Novel material for totally nontoxic non-polyvinyl chloride medical perfusion tube and method for manufacturing same

A polyvinyl chloride and new material technology, applied in the field of polymer medical materials, can solve problems such as difficulties, performance defects, performance gaps of infusion tubes, etc., and achieve the effect of large output and moderate production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

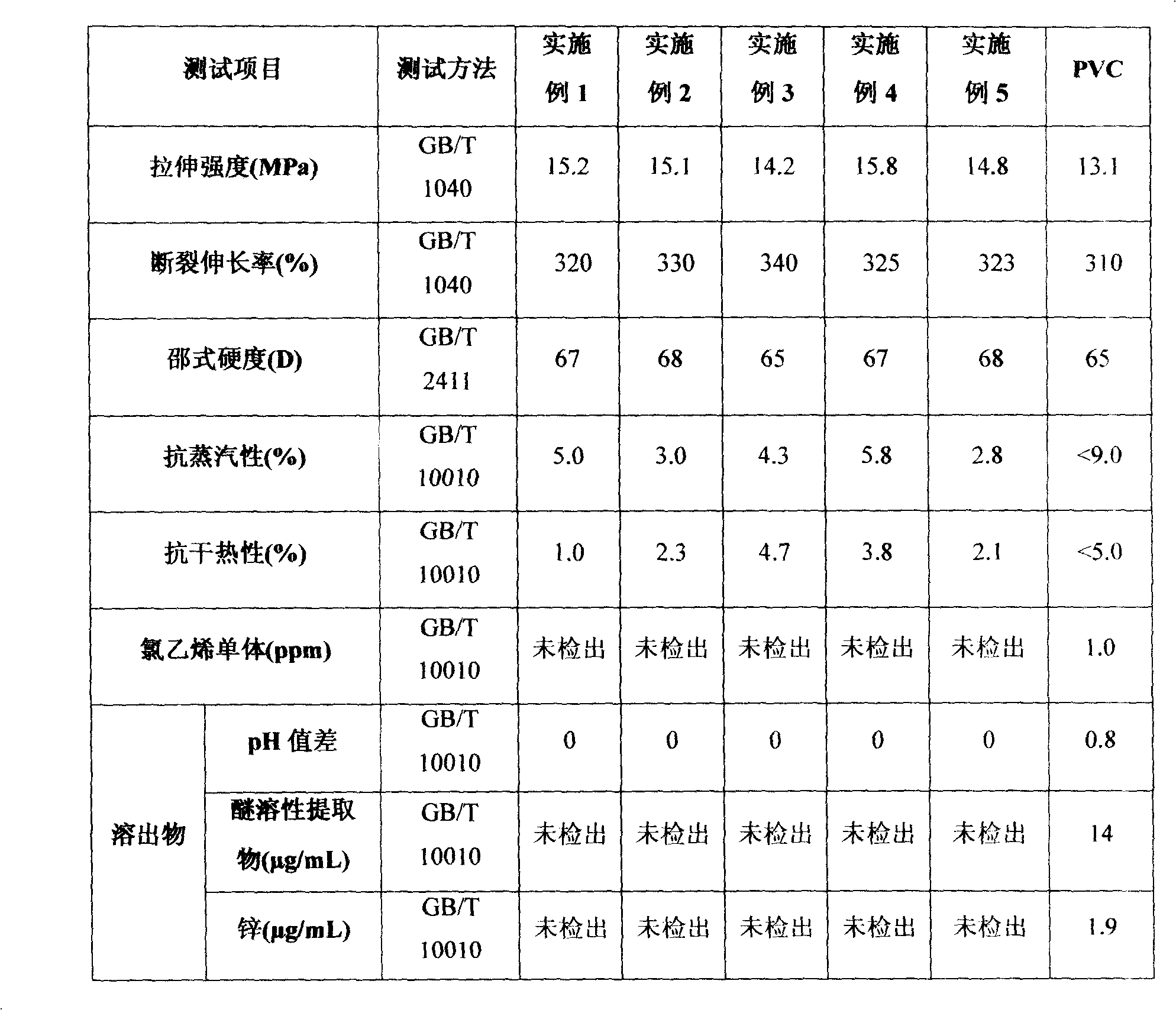

Examples

Embodiment 1

[0020] The completely non-toxic non-polyvinyl chloride medical infusion tube material uses a partially hydrogenated linear diblock styrene-hydrogenated 1,3-butadiene block copolymer with a molecular weight of 30,000, and the auxiliary raw material is low molecular weight ethylene with a molecular weight of 2,000. -Propylene copolymer and modified natural antioxidant vitamin E. The degree of hydrogenation of the linear diblock styrene-hydrogenated 1,3-butadiene block copolymer was 50%. This new type of material for medical infusion tubes is continuously produced by co-rotating twin-screw extruders. The production method is: 100kg of partially hydrogenated partially hydrogenated linear diblock styrene-hydrogenated 1,3-butadiene block copolymer, 5kg of low molecular weight ethylene-propylene copolymer and 0.01kg of modified vitamin E After being fully compounded, it is added to a co-rotating twin-screw extruder for continuous production. The processing temperature of the screw e...

Embodiment 2

[0022]Completely non-toxic non-polyvinyl chloride medical infusion tube material adopts partially hydrogenated star-shaped diblock styrene-hydrogenated 2-methyl-1,3-butadiene block copolymer with a molecular weight of 40,0000, auxiliary raw materials It is a low molecular weight ethylene-propylene copolymer with a molecular weight of 10,000 and a modified natural antioxidant vitamin E. The degree of hydrogenation of the partially hydrogenated radial diblock styrene-hydrogenated 2-methyl-1,3-butadiene block copolymer was 99.6%. This new type of material for medical infusion tubes is continuously produced by a counter-rotating twin-screw extruder. The manufacturing process is: 100kg of partially hydrogenated radial diblock styrene-hydrogenated 2-methyl-1,3-butadiene block copolymer, 200kg of low molecular weight ethylene-propylene copolymer and 10kg of modified Vitamin E is added to the counter-rotating twin-screw extruder after being fully compounded for continuous production,...

Embodiment 3

[0024] Completely non-toxic non-polyvinyl chloride medical infusion tube material adopts partially hydrogenated star-shaped tri-block styrene-hydrogenated 1,3-butadiene block copolymer with a molecular weight of 300,000, and the auxiliary raw material is a low molecular weight with a molecular weight of 6,000 Ethylene-propylene copolymer and modified natural antioxidant vitamin E. The degree of hydrogenation of the partially hydrogenated radial triblock styrene-hydrogenated 1,3-butadiene block copolymer was 90%. This new type of material for medical infusion tubes is manufactured continuously using a four-screw extruder. The manufacturing process is as follows: 100kg of partially hydrogenated radial triblock styrene-hydrogenated 1,3-butadiene block copolymer, 40kg of low molecular weight ethylene-propylene copolymer and 10kg of modified vitamin E are fully formulated After mixing, it is added to a four-screw extruder for continuous production, and the processing temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com