Photocatalysis thin film with illumination and purifying coupling function and manufacture method thereof

A photocatalytic film and functional technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high operation and maintenance costs, difficulty in popularization, low photocatalytic efficiency, etc. Excellent light conversion performance, simple preparation process, and strong coating combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

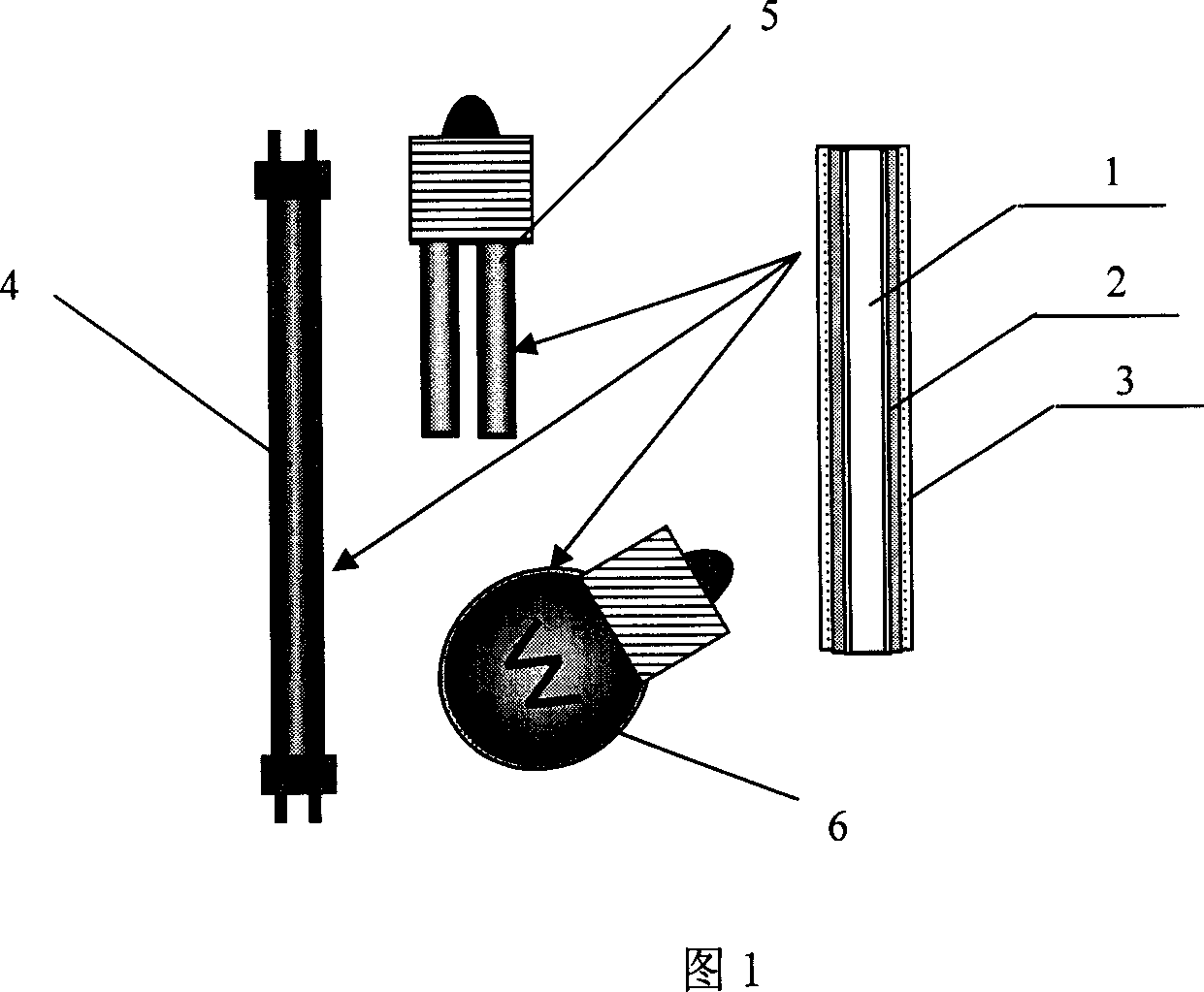

[0060] The preparation steps of the film proposed by the present invention are as follows:

