Electrochemical detection method for uric acid in urine and detection electrode material

A technology for detecting electrodes and uric acid electrodes, which is applied in the field of detection, can solve problems such as differences in electrode detection performance, low detection limit, and limited use range, and achieve good detection stability and small relative standard deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

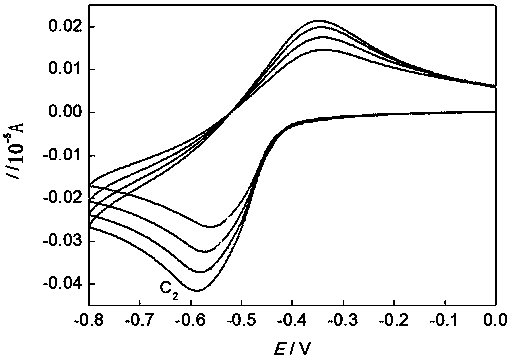

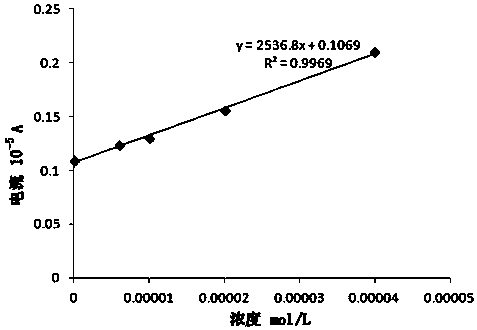

Image

Examples

Embodiment 1

[0035] Uric acid electrochemical detection electrode material steps:

[0036] Step 1, preparing graphene oxide by the Hummers method;

[0037] The second step, the reduction of graphene oxide: disperse the graphene oxide obtained in the first step in water to obtain a 4 mg / mL graphene oxide dispersion, take 50 mL of the graphene oxide dispersion, and slowly drop 30 μL of 70wt % hydrazine hydrate solution, then reacted at 85°C for 1h, filtered out the product, washed, and dried to obtain graphene;

[0038] The 3rd step, the acid modification of graphene: by weight, mix 12 parts of graphene with 25 parts of acid mixed solution, then heat reflux reaction 2h under ultrasonic action, described acid mixed solution refers to by volume A mixture of 75wt% concentrated sulfuric acid and 50wt% concentrated nitric acid compounded at a ratio of 3:1. After the reaction, the product was filtered out, washed with deionized water, and dried to obtain acid-modified carbon nanotubes;

[0039] ...

Embodiment 2

[0045] Uric acid electrochemical detection electrode material steps:

[0046] Step 1, prepare graphene oxide by Hummers method;

[0047] The second step, the reduction of graphene oxide: disperse the graphene oxide obtained in the first step in water to obtain a 8 mg / mL graphene oxide dispersion, take 60 mL of the graphene oxide dispersion, and slowly drop 50 μL of 80wt % hydrazine hydrate solution, then reacted at 90°C for 3h, filtered out the product, washed, and dried to obtain graphene;

[0048] The 3rd step, the acid modification of graphene: by weight, mix 20 parts of graphene with 30 parts of acid mixed solution, then heat and reflux reaction 4h under ultrasonic action, described acid mixed solution refers to by volume A mixture of 85wt% concentrated sulfuric acid and 60wt% concentrated nitric acid compounded at a ratio of 4.5:1. After the reaction is completed, the product is filtered out, washed with deionized water, and dried to obtain acid-modified carbon nanotubes...

Embodiment 3

[0055] Uric acid electrochemical detection electrode material steps:

[0056] Step 1, prepare graphene oxide by Hummers method;

[0057] The second step, the reduction of graphene oxide: disperse the graphene oxide obtained in the first step in water to obtain a 5mg / mL graphene oxide dispersion, take 55mL of the graphene oxide dispersion, and slowly drop 40μL of 75wt % hydrazine hydrate solution, then reacted at 88°C for 2h, filtered out the product, washed, and dried to obtain graphene;

[0058] The 3rd step, the acid modification of graphene: by weight, mix 15 parts of graphene and 28 parts of acid mixed solution, then heat reflux reaction 3h under ultrasonic action, described acid mixed solution refers to by volume A mixture of 80wt% concentrated sulfuric acid and 55wt% concentrated nitric acid compounded at a ratio of 4:1. After the reaction, the product was filtered out, washed with deionized water, and dried to obtain acid-modified carbon nanotubes;

[0059] Step 4, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com