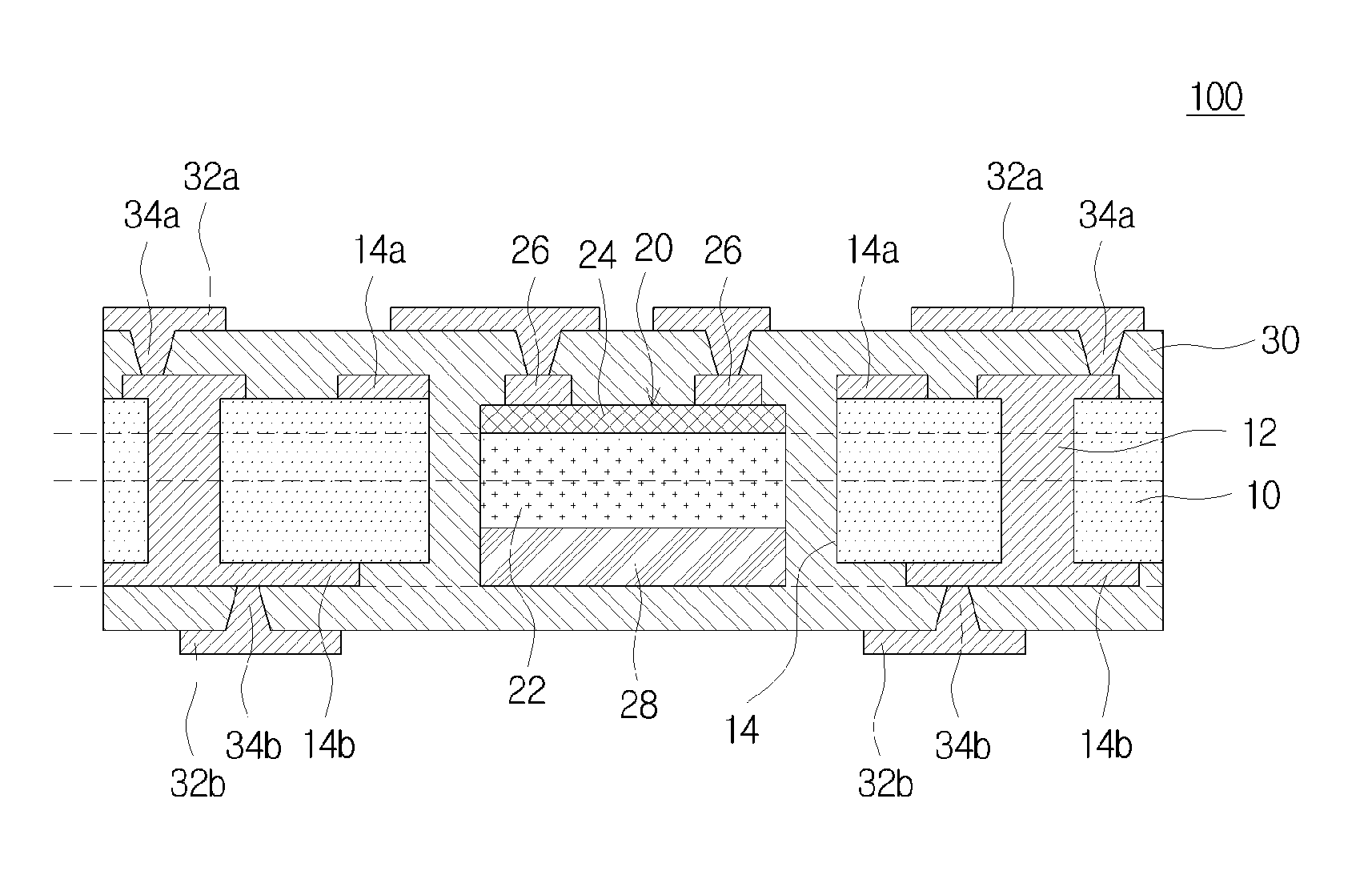

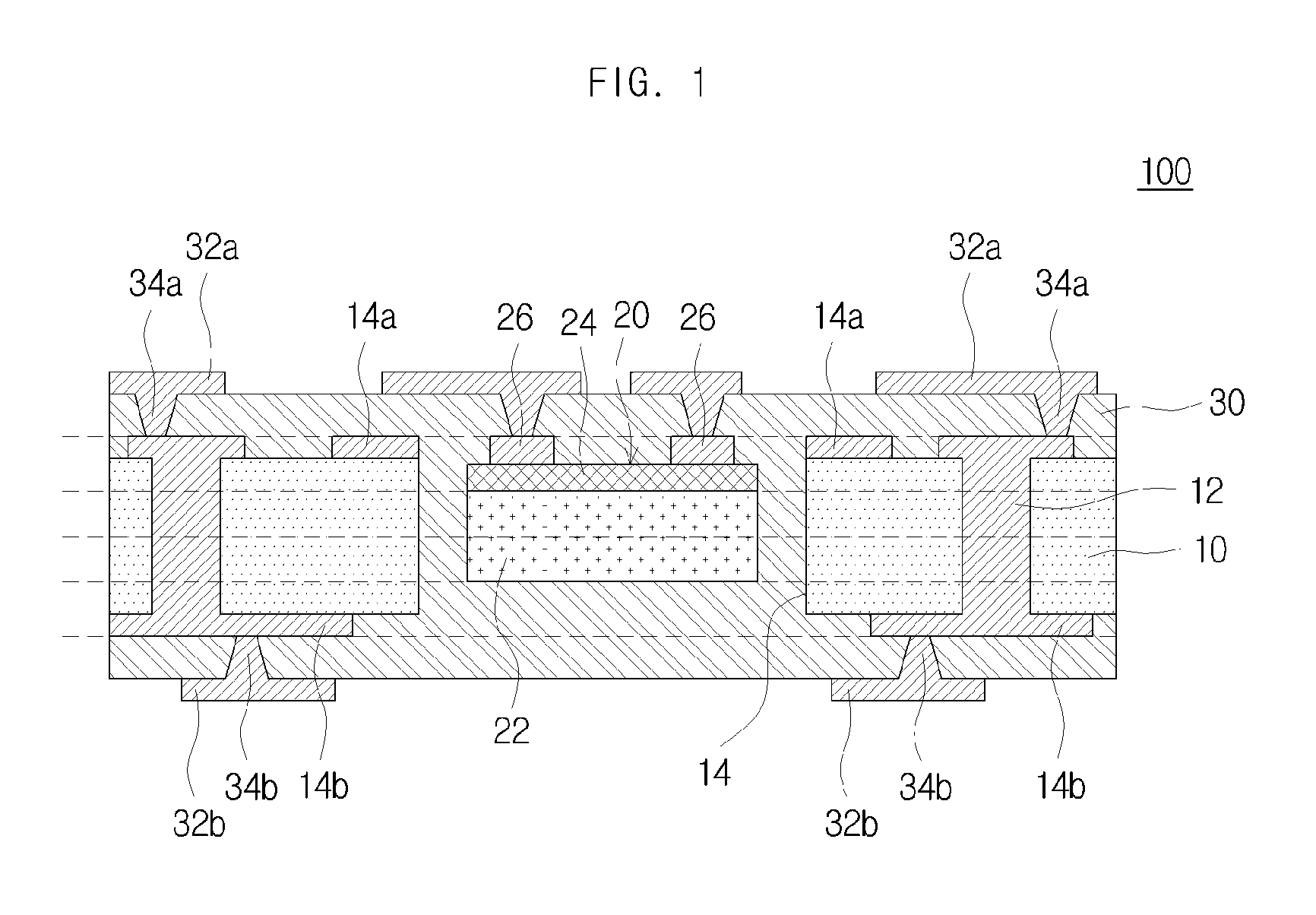

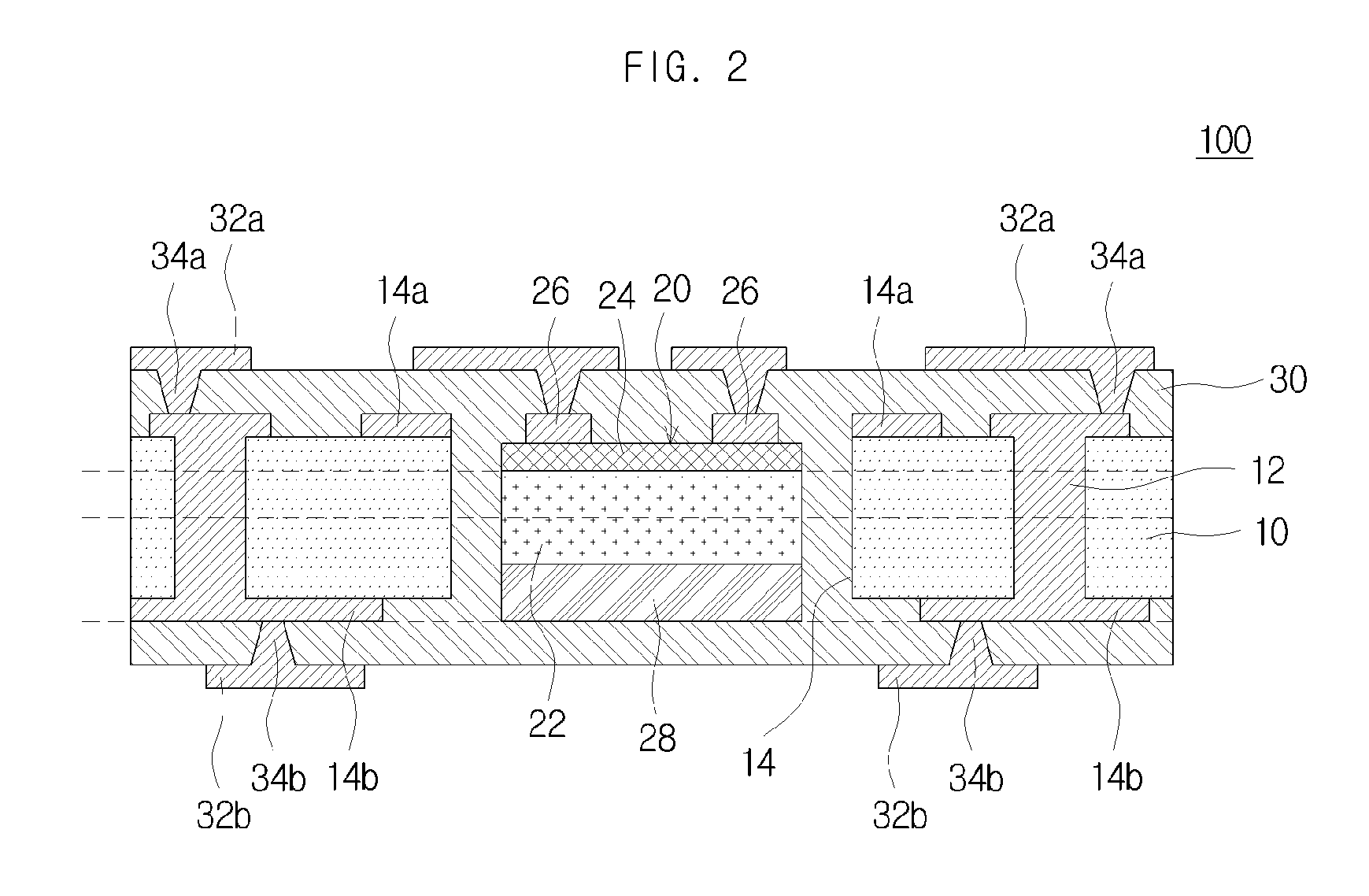

Electronics component embedded PCB

InactiveUS20110100689A1Minimize warpagePrinted circuit assemblingPrinted electric component incorporationPrinted circuit boardElectronics

An electronic component embedded printed circuit board is disclosed. In accordance with an embodiment of the present invention, the electronic component embedded printed circuit board is a printed circuit board in which an electronic component is embedded in a core board, and the electronic component includes a silicon layer and a passivation layer, which is formed on one surface of the silicon layer. Here, a center line of the silicon layer and a center line of the core board are placed on a same line.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Package substrate

InactiveUS20110067901A1Minimize warpageSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringThermal expansion

Disclosed is a package substrate, in which the plating area of a first plating layer formed on a layer which is to be connected to a motherboard is larger than the plating area of a second plating layer formed on a layer which is to be connected to an electronic part, and open portions are formed on the first plating layer, thus balancing the plating areas of the plating layers formed on the layers of the package substrate, thereby minimizing warpage of the package substrate due to differing coefficients of thermal expansion.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Methods of manufacturing photomask blank and photomask

ActiveUS20040110073A1Minimize warpageGood chemical resistancePhotomechanical apparatusSemiconductor/solid-state device manufacturingResistPhotolithography

A photomask blank having a film of at least one layer formed on a substrate is manufactured by forming a film on a substrate and irradiating the film with light from a flash lamp. A photomask is manufactured from the thus manufactured photomask blank by forming a patterned resist on the film on the blank by photolithography, etching away those portions of the film which are not covered with the resist, and removing the resist. The photomask blank and photomask have minimized warpage and improved chemical resistance.

