Method for modifying nano metal oxide by coupling graft

A technology of nano-metal and graft modification, which is applied in the treatment of dyed organic silicon compounds, dyed low-molecular organic compounds, and fibrous fillers. Slow rate, low activity of organic long-chain molecules, etc., to achieve the effects of not easy side reactions, low cost, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

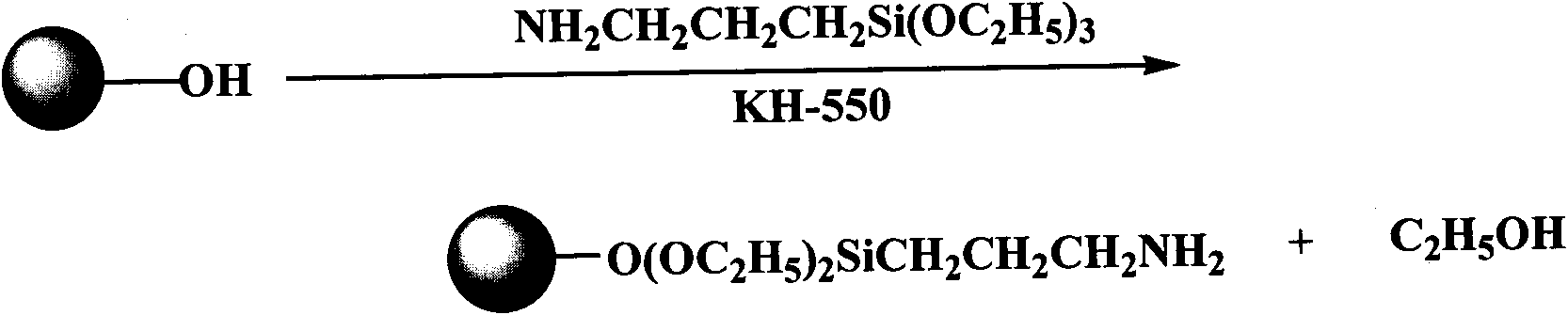

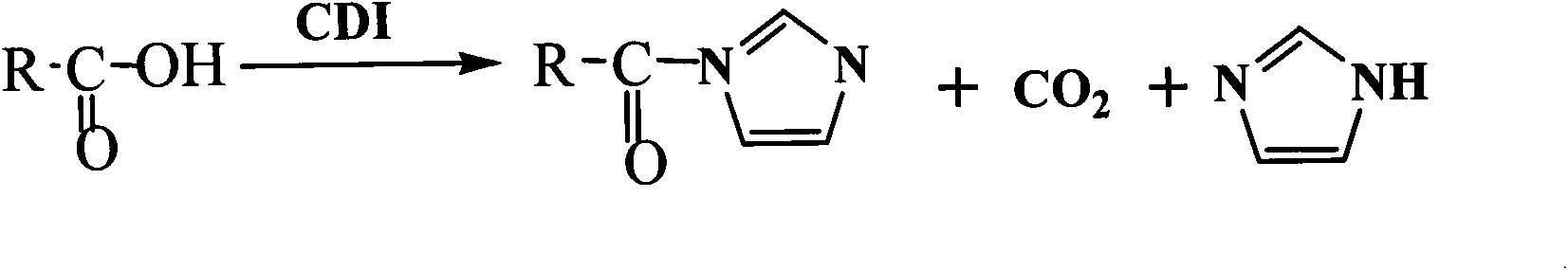

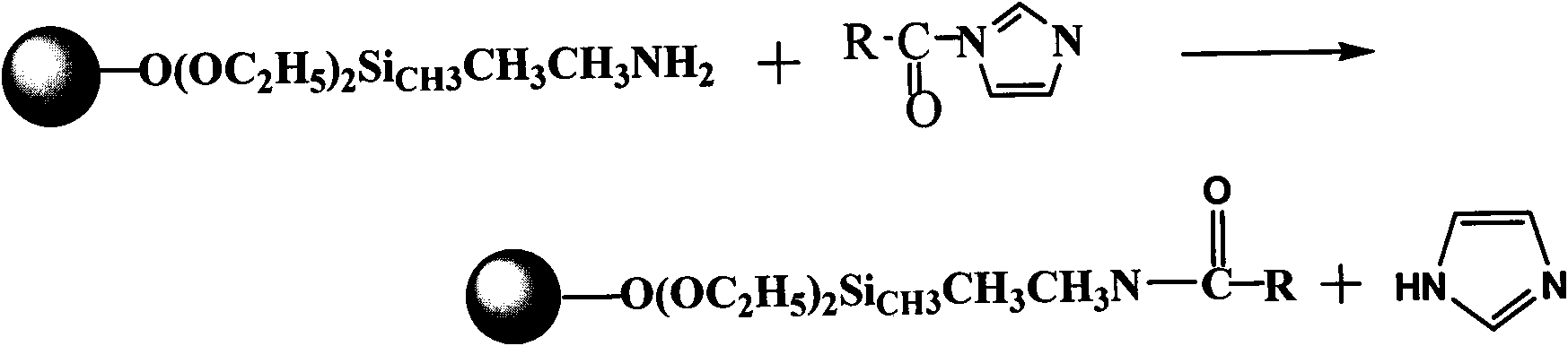

[0034] Such as Figure 1~3 Shown, the concrete steps of a kind of method of coupling graft modification nano-metal oxide are as follows:

[0035] (1) Drying treatment of nanoparticles

[0036] Nano zinc oxide powder with an average particle size of 20nm was put into a high-temperature muffle furnace, and dried at 300° C. for 12 hours.

[0037] (2) Coupling reaction of nanoparticles

[0038] After the first step (1) is completed, first the nano-zinc oxide powder after the drying treatment of the (1) step and aminopropyltriethoxysilane coupling agent and toluene are added in the three-port reaction vessel, and the nano-zinc oxide The mass ratio of powder:aminopropyltriethoxysilane coupling agent:toluene is 1:0.02:50. Then feed high-purity nitrogen into the three-port reaction vessel to isolate the influence of oxygen in the air on the reaction, and heat the temperature of the mixed solution to 80 ° C. At the same time, open the circulating condensed water at the gas outlet of...

Embodiment 2

[0049] A kind of concrete steps of the method for coupling graft modification nano-metal oxide, with embodiment 1, wherein:

[0050] In step (1), the nanometer metal oxide powder used is nanometer titanium dioxide powder with an average particle diameter of 10 nm. The drying temperature was 400° C., and the drying time was 6 hours.

