Patents

Literature

37results about How to "Good clarity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vine root health wine and preparation method thereof

InactiveCN101967439AGood clarityHigh content of active ingredientsDigestive systemAlcoholic beverage preparationChinese herbologyBiotechnology

The invention relates to the field of health wine, in particular to vine root health wine which is prepared from the following components in parts by weight: 20-50 parts of vine root base wine, 1-10 parts of traditional Chinese medicine composition, 1-5 parts of xylitol and 0.01-0.02 part of beta-cyclodextrin. The invention also relates to a preparation method of the vine root health wine, which comprises the three following steps of: preparing the vine root base wine, preparing vine root raw wine and post-treating the vine root raw wine. The vine root health wine has the efficacy of complementing the liver and the kidney, benefiting essence and blood and nourishing the heart and the spleen. The vine root health wine prepared by using the method has the advantages of excellent clarity, high content of effective ingredients and simple operation and is applicable to industrial production.

Owner:重庆康友葛根专业合作社

Instant green tea powder and preparation method thereof

The invention relates to a preparation method of instant green tea powder, relating to a plant extract and a preparation method thereof in the field of foods. The instant green tea powder is prepared through processes, i.e. spreading, de-enzyming, water extraction, filtering, extract concentration and drying, by taking fresh green tea leaves as raw materials. Microwave de-enzyming and flash extraction are characterized in that the effective components of the green tea raw materials can be extracted within shorter time at lower temperature and the chlorophylls and the tea polyphenols of a product are ensured not to be damaged, thereby the extract appears in green and also the effective components and the aromatic substances of green tea are maintained to a greater degree; in addition, the steps of high-speed centrifugation, microfiltration and membrane concentration are all operated at normal temperature, therefore colors, nutrient components and aroma are beneficial to preservation, and the quality of the product is effectively enhanced.

Owner:GUANGZHOU XIANGXUE PHARMA CO LTD

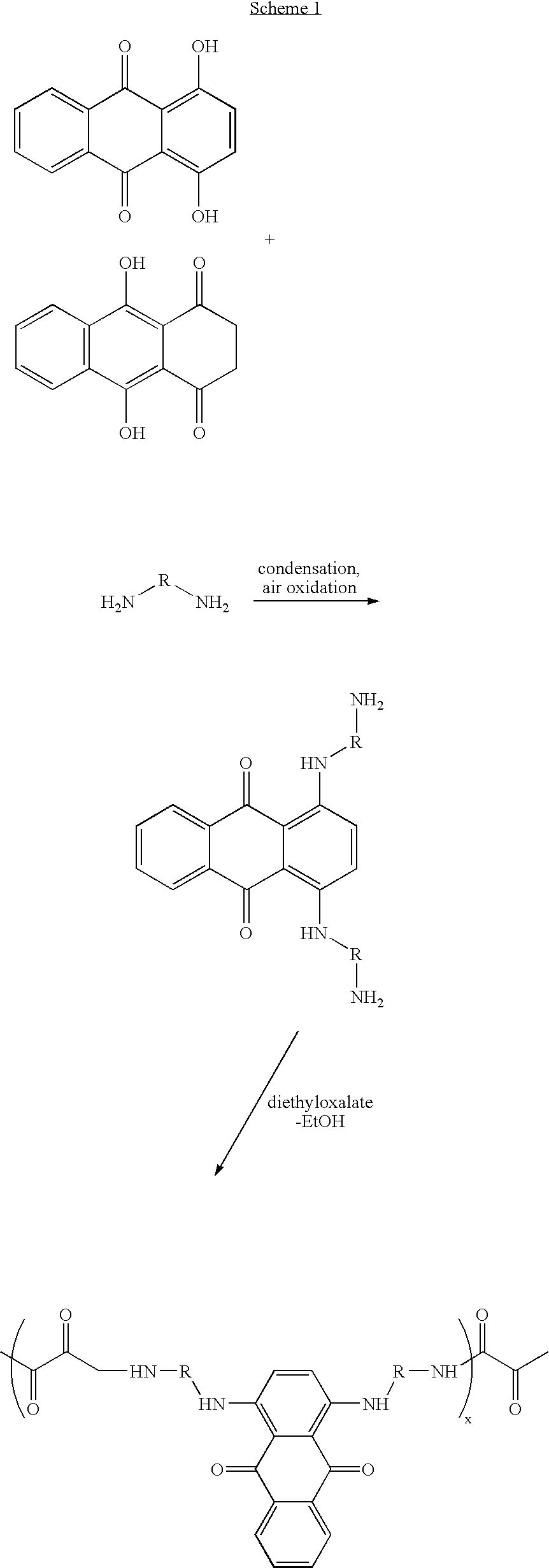

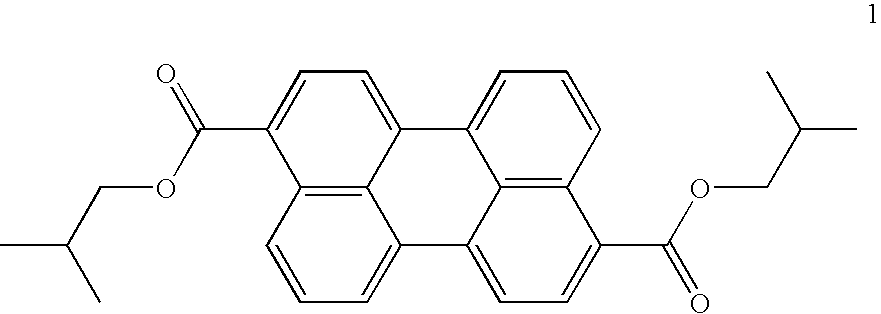

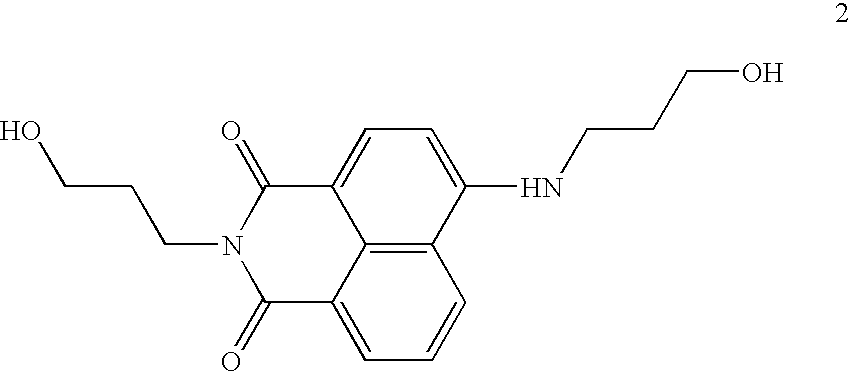

Polymeric colorants

InactiveUS20050080189A1Good clarityWithout adversely affecting clarityOrganic dyesPolymer chemistryColoring agents

A method of coloring a thermoplastic resin without substantially altering its clarity comprising the steps of first, providing a melt comprising a thermoplastic resin, second, adding one or more polymeric colorants to the melt, and third, mixing the thermoplastic resin and the polymeric colorants to form a colored thermoplastic resin having substantially the same clarity as the uncolored thermoplastic resin. Also provided are methods of imparting deep color to a thermoplastic resin without substantially altering its clarity comprising the steps of first, providing a melt comprising a thermoplastic resin, second, adding one or more polymeric colorants to the melt, wherein the amount of colorant is sufficient to impart a deep color, and third, mixing the thermoplastic resin and the polymeric colorants to form a deeply colored thermoplastic resin. Also provided are colored thermoplastic resins made by the methods of the present invention.

Owner:DAY GLO COLOR

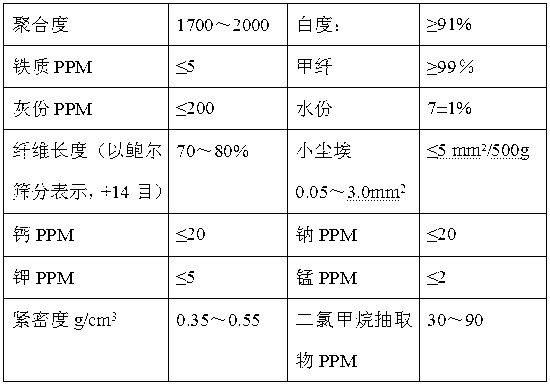

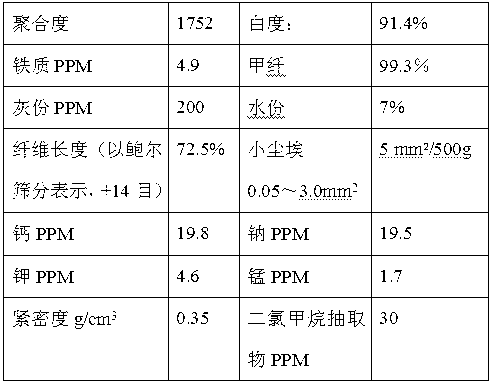

Method for producing cotton pulp used for cellulose triacetate by two-step stewing technology

ActiveCN103015253AReduce turbidityGood clarityPulping with inorganic basesNon-woody plant/crop pulpDichloromethaneChemistry

The invention discloses a method for producing cotton pulp used for cellulose triacetate by a two-step stewing technology. The method comprises the following steps of raw material selection, cotton opening, impurity removal, primary alkali blending, dipping, stewing, secondary alkali blending, dipping, stewing, pre-degritting, pre-pulping, concentration, chlorine dioxide bleaching, hydrogen peroxide bleaching, alkaline extraction, acid treatment, after degritting, after pulping, pulp processing, and finishing. The method has simple processes, utilizes cotton linter as a raw material, adopts a rotary spherical digester two-step stewing technology, carries out primary stewing of impurities in cotton linter by an alkali, hydrogen peroxide and stewing assistants having appropriate concentrations, extrudes a stewing raffinate by steam excess pressure after heat preservation, carries out secondary heat-preservation stewing by re-feeding of certain amounts of the alkali, hydrogen peroxide and the stewing assistants, realizes cotton pulp dichloromethane extract content of 30 to 90PPM, has a waste water COD discharge amount of 20250 to 25050mg / l in the whole pulping process, and reduces sewage treatment stress.

Owner:山东银鹰化纤有限公司

Ginger in vinegar oral liquid and production process

The invention discloses a ginger in vinegar oral liquid belonging to the field of oral liquid. The ginger in vinegar oral liquid consists of the following ingredients: ginger juice, purified water, white sugar, honey, sodium cyclamate, Ansai honey, table vinegar and burnt sugar coloring, wherein the ginger juice is prepared by adding water in ginger and boiling. The ginger in vinegar oral liquid protected by the invention has the effects of preventing cold, alleviating a hangover and protecting liver, and can also be used as leisure drinks.