Owner:SHIN ETSU CHEM IND CO LTD

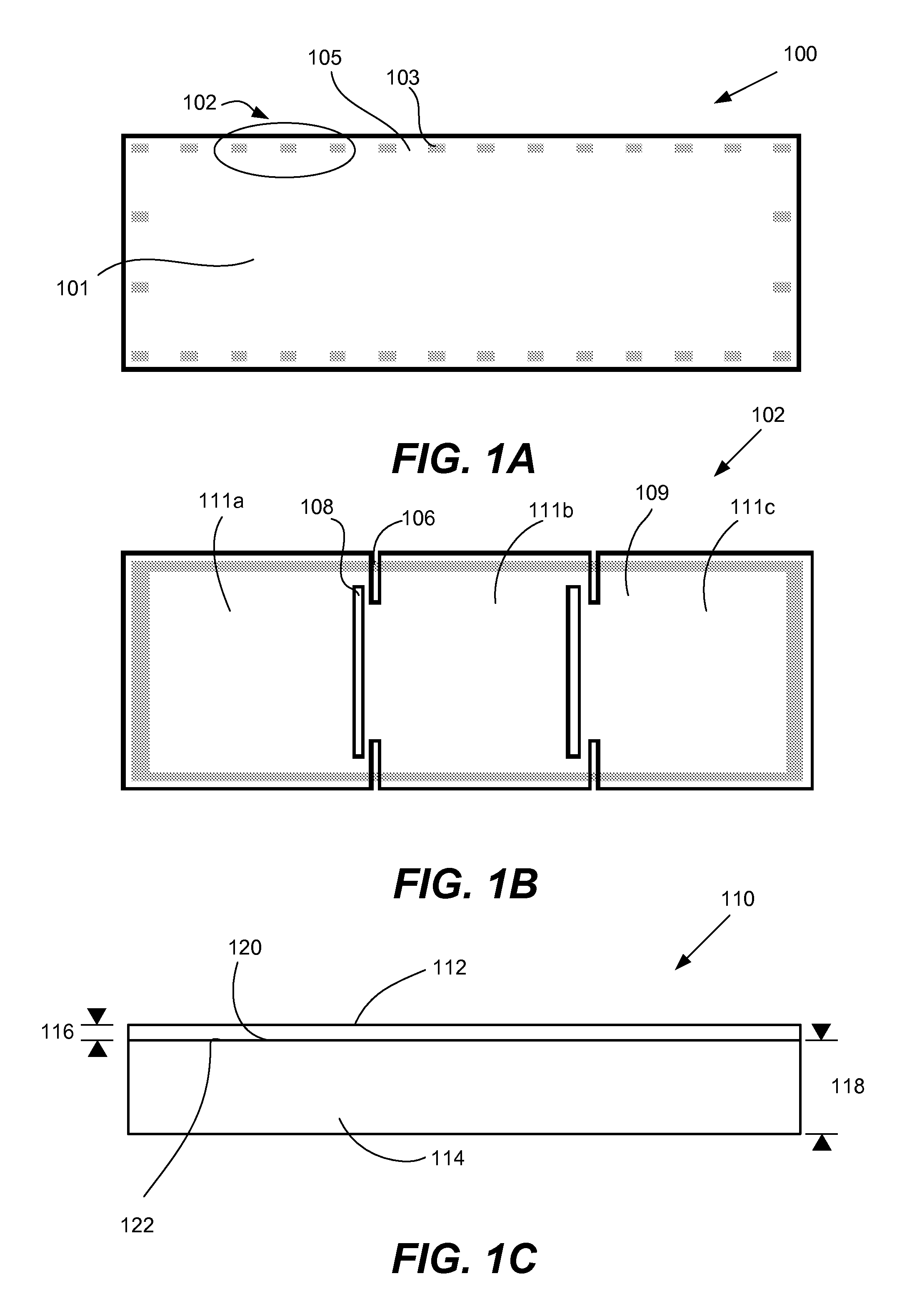

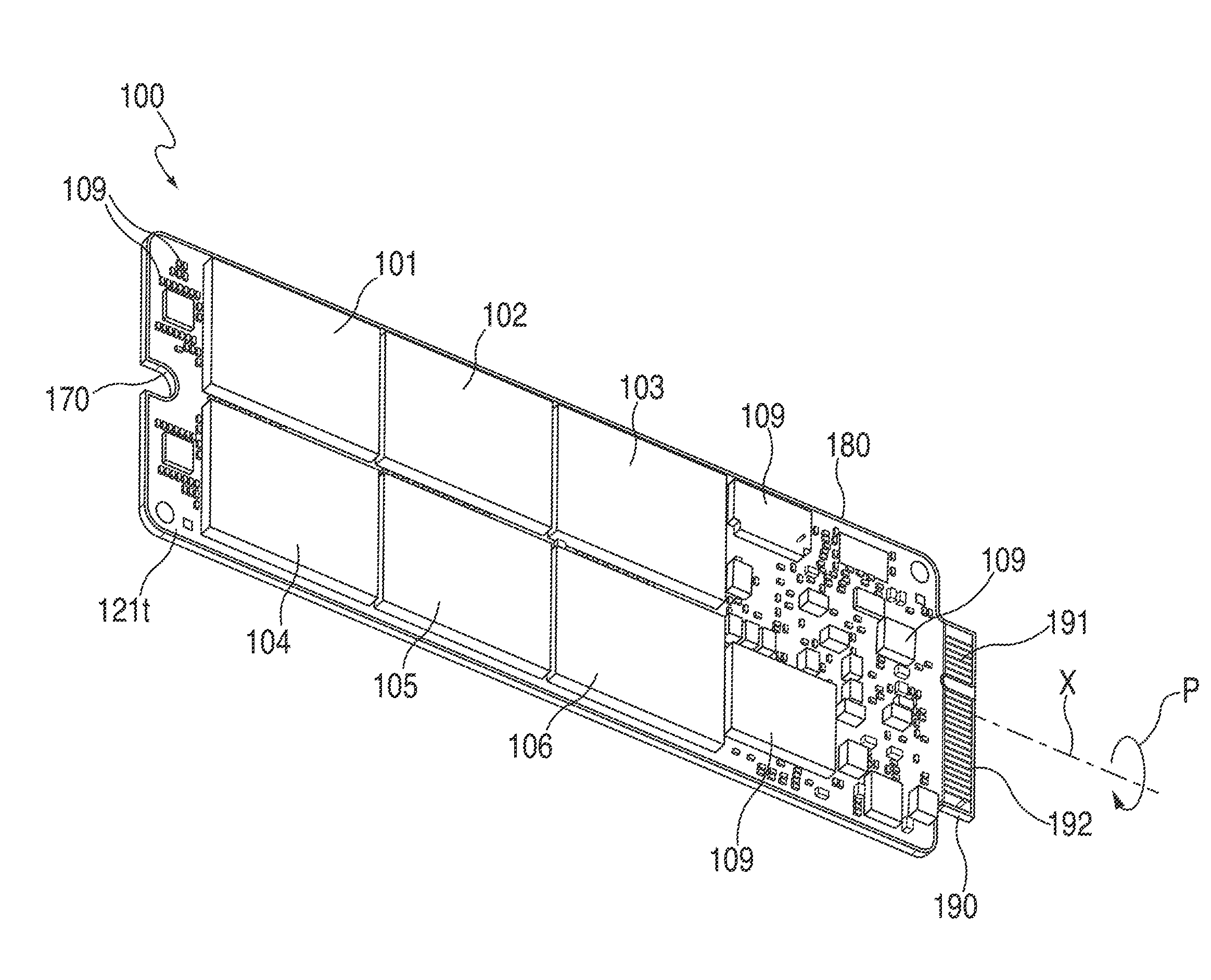

Board assemblies with minimized warpage and systems and methods for making the same

InactiveUS20140055969A1Minimized systemMinimized warpagePrinted circuit assemblingRod connectionsPre-conditionPre conditioning

Board assemblies with minimized warpage and systems and methods for making the same are disclosed. A board may be pre-conditioned by designing the board to mount components in selected areas of the board and by selectively copper flooding certain regions of the board. Pre-conditioning of the board may assist in preventing board warpage. A reflow fixture may fix a board during solder pasting and reflow processing thereof. After reflow, an underfill fixture may fix the board during underfill processing. Each of these fixtures may include respective clamp members that may hold various portions of the board to correct and / or prevent warpage of the board.

Owner:APPLE INC

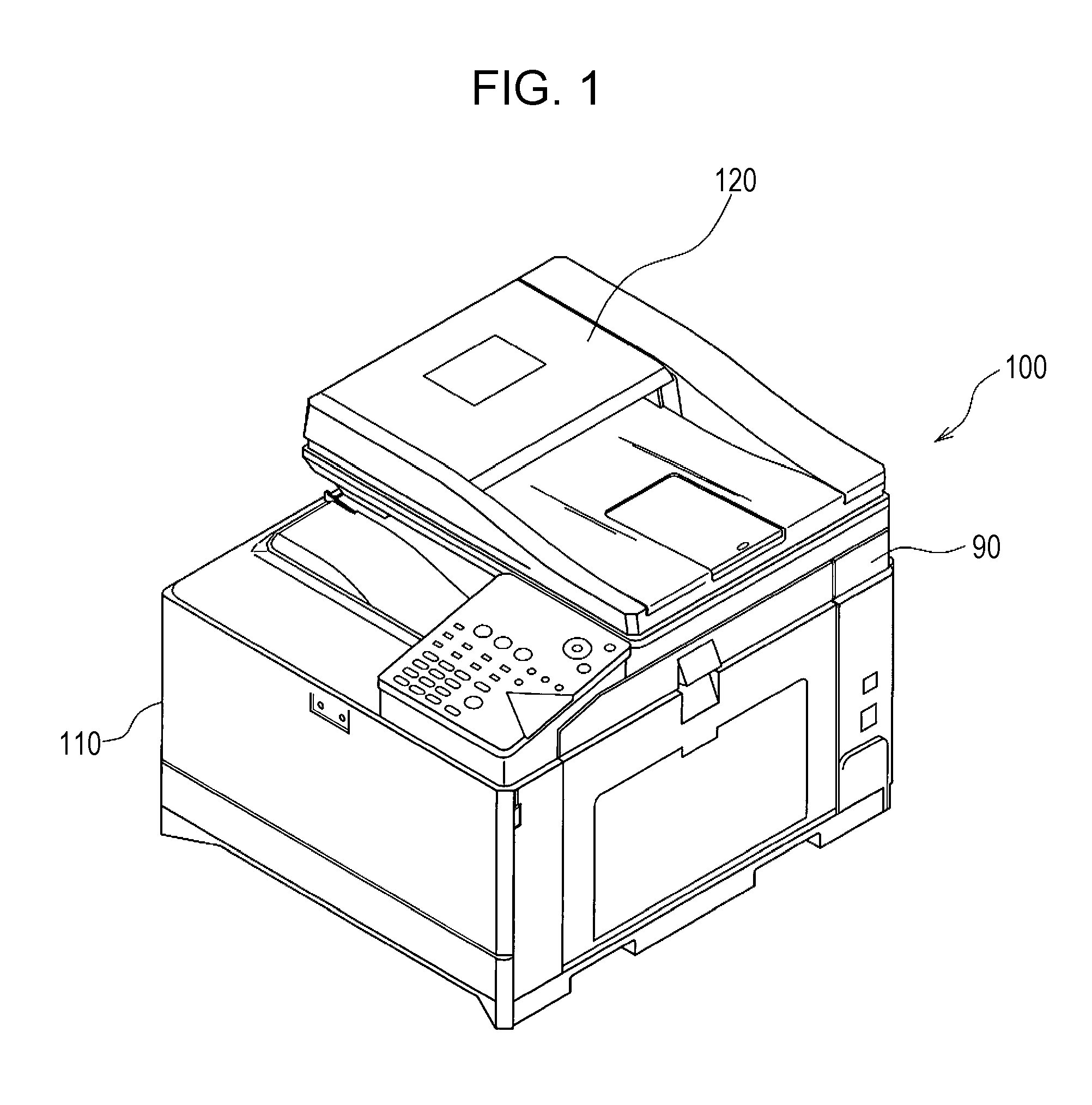

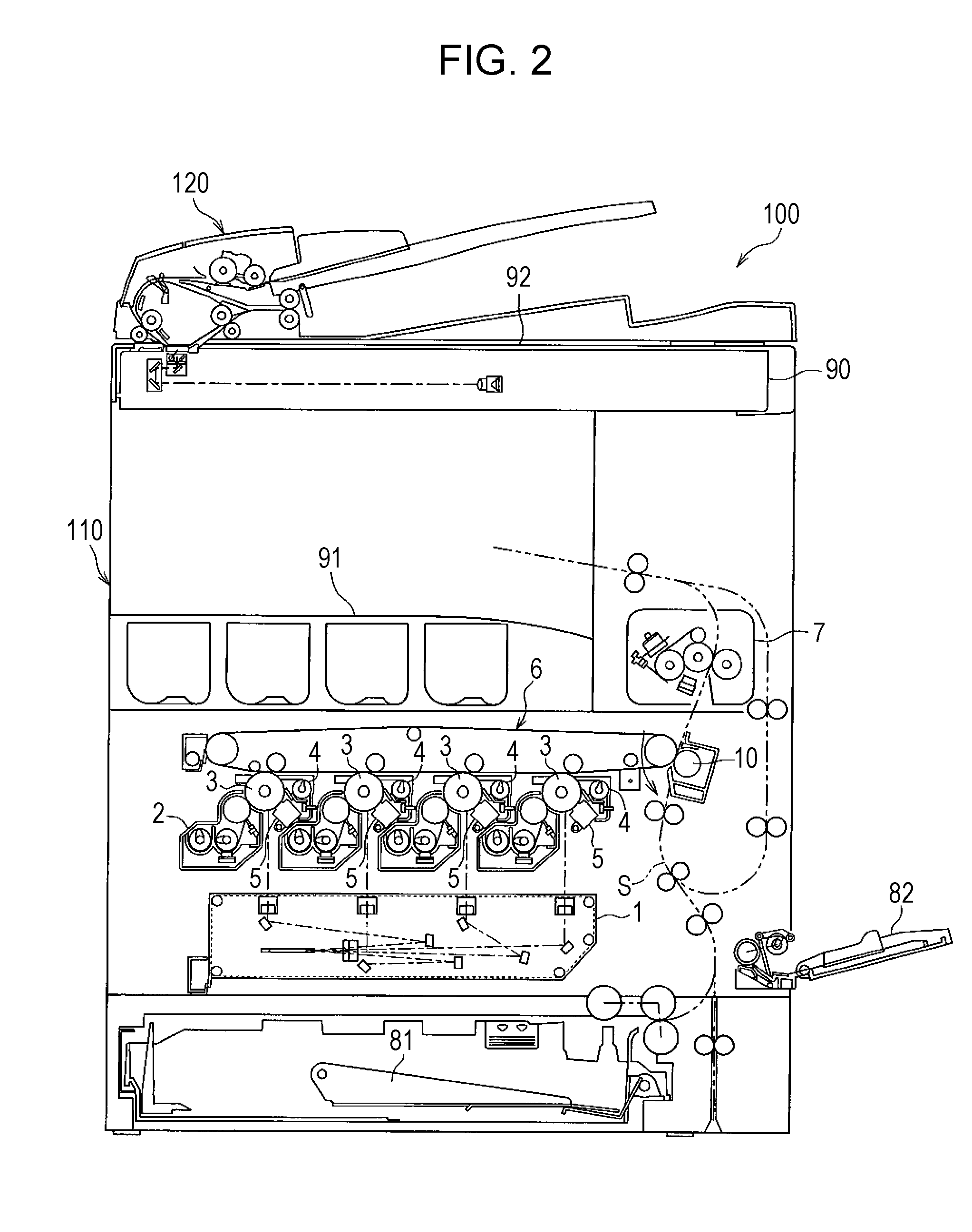

Illuminating device, image reading device, and image forming device including the illuminating device and the image reading device

ActiveUS20160006897A1Minimize warpagePrecise positioningMechanical apparatusFibre light guidesLight guideImage formation

In an image forming device, a light-guiding member includes an integrated ridge extending in the longitudinal direction of the light-guiding member. The light-guiding member further includes a protrusion on the ridge. The illuminating device includes an attachment recess that holds the light-guiding member and a holder member that has a fit portion to which a protrusion is fitted. The protrusion is disposed at a position decentered to one end portion of the light-guiding member in the longitudinal direction of the light-guiding member.

