Manufacturing method of N-warping-degree false eyelashes, manufacturing tool and N-warping-degree false eyelashes

A manufacturing method and technology of false eyelashes, which are applied in the direction of baldness-covering wigs, hat products, clothing, etc., can solve the problems of inconvenient operation, less natural and realistic effect, and no way to achieve customer effect, so as to achieve natural and beautiful shape and easy Grafting, the effect of large market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

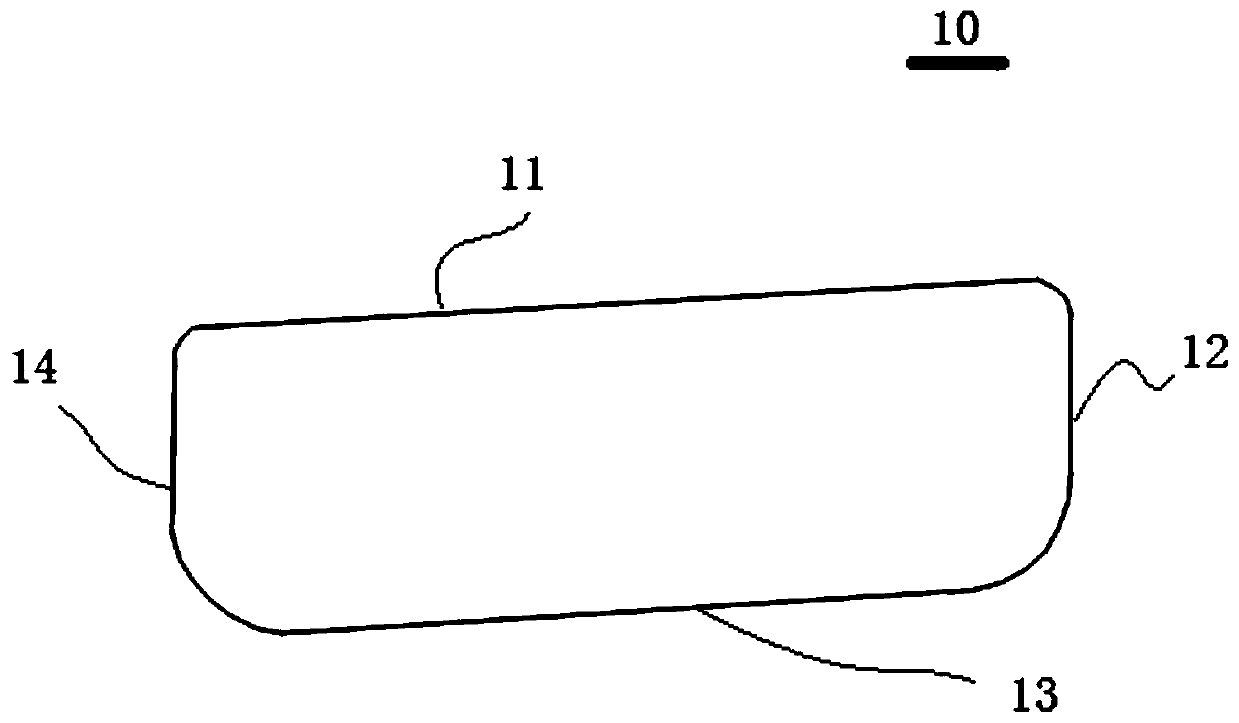

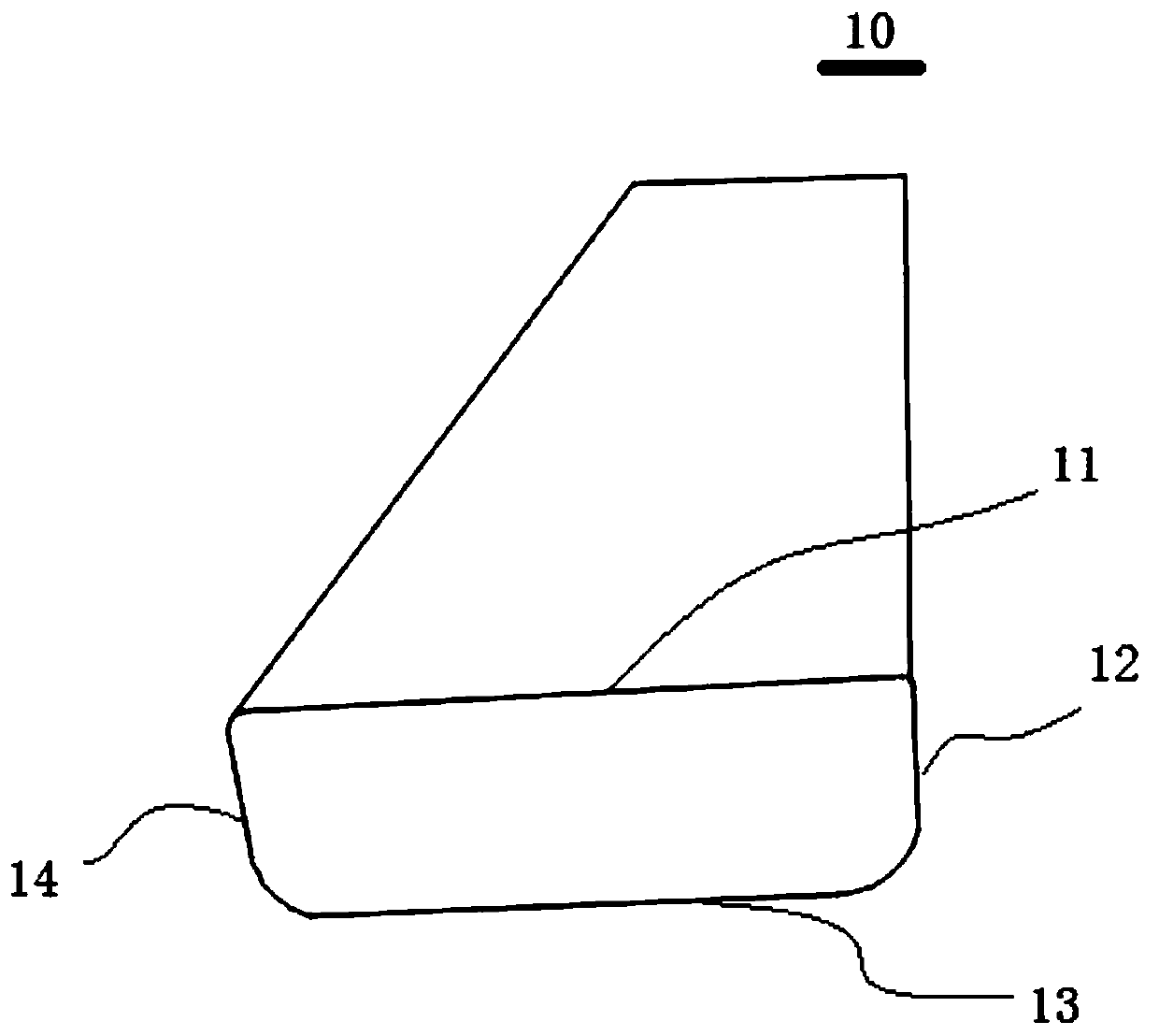

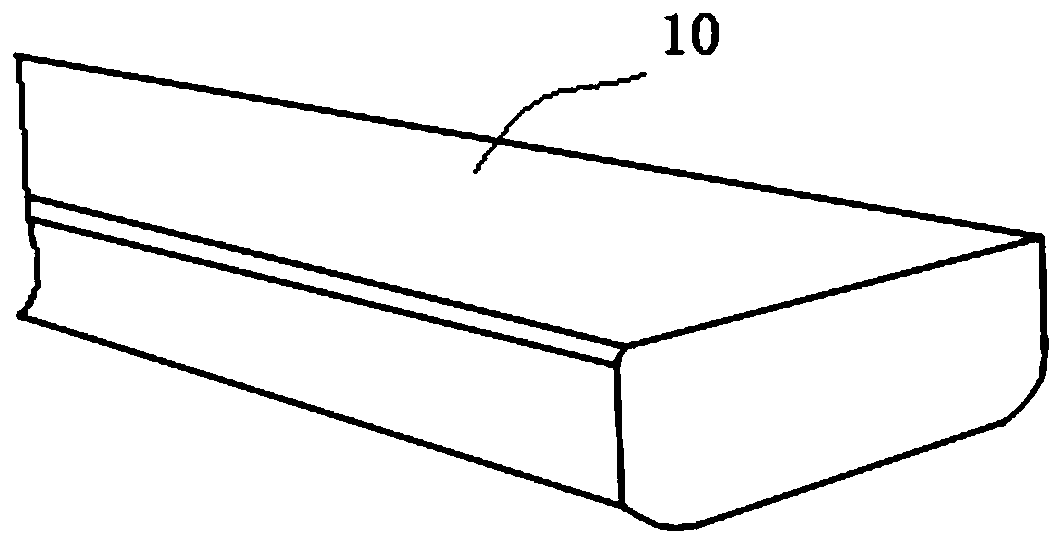

[0037] figure 1 It is a schematic structural diagram of a manufacturing tool for curled false eyelashes according to an embodiment of the present application. figure 2 Yes figure 1 Schematic perspective view of the fabrication tool shown. image 3 Yes figure 1 Schematic perspective view of the fabrication tool shown. Figure 7 It is a schematic structure diagram of N curled false eyelashes according to an embodiment of the present application.

[0038] like figure 1 shown, see also Figure 2-Figure 3 and Figure 7 , the present embodiment provides a manufacturing tool for N-warped false eyelashes, including a shaping tool 10 for making false eyelashes 20 produce N-warping, and the shaping tool 10 is a flat strip. The cross section of the forming tool 10 is rectangular. The cross-section is composed of an upper line 11 , a right line 12 , a lower line 13 and a left line 14 . Wherein, the angle formed by the upper line 11 and the right line 12, and the angle formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com