Bulk acoustic wave sensor with high stability

A high-stability, sensor-based technology, applied in the direction of analyzing fluids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as limiting the application range of body wave sensors and poor stability, and achieve good detection stability, simple stability, and high The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A high-stability bulk acoustic wave sensor of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

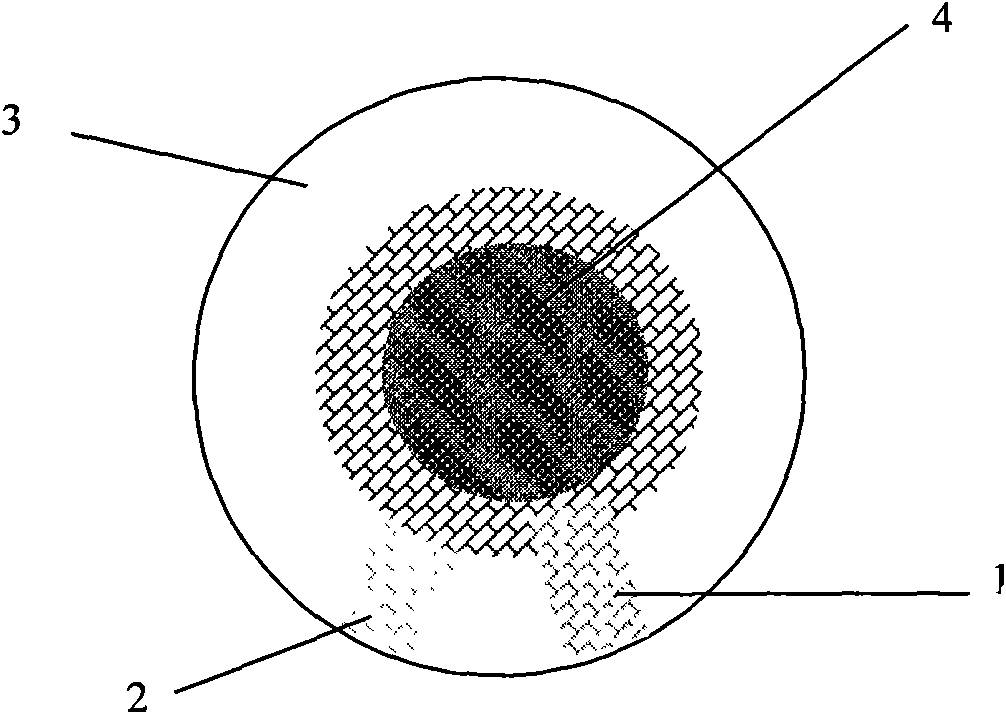

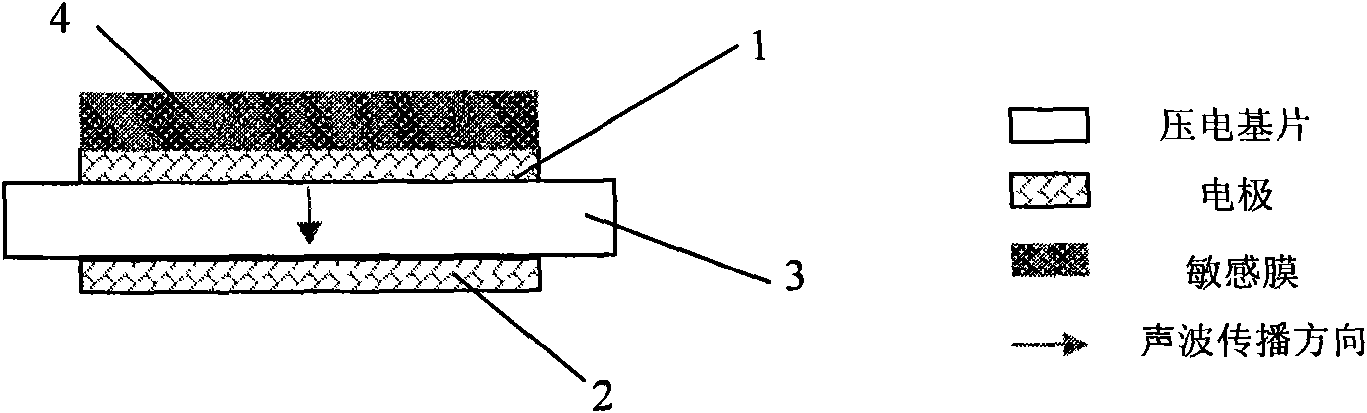

[0018] figure 1 It is a top view of an embodiment of a high-stability bulk acoustic wave sensor of the present invention, figure 2 It is a high stability bulk acoustic wave sensor of the present invention figure 1 A cross-sectional view of the embodiment shown. like figure 1 as well as figure 2 As shown, a high-stability bulk acoustic wave sensor of the present invention includes: a piezoelectric substrate 3, deposited on the piezoelectric substrate 3, lower surface electrodes 1, 2, and a sensitive sensor covering the upper surface electrode 1. Membrane 4, wherein the sensitive membrane 4 is a nano-structured sensitive material layer, and the sound wave is transmitted from one side of the piezoelectric crystal to the other and propagates inside the crystal. When the loaded measured object rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com