Polymer powder puff with oil-absorbing effect and preparation method thereof

A polymer and material technology, applied in the field of polymer powder puff with oil absorption effect and its preparation, can solve the problems of white pollution, environmental hazards, skin damage, etc., and achieve the effects of easy access to sources, environmental protection, and increased elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

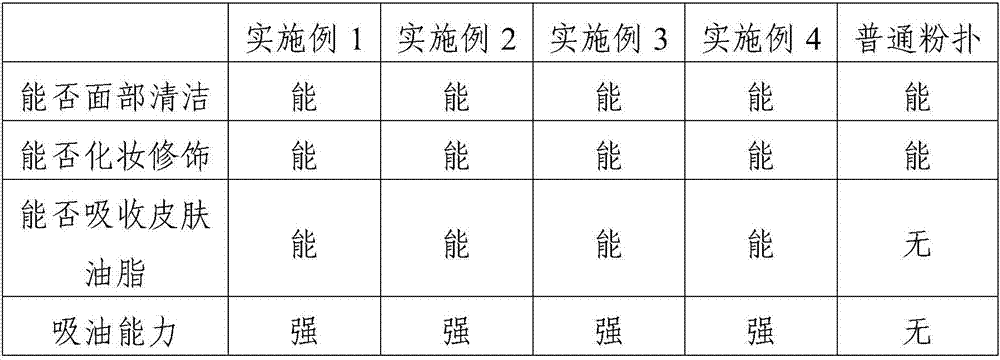

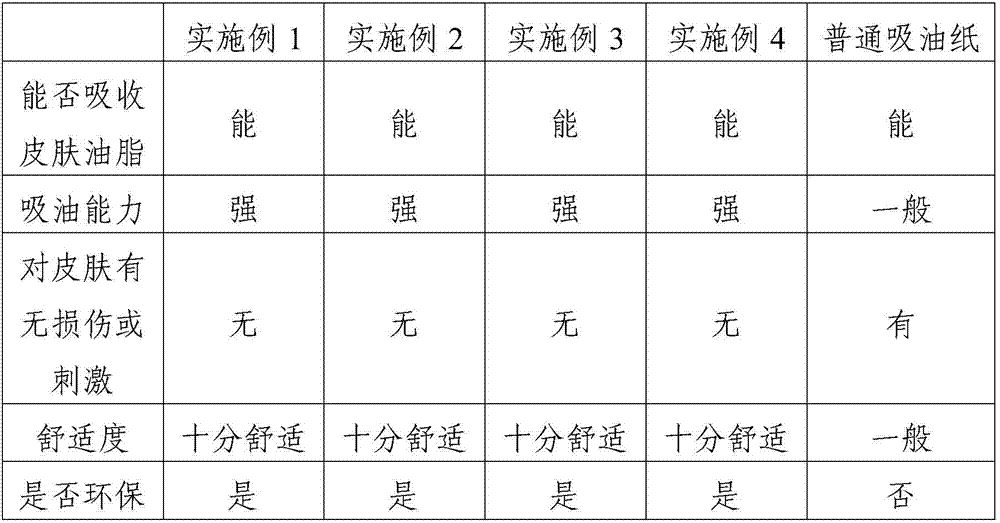

Examples

Embodiment 1

[0030] A polymer powder puff with oil-absorbing effect, made of the following raw materials in parts by weight: 220 parts of polyether polyols, 240 parts of isocyanates, 150 parts of reactive hardeners, 90 parts of foaming agents, 8 parts of catalysts, 15 parts of plant fiber, 11 parts of chamomile extract, 35 parts of alkyl methacrylate, 25 parts of alkyl acetate, 30 parts of crosslinking agent.

[0031] A method for preparing a polymer puff with oil-absorbing effect, comprising the following steps:

[0032] (1) Divide the plant fiber into two equal parts, one part is made into slurry, and the other part is ground into fluff;

[0033] (2) Put the fluffy plant fibers in the reaction kettle, add hydrochloric acid solution, react at 95°C for 2 hours, cool down after the reaction and adjust the pH to neutral with lye, vacuum filter and place in another reactor middle;

[0034] (3) Add alkyl methacrylate, alkyl acetate and crosslinking agent to the reactor in step (2), react at ...

Embodiment 2

[0039] A polymer powder puff with oil-absorbing effect, made of the following raw materials in parts by weight: 200 parts of polyether polyols, 180 parts of isocyanates, 100 parts of reactive hardeners, 80 parts of foaming agents, 6 parts of catalysts, 10 parts of plant fiber, 10 parts of chamomile extract, 30 parts of alkyl methacrylate, 20 parts of alkyl acetate, 20 parts of crosslinking agent.

[0040] A method for preparing a polymer puff with oil-absorbing effect, comprising the following steps:

[0041] (1) Divide the plant fiber into two equal parts, one part is made into slurry, and the other part is ground into fluff;

[0042] (2) Put the fluffy plant fibers in the reaction kettle, add hydrochloric acid solution, react at 90°C for 1 hour, cool down after the reaction and adjust the pH to neutral with lye, vacuum filter and place in another reactor middle;

[0043] (3) Add alkyl methacrylate, alkyl acetate and crosslinking agent to the reactor in step (2), react at 4...

Embodiment 3

[0048] A polymer powder puff with oil-absorbing effect, made of the following raw materials in parts by weight: 240 parts of polyether polyols, 300 parts of isocyanates, 200 parts of reactive hardeners, 100 parts of foaming agents, 10 parts of catalysts, 20 parts of plant fiber, 12 parts of chamomile extract, 40 parts of alkyl methacrylate, 30 parts of alkyl acetate, 40 parts of crosslinking agent.

[0049] A method for preparing a polymer puff with oil-absorbing effect, comprising the following steps:

[0050] (1) Divide the plant fiber into two equal parts, one part is made into slurry, and the other part is ground into fluff;

[0051] (2) Put the fluffy plant fibers in a reaction kettle, add hydrochloric acid solution, and react at 100°C for 3 hours. After the reaction is completed, cool down and adjust the pH to neutral with lye, and vacuum filter and place in another reactor middle;

[0052] (3) Add alkyl methacrylate, alkyl acetate and cross-linking agent to the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com