Owner:SICHUAN LANGZHONG YUQUN AGRI PROD DEV

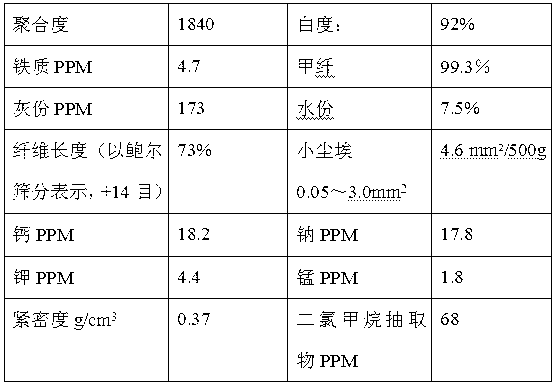

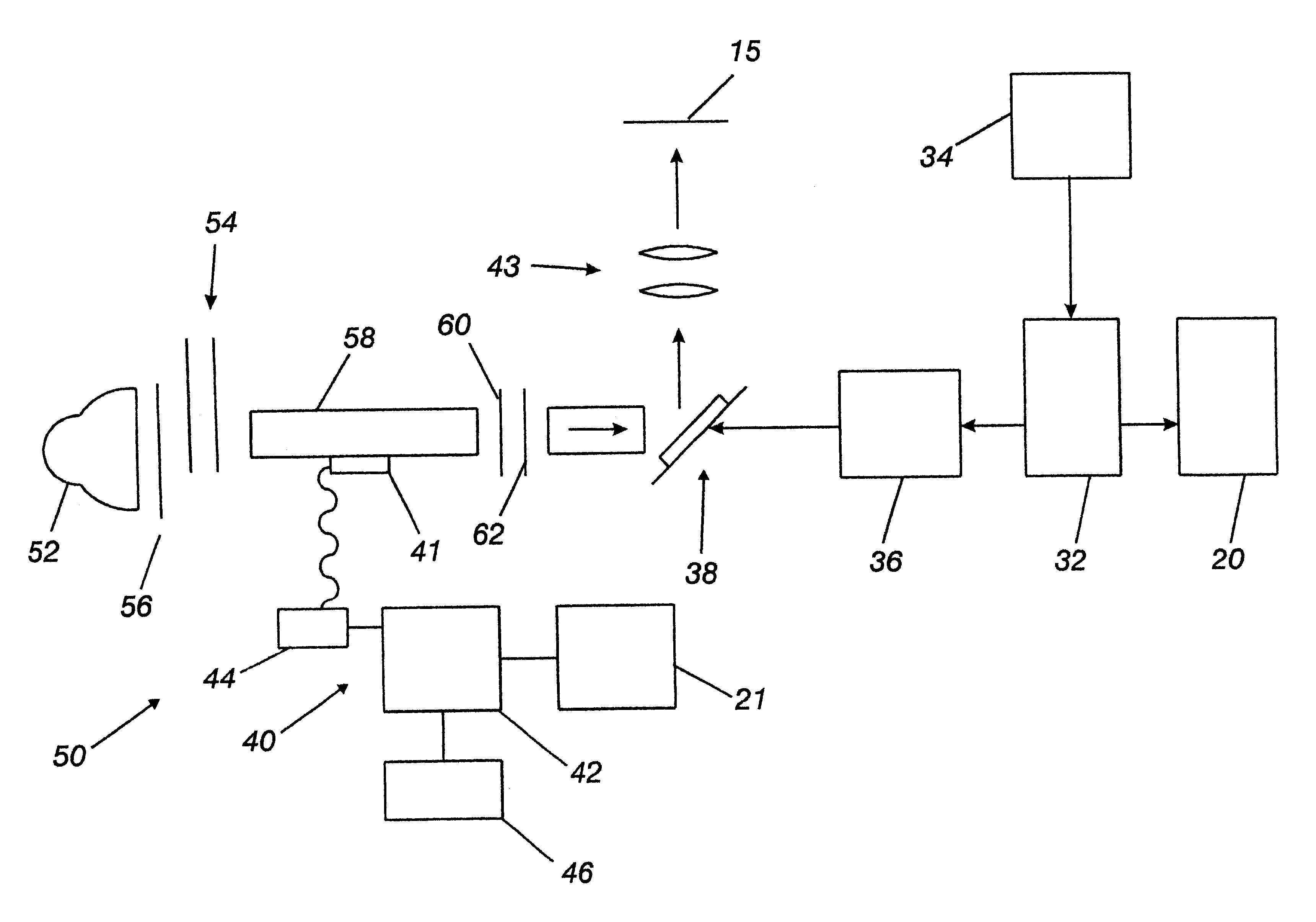

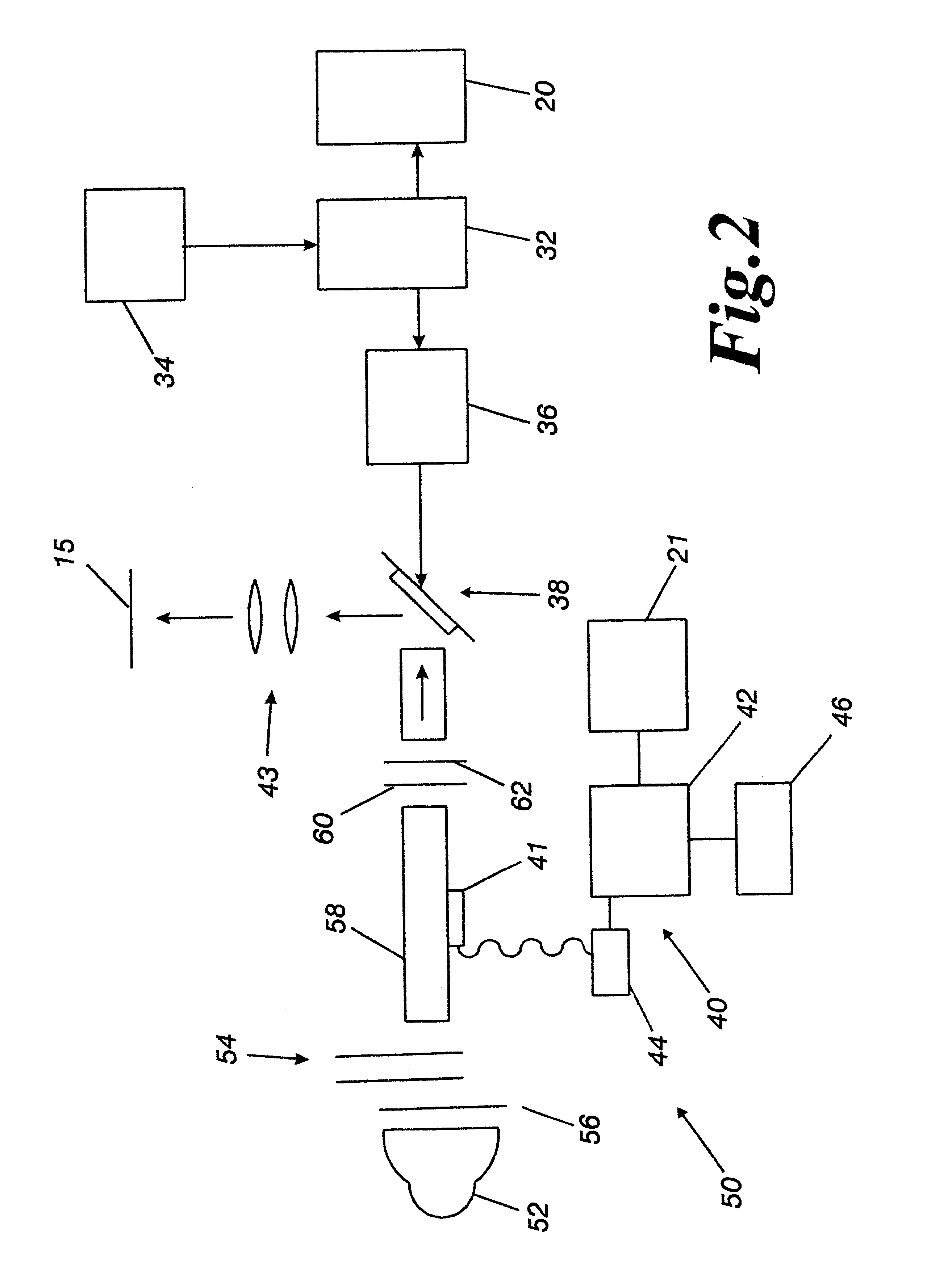

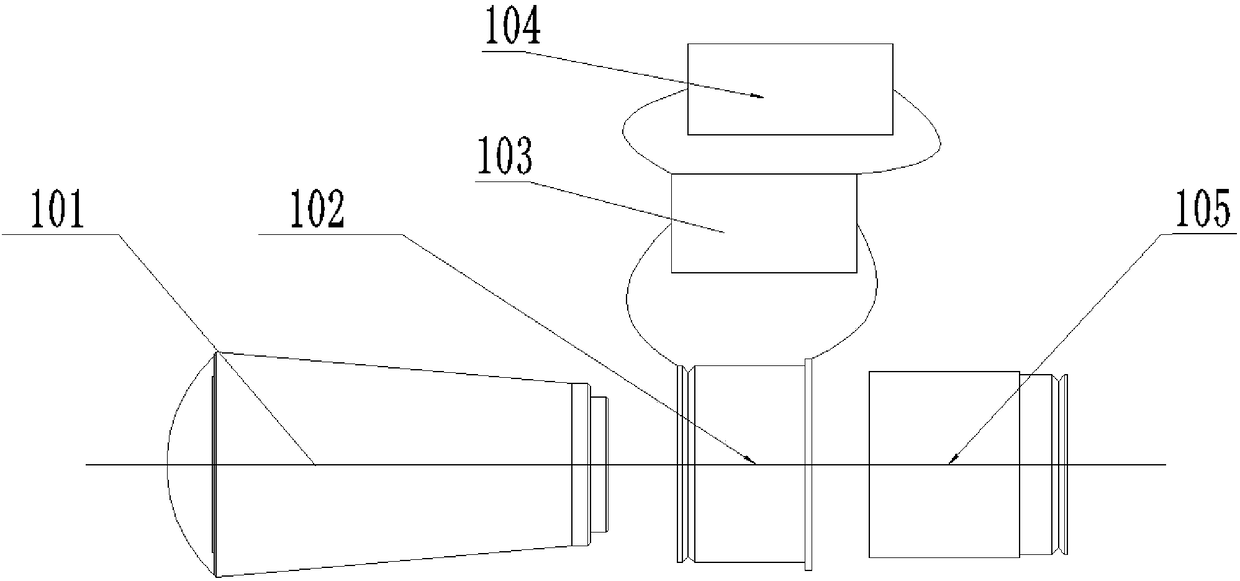

Modular removable digital image apparatus

InactiveUS6829036B1Rapidly produceGood clarityDigitally marking record carriersDigital computer detailsCamera lensPhotographic paper

A method and apparatus for creating a digital image on photographic paper and subsequent correction of color. The method and apparatus provides a digital image printer that is capable of rapidly producing digital images on photographic paper having good clarity and sharpness and correct color content. Further, the method and apparatus provides a digital image printer having a controllable lamp house that is easily removable and may be coupled with conventional photographic printers. The apparatus is a digital printer having a central processor for retrieving digital images stored on a file and for creating an inverted image of the digital images, a projecting means controller that is electrically connected to the central processor, an imaging means that is electrically connected to the projecting means controller for creating and transmitting a color corrected image, a lamp house that is positioned adjacent the imaging means for creating an optical signal and modulating the spectral content of the optical signal, a spectral content analyzer that is attached to the lamp house, a lamp house controller coupled to the lamp house, a lens system for focusing the color corrected image onto photographic paper, and a paper drive means having a supply and take-up for providing and advancing photographic paper.

