Preparation method and application of porous carbon-rich g-C3N4 photocatalyst

A photocatalyst, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of low photocatalytic efficiency, application limitation, low surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Pure g-C3N4 photocatalyst of embodiment 1

[0029] (1) Preparation method

[0030] Measure 2.52 grams of melamine into an alumina crucible, transfer it to a muffle furnace, and bake it at 550°C for 4 hours in an air atmosphere (the heating rate is 5°C.min-1) to obtain pure g-C3N4 photocatalyst.

[0031] (2) Detection

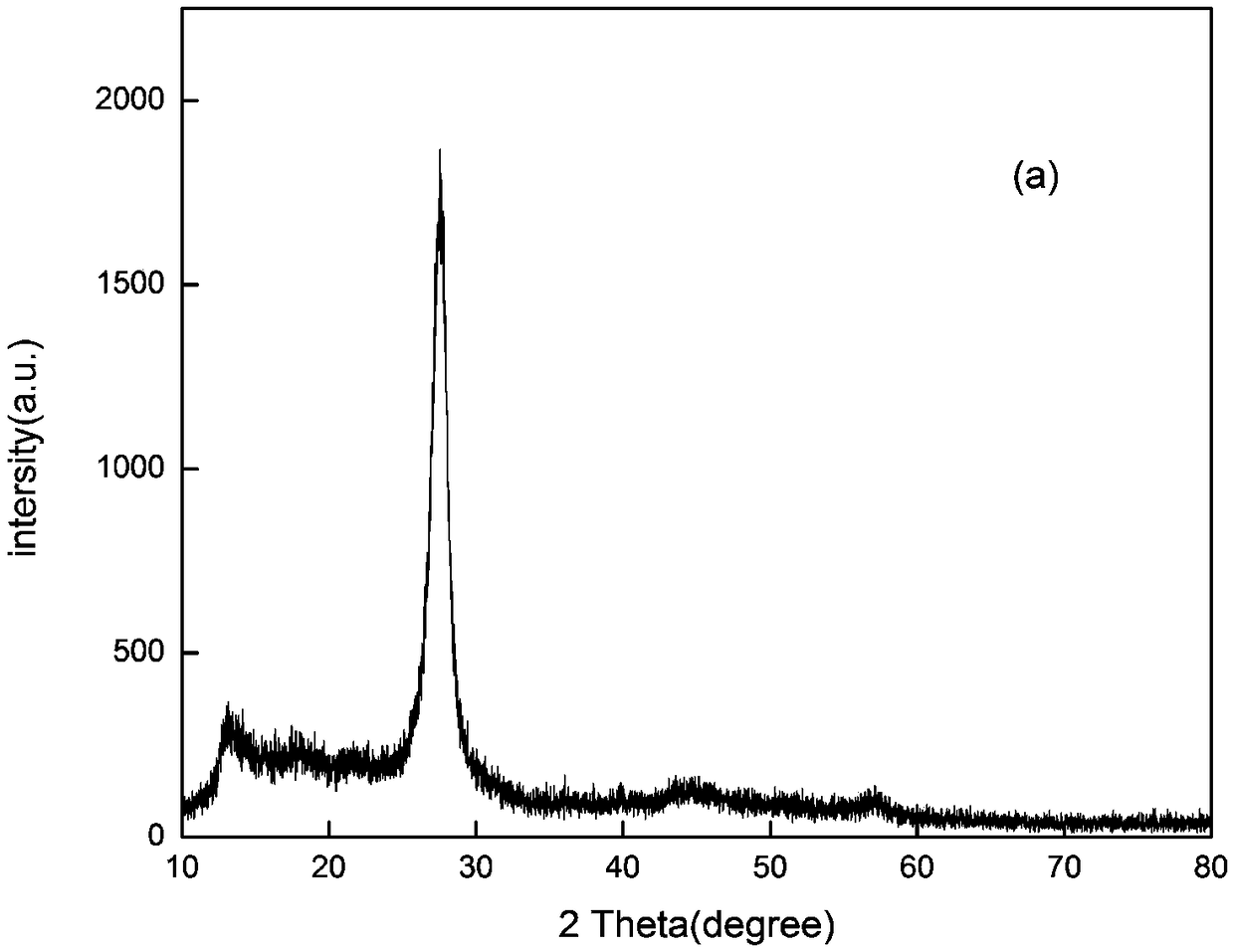

[0032] figure 1 It is the XRD detection of pure g-C3N4 photocatalyst sample. Depend on figure 1 It can be seen that two diffraction peaks appear at 13.1 degrees and 27.4 degrees, corresponding to the (002) and (100) crystal planes of g-C3N4 respectively. It can be seen from the figure that the sample has good crystallinity.

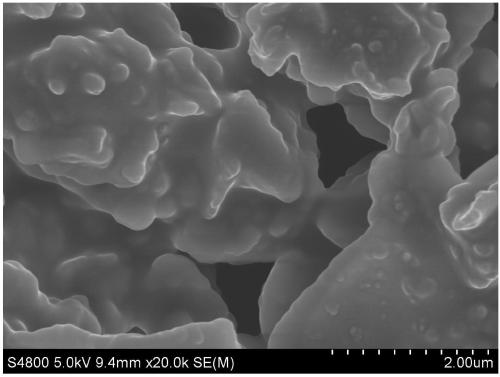

[0033] figure 2 SEM detection for pure g-C3N4 photocatalyst samples. Depend on figure 2 It can be seen that pure g-C3N4 shows a typical block structure, and the sample does not show the existence of pores in the SEM image.

