Method for catalytic oxidation and functional modification of hydrogel material

A catalytic oxidation and hydrogel technology, applied in fermentation and other directions, can solve the problems of protein adsorption capacity, low light permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

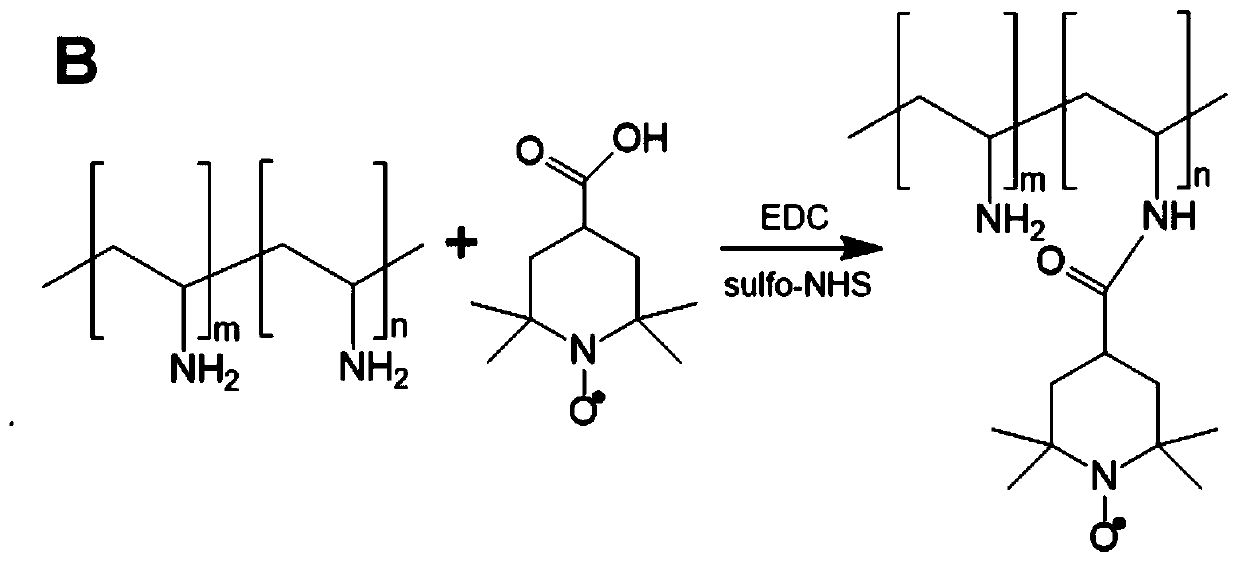

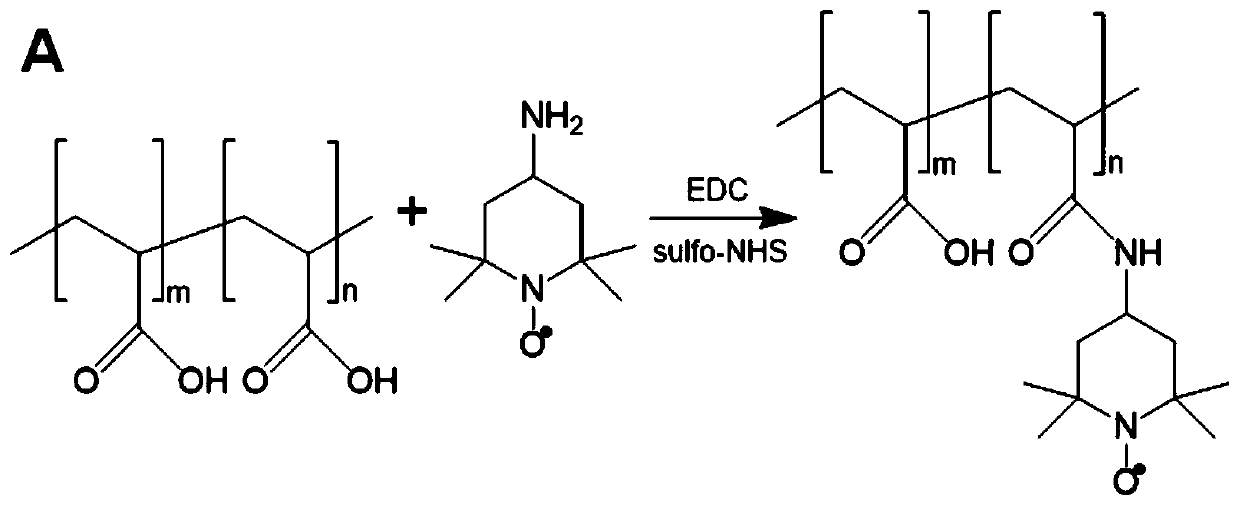

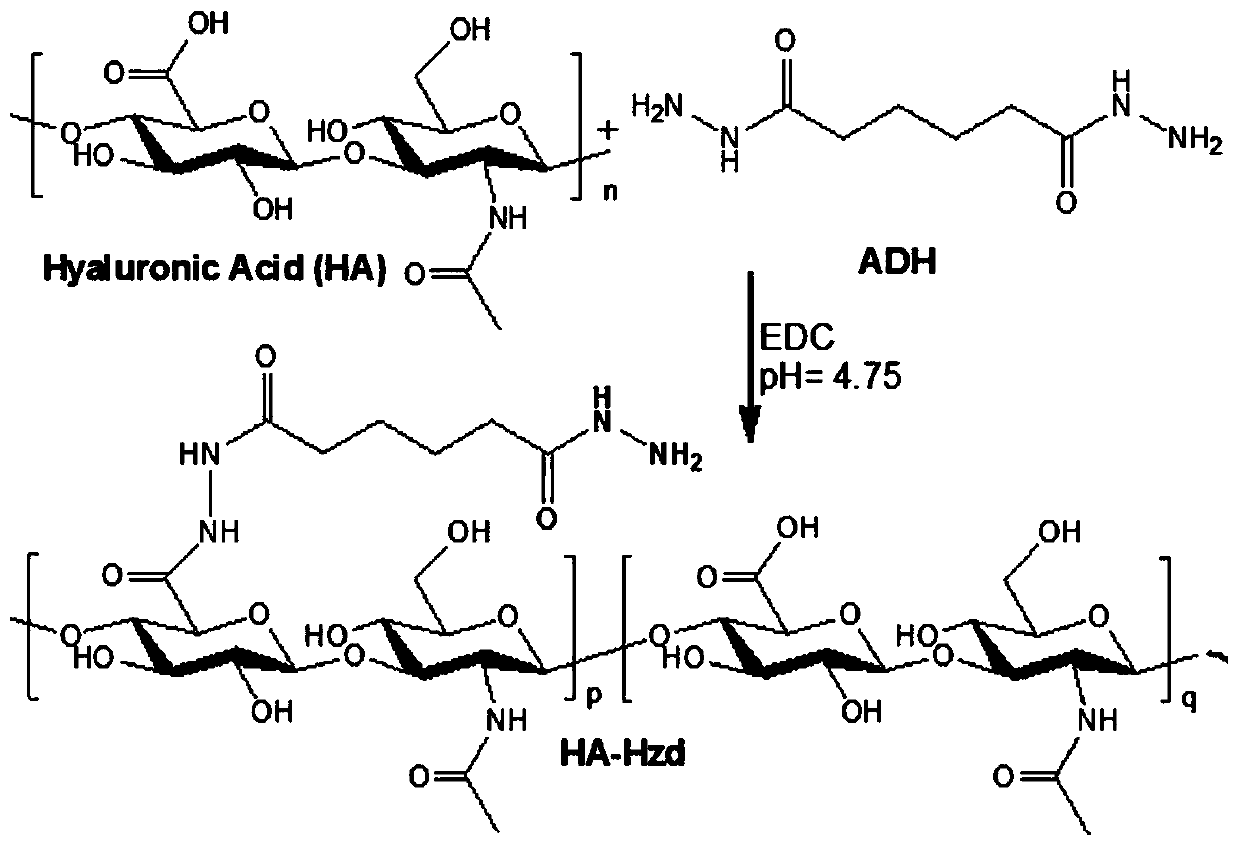

Method used

Image

Examples

Embodiment 1-1

[0057] The hydrogel material of this embodiment is a contact lens containing pHEMA (Bausch & Lomb's colorful annual disposable contact lens, purchased from Bausch & Lomb's self-operated flagship store in JD.com).

Embodiment 1-2-1

[0059] The preparation method of the hydrogel material of the present embodiment comprises the following steps:

[0060] Step 1. Mix and shake 3g hydroxyethyl methacrylate, 90mg ethylene glycol dimethacrylate and 7mg initiator until dissolved to obtain a mixture; the initiator is Irgacure184, and the mixing and shaking time is 5min; The molecular weight of the hydroxyethyl methacrylate is 130.14g / mol, product number 17348; the molecular weight of the ethylene glycol dimethacrylate is 198.22g / mol, the product number 335681; the hydroxyethyl methacrylate and Both ethylene glycol dimethacrylate was purchased from Sigma-Aldrich, and both hydroxyethyl methacrylate and ethylene