Owner:SHARP KK

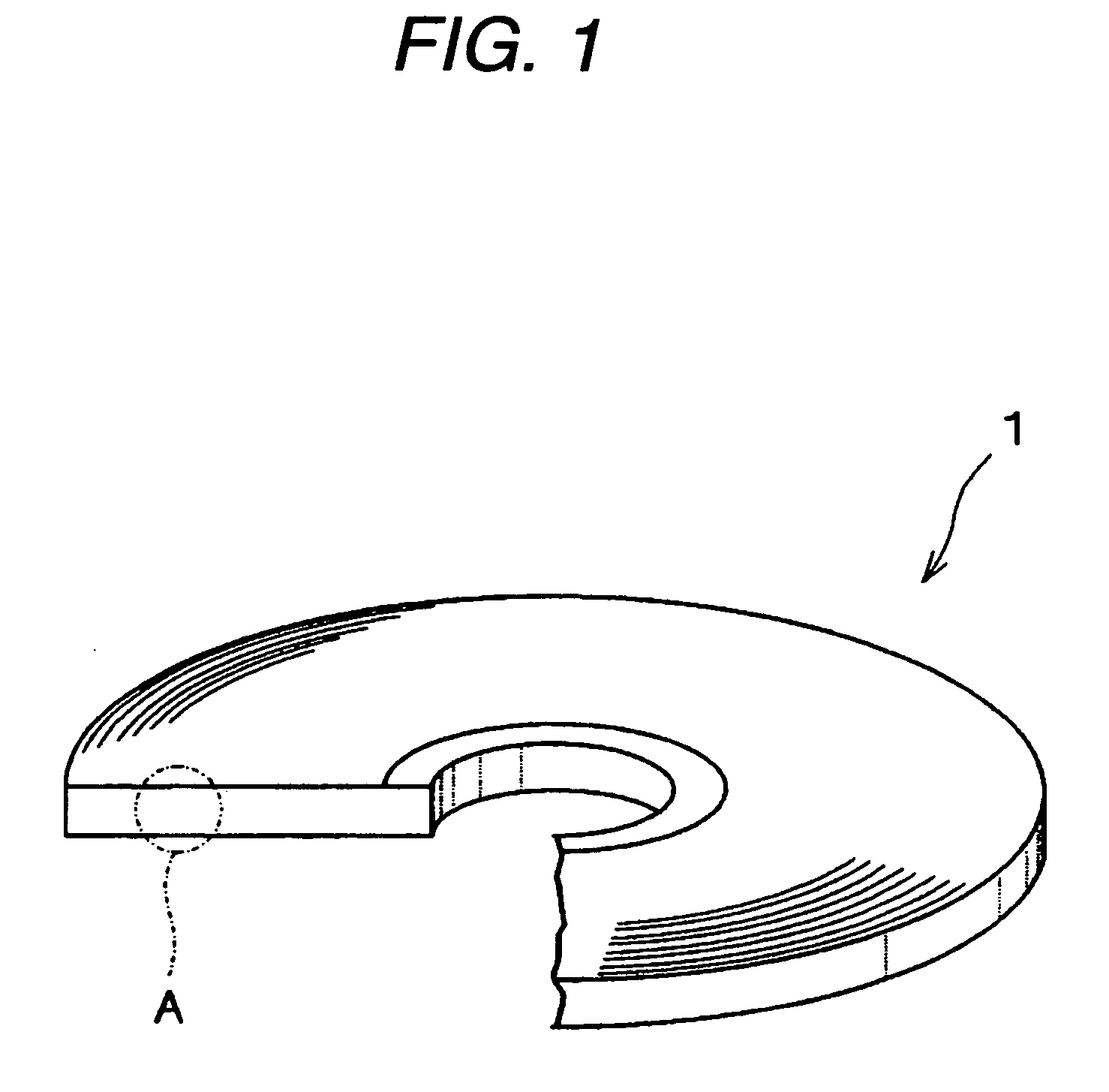

UV-Curable Resin Compositions For Optical Discs And Cured Products Thereof

The UV-curable resin compositions for optical discs are characterized in that they comprise (A) 15-70 wt % of a (meth)acrylate monomer that has an ethylene oxide chain in the molecule, (B) 5-50 wt % of a urethane (meth)acrylate, (C) 2-50 wt % of an epoxy (meth)acrylate, and (D) 1-10 wt % of a photopolymerization initiator, in the resin composition. The glass transition temperature of cured films thereof is 10-65° C., and the maximum value of the dynamic loss factor tan δ of the cured films is in the range of 0.35-0.73.