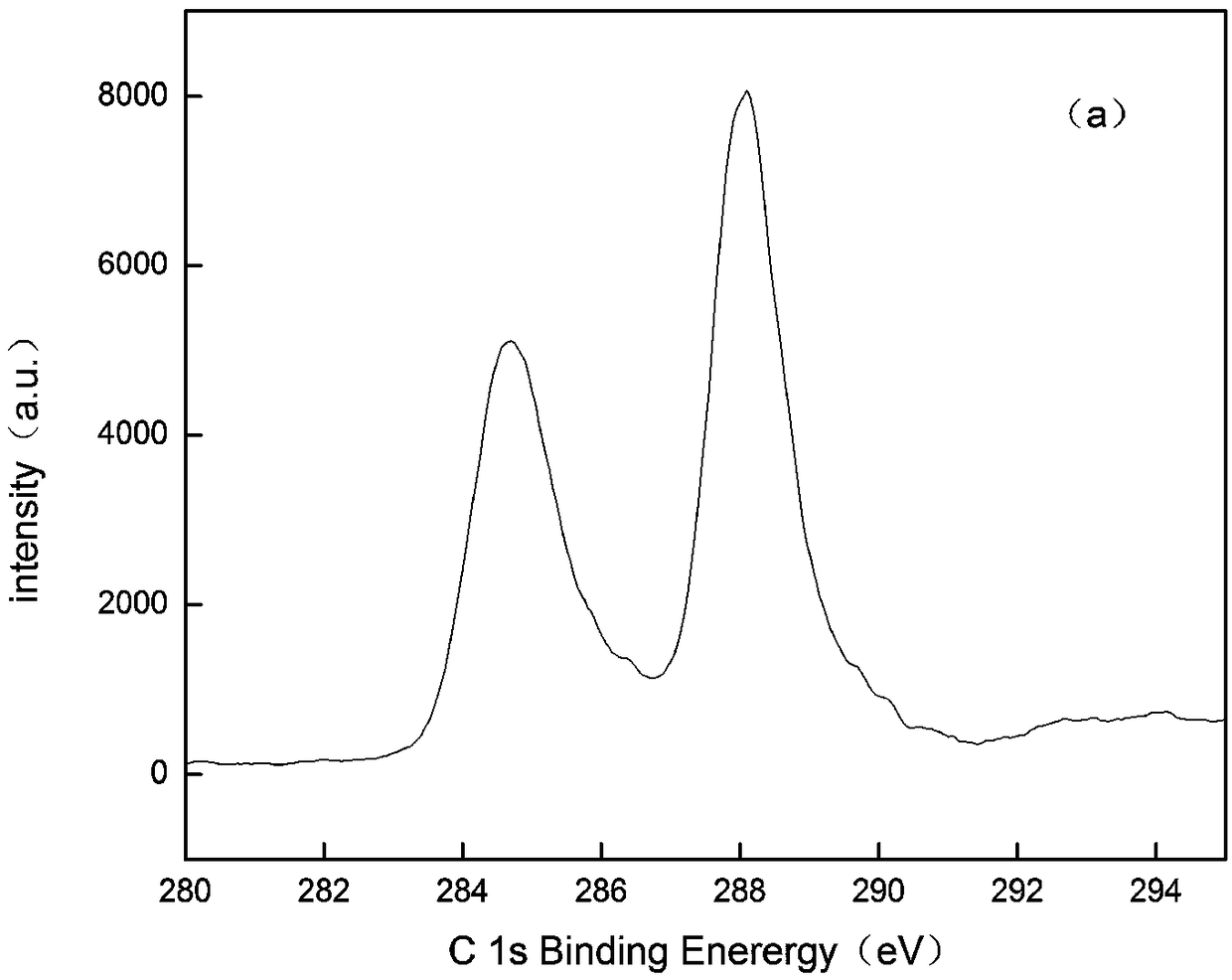

[0034] image 3 It is the XPS detection of pure g-C3N4 photocatalyst sample. Depend on image 3 I...

Embodiment 2

[0036] Example 2 Porous carbon-rich g-C3N4 photocatalyst

[0037] (1) Preparation method

[0038] 1) Add 2.52 g of melamine solid and 0.1512 g of activated carbon powder into 50 ml of absolute ethanol, stir for 2 h until uniformly mixed, and then transfer to an oven for 14 h after ultrasonication for 30 min to obtain a gray intermediate product.

[0039] 2) Grind the obtained gray intermediate product, put it into an alumina crucible, transfer it to a muffle furnace, and in an air atmosphere, bake it at 550°C for 4h (heating rate of 5°C per minute) to obtain g-C3N4 powder.

[0040] 3) After grinding the g-C3N4 powder with amorphous nano-carbon particles again, it is annealed in a muffle furnace at 470 ° C for 2 h (heating rate 5 ° C per minute), and the porous carbon-rich g-C3N4 photocatalyst .

[0041] (2) Detection

[0042] Figure 4 XRD test for porous carbon-rich g-C3N4 samples. Depend on Figure 4 It can be seen that the sample has good crystallinity, as shown in t...

Embodiment 3

[0046] Example 3 Application of porous carbon-rich g-C3N4 photocatalyst (modified precursor g-C3N4)

[0047] The porous carbon-rich g-C3N4 photocatalyst prepared in Example 2 was subjected to a photocatalyst material performance test.

[0048] The method is as follows: 0.05 g of pure g-C3N4 and porous carbon-rich g-C3N4 were weighed and added to 50 ml of rhodamine B solution with a mass fraction of 10 mg / L, and stirred for 30 minutes in the dark to make them fully contact. With a 300W xenon lamp as the light source, adjust the photocurrent to 20mA, adjust the center of the light intensity to irradiate the sample surface, fix the position, mix the pure g-C3N4 rhodamine B solution and the mixed porous carbon-rich g-C3N4 rhodamine respectively Put the B solution under the light source, take 2ml of Rhodamine B every 20 minutes, and test the absorbance of the sample to prove the degradation of Rhodamine B.

[0049] The result is as Figure 8 As shown, after 20 minutes of light ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com