Patents

Literature

212results about How to "Does not cause allergies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marine biological function cosmetic for minimizing pores

ActiveCN102178636ANo side effectsSmall molecular weightCosmetic preparationsToilet preparationsEmulsionActive ingredient

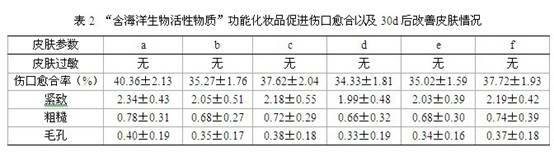

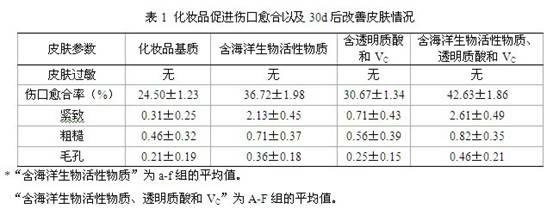

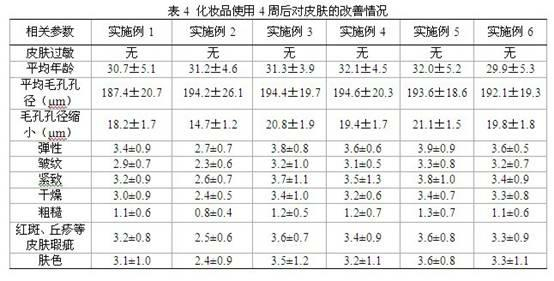

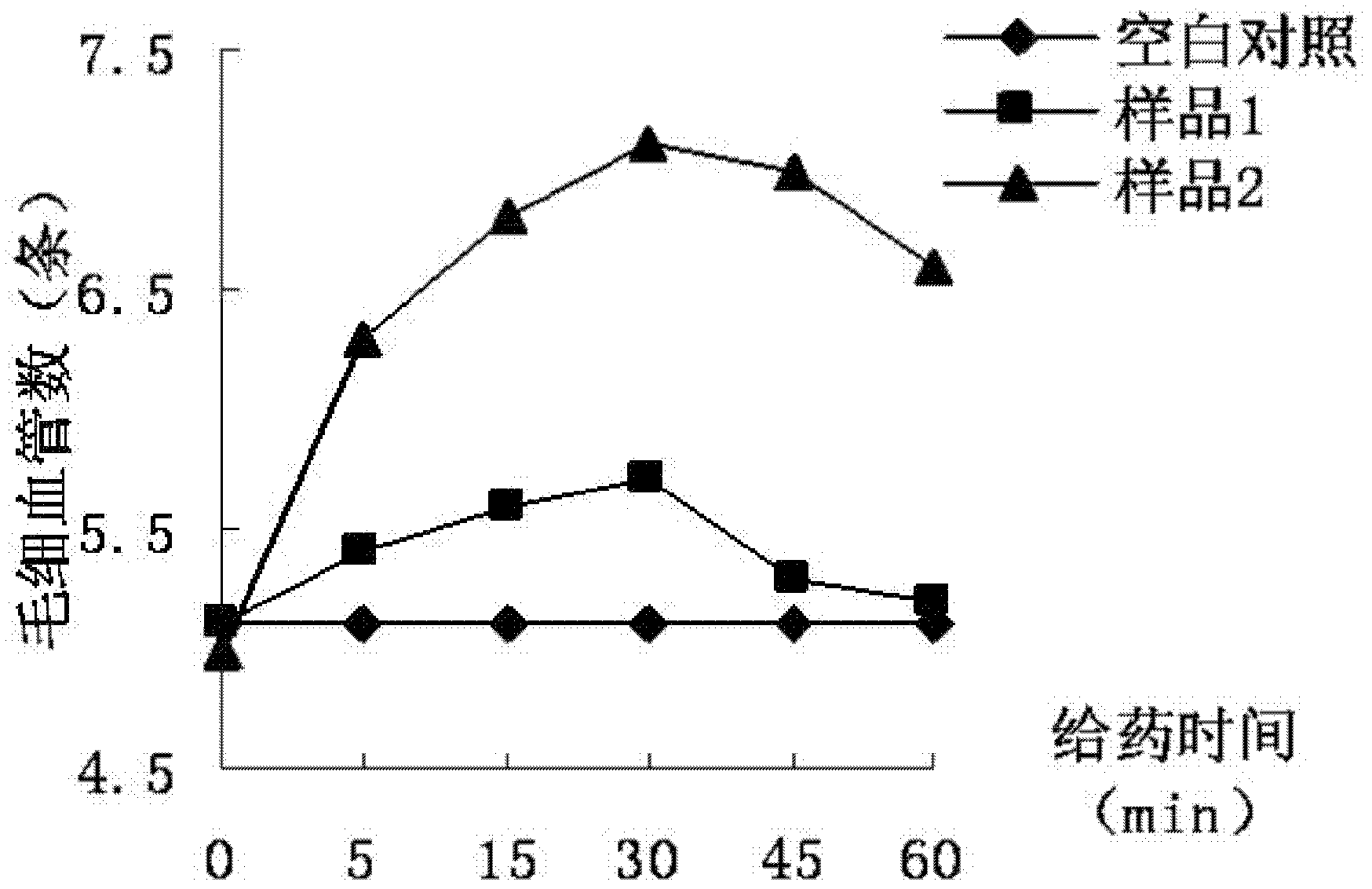

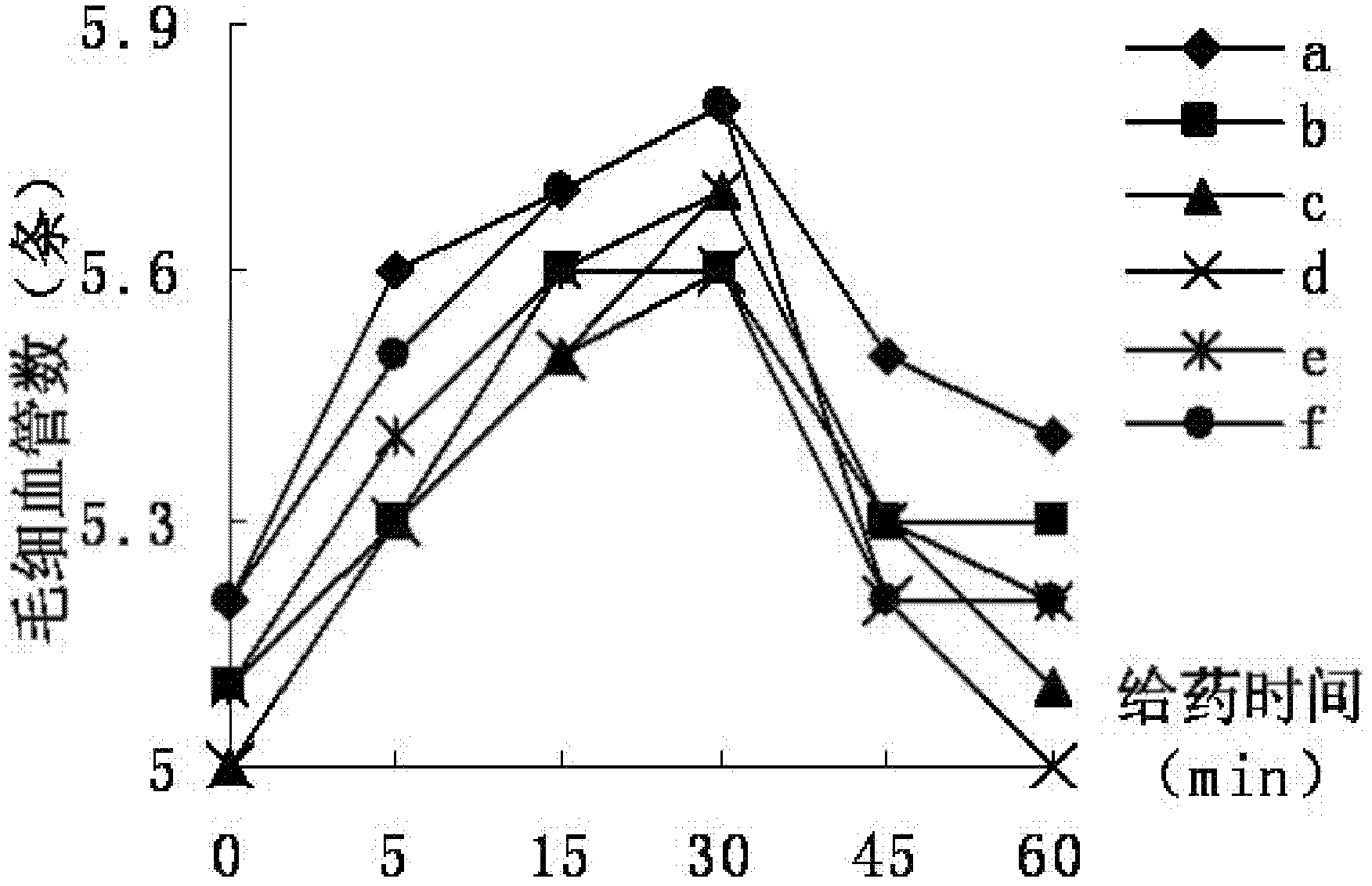

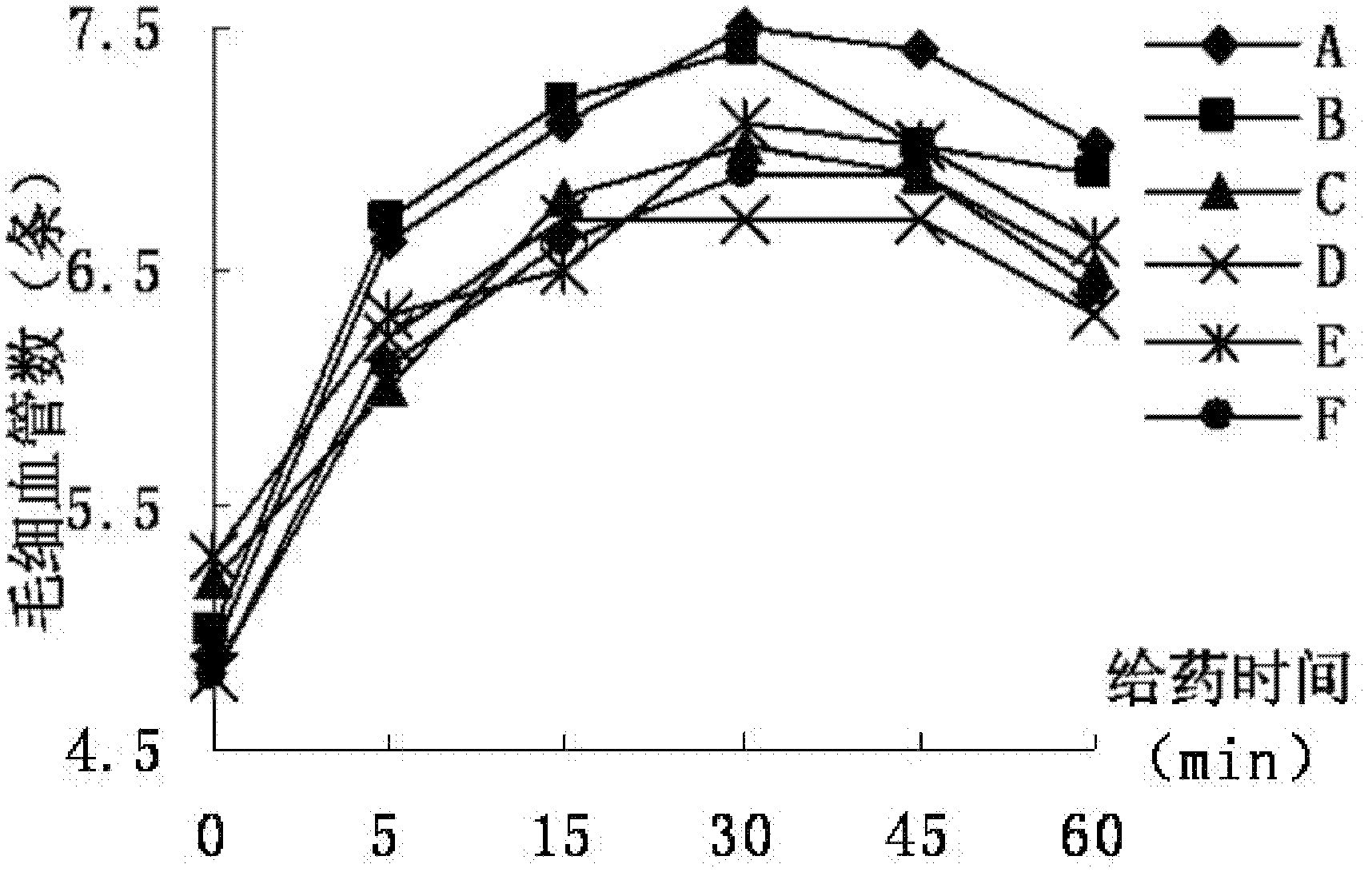

The invention discloses marine biological function cosmetics for minimizing pores. The marine biological function cosmetics for minimizing the pores are prepared by mixing and homogenizing main active ingredients and a cosmetic substrate, wherein the main active ingredients comprise marine shellfish active peptide, marine collagen protein peptide, seaweed polysaccharide and fish oil. Hyaluronic acid and vitamin C (Vc) are added, so that the effect is more obvious. The marine biological function cosmetics for minimizing the pores solve the problems that the conventional cosmetics for minimizing the pores have high irritation and short action time, the marine shellfish active peptide is not applied to cosmetics, the marine biological active substances are not applied to the cosmetics for minimizing the pores and the like. The marine biological function cosmetics for minimizing the pores are safe, mild, high-efficiency and durable, can minimize the pores from inside to outside, recover fineness, softness and smoothness, and enable skin to give out natural, clean and transparent gloss. The marine biological function cosmetics for minimizing the pores have various types, such as cream, emulsion, water agent, gel, spray or masks, have obvious and durable pore-minimizing effect and can serve as the common skin-care products or the cosmetics with the function of minimizing the pores. After the marine biological function cosmetics are not used, the pore bulky symptom is not rebounded.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