[0051] In the (2) step, the aminosilane coupling agent used is 2-aminoethylaminopropyl trimethoxysilane coupling agent, nanometer titanium dioxide powder: 2-aminoethylaminopropyl trimethoxysilane coupling agent The mass ratio of :toluene was 1:0.005:10, the temperature of the mixed solution was heated to 40° C., and the stirring time was 18 hours.

[0052] In step (3), the Soxhlet extraction time is 36 hours, the drying temperature is 100° C., and the drying time is 24 hours.

[0053] In the (4) step, the organic acid used is oleic acid, and the quality of oleic acid is 0.5 times of the quality of the 2-aminoethylaminopropyltrimethoxysilane coup...

Embodiment 3

[0058] A kind of concrete steps of the method for coupling graft modification nano-metal oxide, with embodiment 1, wherein:

[0059] In step (1), the nano metal oxide powder used is a nano silicon dioxide powder with an average particle diameter of 50 nm. The drying temperature was 100° C., and the drying time was 24 hours.

[0060] In the (2) step, the aminosilane coupling agent used is an aminoethylaminopropyltriethoxysilane coupling agent, wherein nano-silica powder: aminoethylaminopropyltriethoxysilane coupling The mass ratio of agent:toluene is 1:0.1:75, the temperature of the mixed solution is heated to 110° C., and the stirring time is 4 hours.

[0061] In step (3), the Soxhlet extraction time is 6 hours, the drying temperature is 270° C., and the drying time is 6 hours.

[0062] In the (4) step, the organic acid used is 12-hydroxy octadecanoic acid, and the quality of 12-hydroxy octadecanoic acid is that of the aminoethylaminopropyl triethoxysilane coupling agent add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com