Owner:NIPPON KAYAKU CO LTD

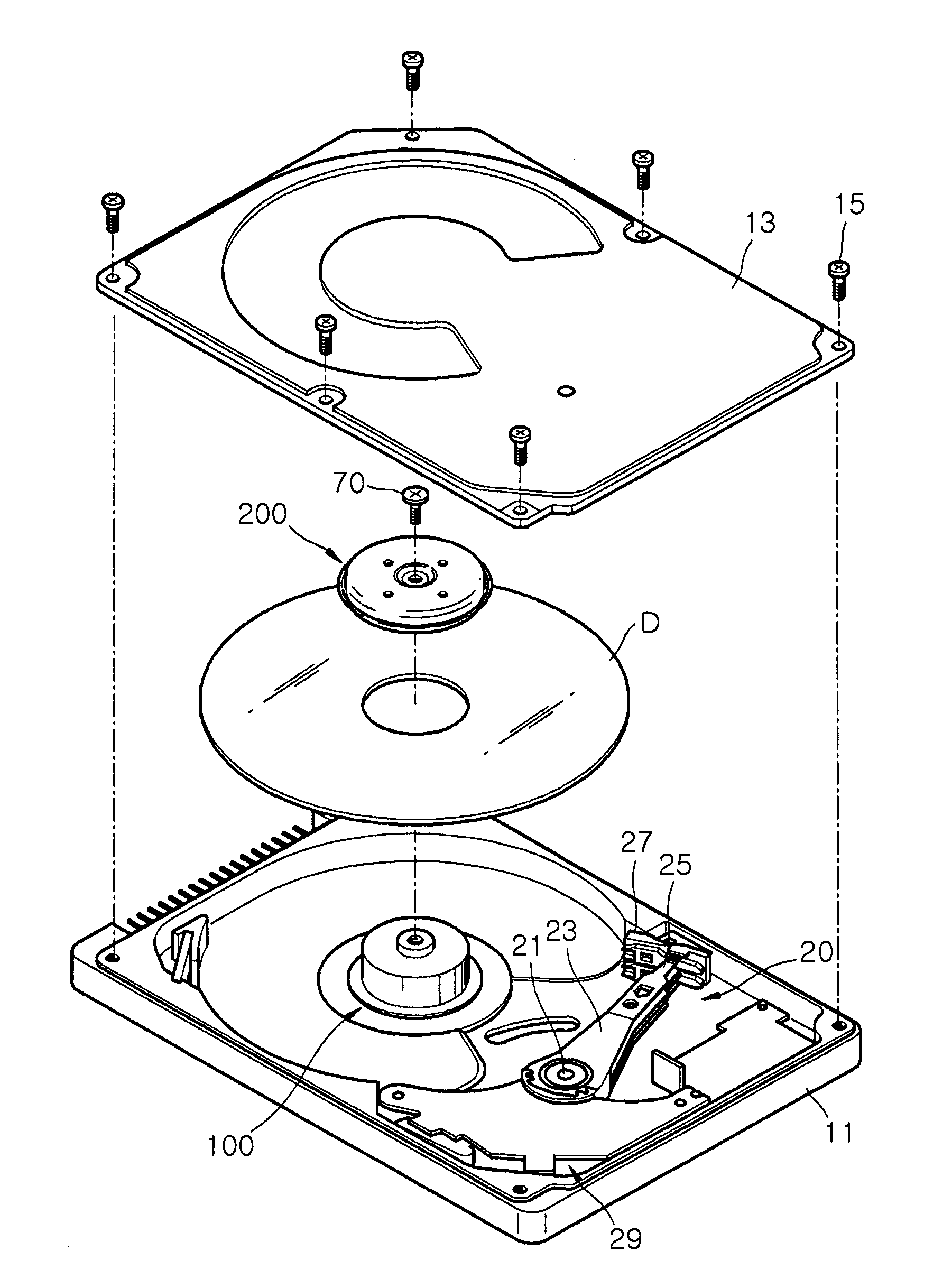

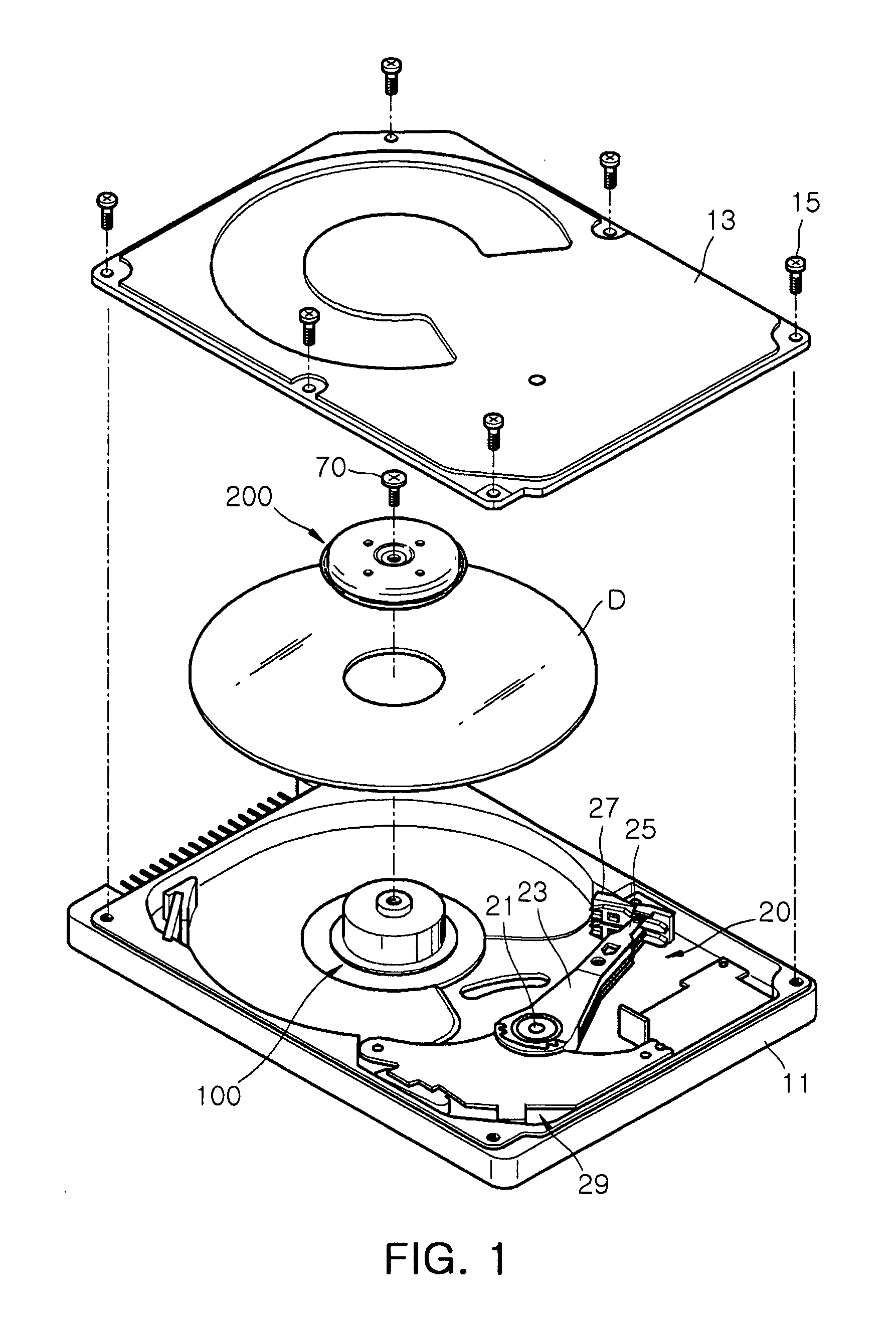

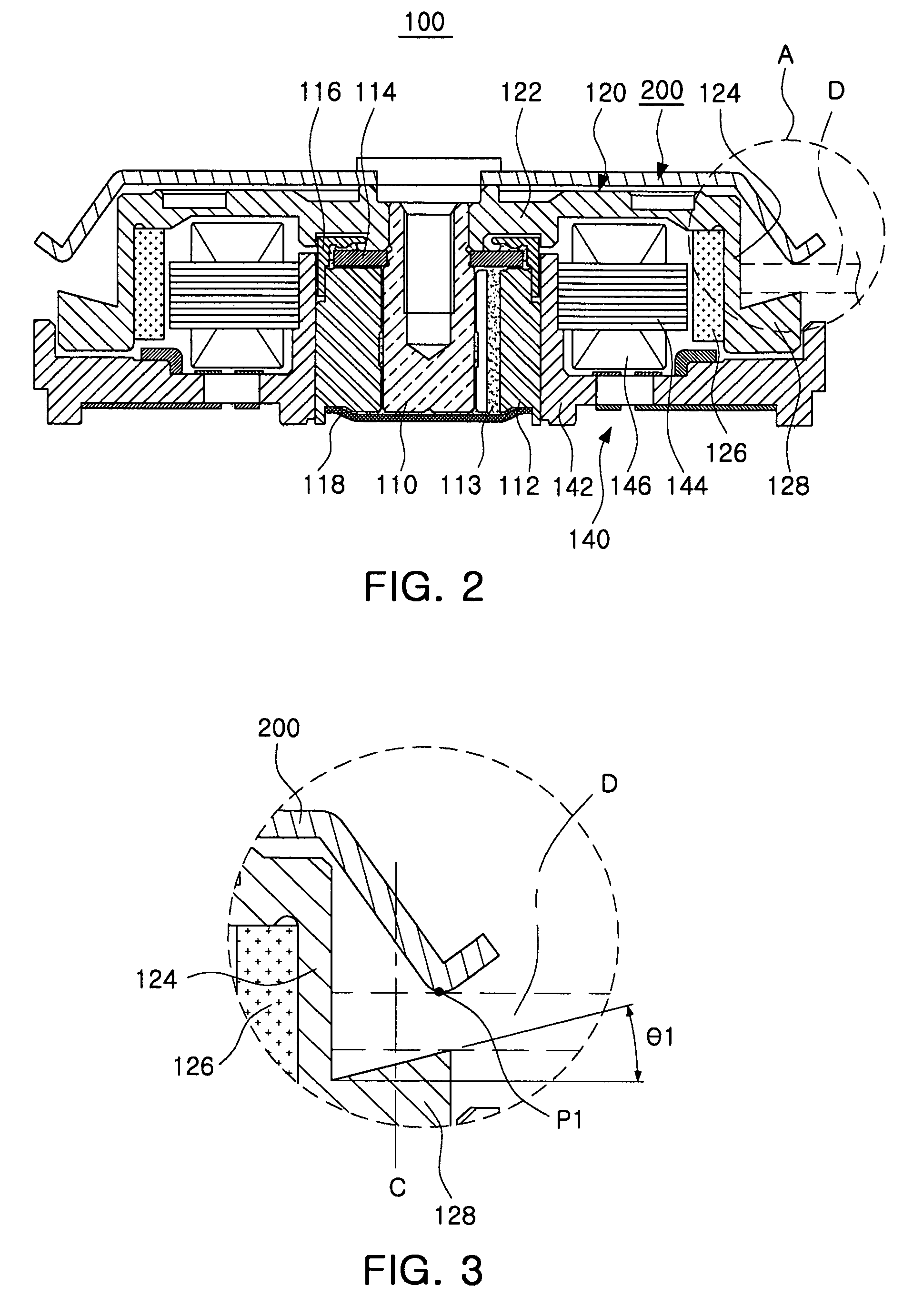

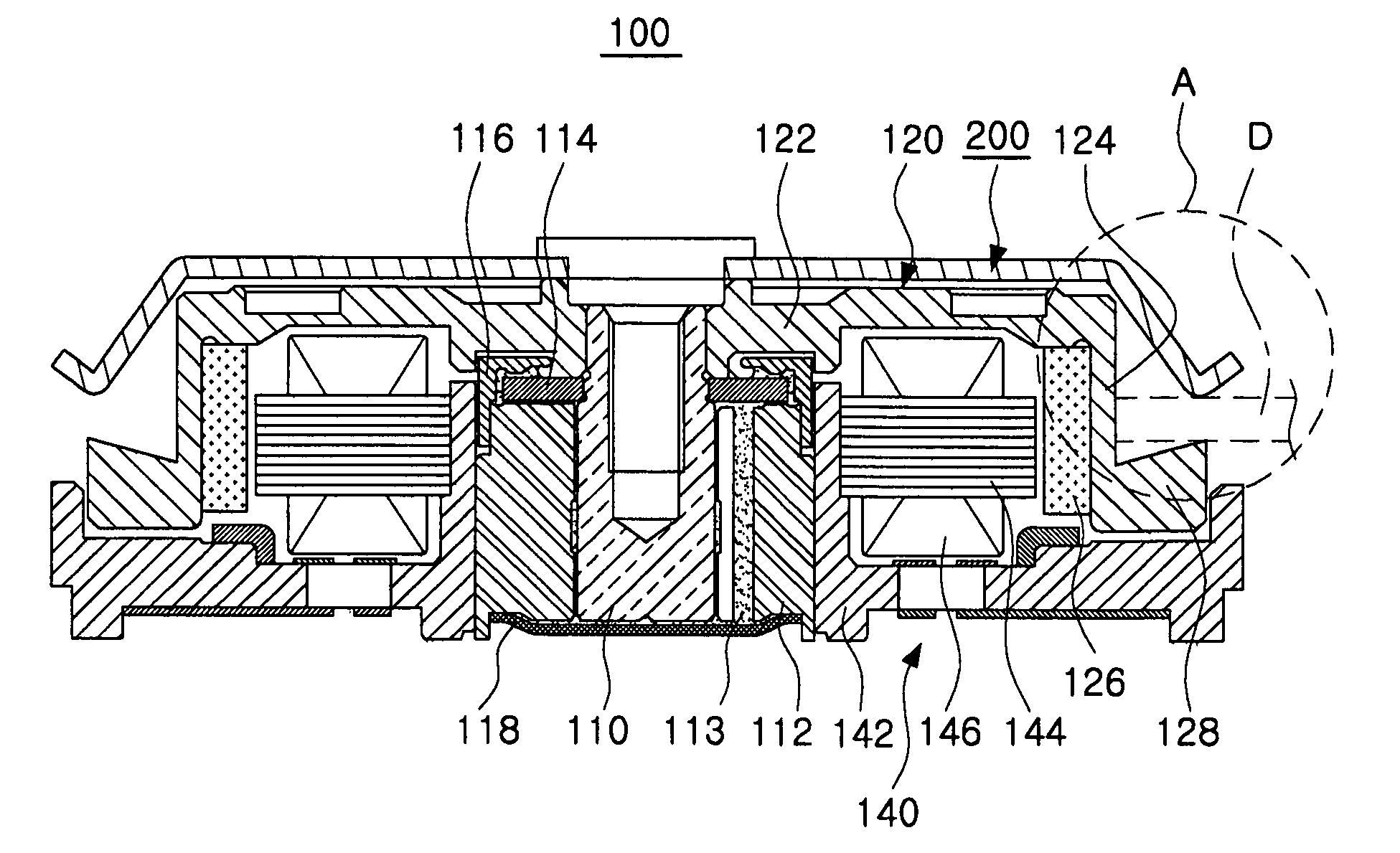

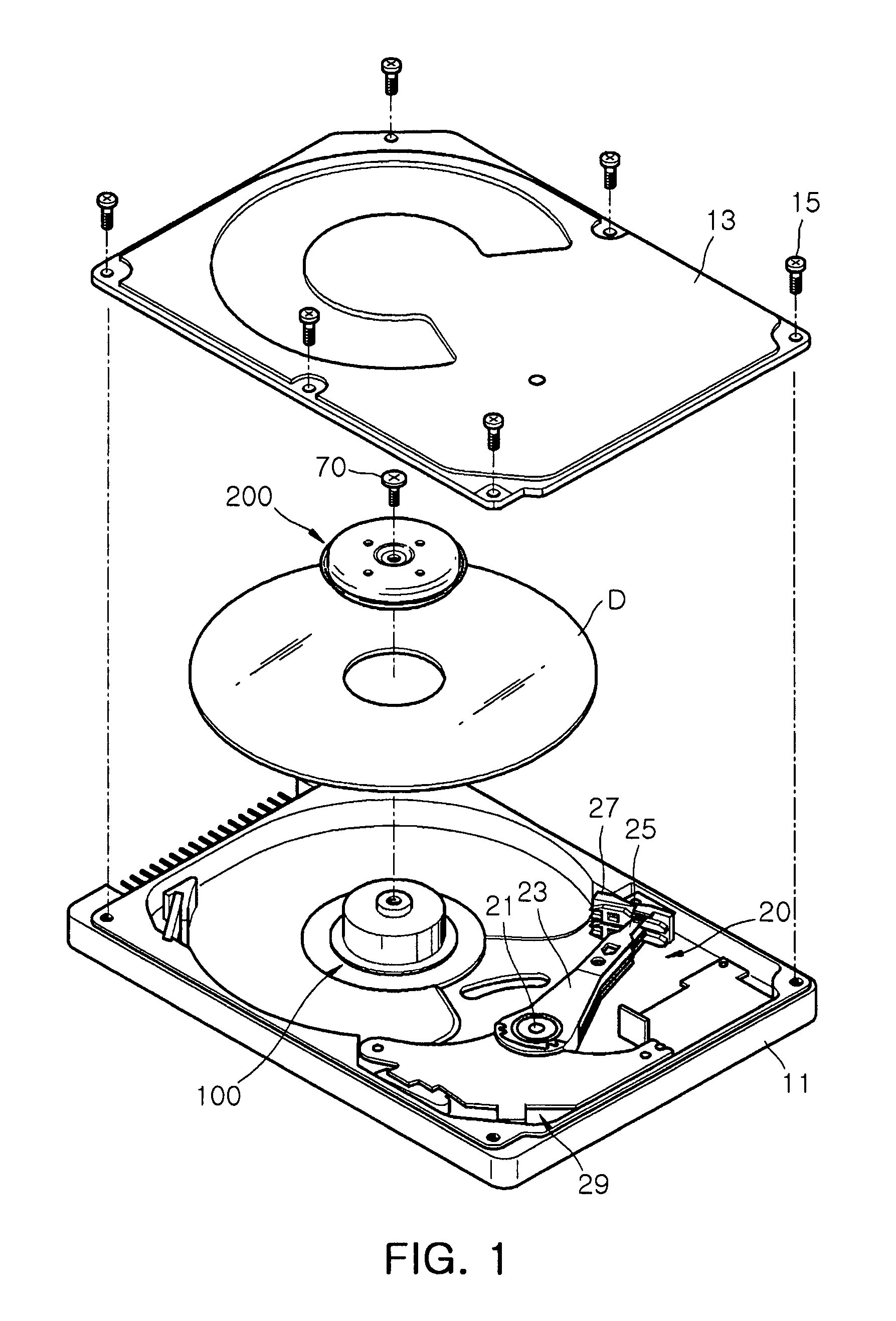

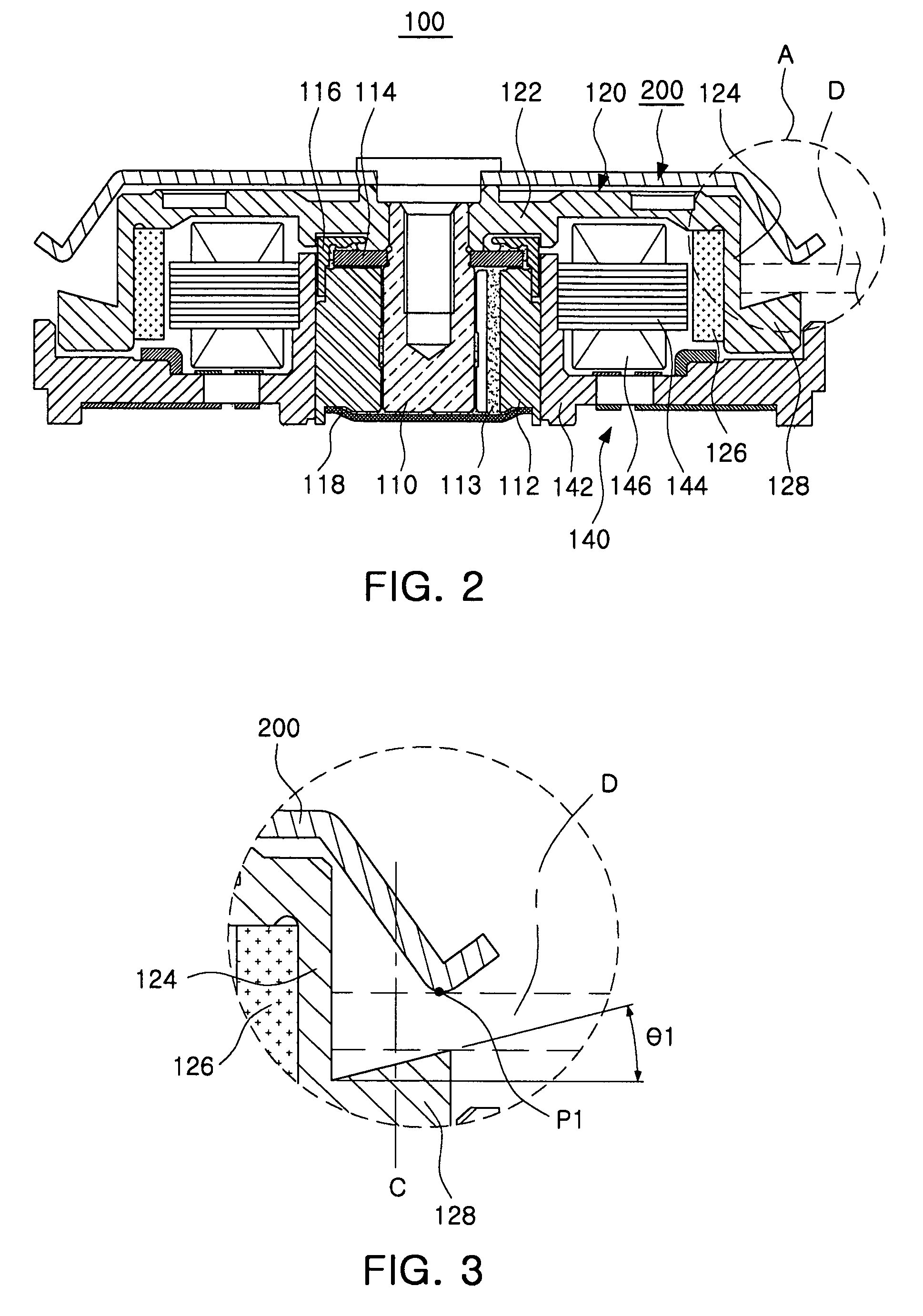

Apparatus for clamping disk and motor assembly having the same

InactiveUS20120050913A1Minimize warpageHigh precisionRecord information storageRecord carrier accessoriesElectric machineEngineering

There are provided an apparatus for clamping a disk and a motor assembly having the same. The apparatus for clamping a disk according to the present invention includes an apparatus for clamping a disk, including: a rotor case jointed with an outer peripheral surface of a shaft and rotating together with the shaft; a flange part including a disk mounting surface formed at a radial outer side of the rotor case and formed to be inclined as the disk mounting surface is toward the radial outer side; and a clamping member pressing and clamping the disk to the rotor case, wherein an inclination of the disk mounting surface of the flange part is changed depending on the position of the pressing point to the disk of the clamping member.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Organic el element sealing member

InactiveUS20140167021A1Prevent degradation of luminescenceEasy to produceElectroluminescent light sourcesSynthetic resin layered productsThin metalThin membrane

The present invention provides a sealing member for organic EL elements that enables organic EL elements, in particular, organic EL elements for illumination devices to maintain stable luminescence over a long period and that can be fabricated at reduced cost. The sealing member for organic EL elements of the present invention includes a barrier film including a plastic film and at least one thin metal layer, and a curable resin composition layer on the barrier film. The curable resin composition layer has a thickness of 5 to 100 μm and the curable resin composition exhibits nonfluidity at 25° C. in an uncured state and gains fluidity at an elevated temperature in the range of 40 to 80° C.