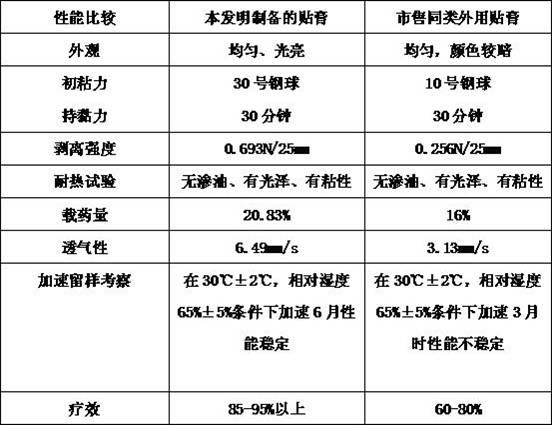

Hot-melt pressure-sensitive adhesive type matrix for medical use and its preparation

InactiveCN1800289AImprove anti-agingOxidative decomposition is goodSurgical adhesivesFilm/foil adhesivesPetroleum resinThermoplastic elastomer

The invention relates to a medical used hot melt pressure-sensitive adhesive type base material and its preparing method which provides a hot melt pressure-sensitive adhesive and an adhesive used paste preparation. The main element of the hot melt pressure-sensitive adhesive is styrenic thermoplastic elastomer SIS (phenylethene -isoprene -phenylethene three block copolymers) with adhesive resin (such as petroleum resin, terpenes polymer, polyisobutylene), flexing oil (such as liquid petrolatum) and aging retarder (such as propyl gallate, BZ) and so on.