Owner:ASBURY III LOUIS H

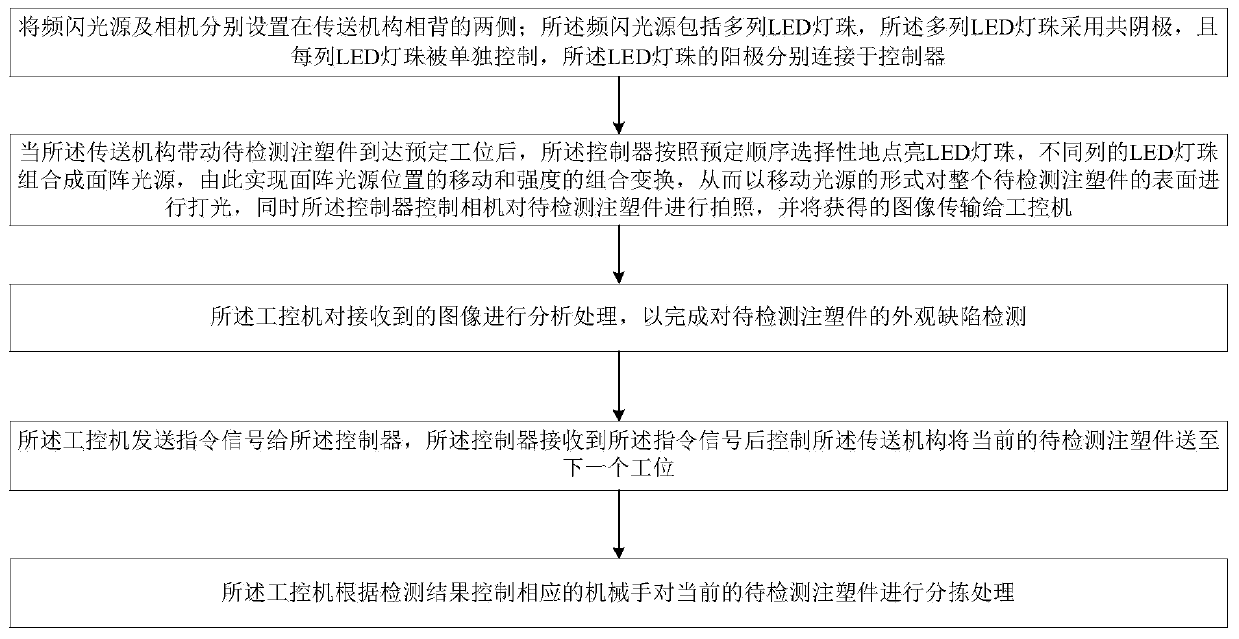

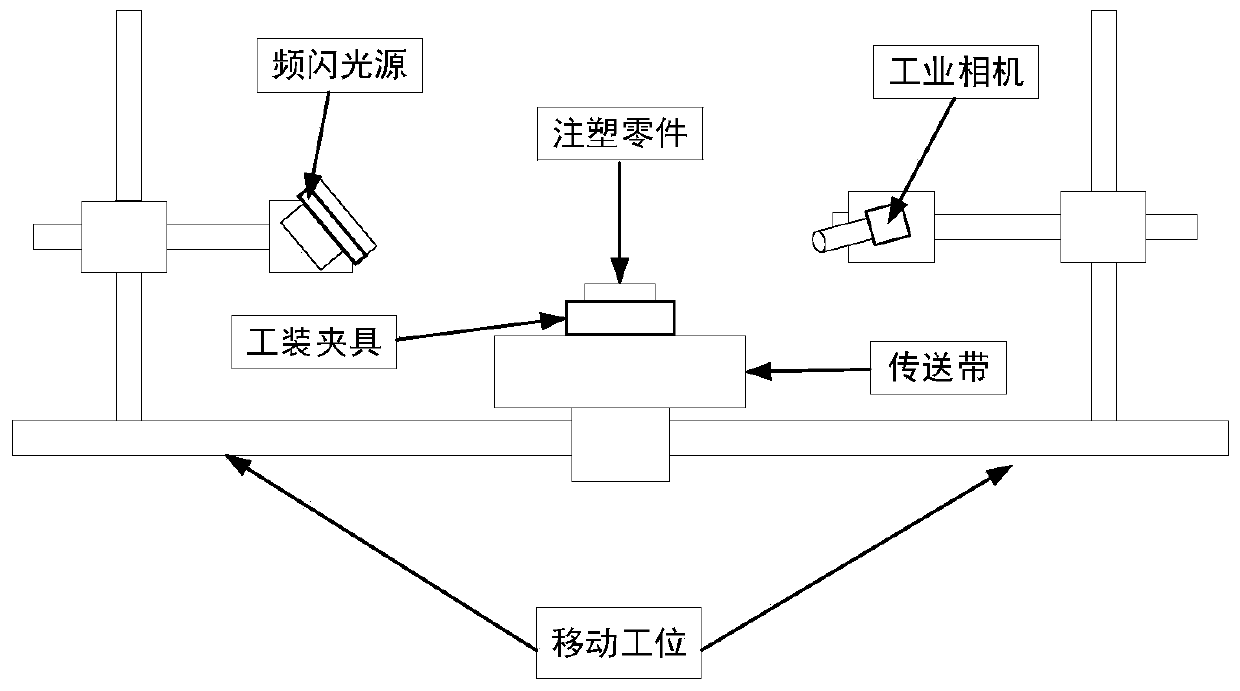

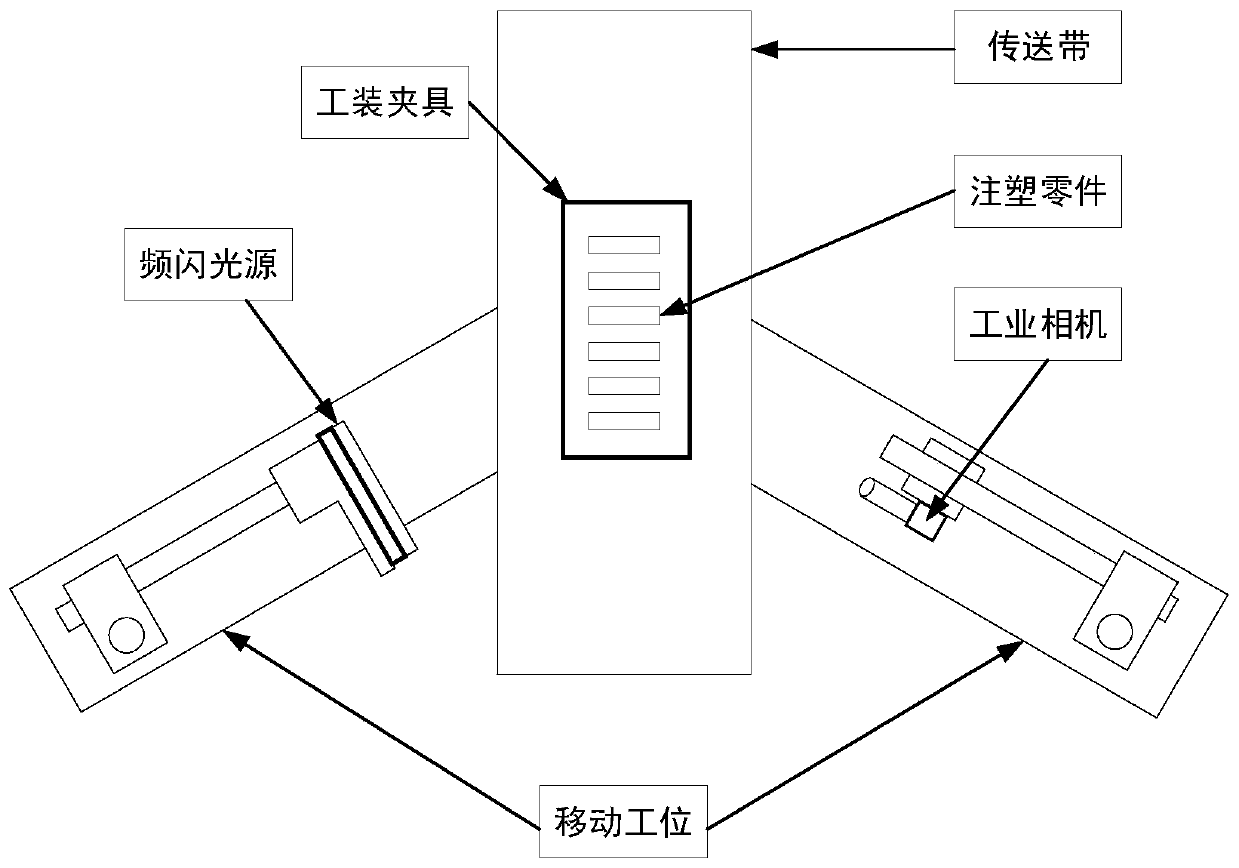

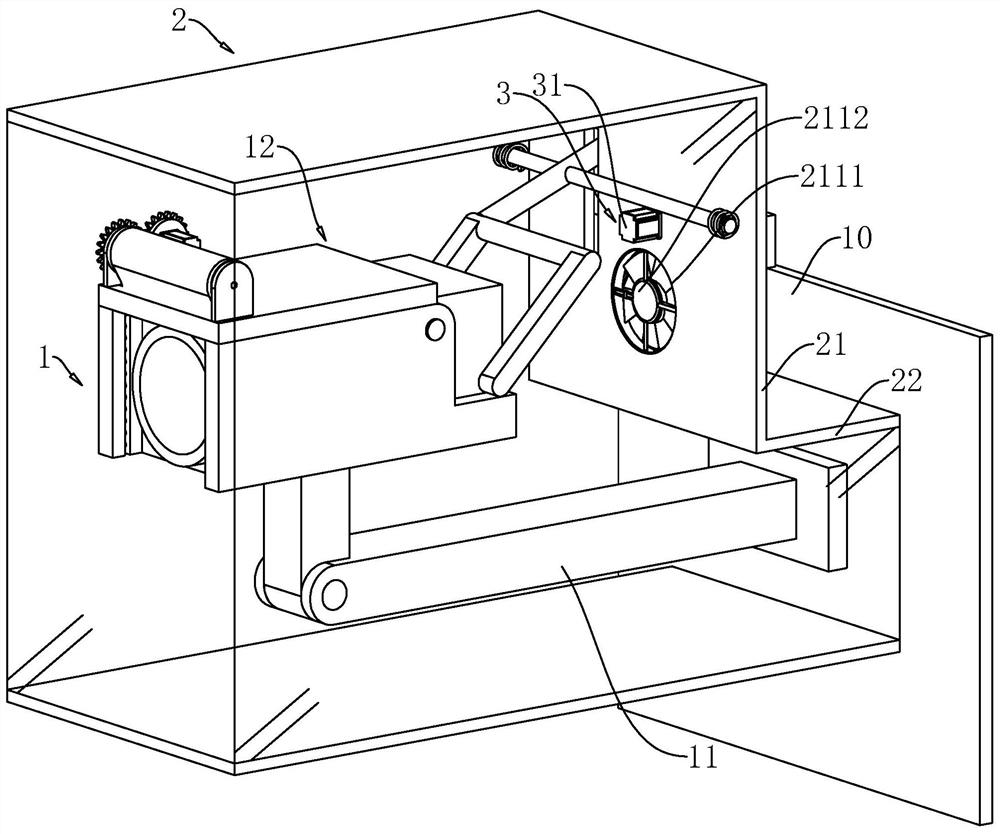

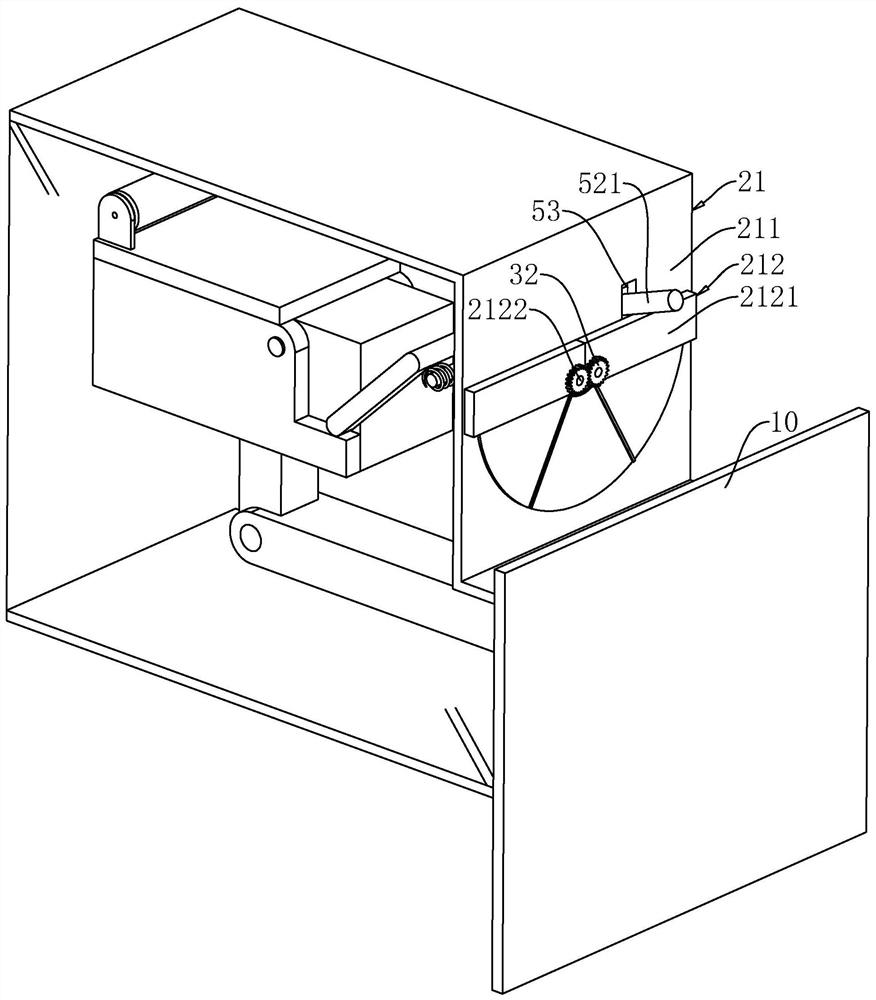

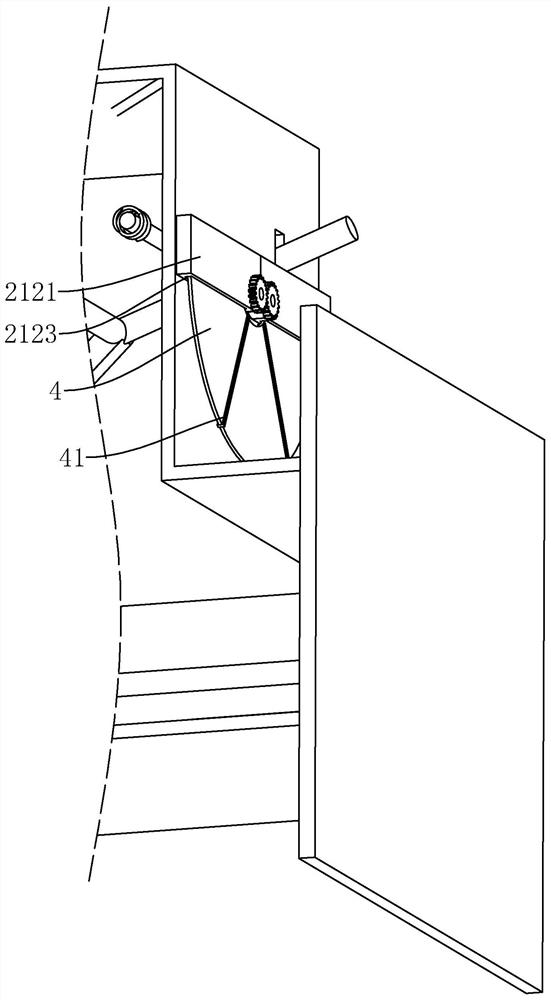

Injection molding part appearance detection method and system based on stroboscopic light source

InactiveCN110161046ASimplify the lighting schemeSave energyOptically investigating flaws/contaminationEngineeringPersonal computer

The invention belongs to the related technical field of visual detection and discloses an injection molding part appearance detection method and system based on a stroboscopic light source; the methodcomprises the following steps that (1) the stroboscopic light source and a camera are arranged on the two opposite sides of a transmission mechanism respectively; the stroboscopic light source comprises multiple rows of LED lamp beads with common cathodes, and anodes of the LED lamp beads are connected with a controller separately; and (2) when the to-be-detected injection molding part reaches apreset station, the controller selectively turns on the corresponding LED lamp beads, and the different columns of lamp beads are combined into a surface array light source, so that the combination conversion of the movement and intensity of the surface array light source positions is realized, the whole to-be-tested injection molding part is polished in the form of a mobile light source; meanwhile, the controller controls the camera to carry out photographing on the to-be-detected injection molding part, and transmits the obtained image to an industrial personal computer; and (3) the industrial personal computer analyzes and processes the received image so as to detect the appearance defect of the injection molding part to be detected. According to the method, the cost is lowered, and theflexibility and applicability are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Nanoparticulate solar control compositions

ActiveUS20100098953A1High strengthGood claritySynthetic resin layered productsVehicle componentsAntimony tin oxideAntimony oxide

Provided are compositions comprising infrared absorptive inorganic nanoparticles and an ethylene copolymer, and methods to produce the compositions. The infrared absorptive inorganic nanoparticles preferably include antimony tin oxide (ATO), indium tin oxide (ITO), lanthanum hexaboride (LaB6), or mixtures thereof. Also provided are polymer blends, polymeric films and sheets, solar control laminates, and processes to produce the polymer blends, polymeric films and sheets and solar control laminates.

Owner:KURARAY EURO GMBH

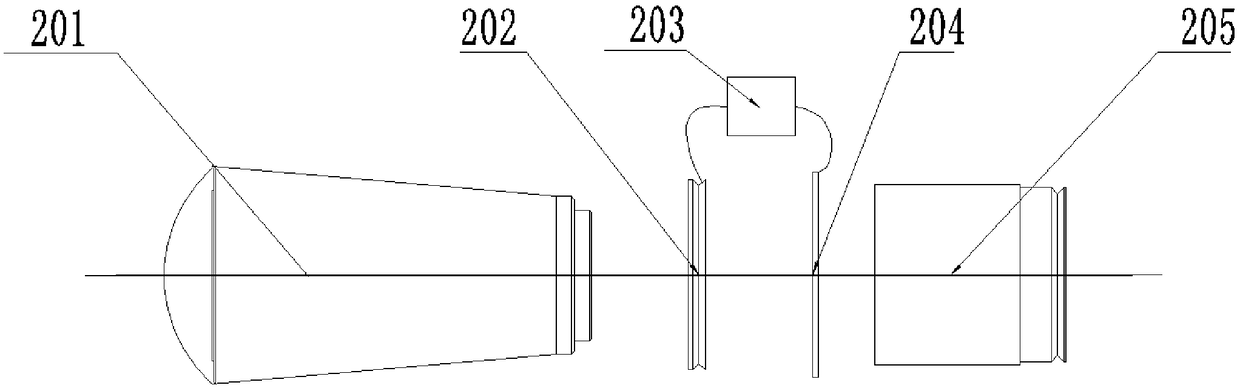

Low-light night vision imaging structure based on RGB-IR imaging chip and application thereof

The invention relates to a low-light night vision imaging structure based on an RGB-IR imaging chip and application thereof. The structure comprises a shell, an objective lens, the RGB-IR imaging chip, an image processor, a display screen and an eyepiece, wherein the objective lens, the RGB-IR imaging chip, the image processor, the display screen and the eyepiece are mounted on the shell separately; the RGB-IR imaging chip is disposed in the light emitting direction of the objective lens and located on the same optical axis as the objective lens; the objective lens is a visible and near-infrared confocal lens, and each lens of the objective lens is plated with a visible and near-infrared broadband anti-reflection film; an RGB output end and an IR output end of the RGB-IR imaging chip are both electrically connected to the image processor for simultaneously transmitting an RGB image signal and an IR infrared black-and-white image signal to the image processor; the image processor renders color information in an RGB image into an IR black-and-white image to obtain a composite image; the image processor is electrically connected with the display screen to transmit the resulting composite image to the display screen for display; a display surface of the display screen is arranged in the light incidence direction of the eyepiece and located on the same optical axis as the eyepiece.

Owner:黄心铭

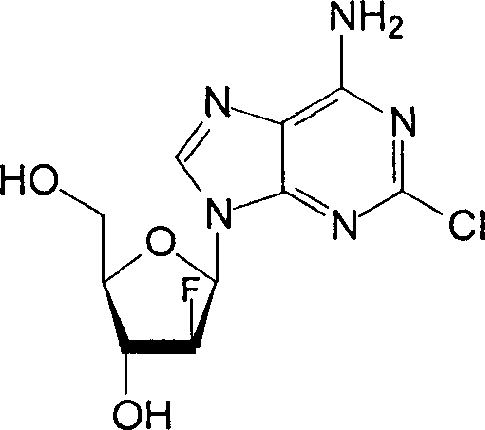

Injectable clofarabine composition

The invention belongs to the field of pharmaceutical preparation, more specifically, the invention relates to a clofarabine composition for injection, which contains clofarabine and pharmaceutically acceptable acids. The composition has good water-solubility, and can be prepared into liquid preparation or freeze-dried preparation.

Owner:吴葆金

Rosa roxburghii tratt powder rich in vitamin C and preparation method thereof

ActiveCN111700247AReduce the degradation of VCGood clarityNervous disorderMetabolism disorderSaccharomyces cerevisiaeMolecular biology

The invention discloses rosa roxburghii tratt powder rich in vitamin C and a preparation method thereof. The preparation method comprises the following steps: (1) pre-treating rosa roxburghii tratt toobtain rosa roxburghii tratt juice or concentrated juice; (2) fermenting the rosa roxburghii tratt juice by using saccharomyces cerevisiae; (3) sequentially filtering by using filter cloth and a nanofilter element ceramic membrane; (4) performing vacuum concentration treatment; and (5) drying. According to the preparation method disclosed by the invention, the saccharomyces cerevisiae is added in the preparation process of the rosa roxburghii tratt powder, and carbohydrates in the feed liquid are effectively reduced through the fermentation effect of the saccharomyces cerevisiae, so that theproportion of the vitamin C in the material is increased, and the content of the vitamin C in the rosa roxburghii tratt powder disclosed by the invention reaches 17% or above. According to the preparation method disclosed by the invention, SOD is effectively enriched, and the content can reach 10-15,000U / g; the yeast and other impurities are filtered by the ceramic membrane, high-temperature treatment is avoided, and degradation of VC is reduced; and the rosa roxburghii tratt powder prepared by the preparation method disclosed by the invention is good in fluidity, effectively inhibits the caking problem, and can be applied to industrial production.

