High-temperature resistant forming oil for forming stainless steel part of automobile and preparation method of oil

A molding oil and stainless steel technology, which is applied in the petroleum industry, base materials, additives, etc., can solve the problems of unsatisfactory lubricating performance, low machining accuracy, poor fatigue resistance, etc., and achieve strong cycle and high efficiency, good color quality , Excellent anti-wear and pressure-reducing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

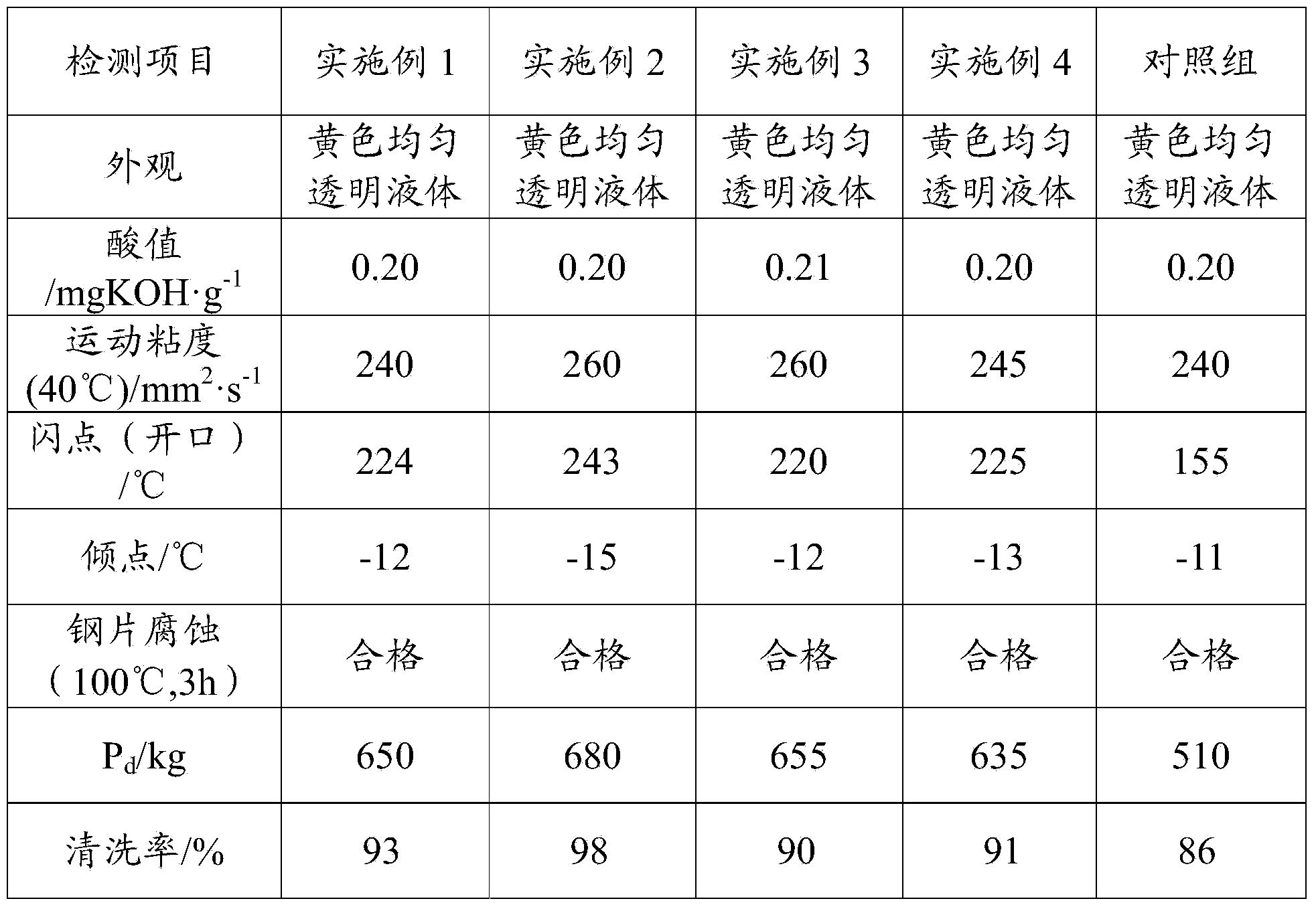

Examples

Embodiment 1

[0045] A high-temperature-resistant and environment-friendly molding oil for molding stainless steel parts of automobiles, the molding oil is prepared from the following raw materials in weight percentage:

[0046] Waste engine oil base oil: 60wt%,

[0047] High oleic sunflower oil: 15wt%,

[0048] Sulfurized olefin: 8wt%,

[0049] Sulfurized fatty acid ester: 5wt%,

[0050] Chlorinated petroleum grease: 9.7wt%,

[0051] Emulsifier: 2wt%,

[0052] Aromatic amine antioxidant - dialkyl diphenylamine: 0.3wt%,

[0053] The preparation method of described waste engine oil base oil, comprises the steps:

[0054] (1) Impurity removal: Add activated clay with an oil content of 4wt% to the recovered waste engine oil, stir for 10 minutes at room temperature, let it settle for precipitation, and separate the activated clay residue in the lower layer to obtain a brownish-reddish black clarified liquid in the upper layer.

[0055] (2) Purification: heat the clarified liquid obtained ...

Embodiment 2

[0061] A high-temperature-resistant and environment-friendly molding oil for molding stainless steel parts of automobiles, the molding oil is prepared from the following raw materials in weight percentage:

[0062] Waste engine oil base oil: 50wt%,

[0063]Tetrapolyglycerol oleate: 25wt%,

[0064] Sulfurized olefin: 5wt%,

[0065] Sulfurized fatty acid ester: 6wt%,

[0066] Chlorinated petroleum grease: 9wt%,

[0067] Emulsifier: 4wt%

[0068] Aromatic amine antioxidant - alkylated N-phenyl-α-naphthylamine: 1wt%,

[0069] The preparation method of described waste engine oil base oil, comprises the steps:

[0070] (1) Impurity removal: add activated clay with an oil content of 3wt% to the recovered waste engine oil, stir at room temperature for 10 minutes, let it stand for precipitation, and separate the activated clay waste residue in the lower layer, and the brownish reddish black clarified liquid in the upper layer;

[0071] (2) Purification: heat the clarified liquid ...

Embodiment 3

[0077] A high-temperature-resistant and environment-friendly molding oil for molding stainless steel parts of automobiles, the molding oil is prepared from the following raw materials in weight percentage:

[0078] Waste engine oil base oil: 53.9wt%,

[0079] Trimethylolpropane oleate: 10wt%,

[0080] Sulfurized olefin: 10wt%,

[0081] Sulfurized fatty acid ester: 10wt%,

[0082] Chlorinated petroleum grease: 15wt%,

[0083] Emulsifier: 1wt%,

[0084] Aromatic amine antioxidant - dialkyl diphenylamine: 0.1wt%,

[0085] The preparation method of described waste engine oil base oil, comprises the steps:

[0086] (1) Impurity removal: add activated clay with an oil content of 2wt% to the recovered waste engine oil, stir at room temperature for 5-10 minutes, let it settle for precipitation, and separate the activated clay waste residue in the lower layer, and the brownish reddish black clarified liquid in the upper layer;

[0087] (2) Purification: heat the clarified liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com