Photographic paper coating material

A technology of coating material and photo paper, applied in the direction of photosensitive material substrate/auxiliary layer, etc., can solve the problems such as ink blurring easily, and achieve the effect of enhanced dispersion, no agglomeration, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

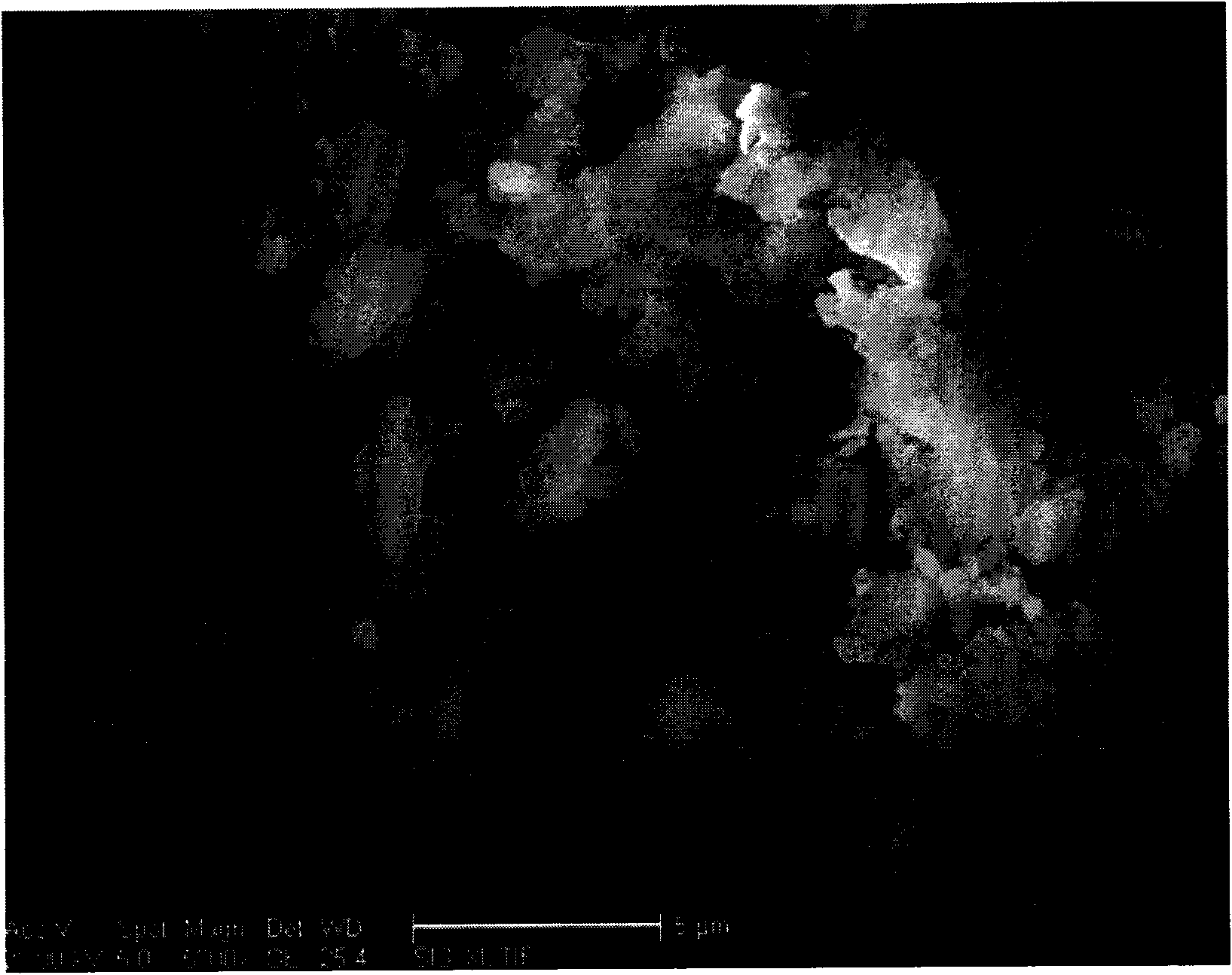

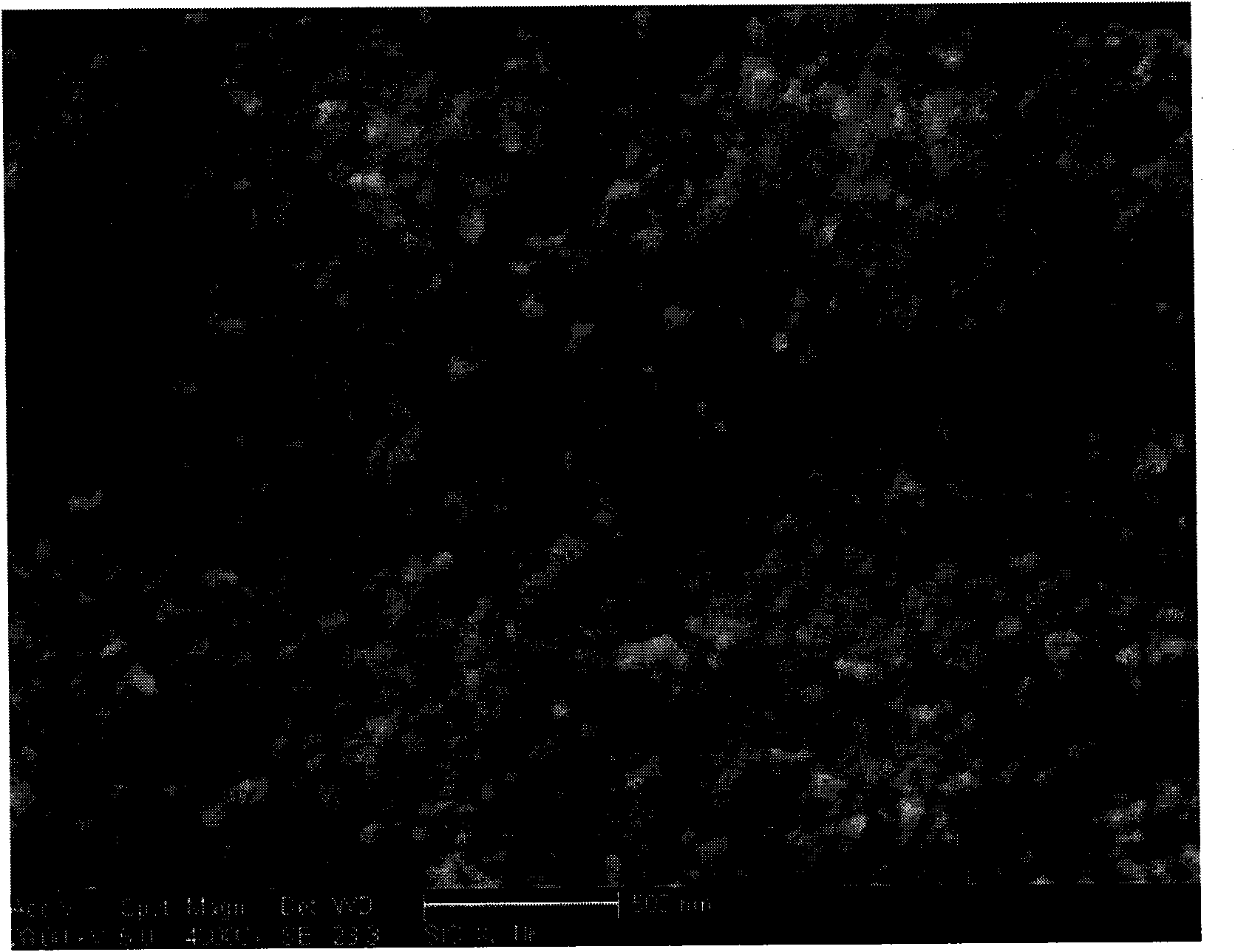

[0008] Specific embodiment 1: In this embodiment, the photo paper coating material consists of 0.5 to 10 parts by weight of polyhedral oligomeric silsesquioxane, 60 to 85 parts of polyvinyl alcohol emulsion, 0.5 to 2 parts of dispersant, 0.5 ~2 parts of water retaining agent and 0.01~0.3 parts of defoamer.

[0009] In this embodiment, the particle size of the polyhedral oligomeric silsesquioxane is 2 to 3 nm.

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the polyhedral oligosilsesquioxane is a polyhedral oligosilsesquioxane with a monofunctional cage structure, and the monofunctional group is hydrogen. , hydroxyl, chlorine, epoxy, isocyanate, amido, imide or amino. Others are the same as in the first embodiment.

[0011] The polyhedral oligomeric silsesquioxanes described in this embodiment are all produced by Bybrib plastics in the United States.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the dispersant is composed of sodium polyacrylate and sodium methylene dinaphthalene sulfonate in a mass ratio of 1:1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com