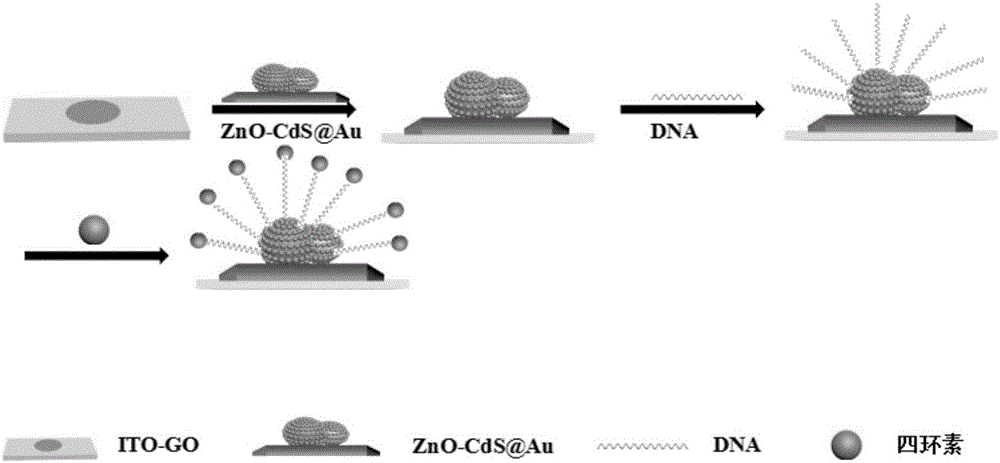

ZnO-CdS@Au nano composite and preparation method and application thereof

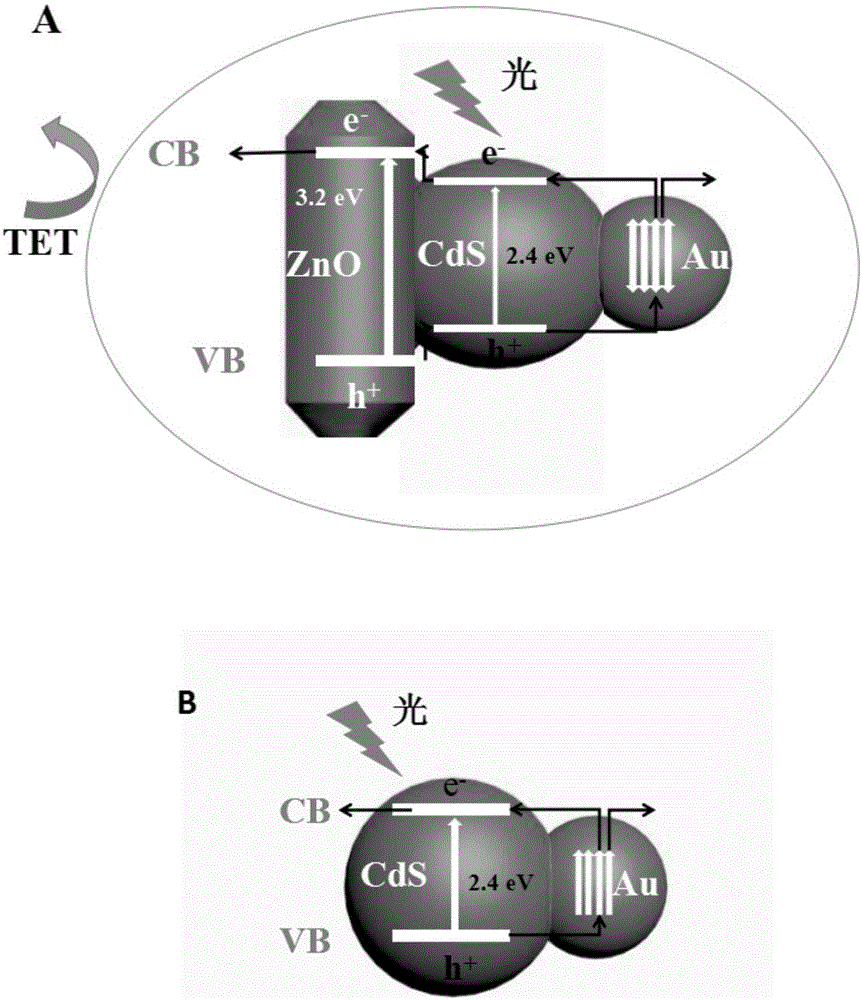

A nanocomposite material and nanoparticle technology, which is applied in the field of ZnO-CdS@Au nanocomposite material and its preparation, can solve the problems of low photocatalytic activity and low use efficiency, and achieve good detection stability, low detection limit, and improved The effect of optoelectronic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