Owner:广东青云山药业有限公司

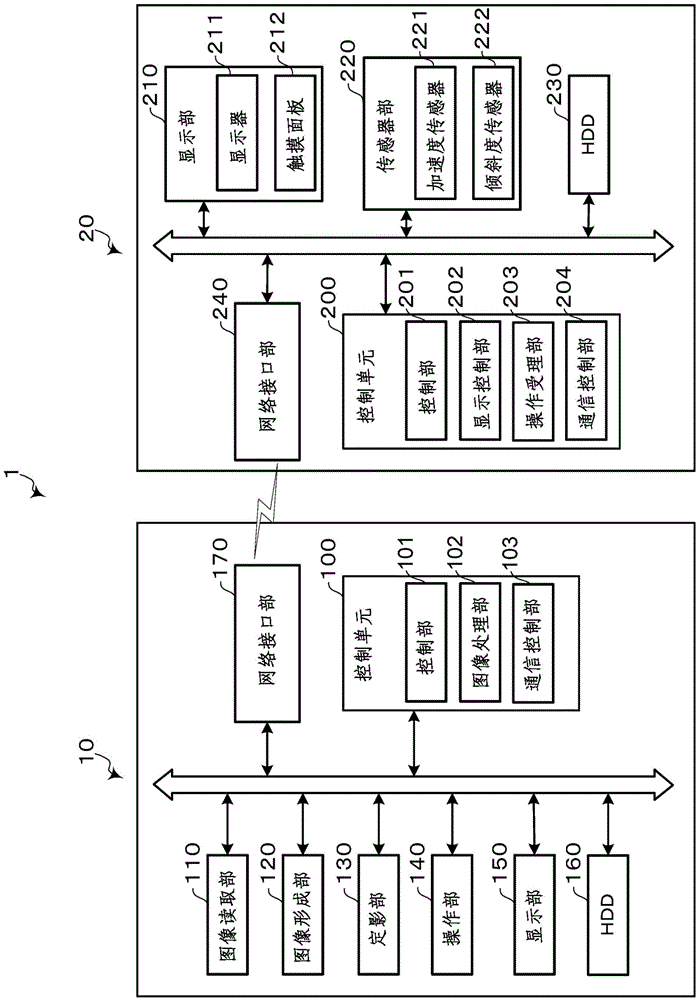

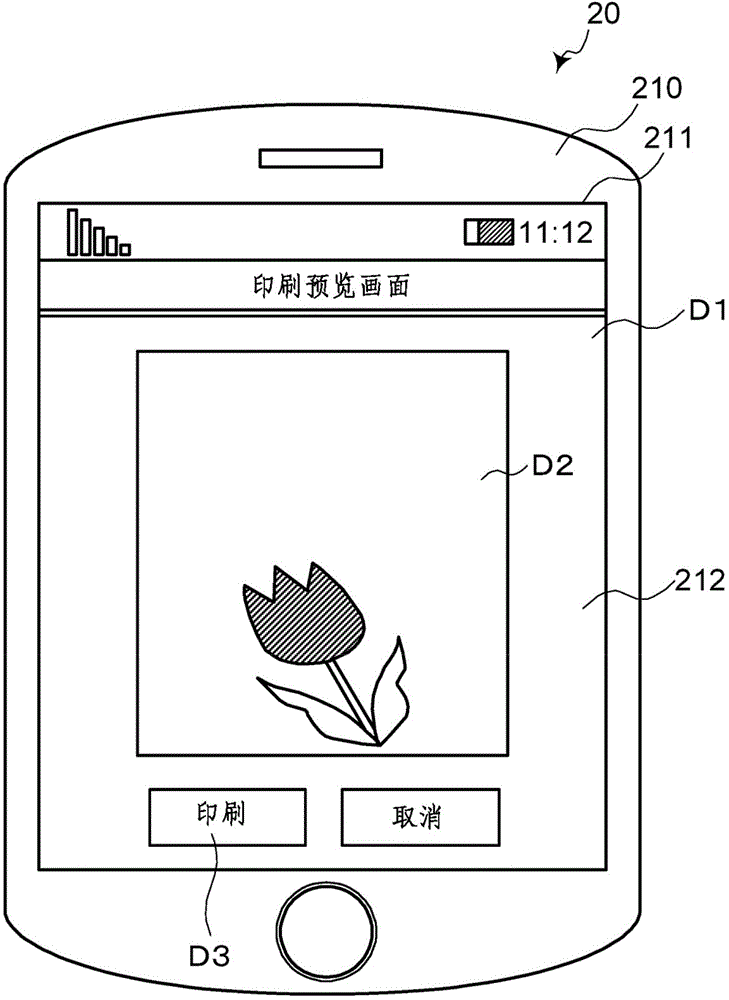

Image processing apparatus, image forming apparatus, mobile terminal apparatus, and image processing system

InactiveCN104811571ASuppress manufacturing costGood clarityInput/output processes for data processingPictoral communicationComputer graphics (images)Imaging processing

An image processing apparatus includes an image reading portion, a storage apparatus, a transmitting portion, a receiving portion, and an image processing portion. The transmitting portion transmits an image read by the image reading portion to an external mobile terminal apparatus as a display destination of the image. The receiving portion receives a movement amount and rotation amount of the image which the mobile terminal apparatus decides based on a user operation. The image processing portion applies, to the image, a movement process in accordance with the movement amount received by the receiving portion and a rotation process in accordance with the rotation amount received by the receiving portion, and makes the storage apparatus store the image after the processing.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Polymeric compositions and films formed therefrom

A polymeric composition which includes a styrene polymer, at least one unsaturated block copolymer having a high monoalkenyl arene content, a modulus less than 100,000 psi, and comprising at least one A block and at least one B block, each A block independently selected from mono alkenyl arene polymer blocks and each B block independently selected from polymer blocks having at least one conjugated diene and at least one mono alkenyl arene and having a controlled distribution. A second polymeric composition which includes a styrene polymer, at least one unsaturated block copolymer as defined hereinbefore; and at least one additional unsaturated block copolymer having a moderate monoalkenyl arene content. The polymeric composition can be used to produce films that have improved impact resistance that can be thermoformed.

Owner:KRATON POLYMERS US LLC

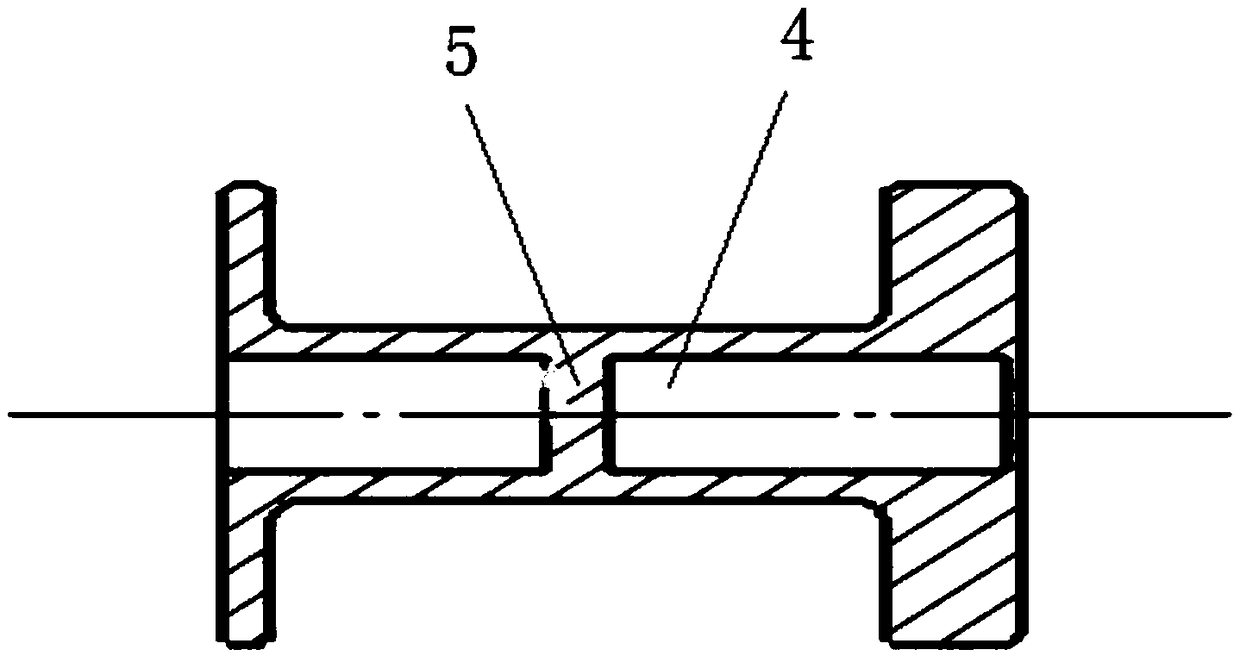

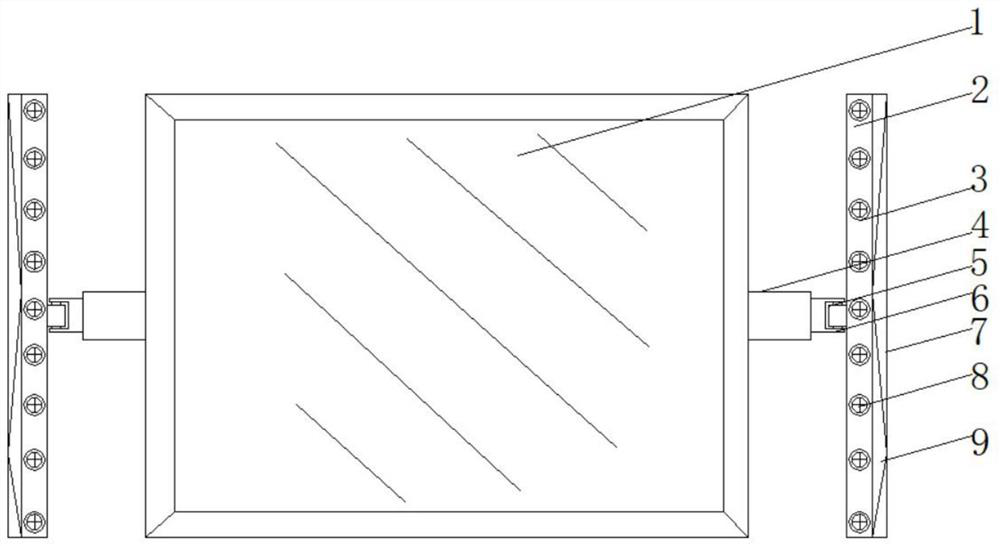

Sleeve tube for arthroscope

PendingCN108938102AEnsure surgical safetyGood clarityDiagnosticsSurgerySurgical instrumentEngineering

The invention discloses a sleeve tube for an arthroscope. The sleeve tube is used for the approaching protection of the arthroscope. The sleeve tube comprises an approaching end, a tube body and an outer end which are sequentially connected, a sealing passage is formed in the part between the tube body and the outer end, the approaching end and the outer end both extend towards the outer side of the tube body to form a flange structure with low flanges on both inner and outer sides, the approaching end and the outer end are embedded in both inner and outer layers of soft tissues respectively to fix the tube body in a soft tissue incision, and therefore a safe and stable entrance and exit for subsequent surgical instruments.