Owner:THREEBOND FINE CHEM CO LTD

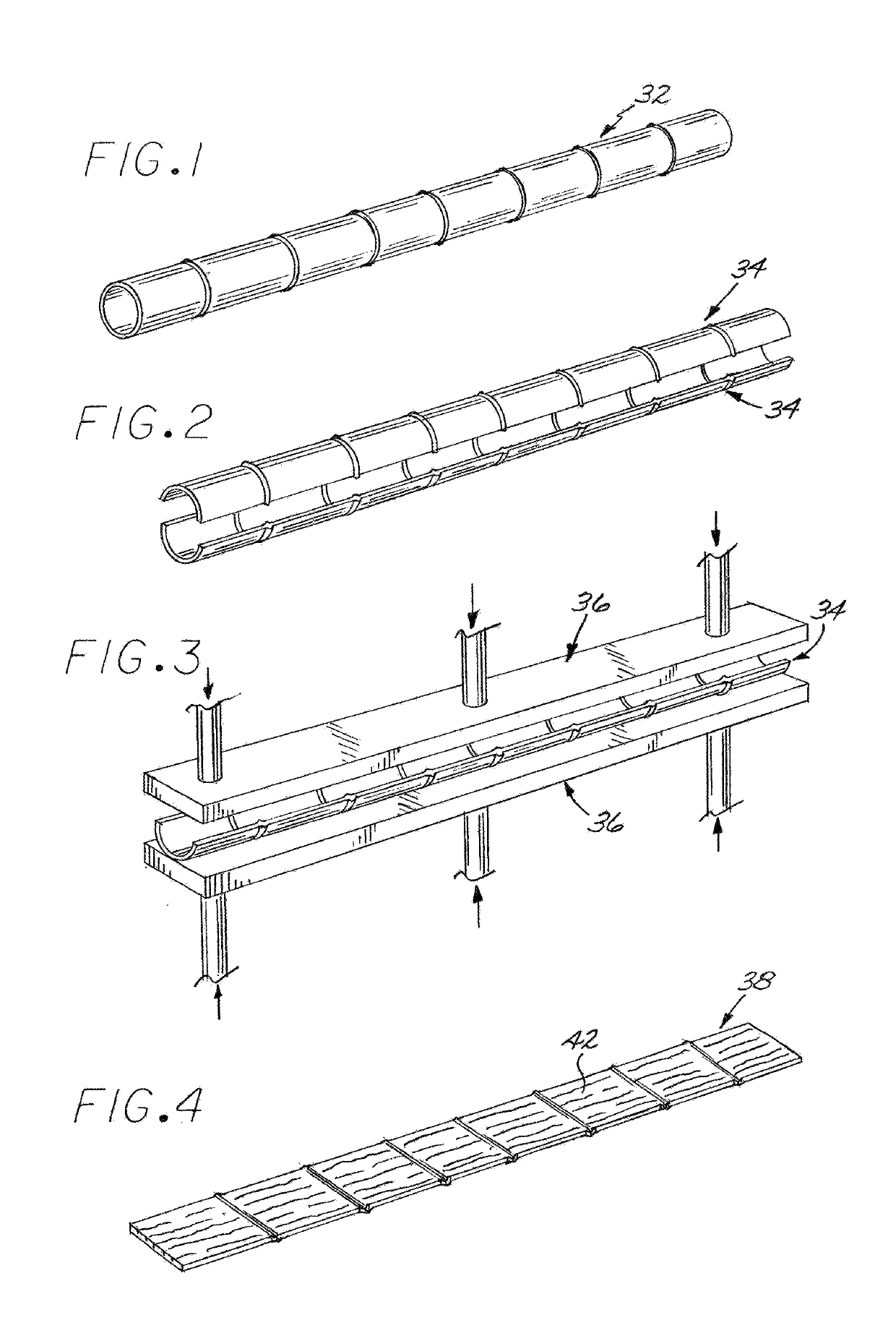

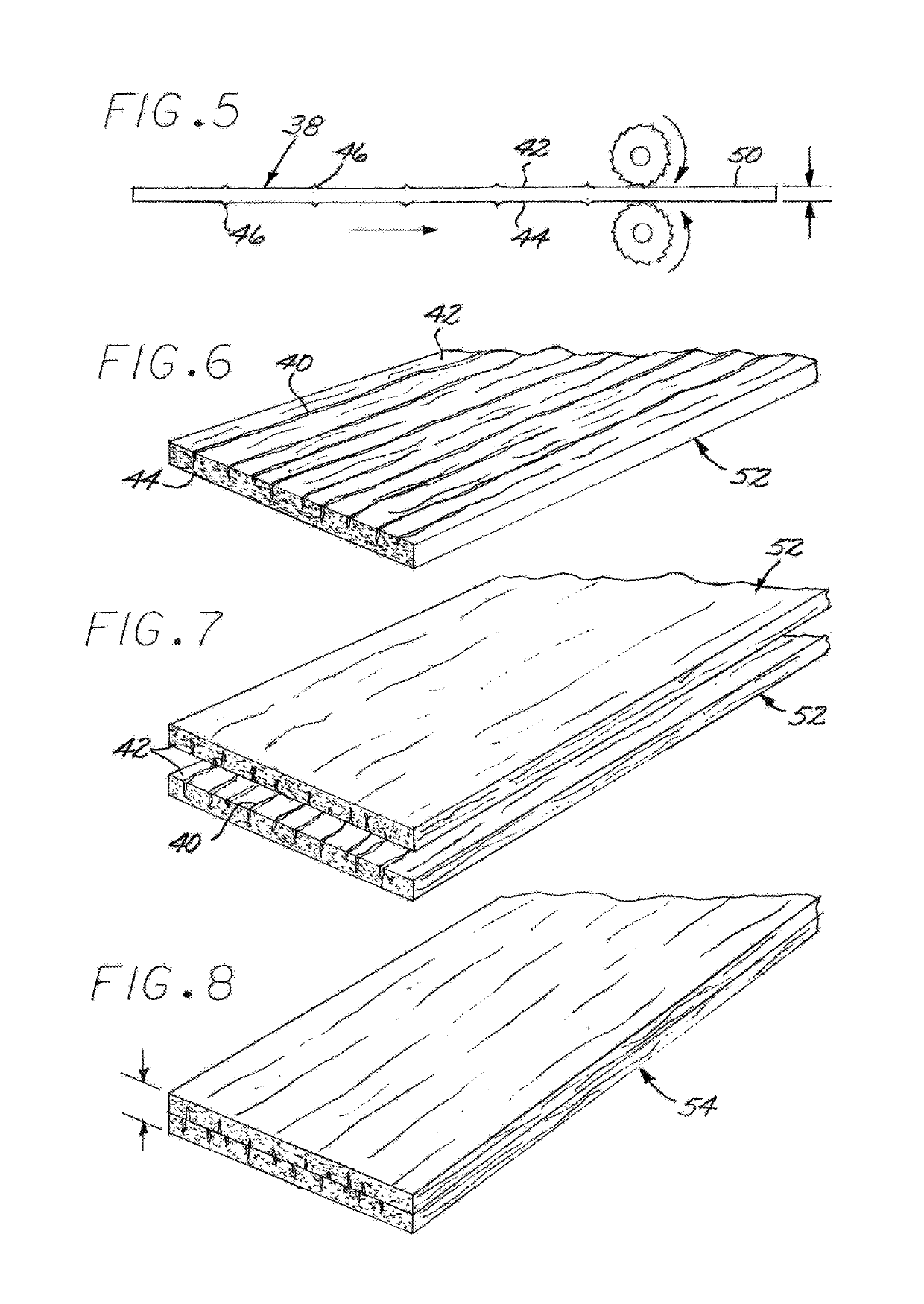

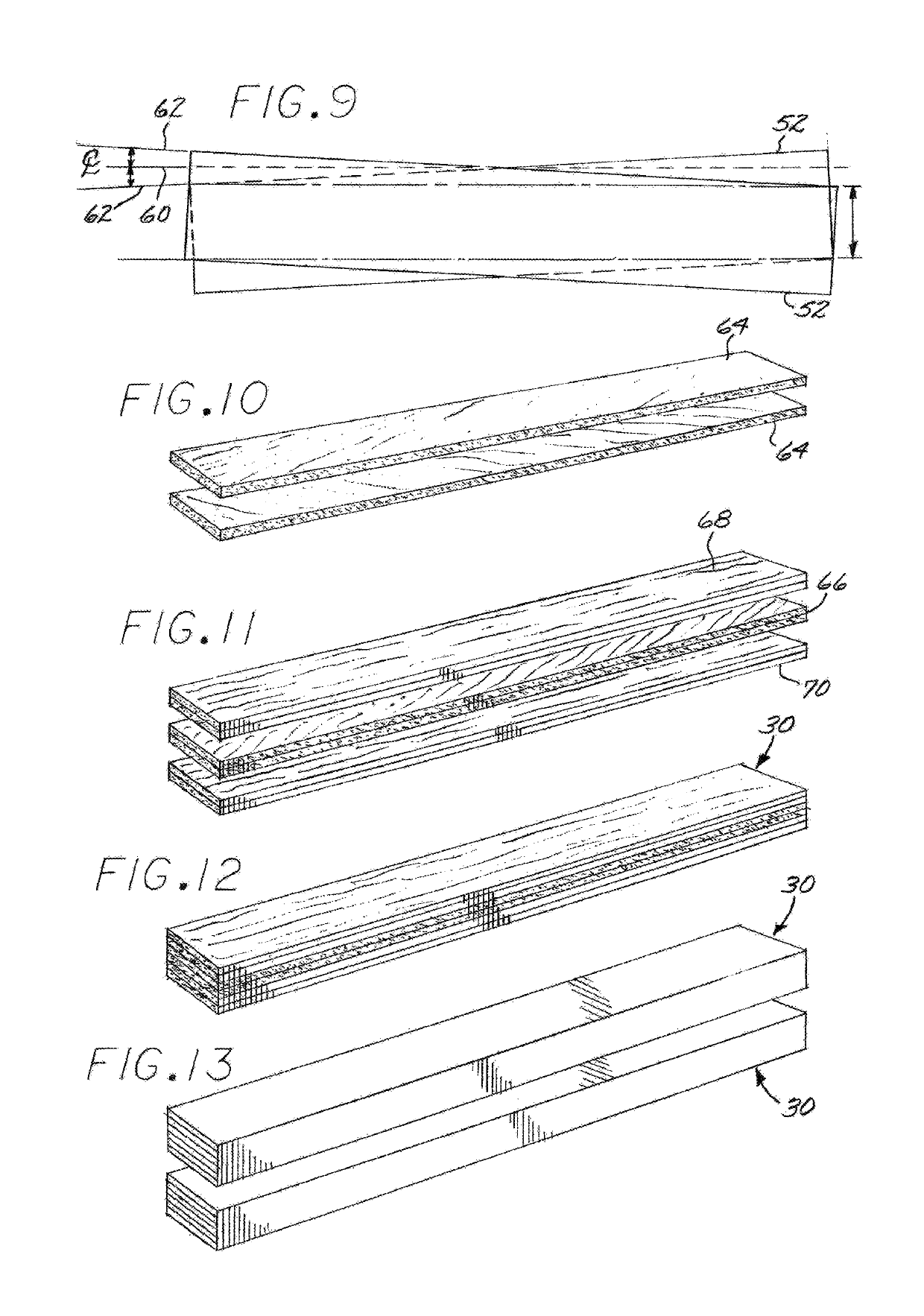

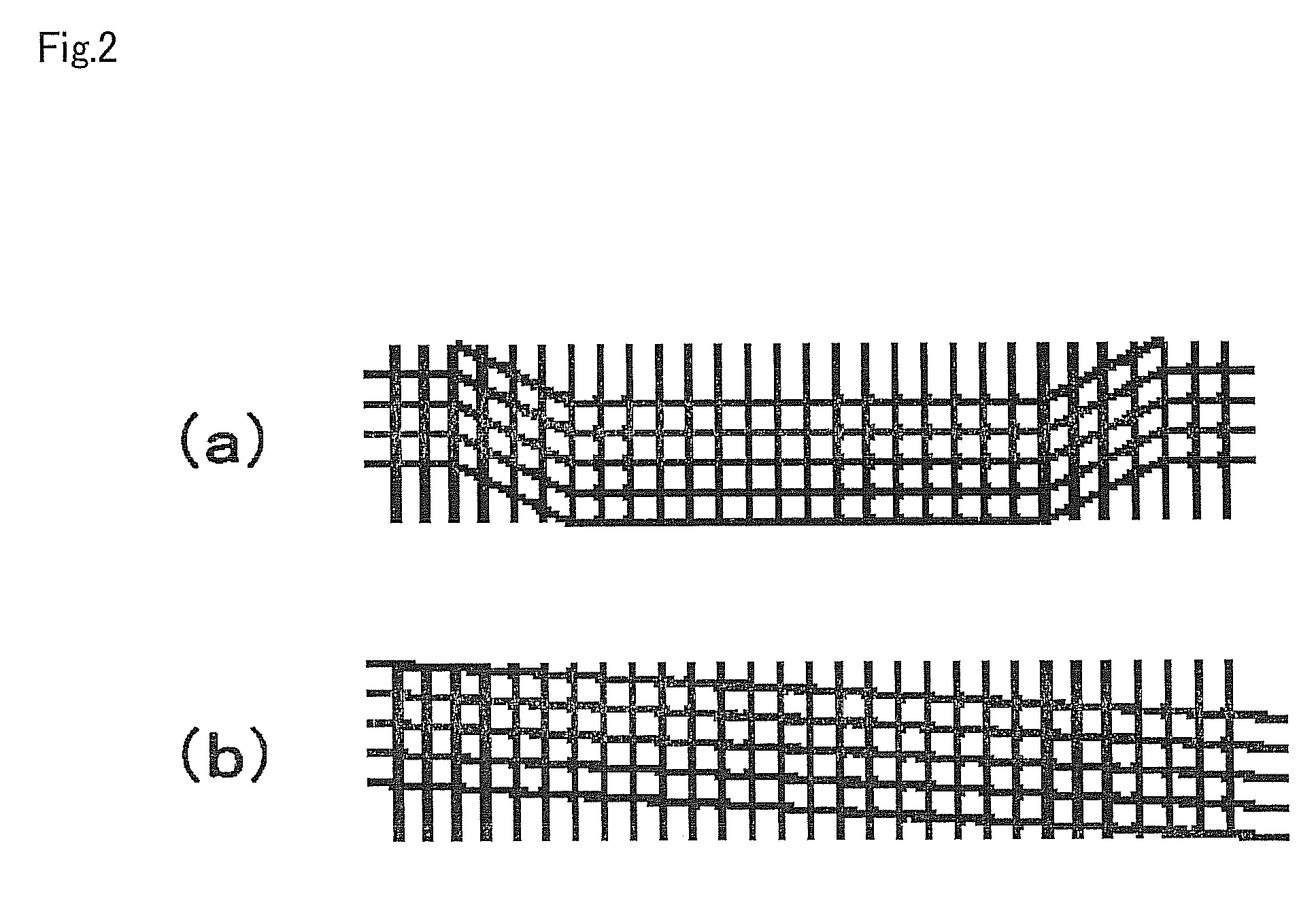

Bamboo laminated lumber and method for manufacturing

ActiveUS10442111B1Uniform and stable structureMaximized strengthWood working apparatusConstructions elementsEngineeringMechanical engineering

A bamboo laminated lumber is provided having structural characteristics meeting or exceeding dimensionally equivalent wood based components. The bamboo laminated lumber is formed from bamboo laminated elements laminated and joined together to form dimensional lumber and engineered lumber components. The bamboo laminated lumber element comprises a combination of linear bamboo starter boards being halves of timber bamboo canes pressed flat with the inner pith surfaces laminated together with the grain aligned and skewed bamboo starter boards being halves of timber bamboo canes pressed flat with the inner pith surfaces laminated together with the grain offset from centerline at a specified angle. Top and bottom linear bamboo starter boards are laminated to a central skewed bamboo starter board yielding a bamboo laminated lumber element.