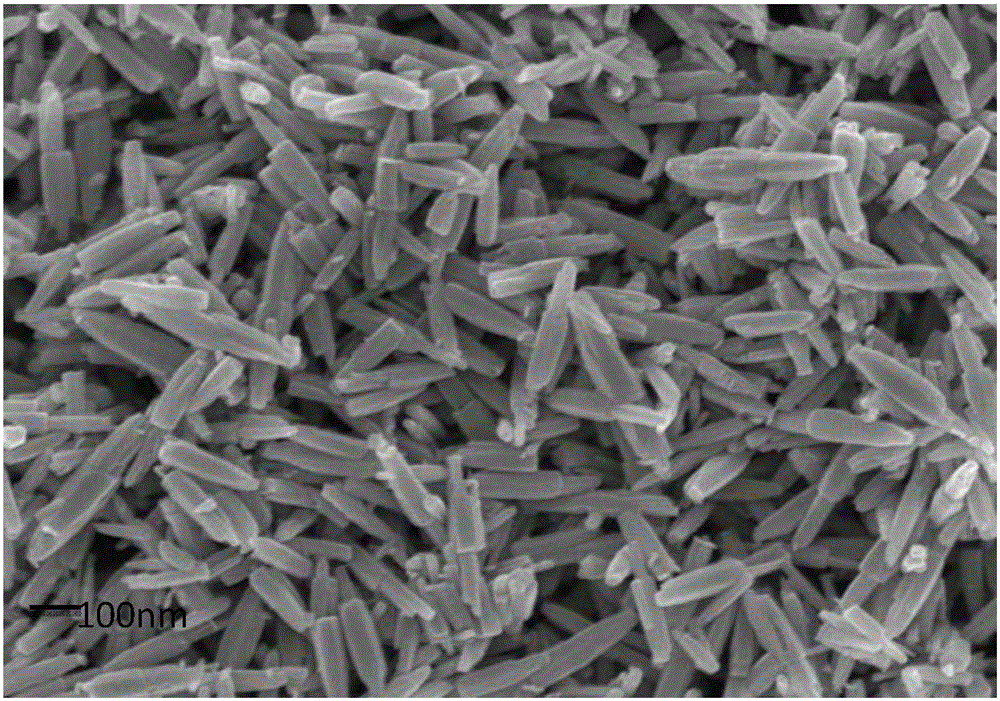

[0038] 1.4875g of Zn(NO 3 ) 2 ·6H 2 O dissolved in 20 mL deionized water, 0.7408 g NH 4 Dissolve F in 10mL deionized water, mix the two, stir well at room temperature, disperse evenly, and place in an oil bath. 0.8002 g NaOH dissolved in 10 mL deionized water was added dropwise. When a small amount of NaOH is added, a white precipitate immediately forms, continues to add NaOH and partially dissolves, and the solution becomes translucent and then turbid. Stir at 100°C for 10 hours at a speed of 2000r / min, cool to room temperature, and centrifuge the product. Alternately washing with deionized water and ethanol for 4 times, a white precipitate was obtained, and dried at 60° C. to obtain crystalline spindle-shaped ZnO nanoparticles.

Embodiment 2

[0040] Take 0.2364g Cd(NO 3 ) 2 4H 2O and 0.0761g thiourea are dissolved in the mixed solution of 100mL deionized water as solution A, the 0.4mg ZnO nanoparticles prepared by embodiment 1 are evenly dispersed in 10mL solution A and then stirred, with the rotating speed of 2000r / min, at 90 After heating in an oil bath at ℃ for 30 min, cool to room temperature, centrifuge, and alternately wash 4 times with deionized water and ethanol to obtain a yellow precipitate ZnO-CdS, which is dried at 60 ℃ to obtain a yellow powder. The change from white to yellow indicates that the CdS nanoparticles were successfully synthesized. deposited on the surface of ZnO nanoparticles.

Embodiment 3

[0042] Take 20 mg of ZnO-CdS prepared in Example 2 and evenly disperse it into 25 mL of deionized water, stir evenly to a clear solution, add 0.54 mL, 1 wt % of chloroauric acid deionized aqueous solution and mix evenly, reflux at 110 ° C, start timing from 108 ° C, After 15 minutes, add 1.5 mL of 0.04 M sodium citrate deionized aqueous solution, heat for 40 minutes, cool to room temperature, centrifuge, wash with deionized water and ethanol four times alternately, and dry at 80°C for 6 hours to obtain the ZnO-CdS@Au nanocomposite Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com