Owner:上海利格泰医用设备有限公司

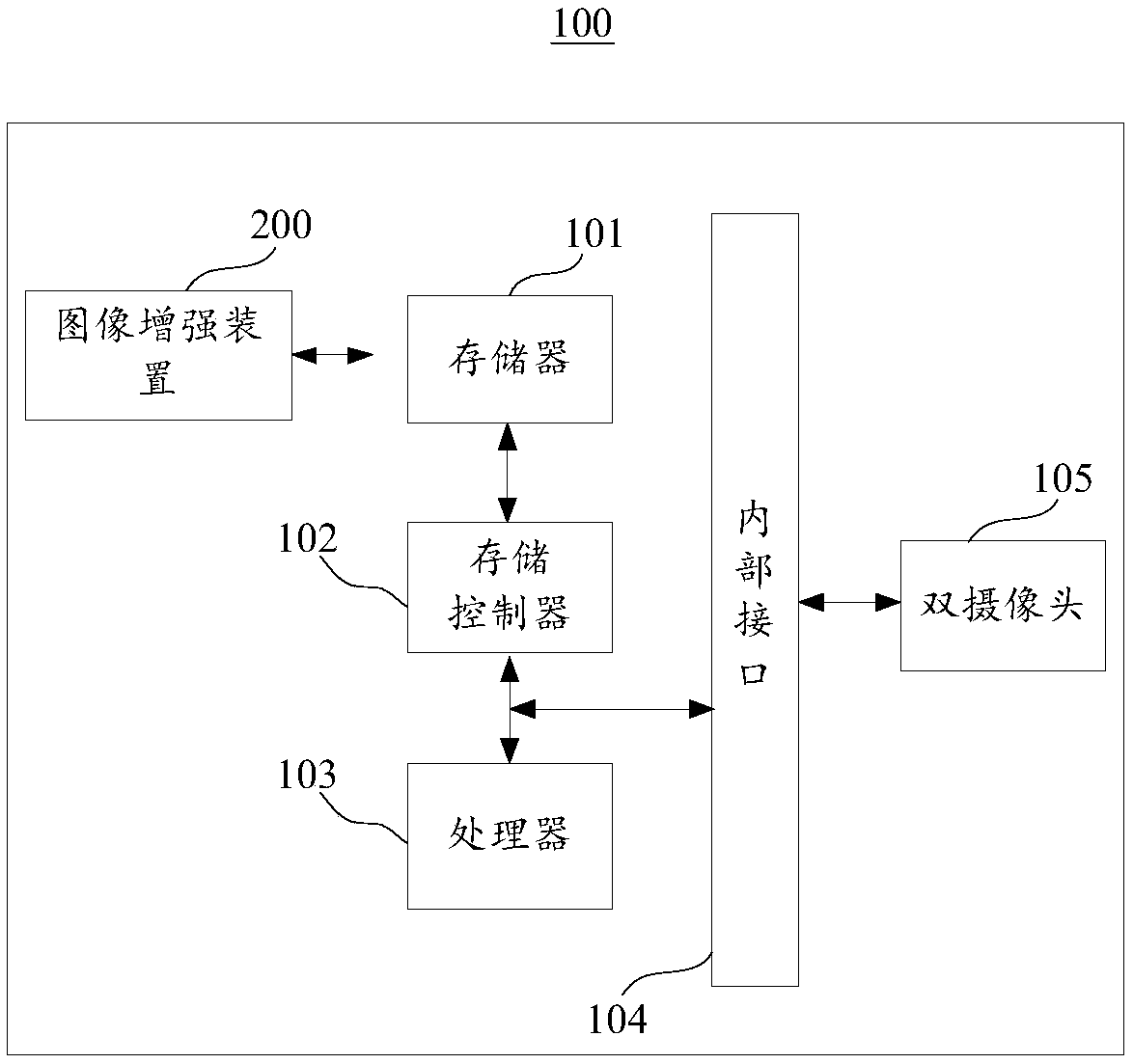

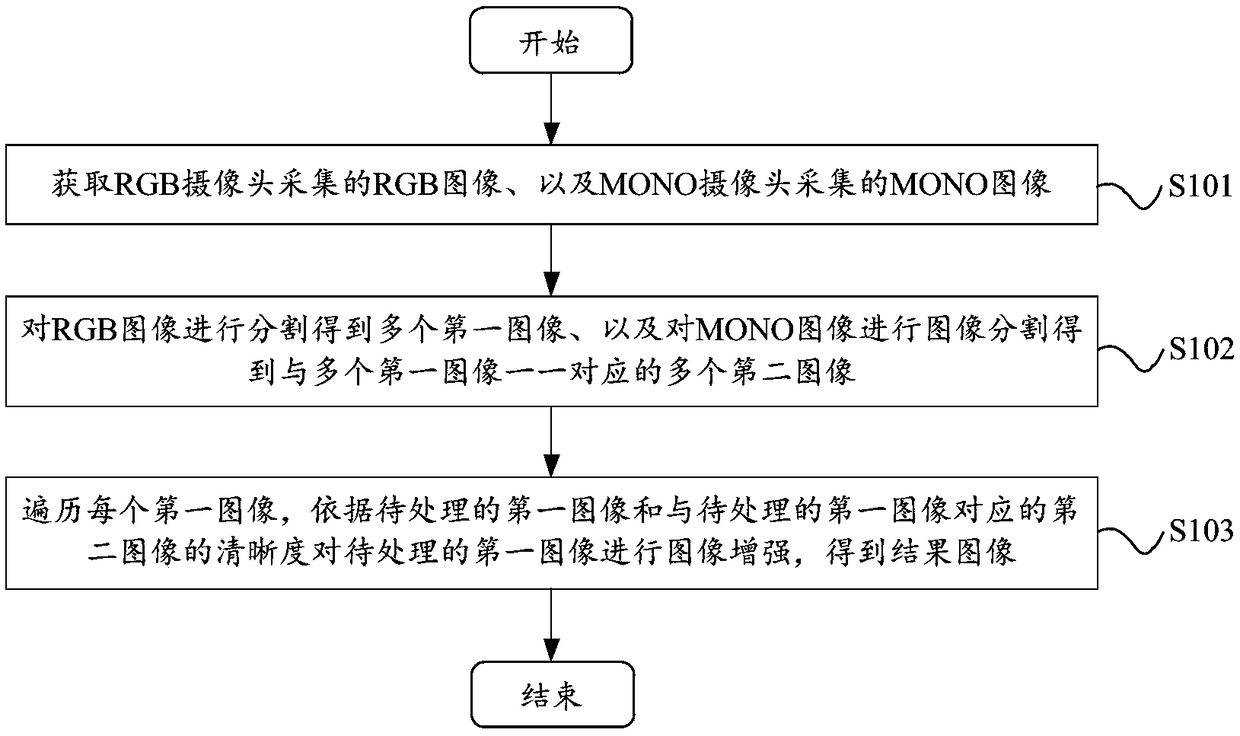

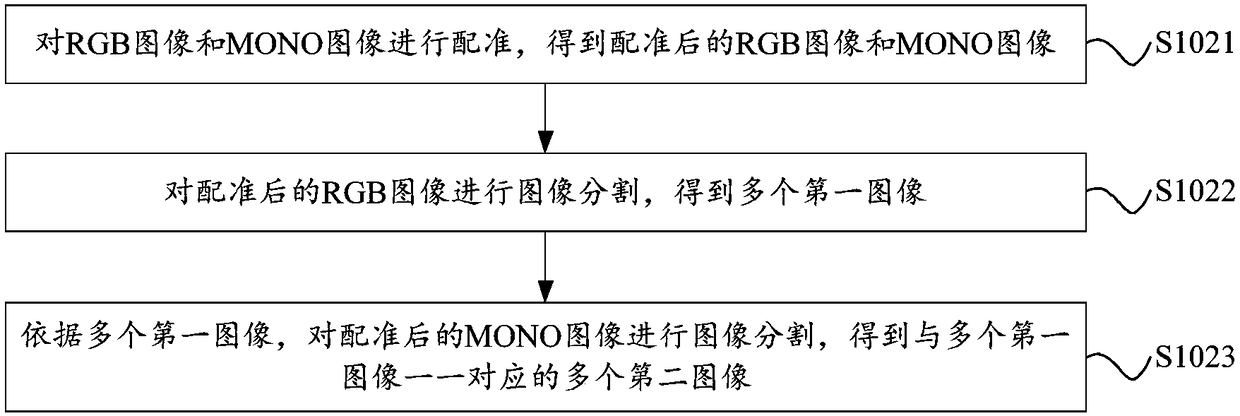

Image enhancement method and device, electronic device and storage medium

ActiveCN108470327ABeautiful imageGood clarityImage enhancementImage analysisImage segmentationImage enhancement

The embodiment of the invention relates to the technical field of image processing and provides an image enhancement method and device, an electronic device and a storage medium. The method comprisessteps of acquiring an RGB image acquired by an RGB camera, and an MONO image acquired by an MONO camera; segmenting the RGB image so as to acquire multiple first images and carrying out image segmentation on the MONO image so as to obtain multiple second images corresponding to the first images; and traversing each first image and according to the definition of the to-be-processed first images andthe definition of the second images corresponding to the to-be-processed first images, carrying out image enhancement on the to-be-processed first images so as to obtain result images. Compared withthe prior art, according to the embodiment, color channels in the RGB image are processed as a whole, so the result images will not suffer from color cast and the images are attractive and are provided with high definition.

Owner:CHENGDU CK TECH

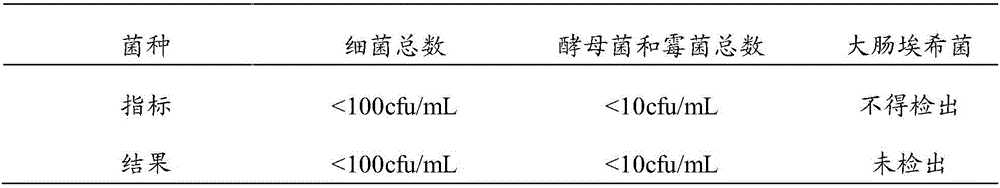

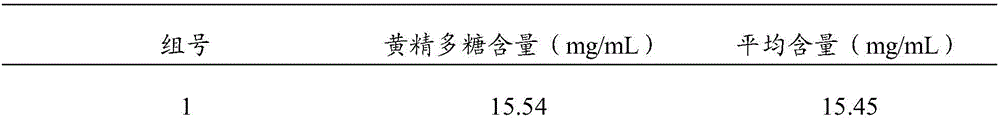

Polygahatous polysaccharide oral liquid and preparing method thereof

InactiveCN106491525AGood clarityStable contentOrganic active ingredientsMetabolism disorderChemistryStabilizing Agents

The invention discloses a polygahatous polysaccharide oral liquid. The polygahatous polysaccharide oral liquid is prepared from, by mass, 0.5%-4% of polygahatous polysaccharides, 0.1%-0.3% of a preservative, 0.1%-0.25% of a stabilizing agent and the balance water. The pH value of the polygahatous polysaccharide oral liquid is 5.5 to 6.5. The invention also discloses a preparing method of the polygahatous polysaccharide oral liquid, the polygahatous polysaccharide oral liquid prepared with the method is good in clarity degree, the muddy phenomenon does not appear, the content is stable, microorganism limit check also meets the pharmacopeia standards, and the polygahatous polysaccharide oral liquid has the promoting effect on the growing performance and the immunologic function of quails.

