A kind of modified polypropylene composite fiber and preparation method thereof

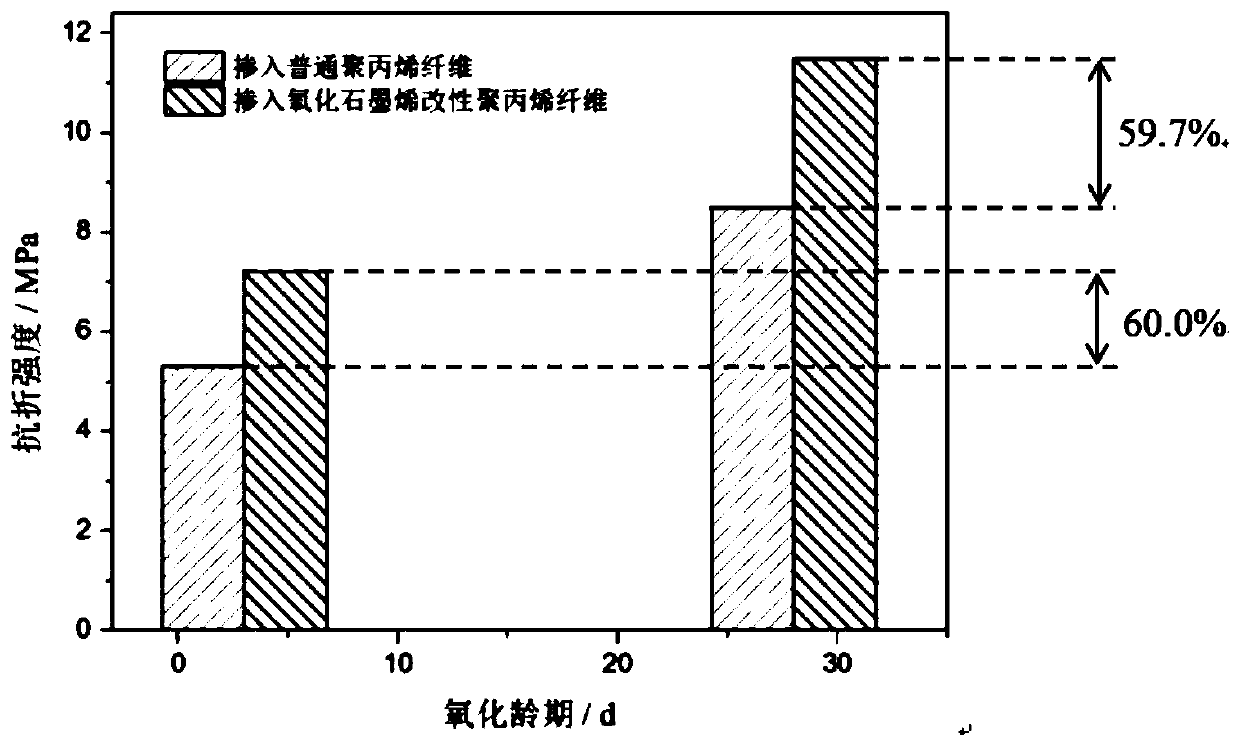

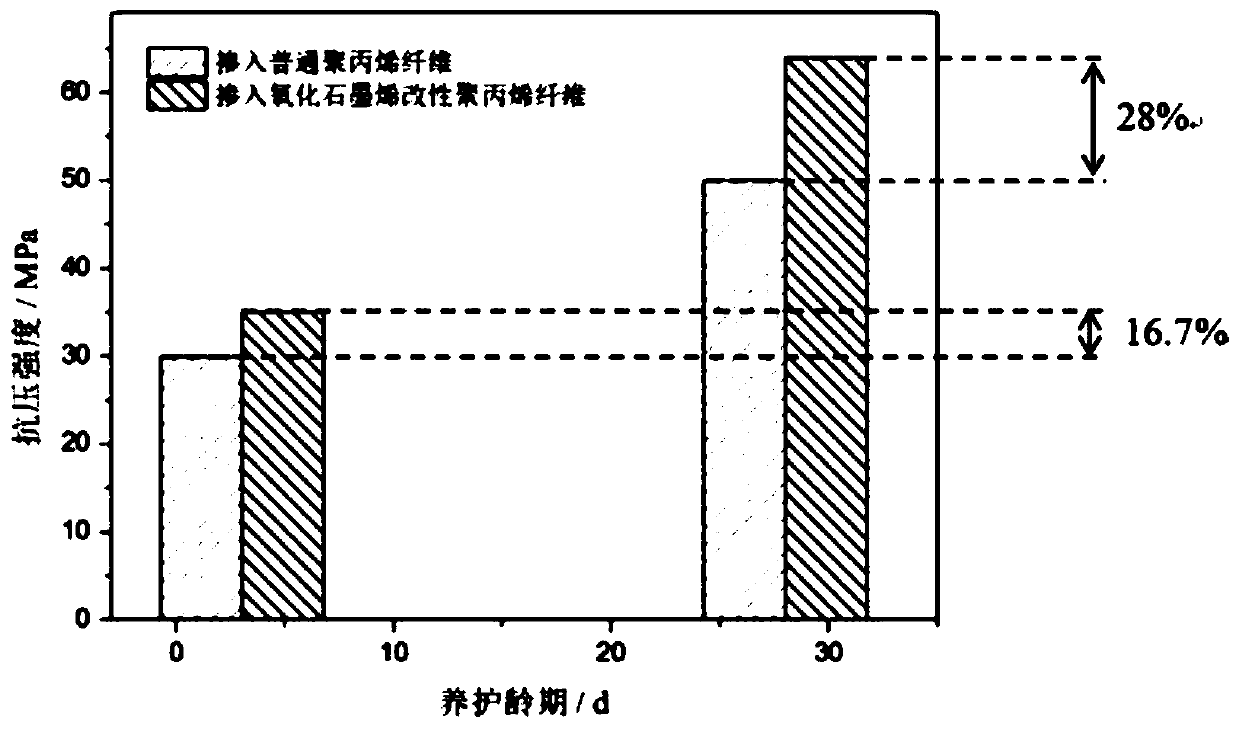

A polypropylene fiber and composite fiber technology, applied in the field of materials, can solve problems such as weak bonding ability, achieve the effects of improving bonding, improving compactness, and regulating flexural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of modified polypropylene composite fiber, comprising:

[0022] React 1-2wt% polypropylene fiber aqueous solution, diisocyanate and oxidizing agent at 50-60°C for 50-70 minutes, raise the temperature to 90-100°C and react with initiator for 1-2 hours to obtain modified polypropylene fiber.

[0023] The mixed solution of the graphene oxide aqueous solution and the modified polypropylene fiber is reacted at 50-60°C for 1-2 hours, and then washed and dried.

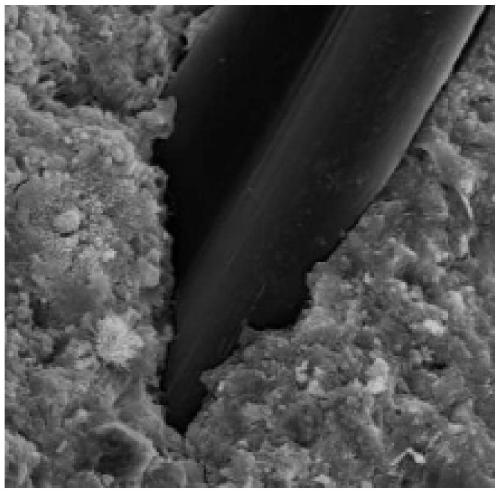

[0024] Diisocyanates and oxidants oxidize polypropylene fibers, increase the activity of polypropylene fibers, and make the carbon-oxygen double bonds of polypropylene fibers more active. Modified polypropylene fibers with highly active carbon-oxygen double bonds are more likely to combine with graphene oxide. graft.

[0025] Graphene oxide is a derivative of graphene, which has a two-dimensional structure similar to graphene. Graphene oxide has super high strength, super large specific surface ...

Embodiment 1

[0045] This embodiment provides a modified polypropylene composite fiber, which is mainly prepared through the following steps:

[0046] Add 1wt% polypropylene fiber aqueous solution, 0.004mol / L potassium permanganate aqueous solution, and diisocyanate into a three-necked flask, wherein: the quality of potassium permanganate is 1.5% of the polypropylene fiber quality; the quality of diisocyanate is 30% of polypropylene fibers. Protected by nitrogen gas, heated to 50°C in DF-1 collector type magnetic heating stirrer, after swelling for 60 minutes, quickly raised the temperature to 90°C, then added the initiator BPO, reacted for 120 minutes, cooled, filtered with suction, washed with acetone and water until After neutralization, vacuum-dry at 60°C to constant weight to obtain modified polypropylene fibers.

[0047]Get modified polypropylene fiber and 1wt% graphene oxide dispersion (the mass ratio of modified polypropylene fiber and graphene oxide dispersion is 50:1), add water ...

Embodiment 2

[0049] This embodiment provides a modified polypropylene composite fiber, which is mainly prepared through the following steps:

[0050] Add 1wt% polypropylene fiber aqueous solution, diisocyanate, and 0.002mol / L potassium permanganate aqueous solution into a three-necked flask, wherein: the quality of potassium permanganate is 1.5% of the polypropylene fiber quality; the quality of diisocyanate 50% of polypropylene fiber. Under nitrogen protection, heat to 60°C in a DF-1 collector type magnetic heating stirrer, after swelling for 60 minutes, rapidly raise the temperature to 100°C, then add the initiator BPO, and react for 120 minutes. Cool, filter with suction, wash with acetone and water until neutral, and dry in vacuum at 60°C to constant weight to obtain modified polypropylene fibers.

[0051] Get modified polypropylene fiber and 3wt% graphene oxide dispersion (the mass ratio of modified polypropylene fiber and graphene oxide dispersion is 50:3), add water to 500ml, ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com