glycol dimethacrylate were removed with inhibitor scavengers to remove the 4-methoxyphenol inhibitor before use , the inhibitor scavenger is purchased from Sigma-Aldrich, product number 306312; the molecular weight of the Irgacure184 is 204.26g / mol;

[0061] Step 2. Place the mixture described in step 1 in a...

Embodiment 1-2-2

[0066] The preparation method of the hydrogel material of the present embodiment comprises the following steps:

[0067] Step 1. Mix and shake 3g hydroxyethyl methacrylate, 90mg ethylene glycol dimethacrylate and 7mg initiator until dissolved to obtain a mixture; the initiator is Irgacure184, and the mixing and shaking time is 8min; The molecular weight of the hydroxyethyl methacrylate is 130.14g / mol, product number 17348; the molecular weight of the ethylene glycol dimethacrylate is 198.22g / mol, the product number 335681; the hydroxyethyl methacrylate and Both ethylene glycol dimethacrylate was purchased from Sigma-Aldrich, and both hydroxyethyl methacrylate and ethylene glycol dimethacrylate were removed with inhibitor scavengers to remove the 4-methoxyphenol inhibitor before use , the inhibitor scavenger is purchased from Sigma-Aldrich, product number 306312; the molecular weight of the Irgacure184 is 204.26g / mol;

[0068] Step 2. Place the mixture described in step 1 in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com