Owner:SICHUAN AGRI UNIV +1

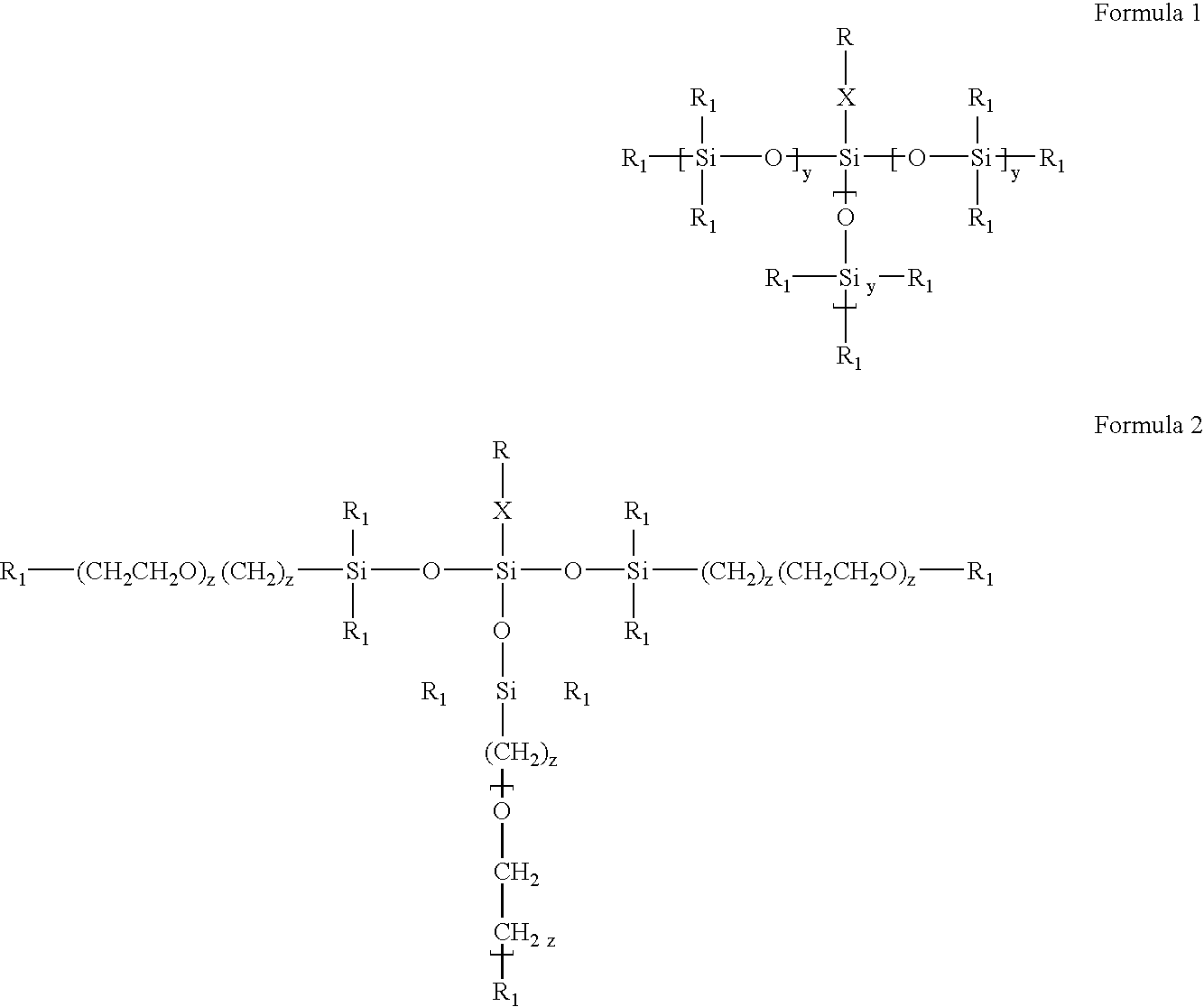

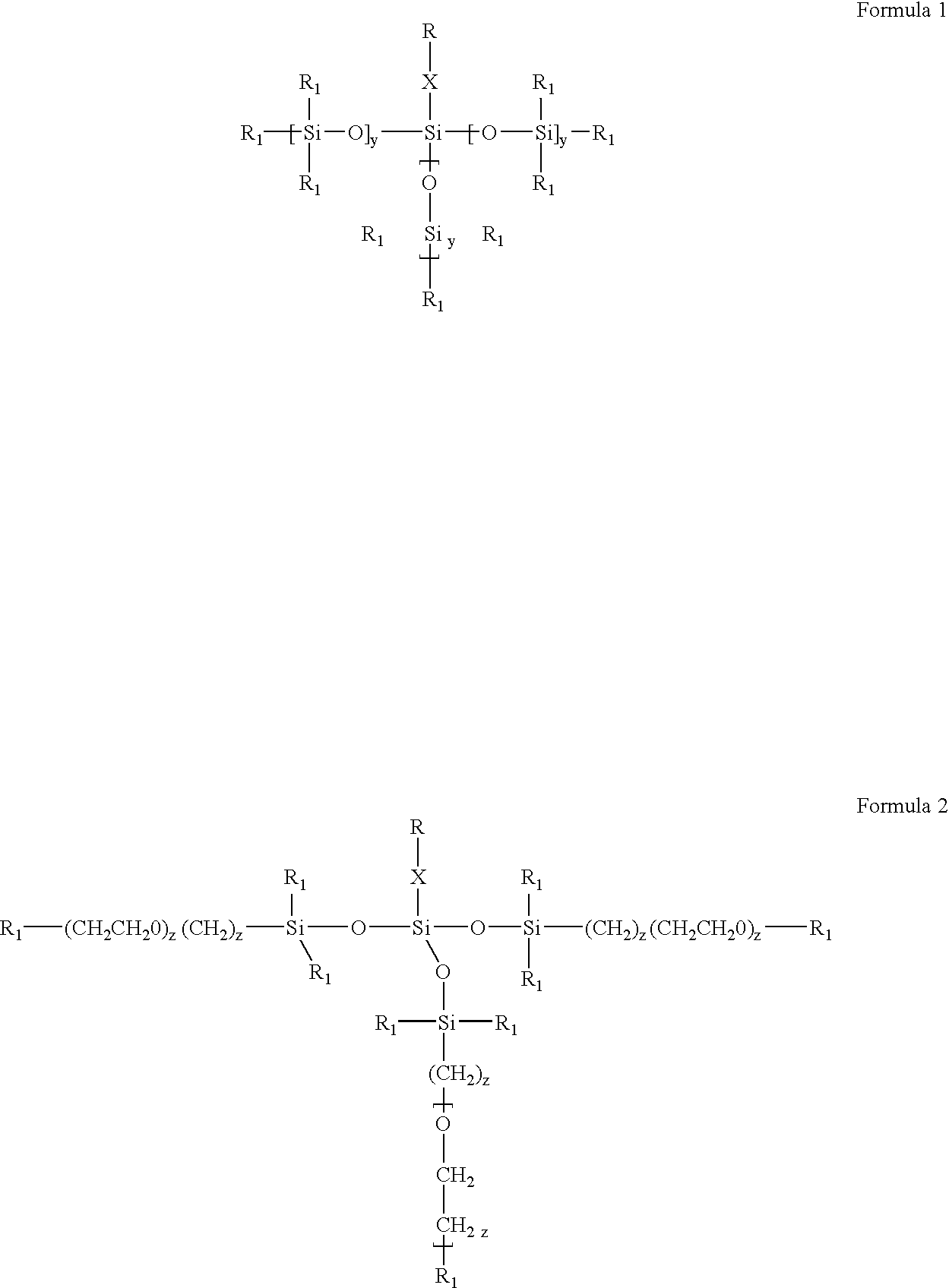

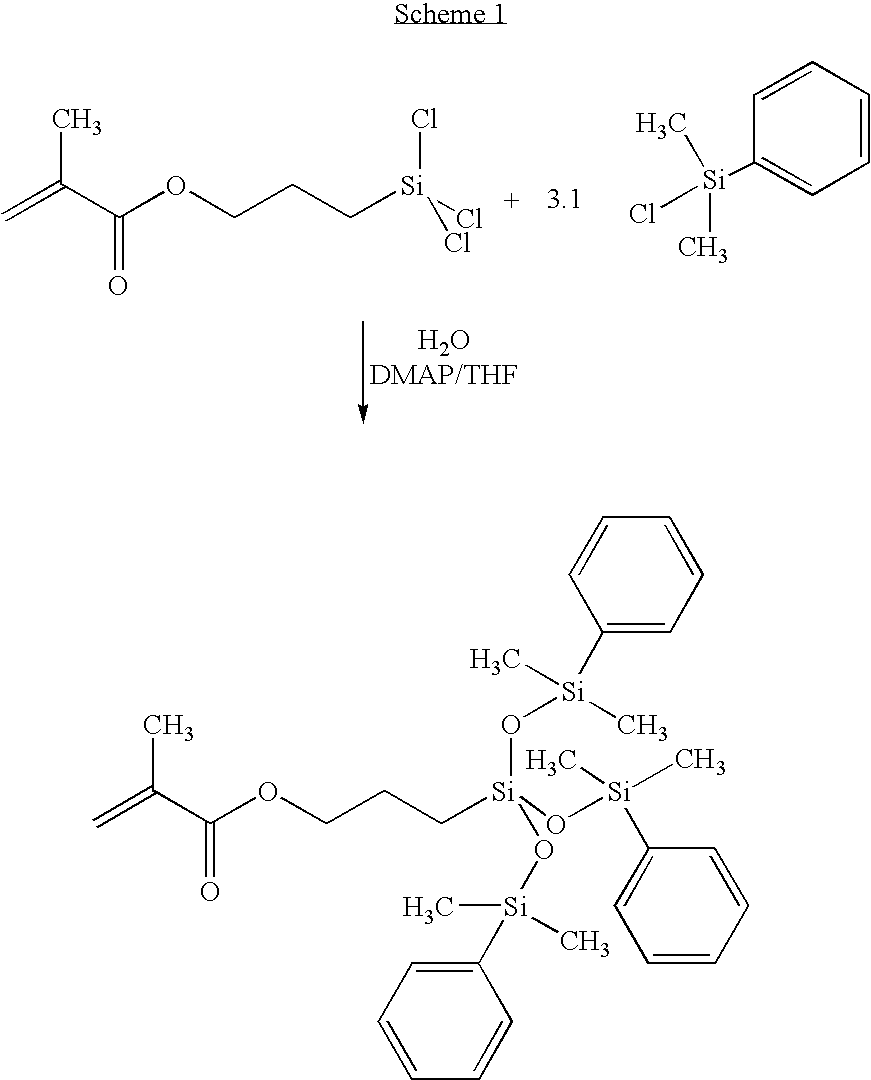

High refractive index polymeric siloxysilane compositions

InactiveUS20050131189A1Good claritySimple to produceSilicon organic compoundsOrganic compound preparationChemistryRefractive index

Optically transparent, relatively high refractive index polymeric compositions and ophthalmic devices such as intraocular lenses, contact lenses and corneal inlays made therefrom are described herein. The preferred polymeric compositions are produced through the polymerization of one or more siloxysilane monomers or the copolymerization of one or more siloxysilane monomers with one or more aromatic or non-aromatic non-siloxy monomers, hydrophobic monomers or hydrophilic monomers.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

Method for preparing primary standard reagent sodium tetraborate

The invention relates to a method for preparing sodium tetraborate as standard reagent. In the method, a sodium carbonate solution and polyacrylate sodium are adopted to remove impurities; and the final drying selects moisture-preserving desiccant, namely a mixture in salt-sugar proportion of 4:1 for drying in a supersaturated state so as to ensure the standard of containing ten crystal waters. A finished sodium tetraborate product is uniform in particles and parallel in content. As the preparation method adopts the polyacrylate sodium which is anionic flocculant, has negative charge and can be combined with metal ion precipitate having positive charge, metal ions can rapidly condense and sink, and the impurity content and clarity can achieve the best effect through filtration. As the moisture-preserving desiccant is selected, the ten crystal waters inside a crystal are stable and no moisture exist outside the crystal so as to ensure that the water content of the finished product achieves the best effect.

Owner:TIANJIN CHEM REAGENT RES INST

Thermoplastic elastomer compounds exhibiting improved stain resistance

A thermoplastic elastomer compound includes acrylic block copolymer and functionalized polysiloxane. Polymeric articles formed from the thermoplastic elastomer compound can have improved stain resistance, while also achieving other desirable properties such as low tackiness (i.e., low coefficient of friction) and good clarity (i.e., low haze).

Owner:AVIENT CORP

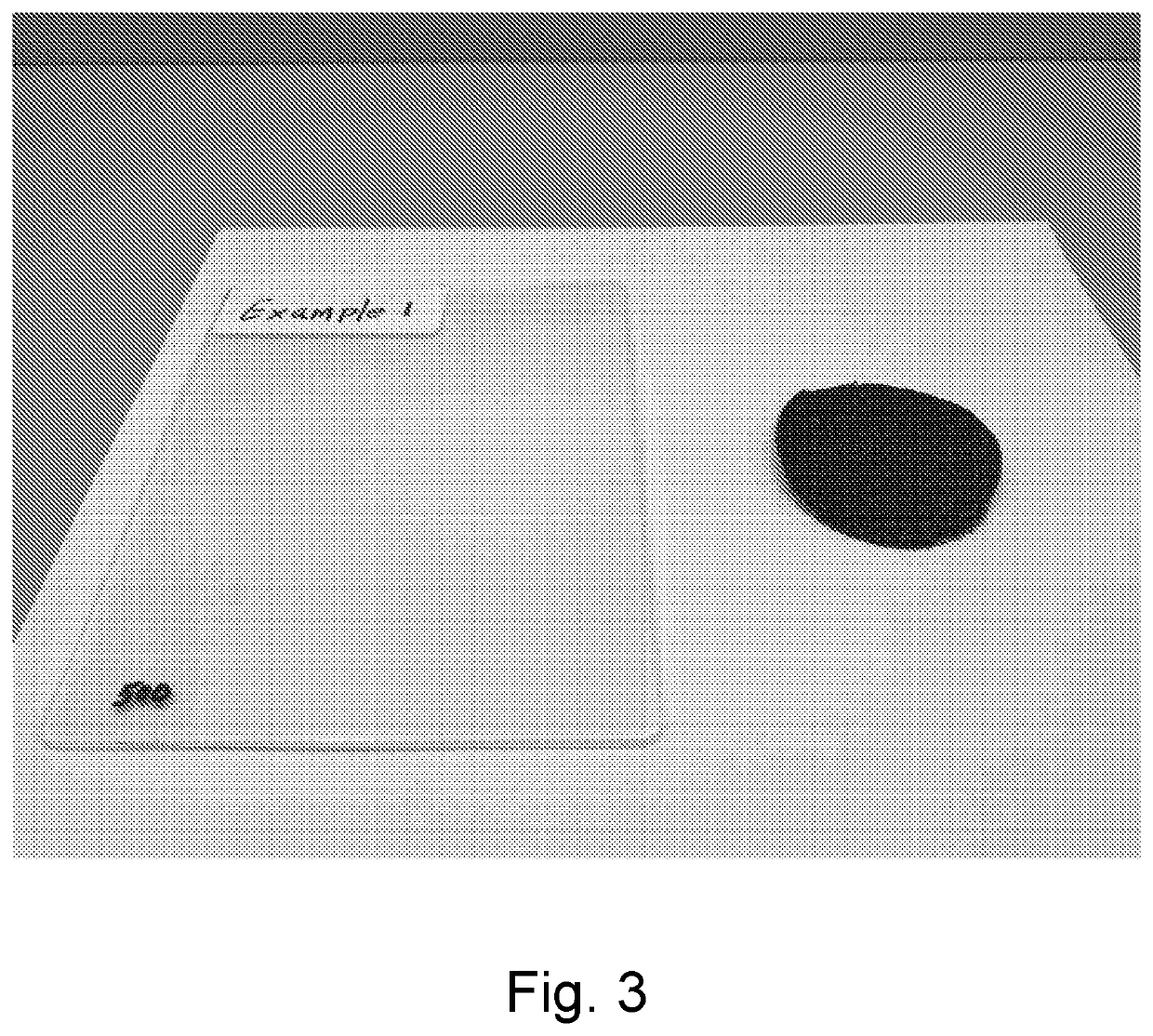

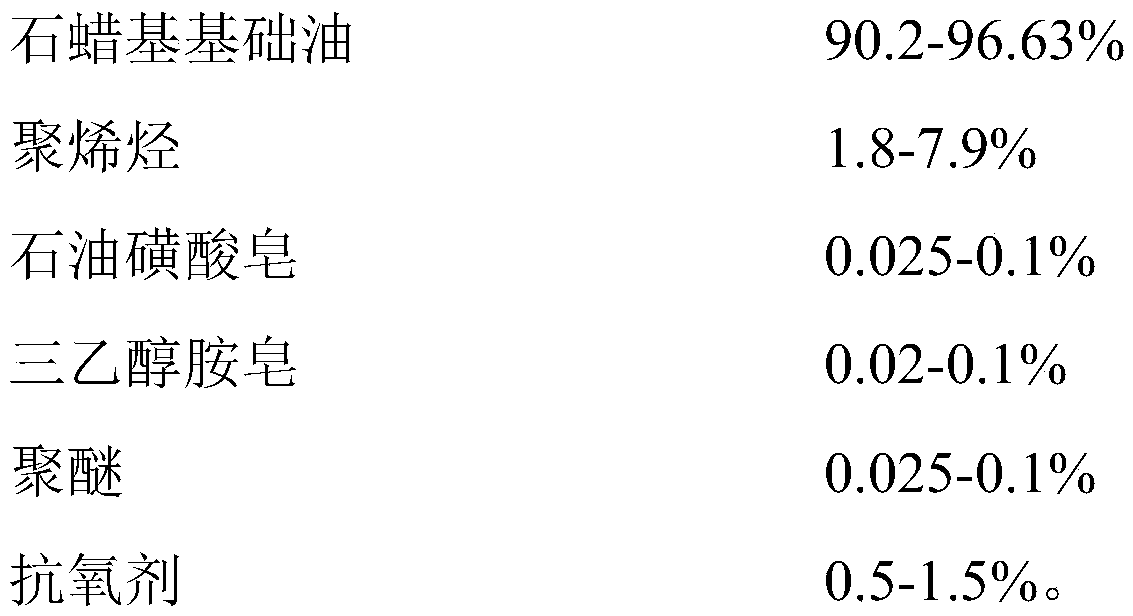

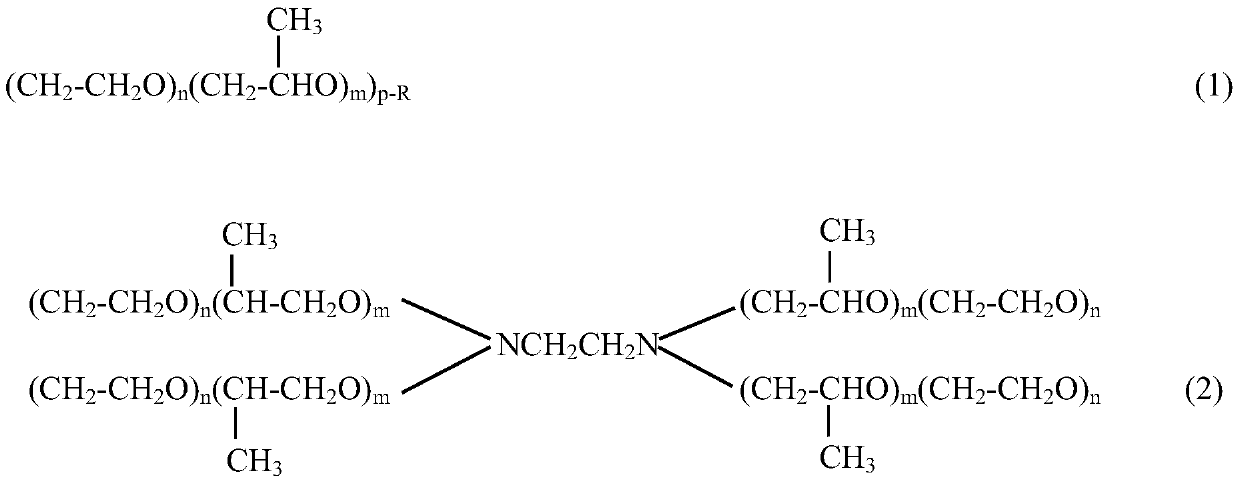

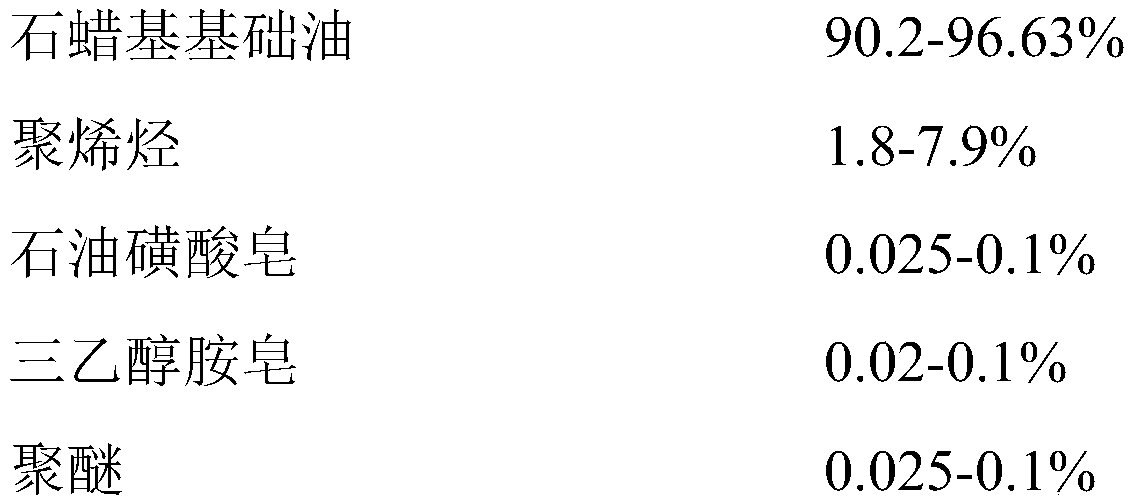

Anti-emulsification rust-proof quenching oil composition and preparation method thereof

InactiveCN110317932AGood dehydration and clarification performanceGood clarityQuenching agentsQuenchingPolyolefin

The invention provides an anti-emulsification rust-proof quenching oil composition and a preparation method of the anti-emulsification rust-proof quenching oil composition. The anti-emulsification rust-proof quenching oil composition comprises, by mass percentage, 90.2-96.63% of paraffin-based base oil, 1.8-7.9% of polyolefin, 0.025-0.1% of petroleum sulfonic acid soap, 0.02-0.1% of triethanolamine soap, 0.025-0.1% of polyether and 0.5-1.5% of antioxidant. According to the anti-emulsification rust-proof quenching oil composition, the triethanolamine soap is introduced into the anti-emulsification rust-proof quenching oil composition, and the triethanolamine soap is blended with the polyether and the polyolefin to realize emulsification prevention and rust prevention. The anti-emulsification rust-proof quenching oil composition has the beneficial effects of water film replacement rust prevention and good dewatering and clarifying performance, the composition is thoroughly mixed with water, and after the sedimentation and drainage, the oil layer has good clarification and less water and can be reused in a quenching oil tank.