[0061] 1) Surface pretreatment of lighting illuminant glass:

[0062] 1.1) Dust removal and degreasing of lamp tubes Since the glass lamp tubes or bulbs used for lighting are inevitably exposed to dust and grease pollution during the manufacturing, inspection, packaging and sales process, in order to improve the adhesion and aesthetics of the photocatalytic film, it must be degreased first. Cleaning of lamps. The process steps include: (1) wiping the glass lamp tube with clean absorbent cotton; (2) further cleaning with ethanol and acetone organic solvents; (3) dipping and degreasing with concentrated NaOH solution heated to 80-100°C; 4) Wash with tap water, deionized water, ethanol and acetone in sequence; (5) Dry the sample with a hair dryer for later use.

[0063] 1.2) Etching on the surface of the lamp tube: In order to improve the adhesion of the light transfer film, it is neces...

Embodiment 1

[0079] 1) Surface pretreatment of lighting illuminant glass:

[0080] Wipe the lamp tube with clean absorbent cotton to remove dust; degrease with concentrated NaOH solution heated to 80°C; clean with tap water, deionized water, ethanol and acetone in sequence; dry with a hair dryer for later use.

[0081] The illuminant glass that has been dedusted and degreased is evenly immersed in a 0.05M ammonium bifluoride solution for etching, and the immersion time is 10 minutes. Then wash with tap water, deionized water, ethanol and acetone, and dry with a hair dryer.

[0082] 2) The glass surface of the lighting illuminant is dip-coated with a light-transferring transparent film:

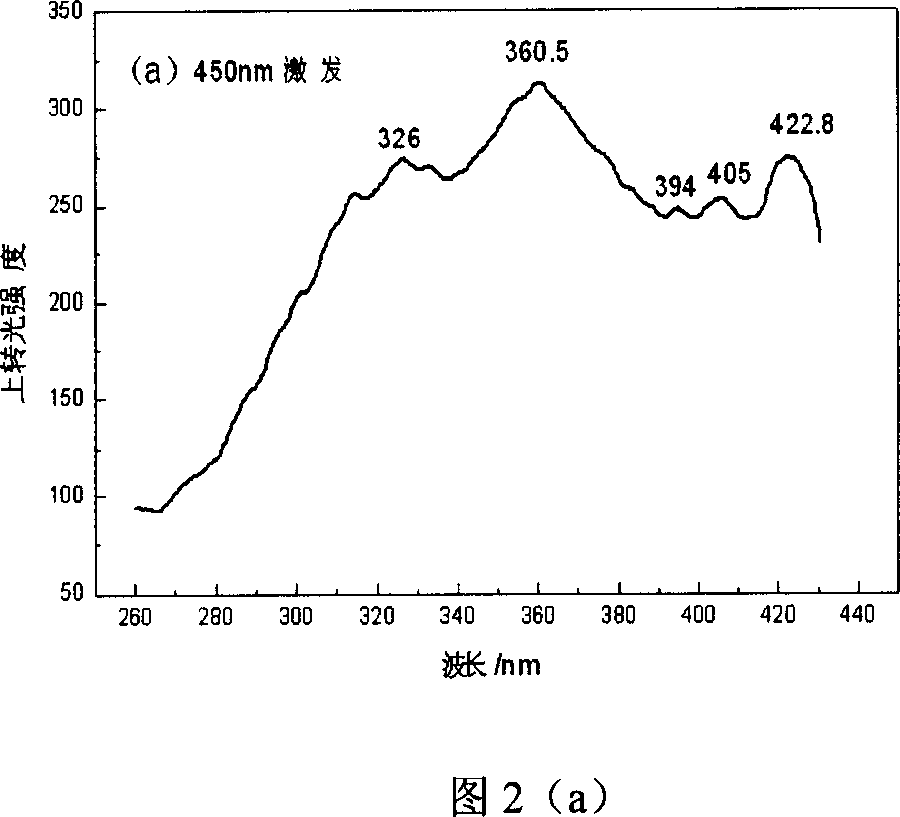

[0083] by SiO 2 Content is 60%, B 2 o 3 Content is 12%, K 2 O+Li 2 O content is 20%, Er 2 o 3 Content is 0.5%, Yb 2 o 3 Combining components with a content of 7.5% to prepare an up-conversion glass precursor, the steps are: prepare 3g / L alkaline silica sol; dissolve the corresponding calculated a...

