Method for producing composite transparent electrode by adopting graphene film and metallic network

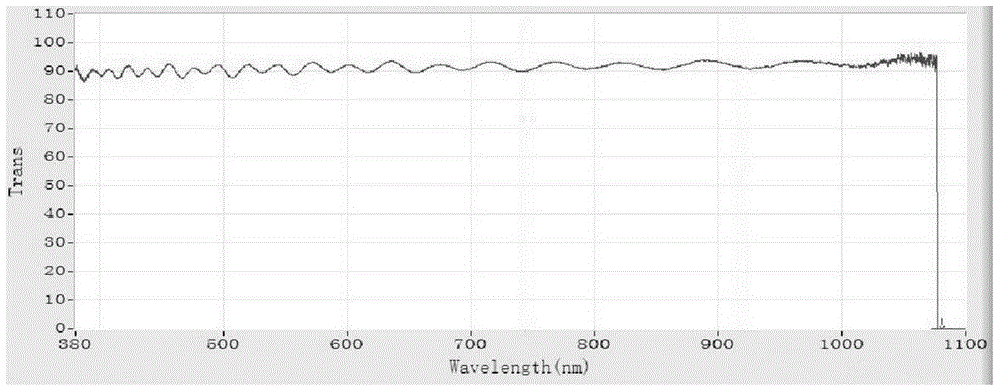

A graphene film and transparent electrode technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high cost, low efficiency, performance requirements of hardware facilities and high production cost, so as to simplify the production process, reduce production cost, Improvement of photoelectric characteristics and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment takes the preparation method of the composite transparent electrode of graphene film and gold metal mesh as an example:

[0023] Step 1: Preparation of egg white gel: After separating the egg white from the egg yolk, put the egg white and 1 / 3 of the water of the egg white volume together in a miniature magnetic stirrer, and stir until uniform at 500r / min. Get egg white gel, set aside;

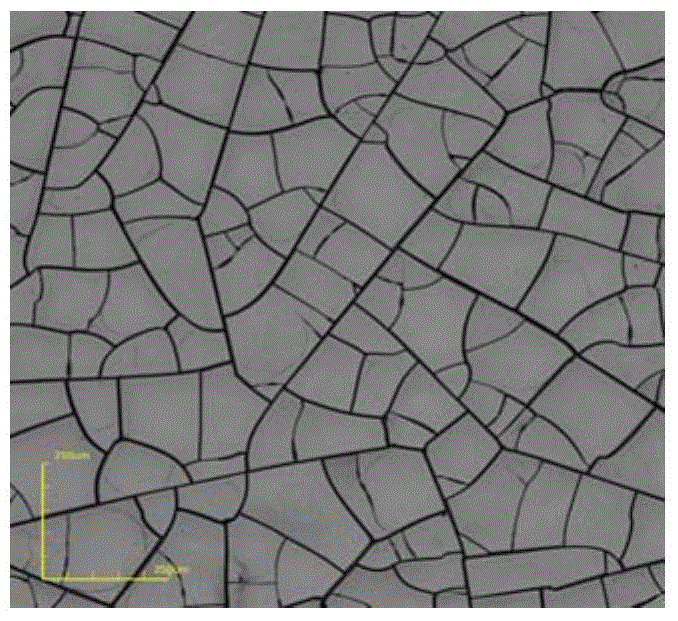

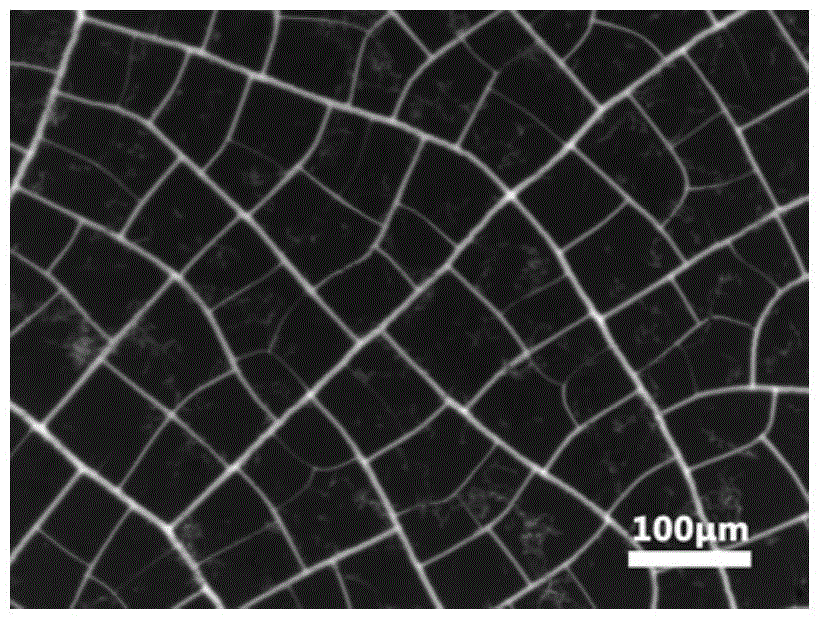

[0024]Step 2: Prepare a sheet body with a network crack film sacrificial layer: first clean and dry the polyethylene terephthalate (PET) substrate, and then evenly coat the egg white gel prepared in step 1 Brush it on the substrate, then send it into an oven and heat and bake it at 60°C until the egg white gel on the substrate forms a film with a network crack with a thickness of 2 μm, thereby making a network crack PET sheet of film sacrificial layer;

[0025] Step 3. Preparation of the metal mesh electrode: use the sacrificial layer of the adhesive film with reticular...

Embodiment 2

[0030] This embodiment takes the preparation method of graphene film and silver (Ag) metal mesh composite transparent electrode as example:

[0031] Step 1: Preparation of egg white gel: after separating the duck egg white from the egg yolk, put the egg white and 1 / 5 of the water of the egg white volume together in a miniature magnetic stirrer, and stir at 500r / min until uniform. Get egg white gel, set aside;

[0032] Step 2: Prepare a quartz glass sheet with a network-shaped crack adhesive film sacrificial layer: first, clean and dry the quartz glass substrate, and then evenly paint the egg white gel prepared in step 1 on the substrate, and then apply Send it into an oven and heat and bake it at 70°C until the egg white gel on the substrate becomes a film with a thickness of 1 μm with grid-like cracks, so as to obtain a quartz glass sheet with a sacrificial layer of the film with grid-like cracks;

[0033] Step 3. Preparation of the silver metal mesh electrode: the sacrifici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com