Apparatus and method manufacturing hard book cover assemblies

A cover and book technology, applied in book binding, book cover, book case for binding, etc., can solve major downtime, waste, cost increase and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

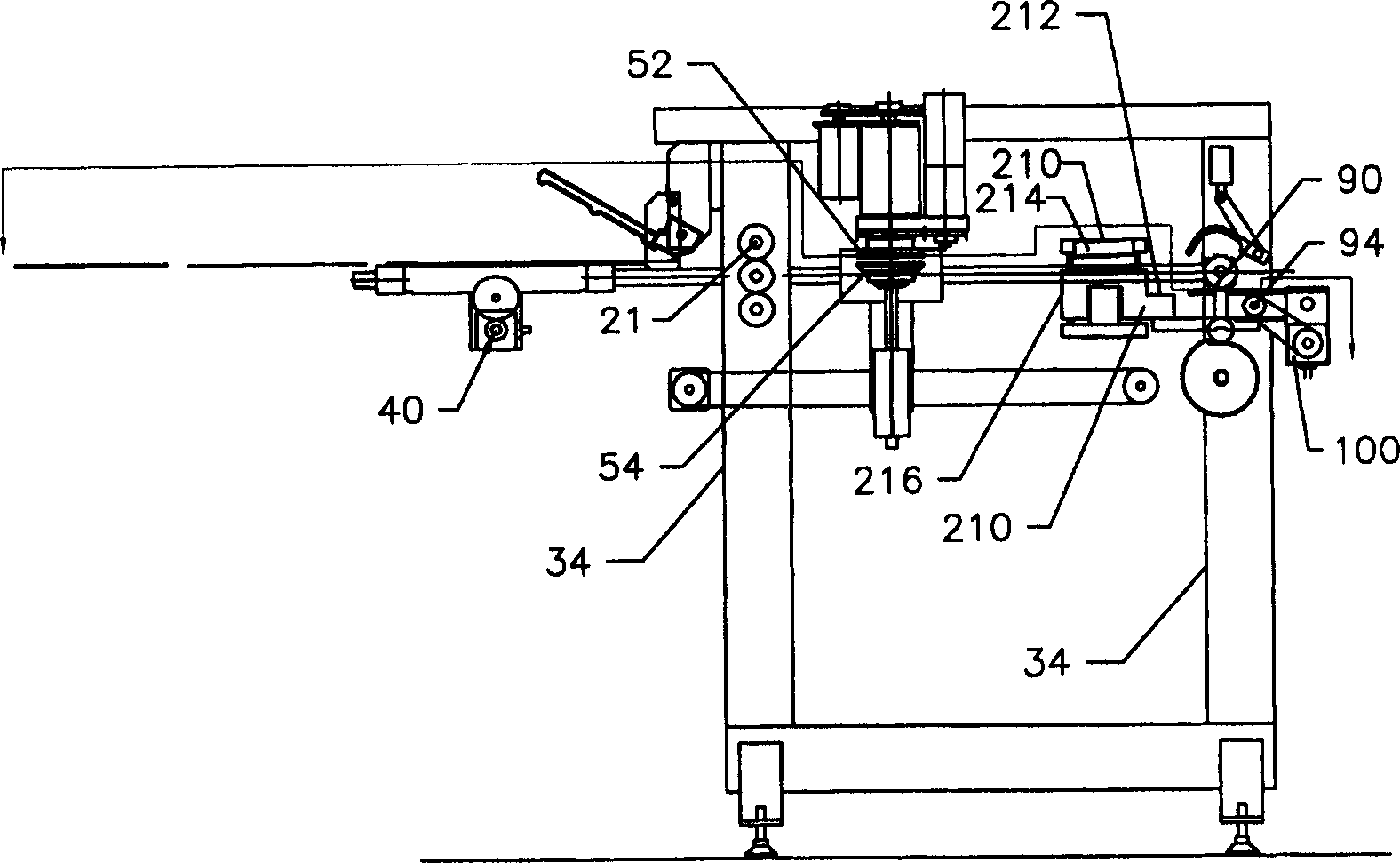

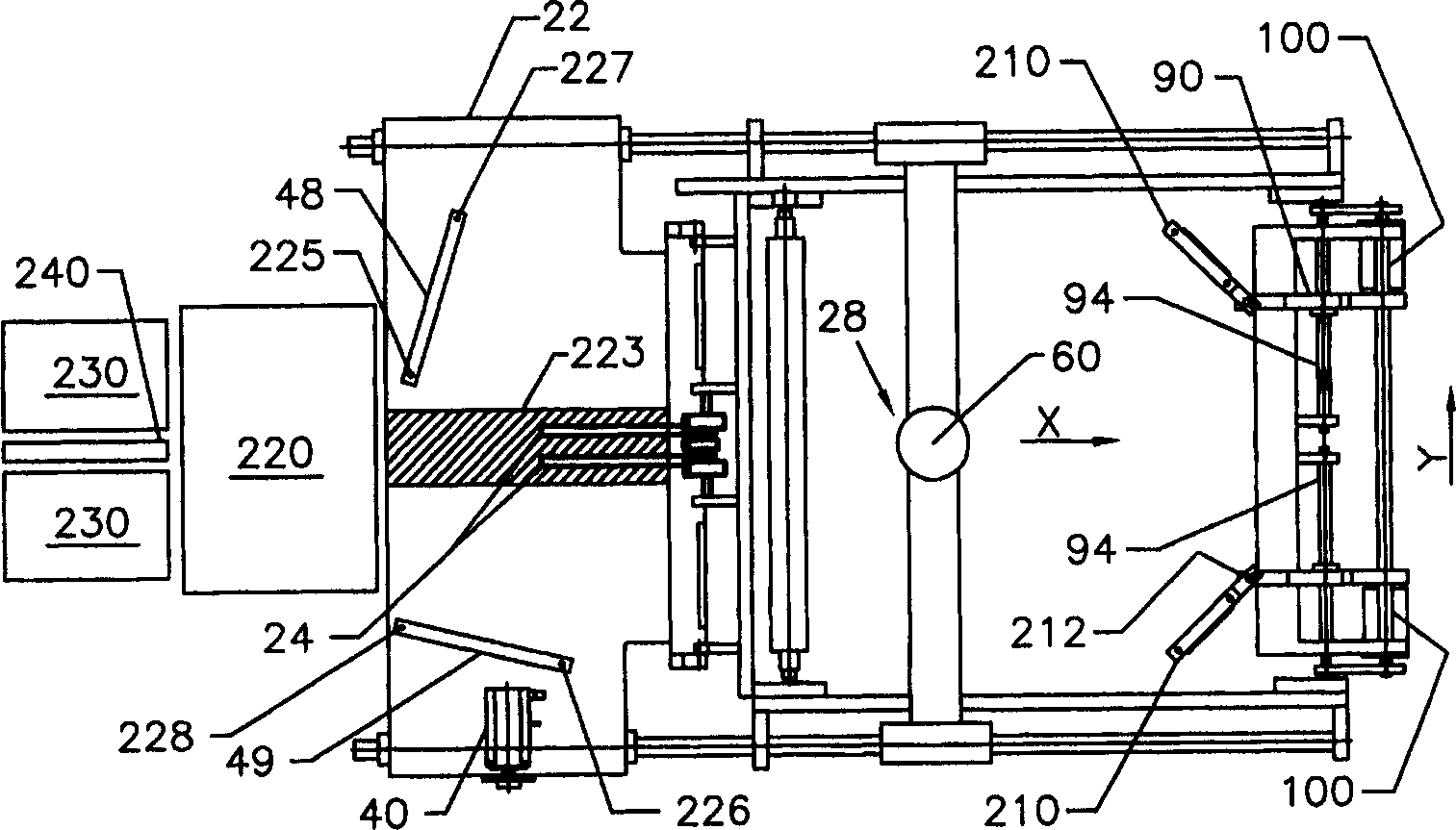

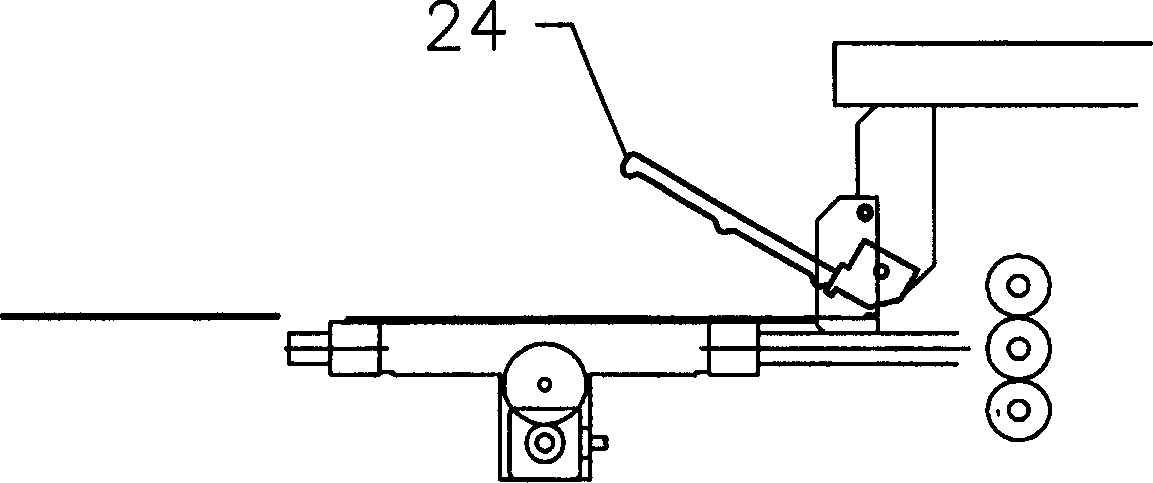

[0058] A rigid book cover assembly includes a cover material, a rigid board part, and an adhesive that joins the cover material and the rigid board part. The rigid board part is usually a spine and two cover panels, but in some cases there may be no spine, and in some cases only one cover panel may be used. The adhesive may be a separate substance or may be included in or on the rigid board part and / or cover material for joining the cover material to the rigid board part. As used herein, rigid book cover assemblies include book covers (housings) as well as catalog covers, calendars, game boards, binders, and other items that may be made by affixing cover material to rigid board components as will be apparent to those skilled in the art. product.

[0059] As described in commonly-owned U.S. Patent No. 6,379,094 (the '094 patent), which is incorporated herein by reference, book covers for hardcover books are made by placing a spine and two opposing cover panels on an adhesive-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com