Owner:SHANGHAI ARIBA ELECTRIC

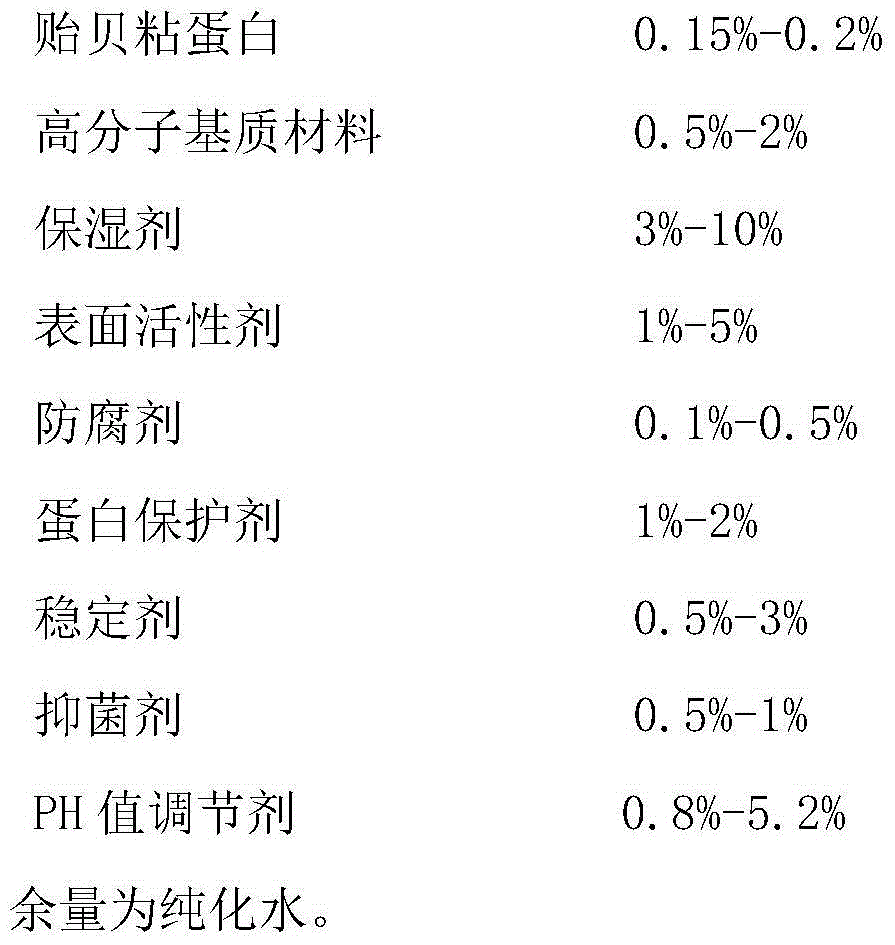

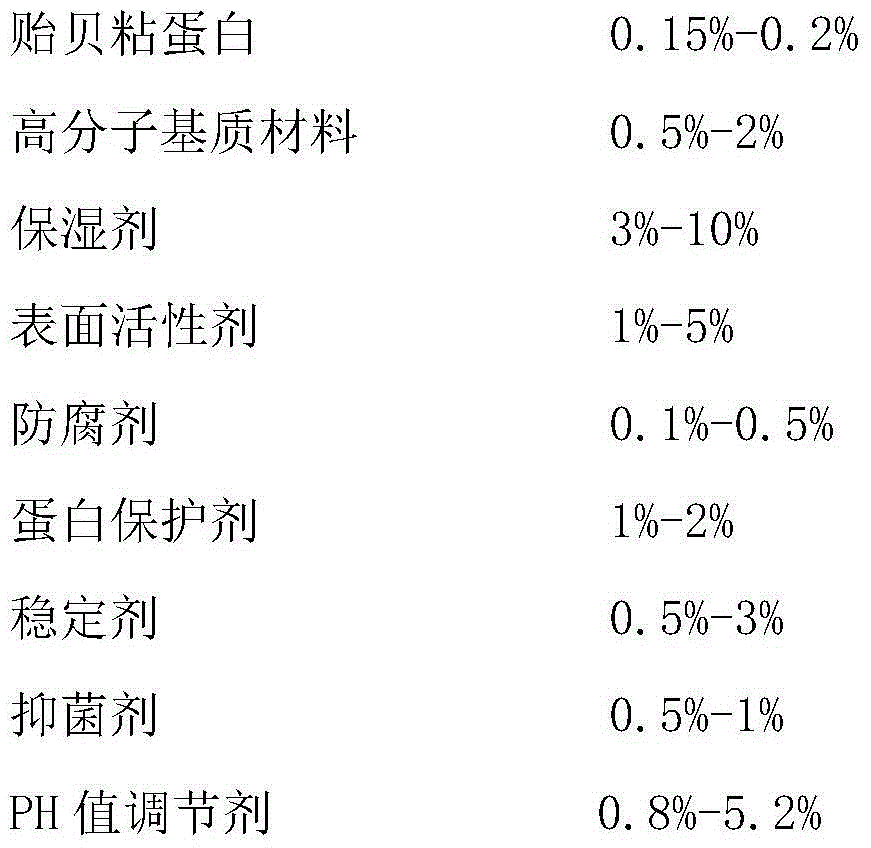

Mussel mucoprotein gel for repairing and reliving itching and preparation method of mussel mucoprotein gel

InactiveCN104645313ANo stimulationGood bioadhesionPeptide/protein ingredientsAerosol deliveryBiocompatibility TestingWound surface

The invention discloses a mussel mucoprotein gel for repairing and reliving itching. The mussel mucoprotein gel is prepared from the following components in percentage by weight: 0.15%-0.2% of mussel mucoprotein, 0.5%-2% of a macromolecule host material, 3%-10% of a humectant, 1%-5% of a surfactant, 0.1%-0.5% of a preservative, 1%-2% of a protein protectant, 0.5%-3% of a stabilizer, 0.5%-1% of a bacteriostatic agent, 0.8%-5.2% of a pH modifier and the balance of purified water. The mussel mucoprotein gel has good biological adhesion, is rapidly and effectively adhered to a wound surface, is capable of rapidly reliving itching and easing pain, and has the advantages of being low in immunogenicity, good in biocompatibility with a human body, convenient to use, free of thrill to skin, safe, nontoxic and free of bad reaction.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Hot-melting pressure sensitive adhesive and preparation method thereof

ActiveCN102634307ADoes not cause allergiesImprove anti-agingMineral oil hydrocarbon copolymer adhesivesHydroxy compound active ingredientsPressure sensitiveWeather resistance

The invention relates to a hot-melting pressure sensitive adhesive and a preparation method thereof. The hot-melting pressure sensitive adhesive effectively solves the problems that the compatibility of a pressure sensitive adhesive and medicines is poor, the pressure sensitive adhesive is easy to oxidize, poor in weather resistance, stability and ventilation and can stimulate the skin. The hot-melting pressure sensitive adhesive is prepared from the following raw materials by weight percent: 20%-45% of thermoplastic elastomer SIS (Styrene Isoprene Styrene), 20%-40% of tackifying resin, 15%-35% of softener, 1%-8% of antioxidant and 3%-15% of filler. The preparation method comprises the following steps of: heating, mixing and stirring the thermoplastic elastomer SIS, the softener and 0.25%-2% of antioxidant to the melting state; then adding the tackifying resin and 0.25%-2% of antioxidant, heating, mixing and stirring to the melting state; and adding the filler and 0.5%-4% of antioxidant, and heating, mixing and stirring to the melting state. The hot-melting pressure sensitive adhesive is transparent and environment-friendly, can not cause skin allergy, has good aging resistance and good aerobic degradation effect, and is also applied to emplastrum.