Owner:JIANGSU XINLU CHEM NEW MATERIAL

BIM-based digital engineering monitoring system

ActiveCN113709341AGood clarityImprove clarityTelevision system detailsColor television detailsSurveillance cameraEnvironmental geology

The invention relates to a BIM-based digital engineering monitoring system, which comprises a monitoring camera body and a protective cover for accommodating the monitoring camera, and is characterized in that the protective cover comprises a main cover and a secondary cover which are communicated with each other, the secondary cover is used for being fixed with a wall surface, and one end, far away from the wall surface, of the secondary cover is communicated with the side wall of the bottom end of the main cover; the main cover comprises an outer cover and a cover plate, a through opening is formed in the side wall, facing the wall surface, of the top end of the outer cover, and the cover plate is used for closing the through opening; the driving source is arranged on the outer cover and used for driving the cover plate to move and then opening the through opening; the exhaust fan is arranged on the outer cover and is used for driving air in the protective cover to flow out of the through hole; and the humidity sensor and the central processing unit are arranged in the protective cover, and the central processing unit is electrically connected with the humidity sensor, the driving source and the exhaust fan. The exhaust fan exchanges air in the protective cover with the outside, so that the humidity in the protective cover is consistent with that of the outside, the inner wall of the protective cover is not easy to be covered with fog water, and the monitoring picture of the camera is kept clear.

Owner:浙江新和兴建设有限公司

Solvent Free Polyurethane Laminating Adhesive With High Oxygen Transfer Rate

A solventless two component laminating adhesive comprising a Part A prepolymer and a Part B curative. The prepolymer comprises a lower molecular weight polyether polyol and a higher molecular weight polyether polyol. The laminating adhesive can be applied to flexible films with high oxygen transfer rate to form flexible packaging, particularly for fresh produce, such as pre-prepared salads and other green leaf products.

Owner:ASHLAND LICENSING & INTPROP LLC

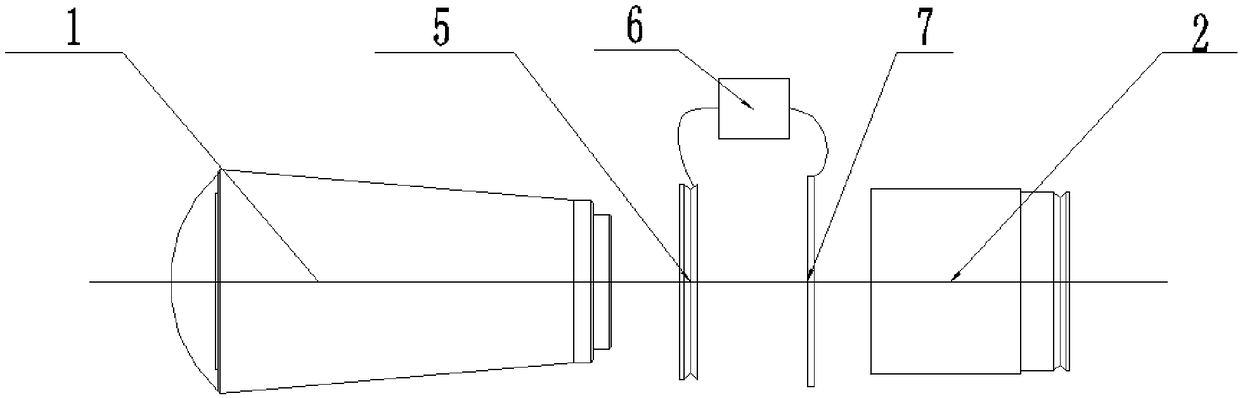

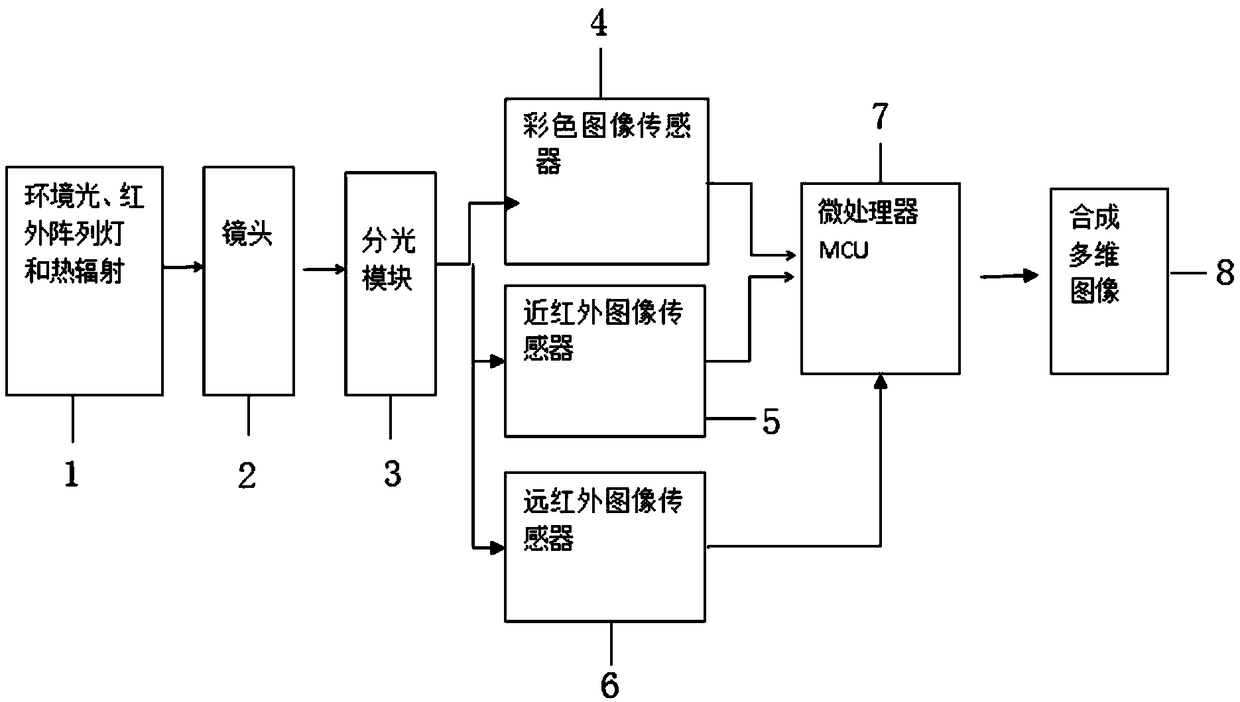

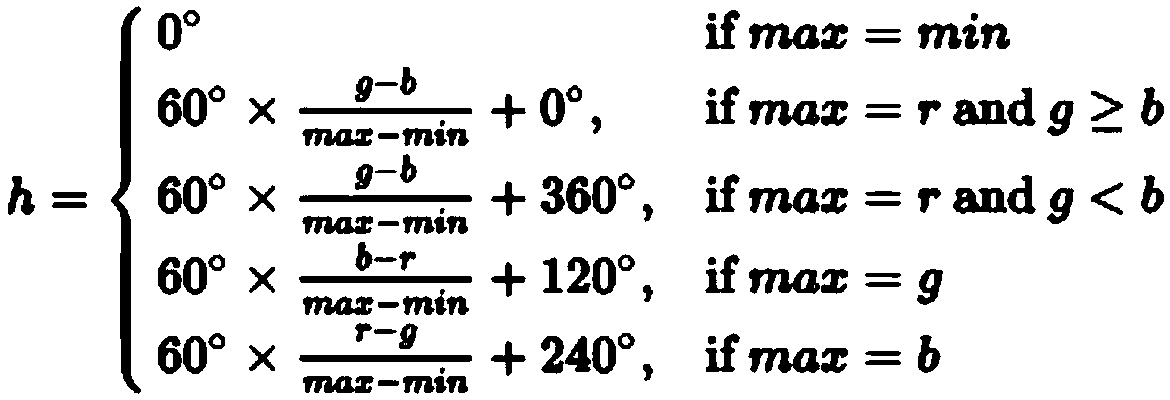

Three-light integrated multi-dimensional camera system and image display method thereof

InactiveCN109510930AGood clarityReduce noiseTelevision system detailsColor television detailsInfrared lampVisible spectrum

The invention provides a three-light integrated multi-dimensional camera system and an image display method thereof. The system comprises a camera lens, an active infrared light, a color image sensor,a near-infrared image sensor, a far infrared image sensor, a microprocessor and an image display; a projection direction of the active infrared light is corresponding to a light receiving direction of the camera lens; and the active infrared light is in signal connection with the microprocessor. According to the system and method provided by the invention, the visible light and 850nm infrared light in the environment can be separately sensed via the color and near-infrared image sensor channels under low illumination level, then the color and brightness of the image are extracted via the microprocessor, the synthesized image is the full-color image with good definition, small noise and high color saturation; then the 8-14 microns far infrared light is sensed via the far infrared image sensor to form the thermal image, and the thermal image is proportionally scaled and overlapped to the lower right corner or other positions of the full-color image, and thus the multi-dimensional imageintegrating color, details and thermal image distribution is synthesized.

Owner:TIANJIN TIANDI WEIYE INFORMATION SYST INTEGRATION CO LTD

Decorating plate brick producing process

The production process of a decoration board brick sprays a layer of epoxide resin varnish evenly on the surface, then a layer of laser powder fleck on the surface, sweeping and pressing the surface with the laser powder evenly attached on the glass brick, resting until drying of the varnish, spraying bottom paint on the laser powder fleck and baking in 150 degree for 30-60 minutes, cooling, net printing the bottom color paint with plastic rubber till its natural drying or baking it to dryness. It is cheap in cost, good in luster, straightness, transparency and intensity with strong cubic effect, free from erosion with long durability.