Owner:BAMCORE

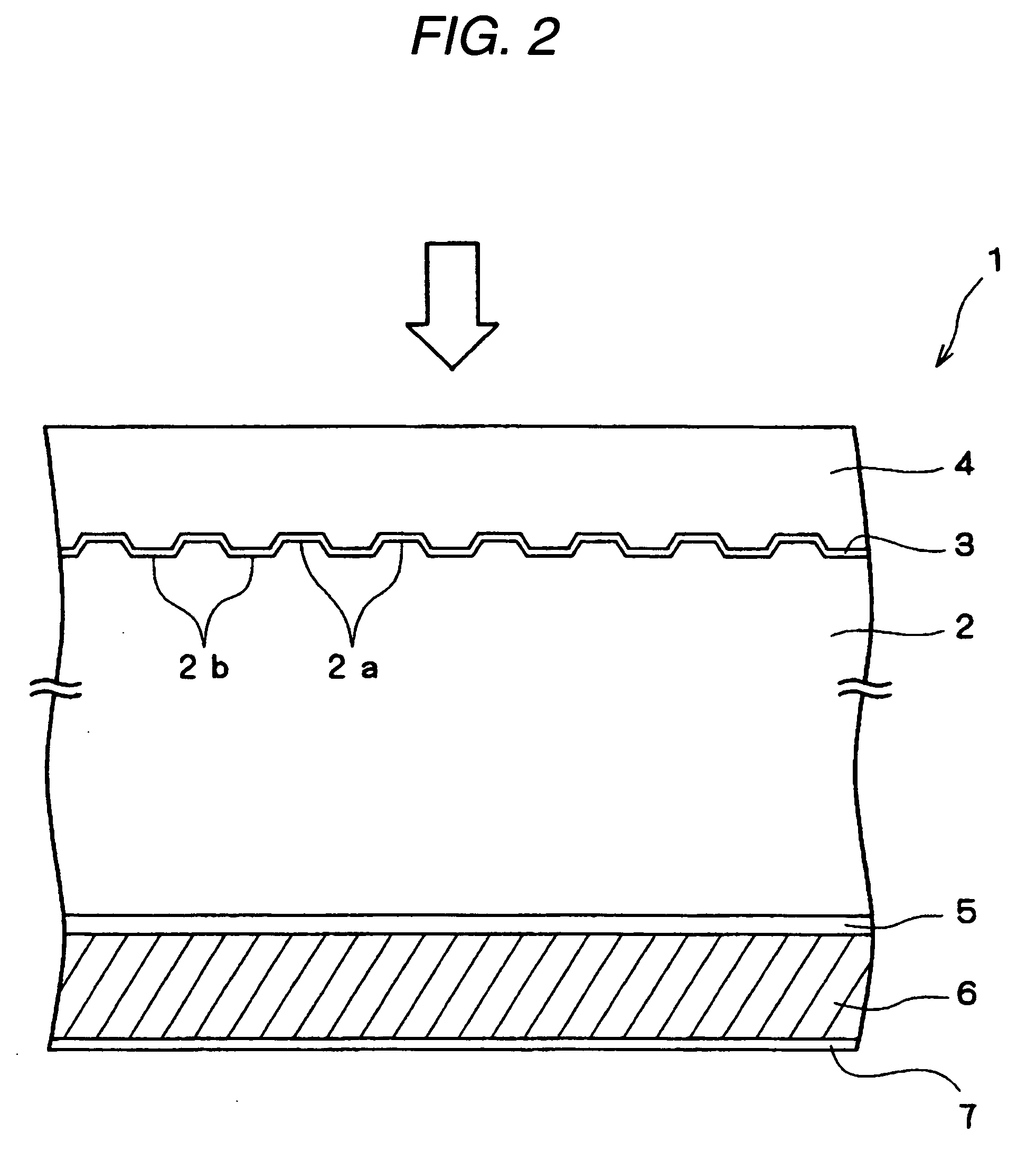

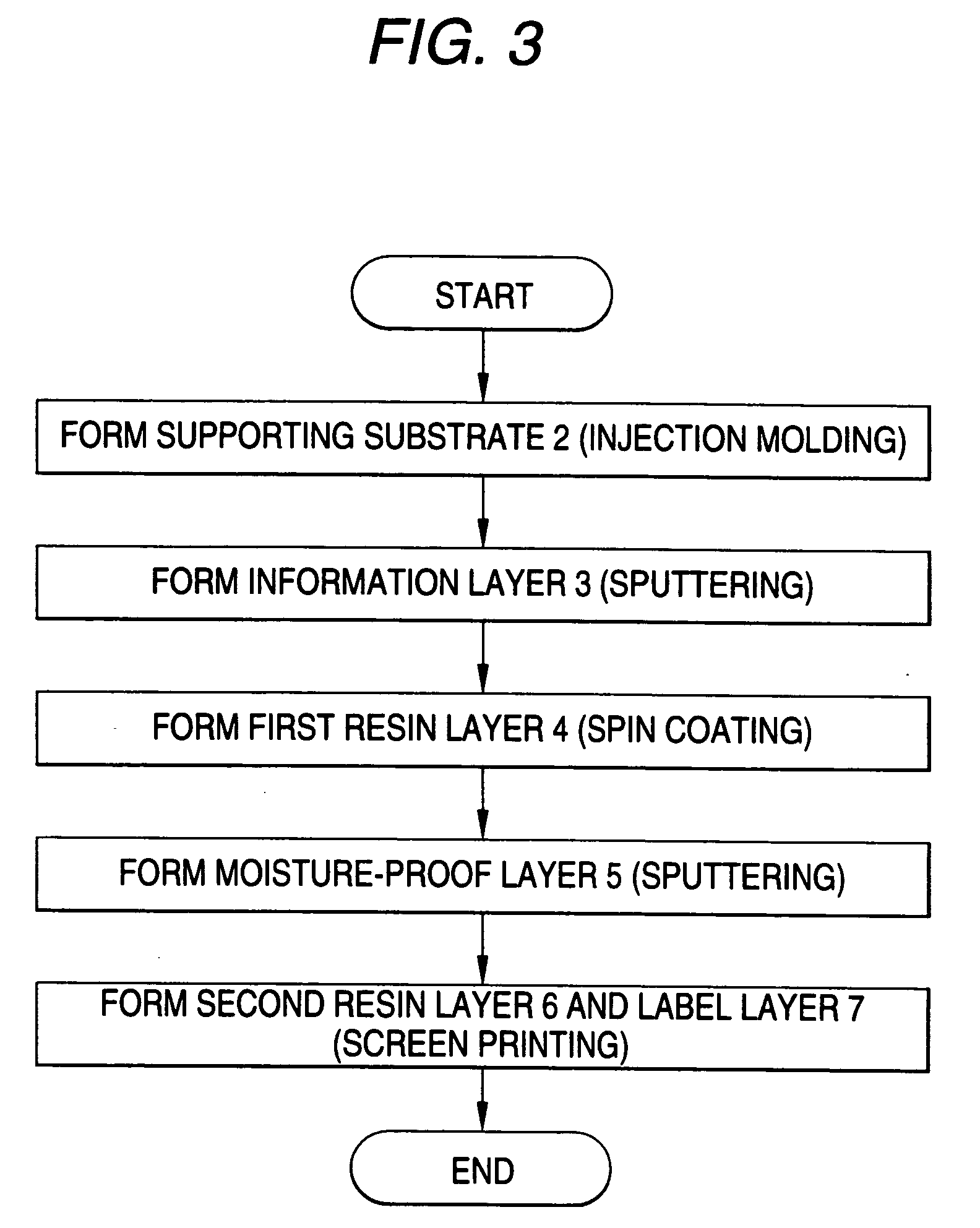

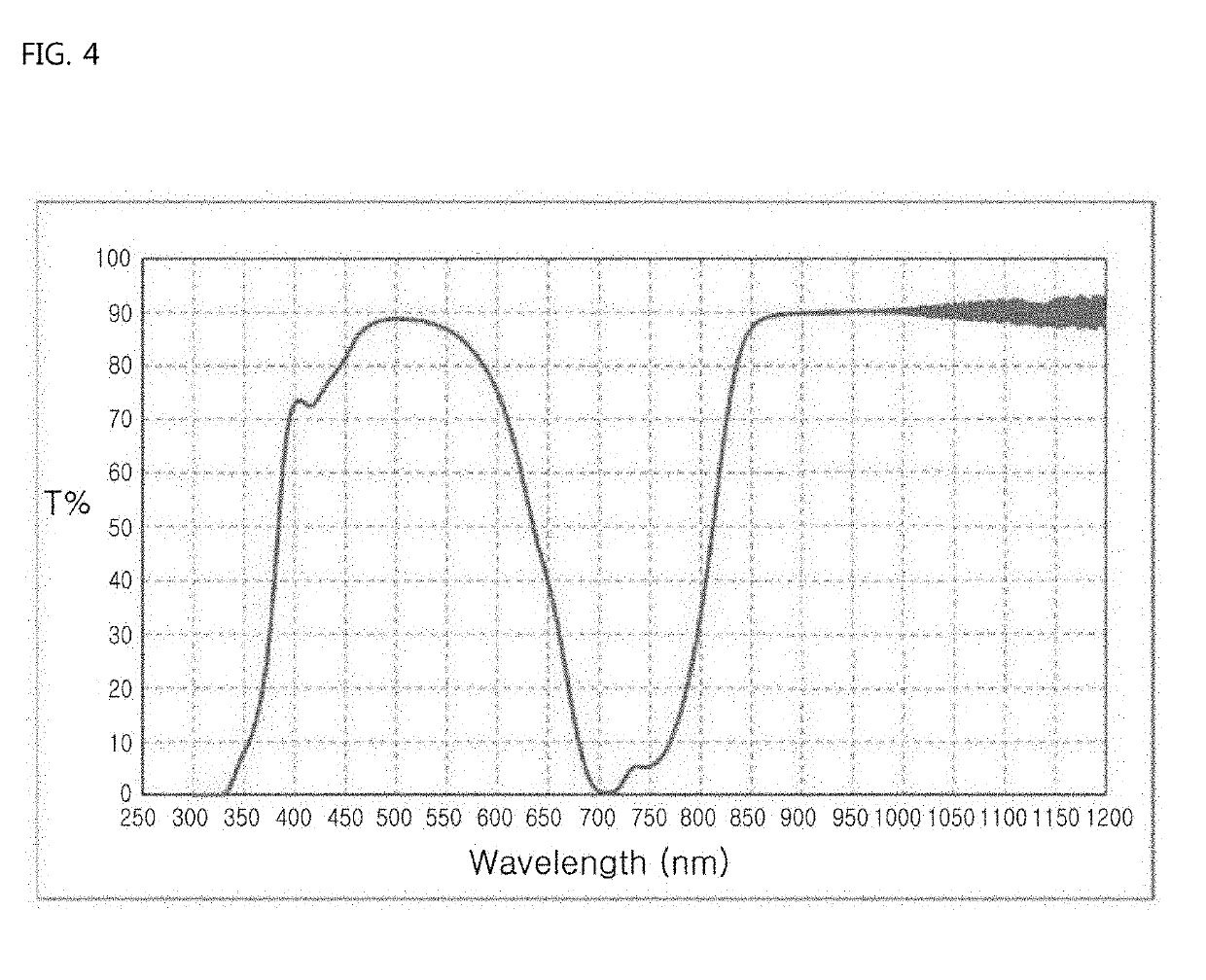

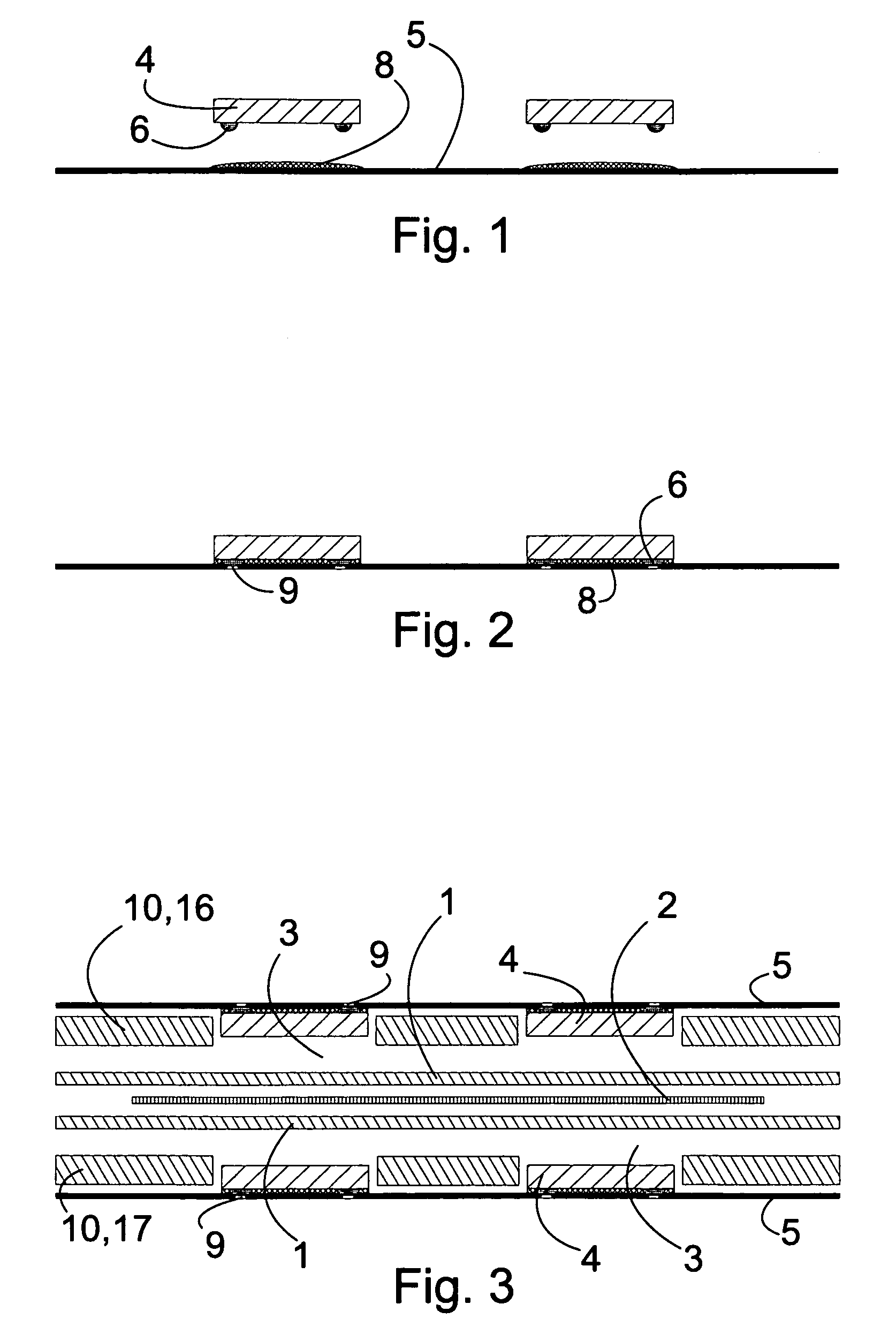

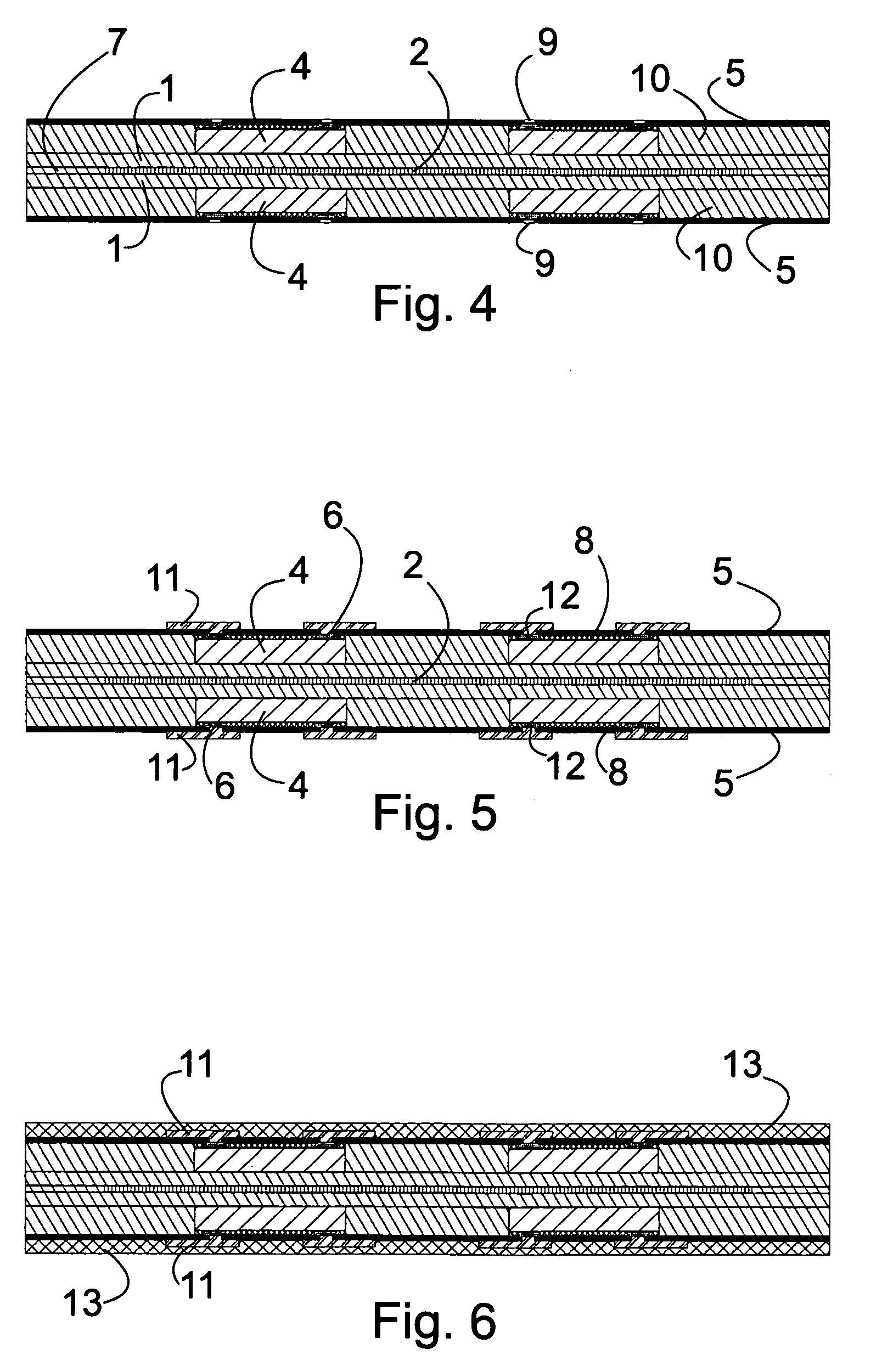

Optical recording medium

InactiveUS20050255283A1Avoid rising costsMinimize warpageLayered productsRecord information storageInformation layerScreen printing

The optical recording medium includes a supporting substrate 2, an information layer 3 formed on a surface of the supporting substrate 2, a first resin layer 4 formed on the information layer 3 and having a thickness of 30 to 200 μm, a moisture-proof layer 5 formed on a rear surface of the supporting substrate 2, a second resin layer 6 formed on the moisture-proof layer 5 and having a thickness of 30 to 200 μm, and a label layer 7 formed on the second resin layer 6. The second resin layer 6 contains a filler and is formed by a screen printing method.

