Device and method for detecting response non-uniformity and linearity of CCD

A technology of non-uniformity and detection device, applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problem of response non-uniformity and low detection accuracy of linearity, difficult to avoid the stability of integrating sphere, unable to eliminate detection errors, etc. problem, to achieve the effect of controllable detection, reduction of measurement error, and reduction of detection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

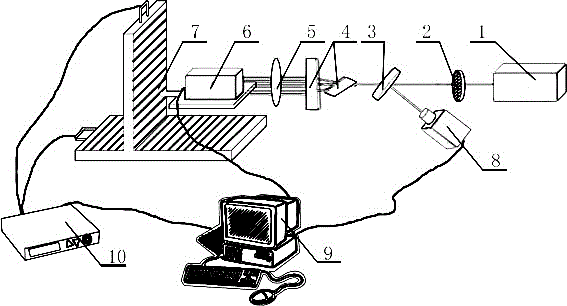

[0057] A CCD response non-uniformity and linearity detection device, including a test light source 1, an attenuation film 2, a sampling mirror 3, an optical pair 3, a telephoto converging lens 5, a CCD to be tested 6, a two-dimensional translation stage 7, and an energy meter 8 , a computer 9, a controller 10 and a black box, the incident laser light produced by the test light source 1 passes through the attenuation sheet 2 and the sampling mirror 3 in turn to generate reflected laser light and transmitted laser light on the sampling mirror 3, and the reflected laser light is directly incident on the energy meter 8. The transmitted laser light is incident on the CCD 6 to be tested after passing through the optical pair 3 and the telephoto converging lens 5 in sequence. All placed in a black box, the two-dimensional translation stage 7 is electrically connected to the controller 10, and the CCD 6 to be tested, the energy meter 8 and the controller 10 are all electrically connect...

Embodiment 2

[0059] A CCD response non-uniformity and linearity detection device, including a test light source 1, an attenuation film 2, a sampling mirror 3, an optical pair 3, a telephoto converging lens 5, a CCD to be tested 6, a two-dimensional translation stage 7, and an energy meter 8 , a computer 9, a controller 10 and a black box, the incident laser light produced by the test light source 1 passes through the attenuation sheet 2 and the sampling mirror 3 in turn to generate reflected laser light and transmitted laser light on the sampling mirror 3, and the reflected laser light is directly incident on the energy meter 8. The transmitted laser light is incident on the CCD 6 to be tested after passing through the optical pair 3 and the telephoto converging lens 5 in sequence. All placed in a black box, the two-dimensional translation stage 7 is electrically connected to the controller 10, and the CCD 6 to be tested, the energy meter 8 and the controller 10 are all electrically connect...

Embodiment 3

[0062] A CCD response non-uniformity and linearity detection device, including a test light source 1, an attenuation film 2, a sampling mirror 3, an optical pair 3, a telephoto converging lens 5, a CCD to be tested 6, a two-dimensional translation stage 7, and an energy meter 8 , a computer 9, a controller 10 and a black box, the incident laser light produced by the test light source 1 passes through the attenuation sheet 2 and the sampling mirror 3 in turn to generate reflected laser light and transmitted laser light on the sampling mirror 3, and the reflected laser light is directly incident on the energy meter 8. The transmitted laser light is incident on the CCD 6 to be tested after passing through the optical pair 3 and the telephoto converging lens 5 in sequence. All placed in a black box, the two-dimensional translation stage 7 is electrically connected to the controller 10, and the CCD 6 to be tested, the energy meter 8 and the controller 10 are all electrically connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com