Owner:潘文建

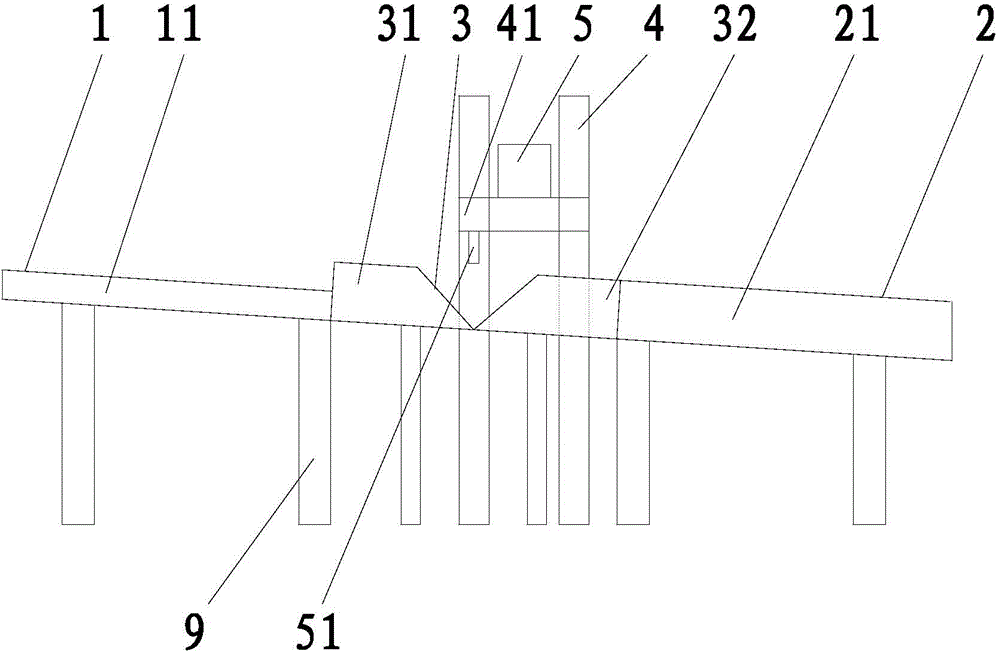

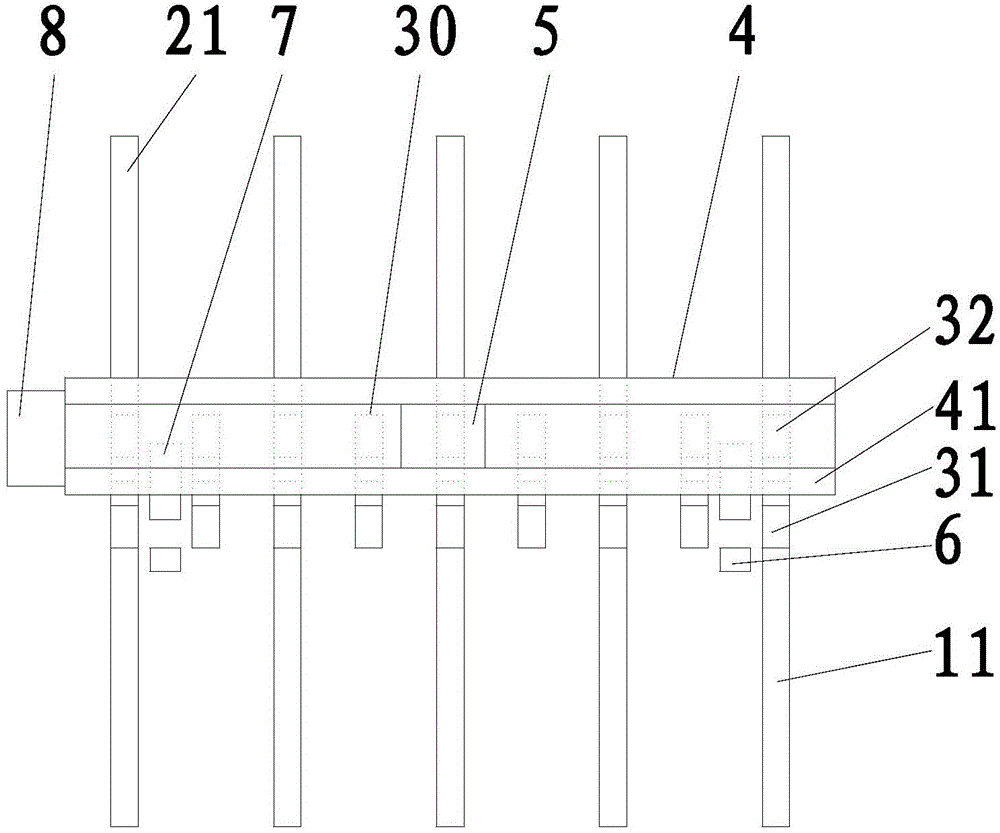

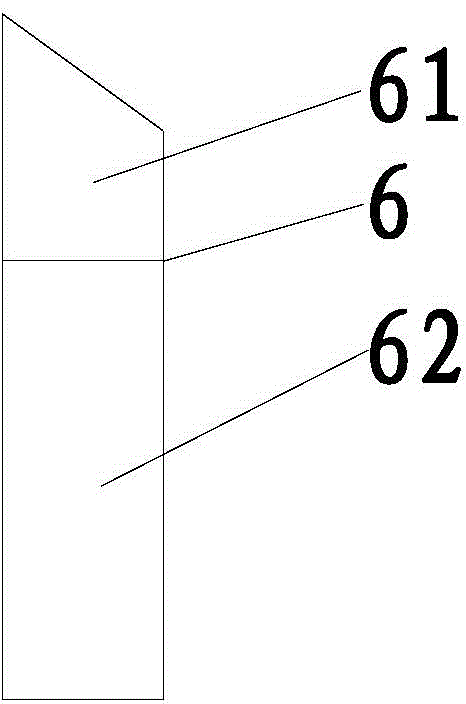

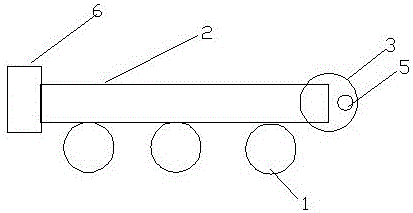

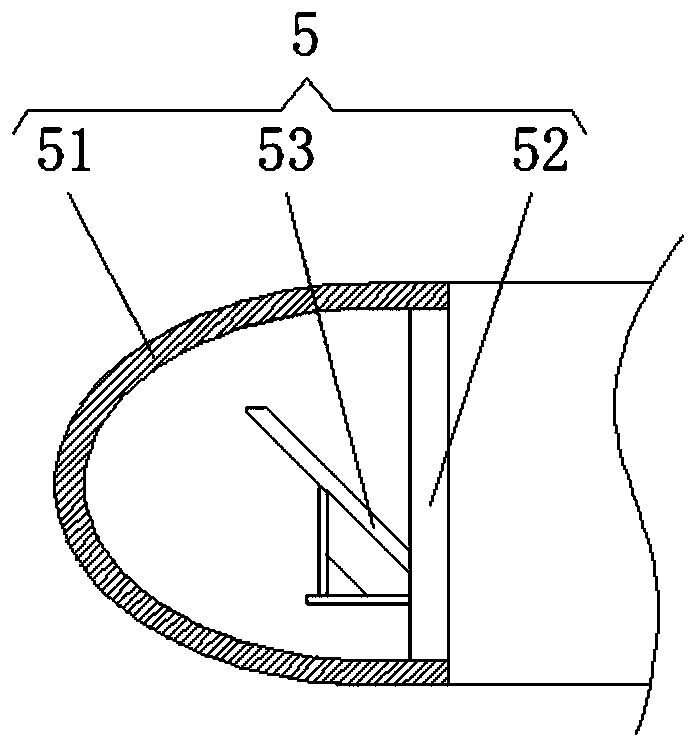

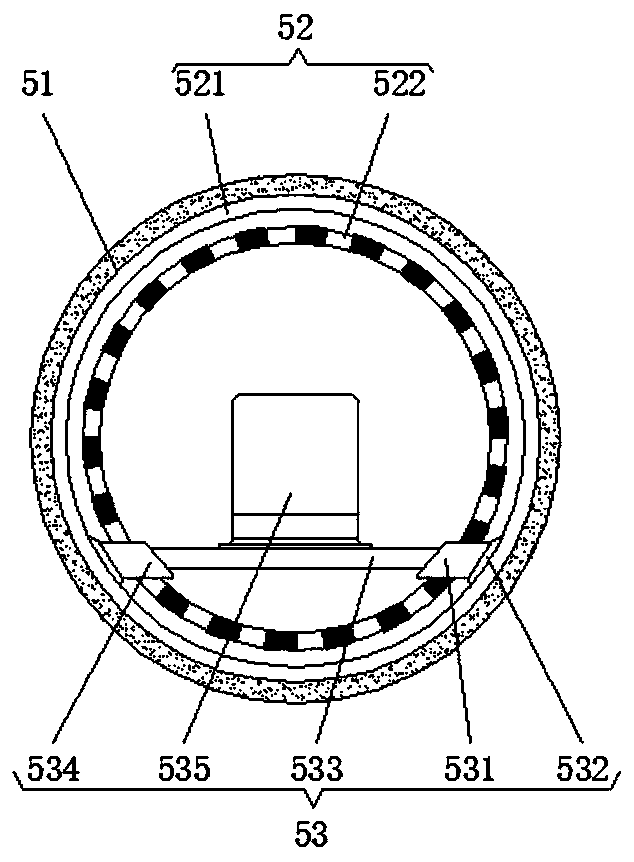

Spray head moving type round tube code spraying line

InactiveCN104527233AWell-proportioned fontGood clarityTypewritersPower drive mechanismsAgricultural engineeringEngineering

The invention discloses a spray head moving type round tube code spraying line. The spray head moving type round tube code spraying line comprises a feeding platform, a discharging platform, a V-shaped groove platform, a portal frame and a code sprayer, wherein the feeding platform is composed of multiple horizontally arranged first supporting rods, the discharging platform is composed of multiple horizontally arranged second supporting rods, the V-shaped groove platform is composed of multiple V-shaped groove sets, each V-shaped groove set is composed of a left V-shaped groove block and a right V-shaped groove block, the bottom of each first supporting rod, the bottom of each second supporting rod, the bottom of each left V-shaped groove block and the bottom of each right V-shaped groove block are each provided with multiple stand columns, multiple first lifting rods are arranged between the multiple first supporting rods, multiple second lifting rods are arranged between the V-shaped groove sets, the portal frame is arranged above the V-shaped groove platform, and the code sprayer is installed on the portal frame. According to the spray head moving type round tube code spraying line, a spray head of the code sprayer is installed on a cross beam of the portal frame, movement of the spray head is achieved, so that code spraying is achieved by moving the spray head instead of a pipe, and then sprayed typeface is even and clearness and straightness are high.

Owner:浙江富丽华铝业有限公司

High definition monitor

InactiveCN106161899AImprove performanceGood clarityTelevision system detailsColor television detailsAluminiumHigh definition

The invention relates to the technical field of monitors and particularly relates to a high definition monitor. The high definition monitor comprises a high definition lens, an aluminium part framework, a transformation part, a disk and infrared equipment, wherein the high definition lens is mounted on the aluminium part framework, the transformation part is arranged on the upper arm surface of the aluminium part framework, the disk is arranged on the aluminium part framework, and the infrared equipment is arranged on the aluminium part framework. The high definition monitor provided by the invention is improved in performance and has a relatively good high definition effect.

Owner:常州市维尔克电子科技有限公司

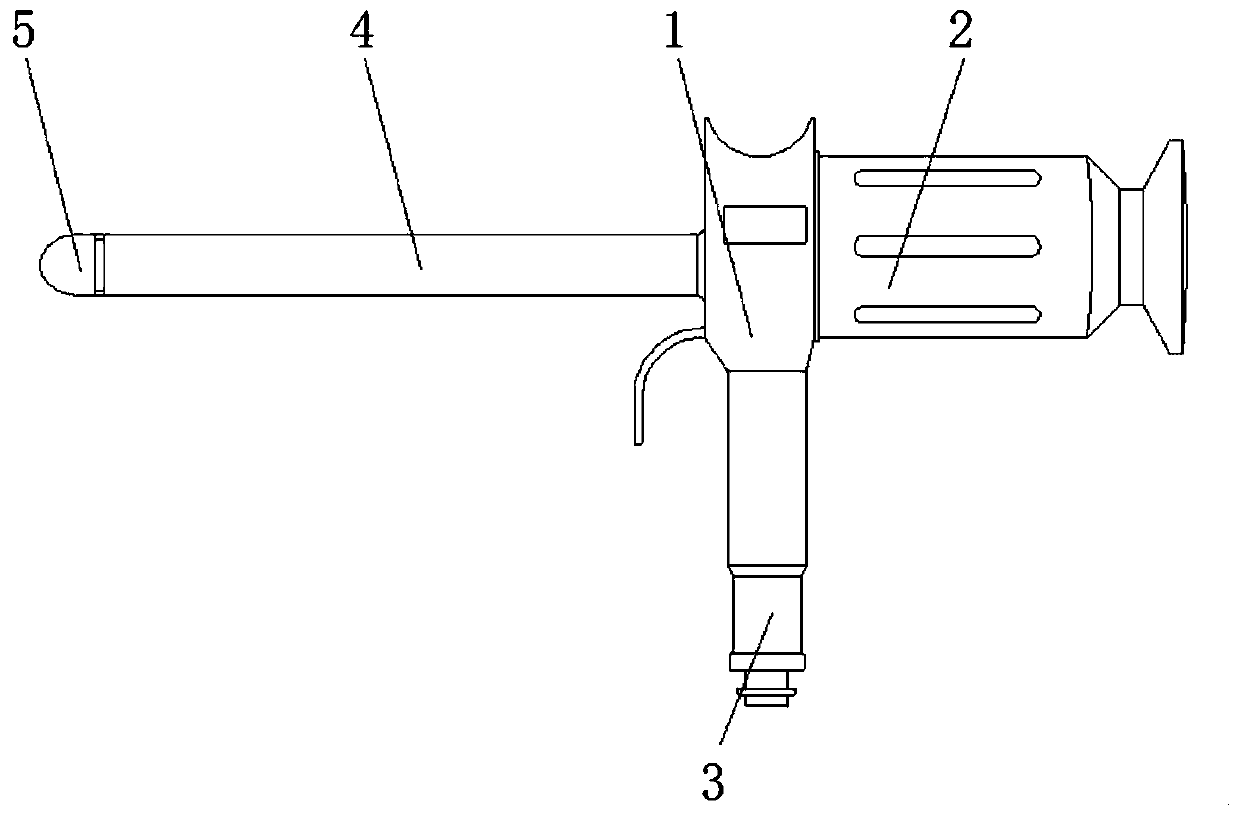

Straight-rod non-separable hard-tube endoscope with infinite visual angle

ActiveCN110403562AFlexible adjustment of viewing angleReduce harmSurgeryEndoscopesCamera lensEyepiece

The invention relates to the technical field of medical imaging equipment, and discloses a straight-rod non-separable hard-tube endoscope with infinite visual angle, wherein the endoscope includes anendoscope body; one side of the endoscope body is fixedly provided with an eyepiece tube, the other side of the endoscope body is fixedly provided with an outer mirror tube, and one end of the outer mirror tube is fixedly provided with an endoscope lens. According to the straight-rod non-separable hard-tube endoscope with infinite visual angle, through arrangement of a magnetic ring and an electromagnetic coil, a reflecting mirror plane can rotate 360 DEG independently without rotation of the whole structure of the endoscope. Compared with a conventional endoscope, in the case of indetermination of specific orientation of a sick body of a patient, the endoscope with different visual angles is not needed to be continuously selected, or the best observation visual field and clarity are obtained by rotating the endoscope, the diagnostic efficiency of medical staff when the endoscope is used can be effectively improved, the injury to the patient is reduced, and the use effect is good.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

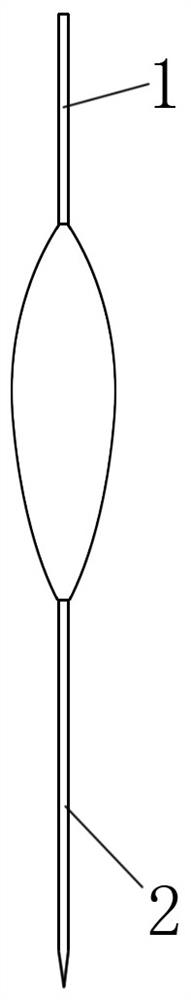

Method for manufacturing images and texts on float body of fishing float through engraving

The invention relates to a method for manufacturing images and texts on a float body of a fishing float through engraving, and belongs to the technical field of fishing float manufacturing. The methodsolves the problem that images and texts on the float body manufactured by adopting a spraying method at present are poor in resolution degree. The method comprises the steps that the images and texts on the float body of the fishing float are manufactured by adopting an engraving method, wherein the images and texts are symmetrically engraved; and the method further comprises the step that the images and texts on the float body of the fishing float are manufactured by adopting the spraying method. The method for manufacturing the images and texts on the float body of the fishing float through engraving is used for manufacturing the images and texts on the float body of the fishing float.

Owner:霍勇诚

Side-light type intelligent LED television

PendingCN113225504AGood clarityReduce limitationsTelevision system detailsColor television detailsEngineeringMechanical engineering

The invention discloses a side-light type intelligent LED television which comprises an LED television body, an end cover is movably installed on the rear side of the LED television body, a connecting block is fixedly installed on the surface of one side of the end cover, an installation limiting assembly is arranged on the outer side of the connecting block, and drawing extension assemblies are arranged on the two sides of the LED television body, adjusting rotating assemblies are arranged at the outer ends of the drawing extending assemblies correspondingly. According to the side-light type intelligent LED television, according to different requirements of real-time change of actually watched light rays, the drawing rod is manually pushed and pulled to slide on the inner side of the sleeve rod in real time, the illumination distance between the lamp body and the LED television body is adjusted in real time, meanwhile, a rotating block is pushed to rotate by a certain angle in a rotating groove, the angle of side light illumination is adjusted in real time, so that the side light illumination effect is better, the viewing definition is higher, the use limitation is reduced, and the use flexibility is improved.

Owner:广西千凝电子科技有限公司

Cleaning method of combined wheat harvester radiator

InactiveCN106767130AShorten clear timeGood clarityCleaning heat-transfer devicesLiquid temperatureUltrasonic generator

The invention discloses a cleaning method of a combined wheat harvester radiator. The cleaning method comprises the following steps that 1, it is ensured that an engine is cooled before the radiator starts to be washed, and soapy water with the temperature of 20-25 DEG C is selected for washing; 2 dust or dirt accumulated on a barrier is thoroughly removed through a brush when the radiator is washed; 3, the radiator is placed in a cleaning tank, a 4%-6% diluted hydrochloric acid solution is prepared, and the radiator is immersed in the diluted hydrochloric acid solution for 10 min or longer; 4, an ultrasonic generator is arranged at the bottom of the cleaning tank of the radiator, cleaning is carried out for 5-10 min, meanwhile, a corrosion inhibitor is added, and the liquid temperature is controlled to be 40-50 DEG C; 5, the ultrasonic generator is turned off and kept in a standing state for 20 min; and 6, the radiator is carefully taken out of the cleaning tank, thoroughly washed with clean water and dried in the sun or wind.

Owner:HECHI TECH DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com