Full-automatic production line for double-surface cover of paper board

A fully automatic, production-line technology, applied in book binding, book case for binding, printing, etc., can solve the problem of inability to detect and correct deviation from bottom to top, and achieve outstanding substantive features, significant progress, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

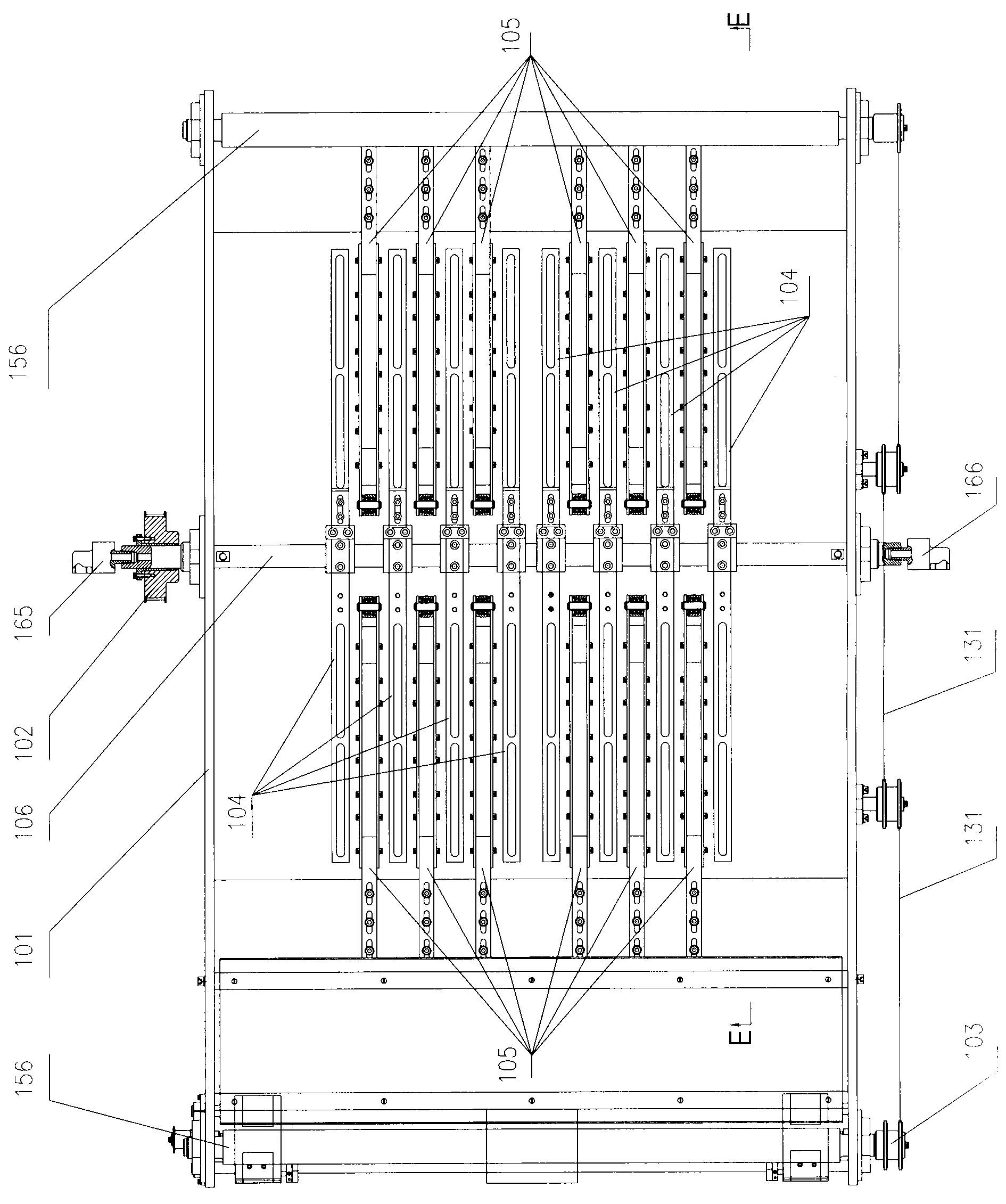

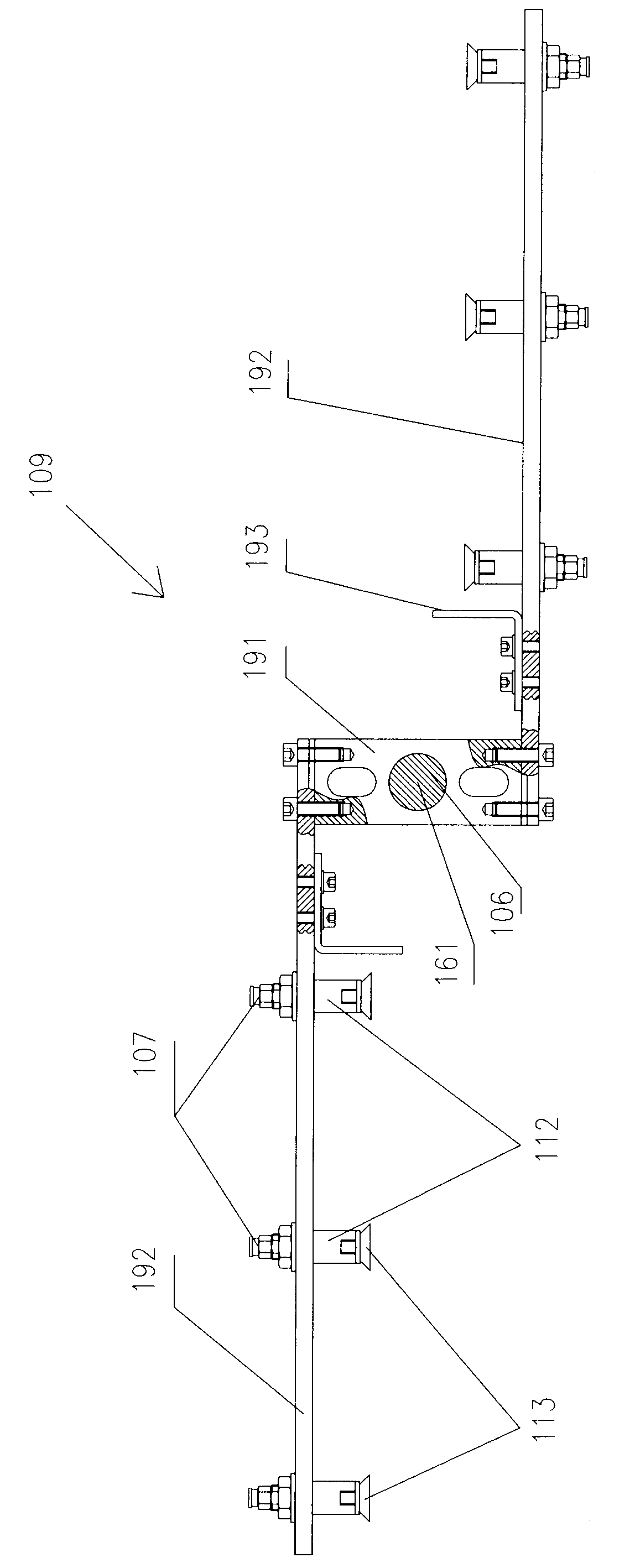

[0035] The relevant details of the embodiments of the present invention are described below with reference to the accompanying drawings.