Owner:TDK CORPARATION

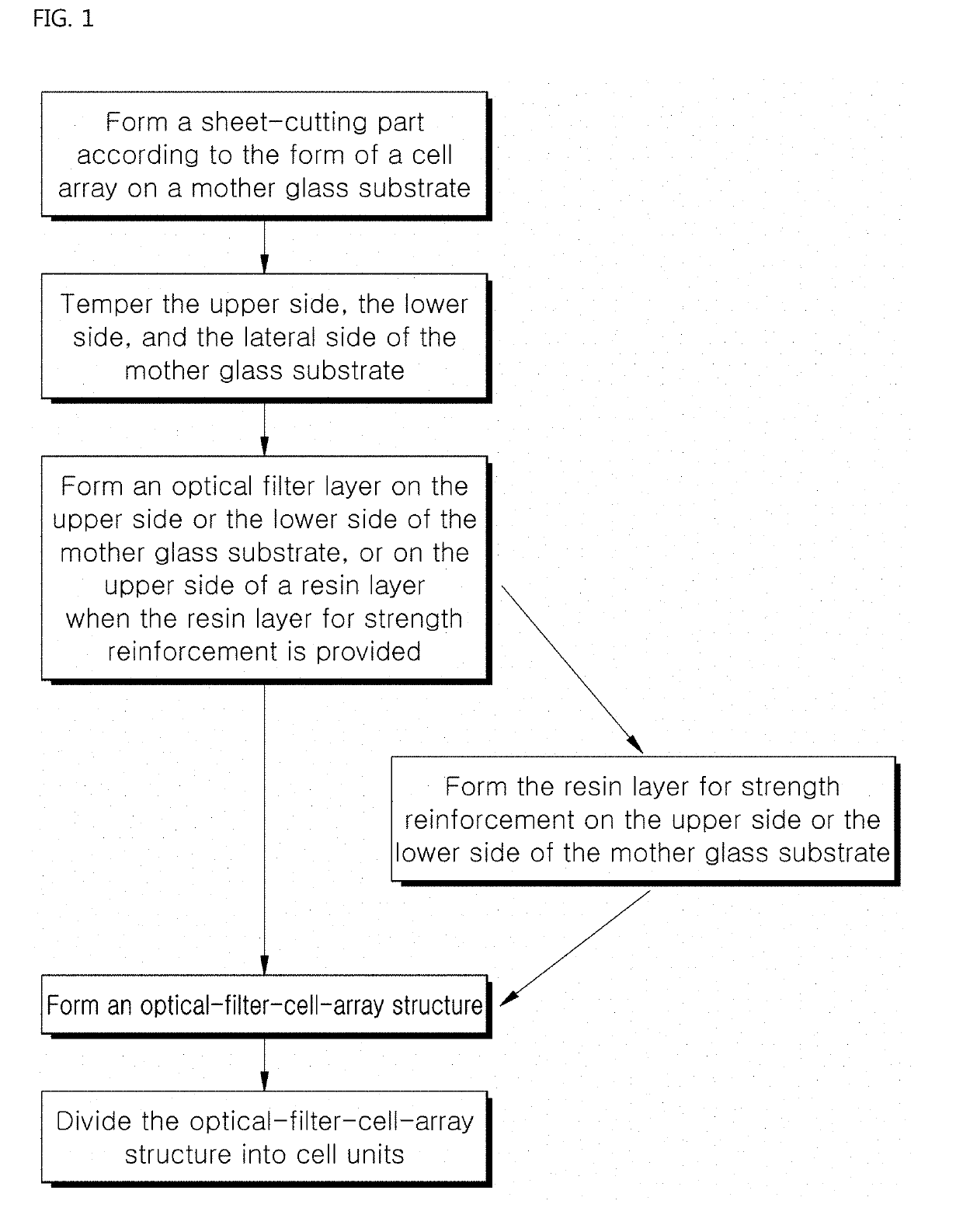

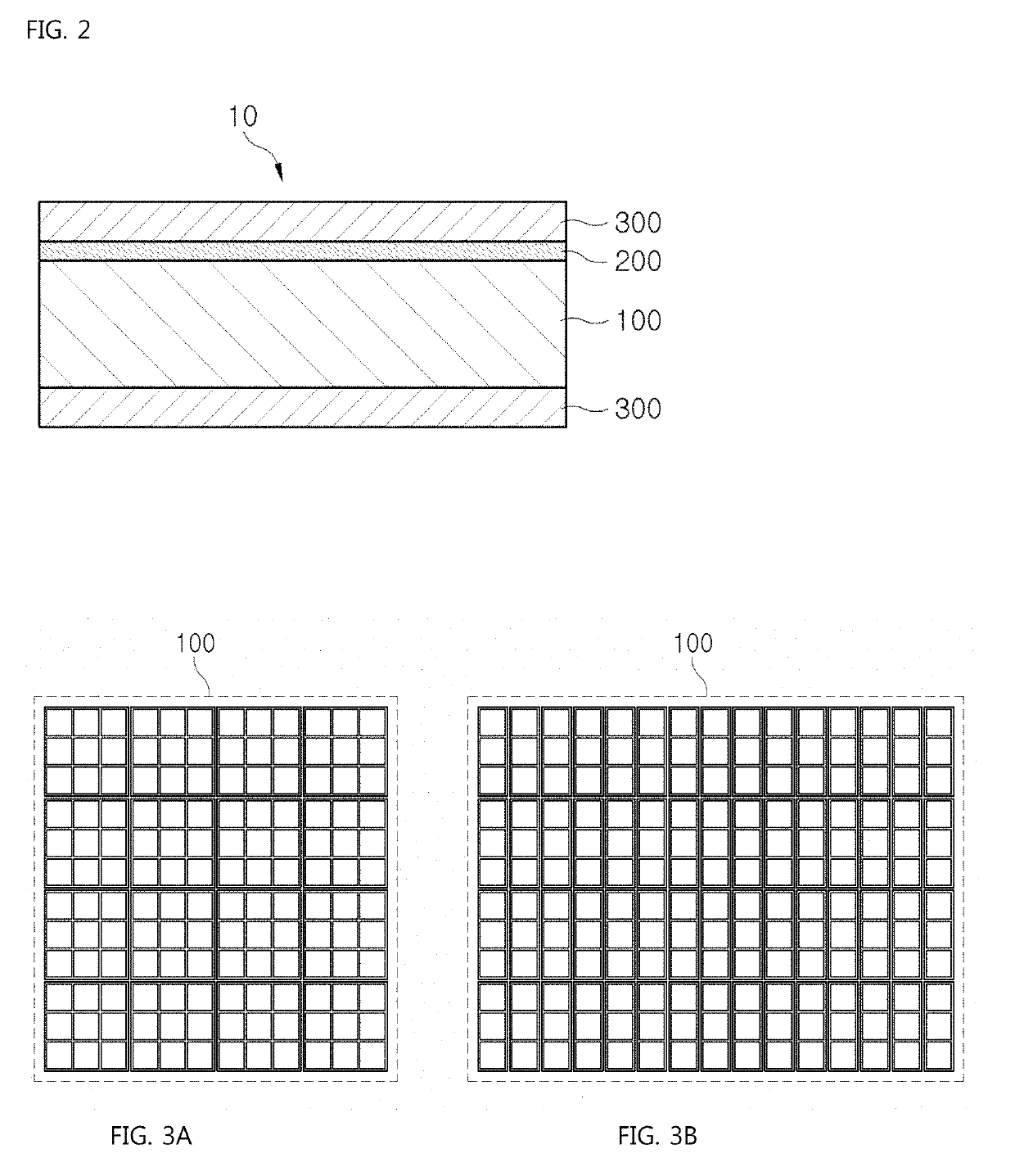

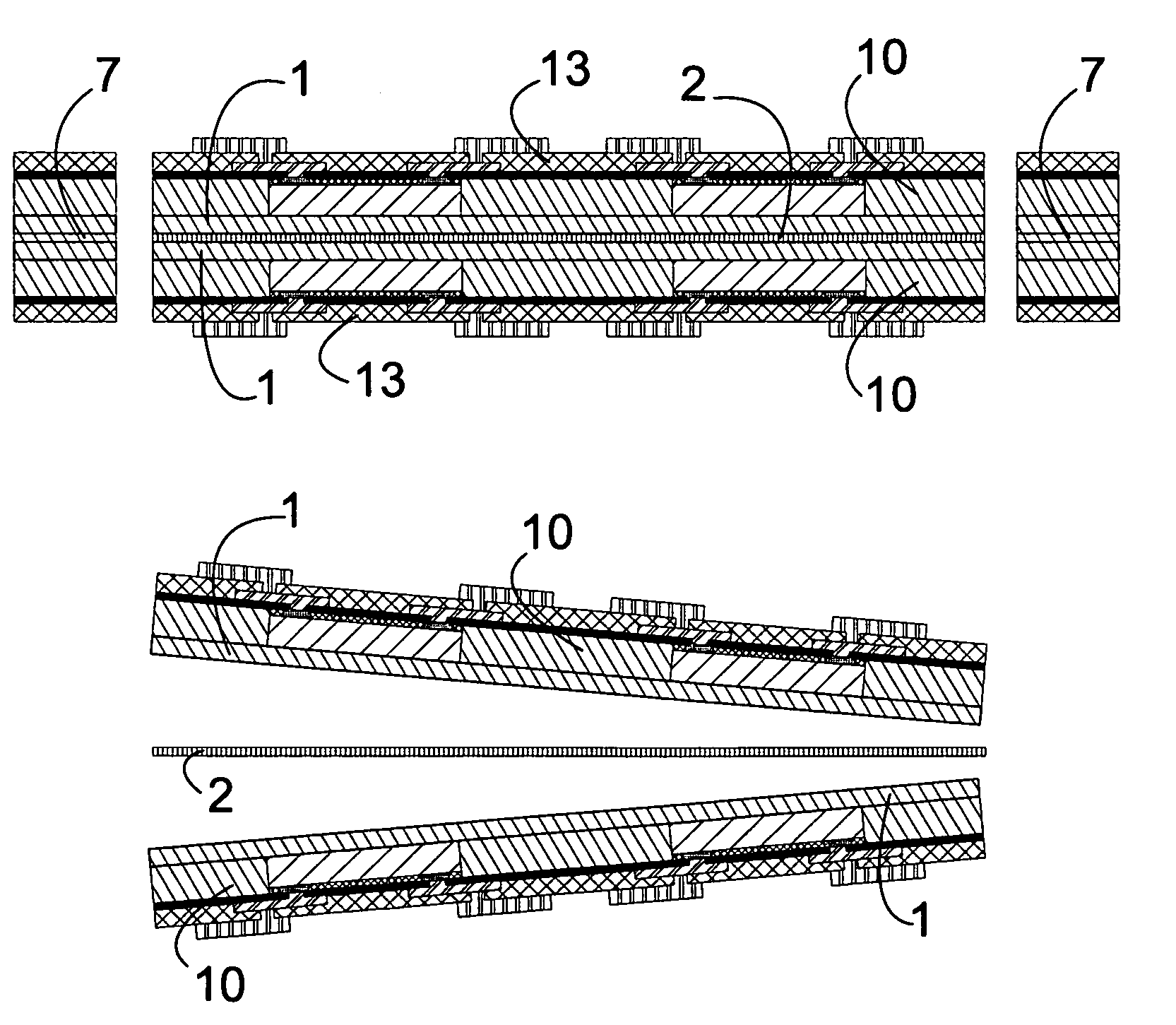

Optical-Filter-Cell-Array Structure and Method of Manufacturing the Same

Disclosed is an optical-filter-cell-array structure and a method of manufacturing the same. An optical filter which includes an optical filter layer for blocking light of a specific wavelength formed on an upper side or a lower side of a tempered glass substrate is provided in the form of a cell array. The method includes forming a sheet-cutting part according to the form of a cell array on a mother glass substrate, tempering the mother glass substrate so that a lateral side of the mother glass substrate is tempered through the sheet-cutting part while an upper side and a lower side of the mother glass substrate are tempered, and forming an optical filter layer on the upper side or the lower side of the mother glass substrate.

Owner:UTI INC

Method of manufacturing a wiring board

ActiveUS8286341B2Structure miniaturizationSimplify the manufacturing processPrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

Owner:IMBERATEK LLC

Laminated body, circuit board including laminated body, semiconductor package and process for manufacturing laminated body

InactiveUS8871660B2Improve rigidityLarge warpageAdhesivesThin material handlingFiberSemiconductor package

Owner:SUMITOMO BAKELITE CO LTD

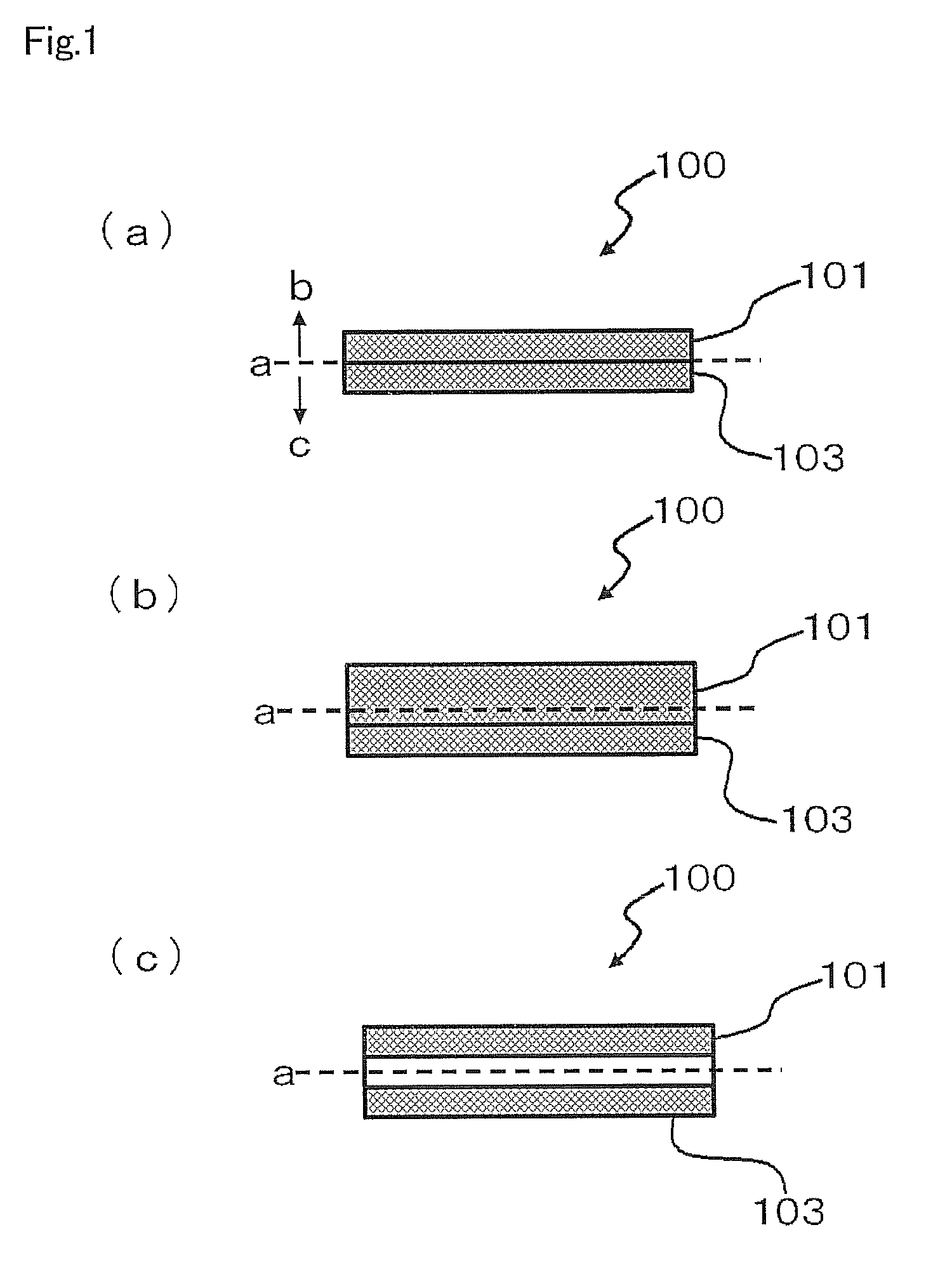

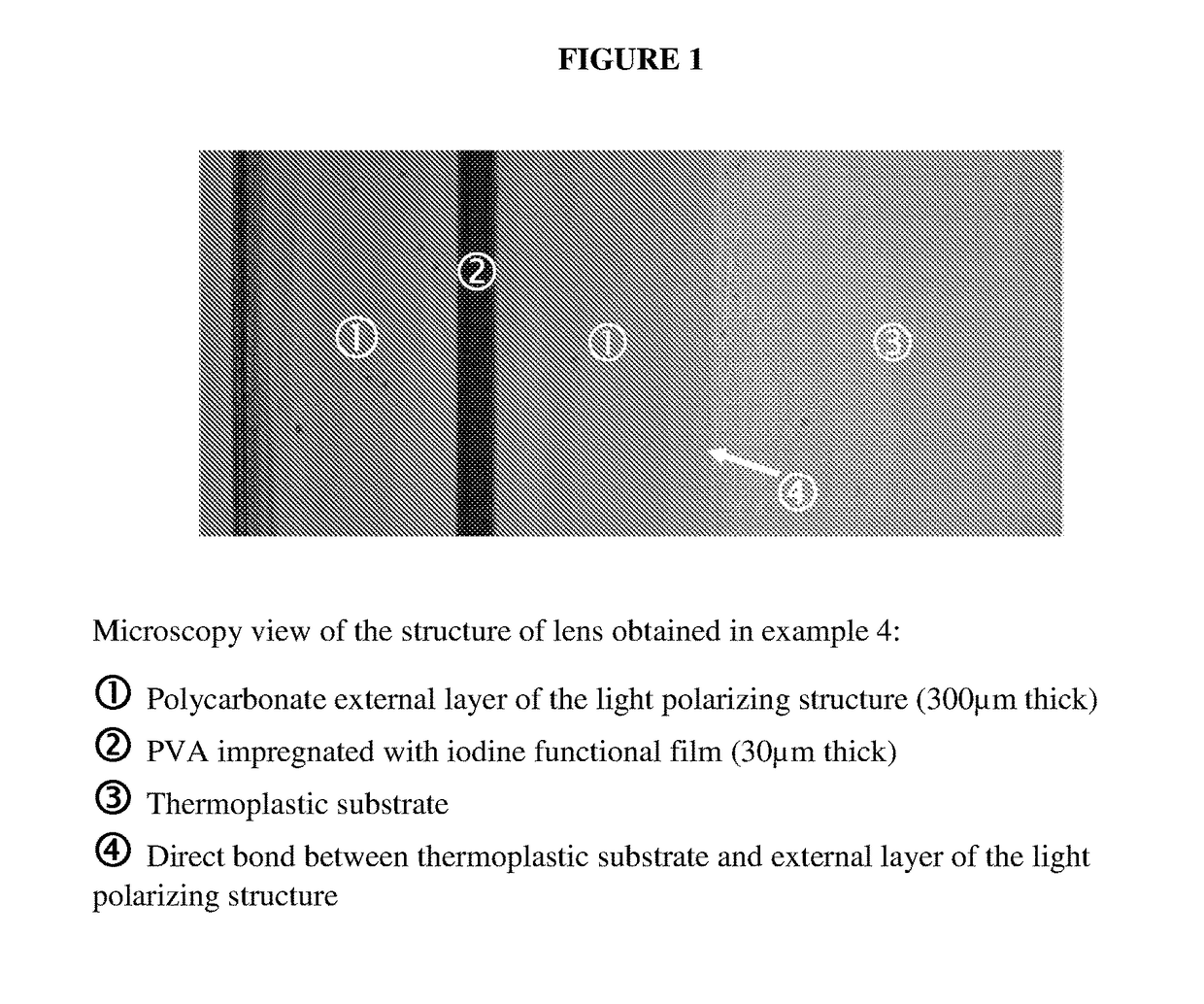

Ophthalmic lens with reduced warpage

Ophthalmic lens comprising an ophthalmic thermoplastic substrate and a light polarizing structure onto said substrate. The ophthalmic lens reduced warpage, in particular when submitted to mechanical, thermal and / or chemical treatment.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Electronics component embedded PCB

InactiveUS8618421B2Minimize warpagePrinted circuit assemblingPrinted electric component incorporationElectronic componentPrinted circuit board

An electronic component embedded printed circuit board is disclosed. In accordance with an embodiment of the present invention, the electronic component embedded printed circuit board is a printed circuit board in which an electronic component is embedded in a core board, and the electronic component includes a silicon layer and a passivation layer, which is formed on one surface of the silicon layer. Here, a center line of the silicon layer and a center line of the core board are placed on a same line.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Apparatus for clamping disk and motor assembly having the same

InactiveUS8467146B2Minimize warpageHigh precisionRecord information storageRecord carrier accessoriesElectric machineFlange

There are provided an apparatus for clamping a disk and a motor assembly having the same. The apparatus for clamping a disk according to the present invention includes an apparatus for clamping a disk, including: a rotor case jointed with an outer peripheral surface of a shaft and rotating together with the shaft; a flange part including a disk mounting surface formed at a radial outer side of the rotor case and formed to be inclined as the disk mounting surface is toward the radial outer side; and a clamping member pressing and clamping the disk to the rotor case, wherein an inclination of the disk mounting surface of the flange part is changed depending on the position of the pressing point to the disk of the clamping member.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com