Owner:HENAN LINGRUI PHARMA

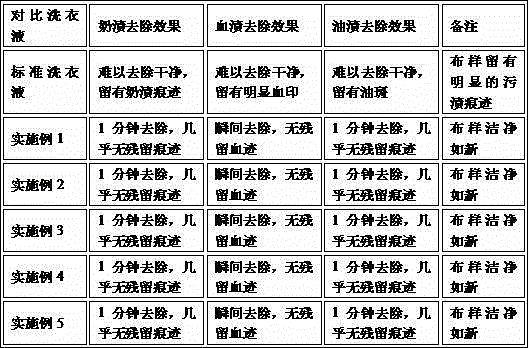

Protease super-concentrated laundry detergent and preparation method thereof

ActiveCN105062703AMild in natureGentle to the touchOrganic detergent compounding agentsNon-ionic surface-active compoundsActive agentBiology

The present invention discloses a protease super-concentrated laundry detergent, which mainly comprises, by mass, 3-38% of a non-ionic surfactant, 1-22% of an anionic surfactant, 0.1-1% of protease, 0.1-2% of triethanolamine, 0.1-2% of sodium citrate, 0.1-2% of refined salt and 60-70% of deionized water, wherein the protease comprises biological protease and compound protease. According to the present invention, the protease super-concentrated laundry detergent product is neutral and has characteristics of mild nature, no stimulation, soft hand-feeling, no alkaline residue after washing, no skin allergy and other symptoms, no damage on fabrics, water solubility, easy use, easy use amount control, easy storage, and easy use; and the process operation of the preparation method is simple, and the method is easily subjected to industrial production.

Owner:DONGGUAN XIANGYU CHEM

Marine biological functional cosmetic for removing acne

ActiveCN102525864APromote absorptionDoes not cause allergiesCosmetic preparationsToilet preparationsIrritationVitamin B6 synthesis

The invention discloses marine biological functional cosmetics for removing acne. The marine biological functional cosmetics contain marine shellfish active peptides, algal polysaccharides and pearl powder as major active ingredients, in addition of linoleic acid, allantoin, vitamin A palmitate, vitamin B6 and aloe juice, and have a remarkable and highly-effective anti-acne effect. The invention solves the problems in the prior art that the existing anti-acne cosmetics have serious irritation and possibly causes skin allergy, the Chinese medicinal anti-acne cosmetics possibly causes dark acnescars and have unpleasant odor, and the use of marine shellfish active peptides in anti-acne cosmetics is unknown. The anti-acne functional cosmetics are safe, mild and sustained, and can significantly kill microbes, relieve inflammations, keep oil secretion in balance, promote wound healing, heal scars, remove acne scars and inhibit pigmentation. The anti-acne functional cosmetics are available in various forms such as creams, emulsions, lotions, gels, sprays or facial masks, have remarkable and long-lasting anti-acne effects, prevent acne recurrence after withdrawal, and are suitable for various populations suffering from acnes, scars or acne scars.