Embodiment 2

[0089] 1) Surface pretreatment of lighting illuminant glass:

[0090] Wipe the illuminant glass with clean absorbent cotton to remove dust from the lamp tube; dip and degrease it several times with concentrated NaOH solution heated to 100°C; clean it with tap water, deionized water, ethanol and acetone in sequence; dry it with a hair dryer for later use. The illuminant glass that has been dedusted and degreased is uniformly immersed in 0.5M ammonium bifluoride solution for etching, and the immersion time is 0.5 minutes. Then wash with tap water, deionized water, ethanol and acetone, and dry with a hair dryer.

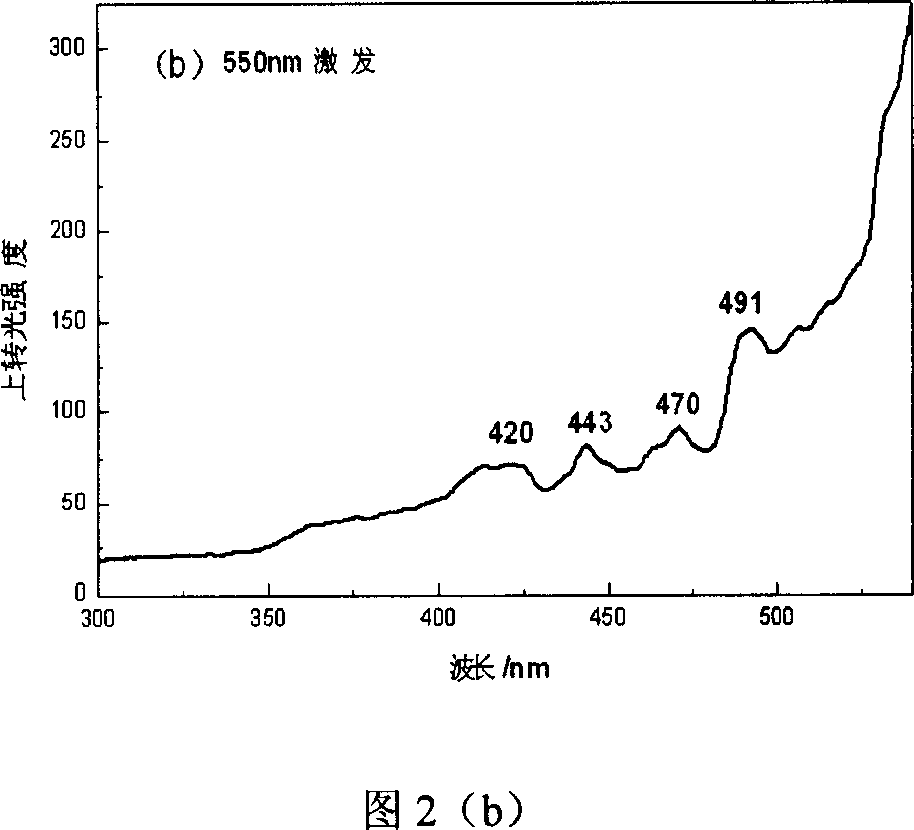

[0091] 2) The glass surface of the lighting illuminant is dip-coated with a light-transferring transparent film:

[0092] by SiO 2 Content is 62%, B 2 o 3 Content is 10%, K 2 O+Li 2 O content is 15%, Pu 2 o 3 Content is 3%, Yb 2 o 3 Combining components with a content of 10% to prepare an up-conversion glass precursor, the steps are: prepare 30g / L alkaline sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com