Method for producing cotton pulp used for cellulose triacetate by two-step stewing technology

A technology of cellulose triacetate and secondary cooking, applied in pulping of cellulose raw materials, pulping with inorganic alkali, fiber raw material treatment, etc., can solve the problem of high content of dichloromethane extract, achieve excellent clarity, improve Quality, less dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

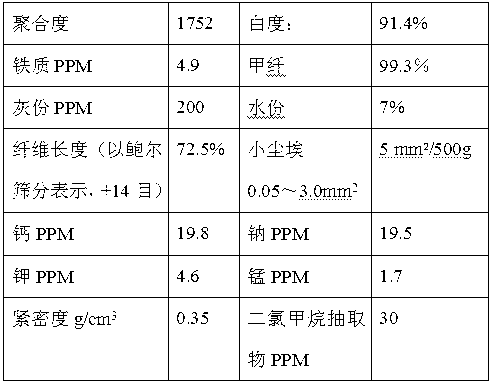

Embodiment 1

[0036] A method for producing cotton pulp for cellulose triacetate by a secondary cooking process, the specific operations are as follows:

[0037] (1) Material selection, cotton opening, and impurity removal process: select three types of first-class cotton linters with a maturity ≥ 80%, and use a cotton opener to tear the linters, then loosen and remove impurities through the impurity remover, Then transfer to the cotton extruder, after selection and removal of impurities, it is sent to the screw press and impregnation through the cyclone separator;

[0038] (2) One-time alkali mixing, impregnation, and cooking process: the temperature of alkali mixing is controlled at 80°C, the total alkali is 5.2% relative to the dry pulp weight in terms of NaOH, the ratio of alkali solution is 1: 4.5%, and the relative dry pulp weight of hydrogen peroxide is 0.5%, the scouring agent is 0.5% relative to the weight of the absolute dry pulp; it is sprayed with lye in the cyclone separator, s...

Embodiment 2

[0061] A method for producing cotton pulp for cellulose triacetate by a secondary cooking process, the specific operations are as follows:

[0062] (1) Material selection, cotton opening, and impurity removal process: select three types of first-class cotton linters with a maturity ≥ 80%, and use a cotton opener to tear the linters, then loosen and remove impurities through the impurity remover, Then transfer to the cotton extruder, after selection and removal of impurities, it is sent to the screw press and impregnation through the cyclone separator;

[0063] (2) One-time alkali blending, impregnation, and cooking process: the temperature of alkali blending is controlled at 85°C, the total alkali is 6.3% relative to the dry pulp weight in terms of NaOH, the ratio of alkali solution is 1:5.2%, and the relative dry pulp weight of hydrogen peroxide is 1.0%, the scouring agent is 1% relative to the weight of the absolute dry pulp; it is sprayed with lye in the cyclone separator, ...

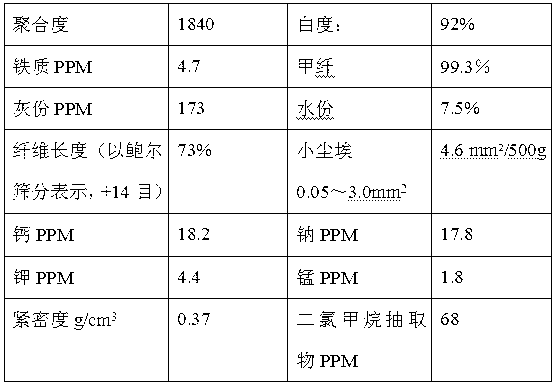

Embodiment 3

[0086] A method for producing cotton pulp for cellulose triacetate by a secondary cooking process, the specific operations are as follows:

[0087] (1) Material selection, cotton opening, and impurity removal process: select three types of first-class cotton linters with a maturity ≥ 80%, and use a cotton opener to tear the linters, then loosen and remove impurities through the impurity remover, Then transfer to the cotton extruder, after selection and removal of impurities, it is sent to the screw press and impregnation through the cyclone separator;

[0088] (2) One-time alkali blending, impregnation, and cooking process: the temperature of alkali blending is controlled at 83°C, the total alkali is 5.7% relative to the dry pulp weight in terms of NaOH, the alkali liquor ratio is 1: 4.8%, and the relative dry pulp weight of hydrogen peroxide is 0.7%, the scouring agent is 0.7% relative to the dry pulp weight; it is sprayed with lye in the cyclone separator, screw extruded, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com