Owner:FOSHAN UNIVERSITY

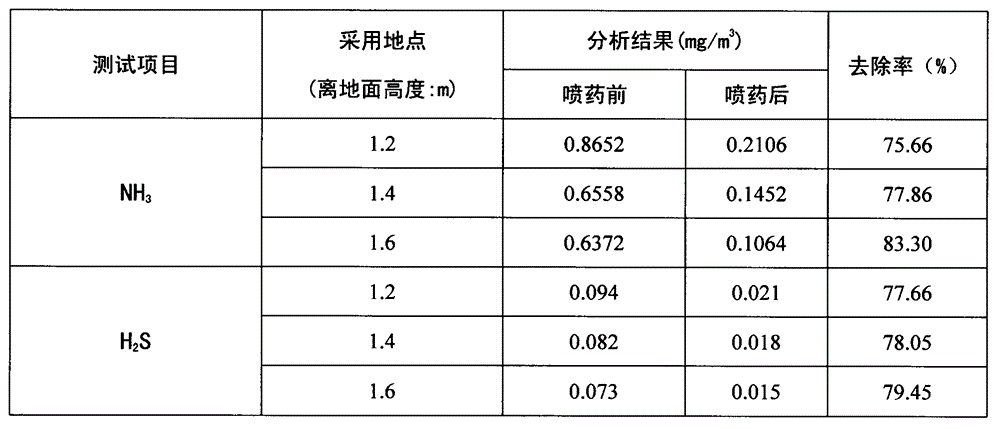

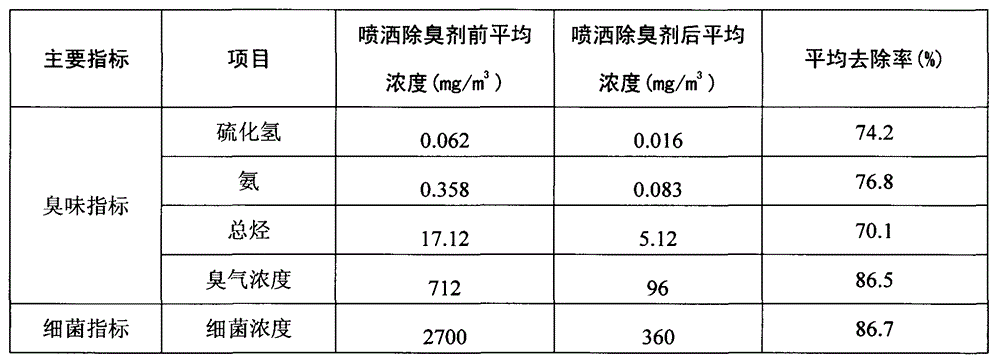

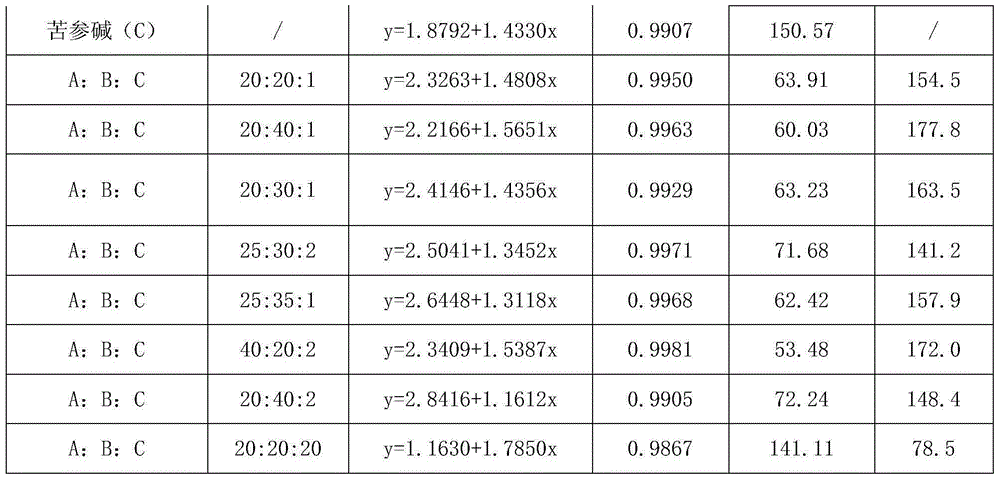

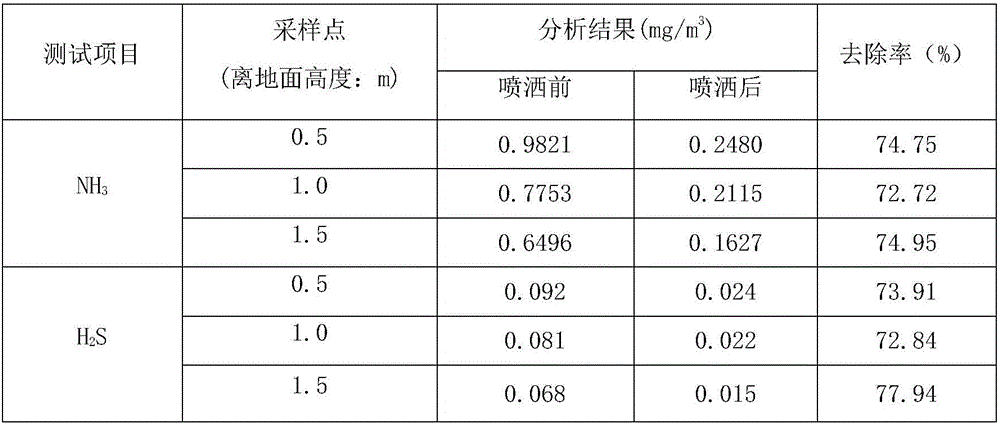

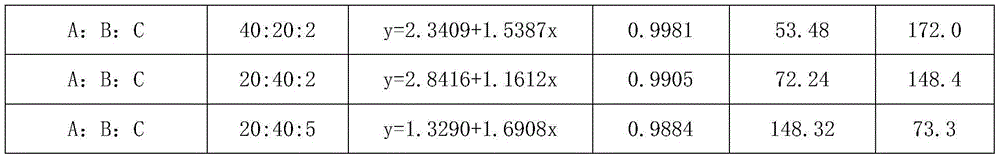

Plant-source deodorant for urban garbage disposal

The invention provides a plant-source bactericidal and bacteriostatic deodorant for urban garbage disposal, comprising the following active ingredients: cinnamon bark extract, clove extract and eucalyptus leaf extract, wherein the mass ratio of the cinnamon bark extract to the clove extract to the eucalyptus leaf extract in the deodorant is (2-10):(1-15):(5-10); the weight percentage of the cinnamon bark extract in the deodorant is 0.2-1.0%, the weight percentage of the clove extract in the deodorant is 0.1-1.5%, the weight percentage of the eucalyptus leaf extract in the deodorant is 0.5-1.0%, and the weight percentage of a surfactant in the deodorant is 1.0-5.0%. The plant-source deodorant has an obvious synergistic bactericidal and bacteriostatic effect due to blending of the three active ingredients in a certain ratio range; meanwhile, the plant-source deodorant can be automatically degraded so as to avoid secondary pollution to the environment, allergy of the skin or the respiratory system and various adverse responses, and has the characteristics of no toxicity, no harm, safety and convenient use, significant deodorization effect, long acting and the like.