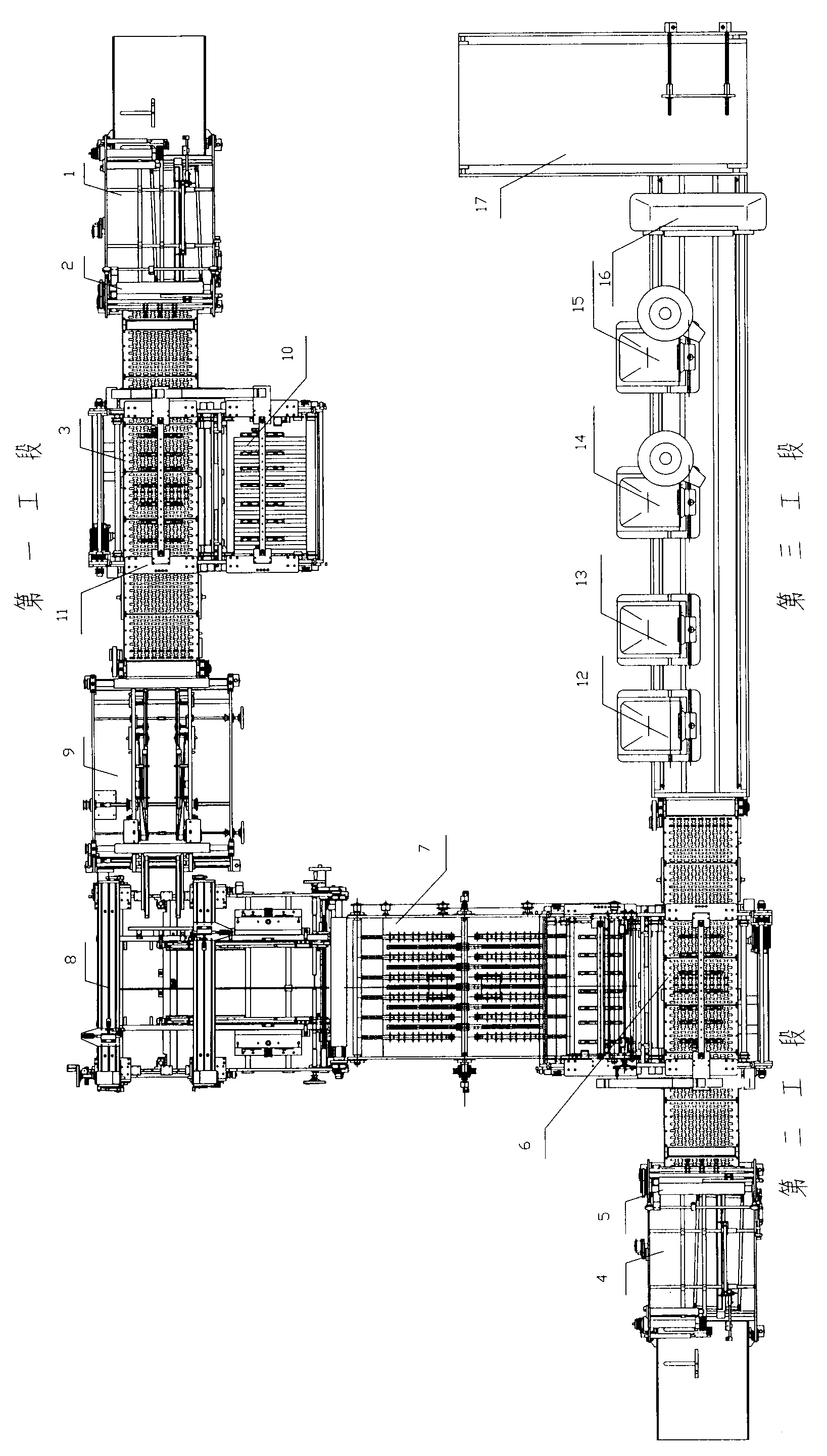

[0036] see figure 1, in order to realize the double-sided cover of cardboard, the production line of this automatic double-sided cover of cardboard includes a first section, and the first section mainly includes a first surface paper conveying mechanism, a first gluing mechanism and a first cover mechanism. The production line also includes a second section, which mainly includes a second surface paper conveying mechanism, a second gluing mechanism and a second cover mechanism, and a semi-finished product horizontal turning mechanism is arranged between the first section and the second section. The first cover mechanism will mainly include an automatic cardboard conveying device and a paper transfer conveying manipulator device, which is not described in the prior art; and the second cover mechanism does not require an automatic cardboard c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com