Owner:彭科 +1

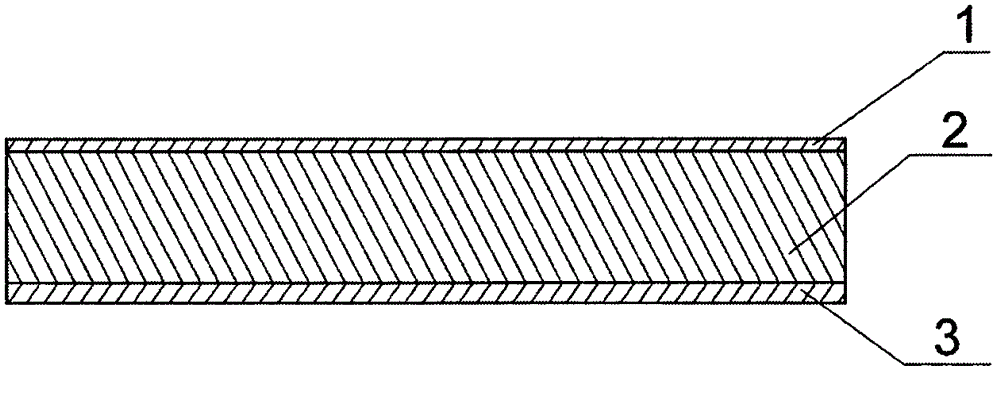

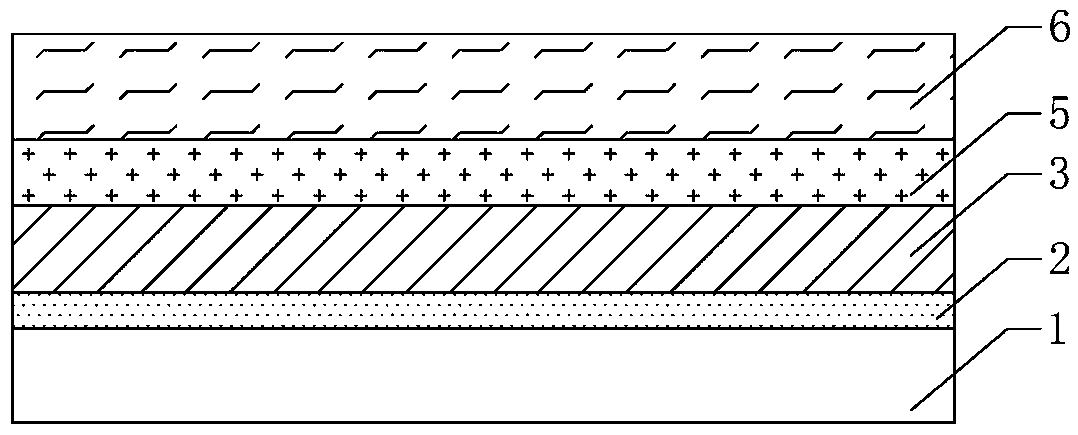

Medical cold compress plaster and preparation process thereof

InactiveCN105878217ASimple production processEase of mass productionAntipyreticAnalgesicsTriclosanVitamin C

The invention provides a medical cold compress plaster. The medical cold compress plaster is composed of a support layer, a gel layer and an isolating layer, and has the special shape according with the physiological curve of the applied part. An oil phase and a water phase forming the hydrophilic gel layer respectively comprise the following components in percentage by weight: the oil phase: 20-35% of a dispersing agent, 5-7% of macromolecule resin, 0.05-0.15% of dihydroxyaluminium aminoacetate, 0.01-0.15% of ethylene diamine tetraacetic acid, 0.15% of absolute ethyl alcohol, 0.04-0.1% of menthol, 0.1-1% of vitamin E, and 0.05-0.1% of triclosan; the water phase: 0.2-0.8% of tartaric acid, 1.2-2% of carbomer, 0.5-1% of sodium carboxymethylcellulose, 0.01-0.1% of vitamin C, the balance of medical purified water, and the total weight percentage is 100%. A preparation process comprises the following steps: dispersing all the components of the oil phase into the dispersing agent, and uniformly stirring the components; dissolving all the components of the water phase into water, and uniformly stirring the components; mixing the water phase and the oil phase, uniformly stirring the water phase and the oil phase in a vacuum mixing pot, thus obtaining the hydrophilic gel substrate of the medical cold compress plaster, coating the support layer with the hydrophilic gel substrate, meanwhile covering with the isolating layer, and carrying out cutting, solidifying and packaging to obtain the needed medical cold compress plaster product.

Owner:HANGZHOU JIERSI BIOTECH CO LTD

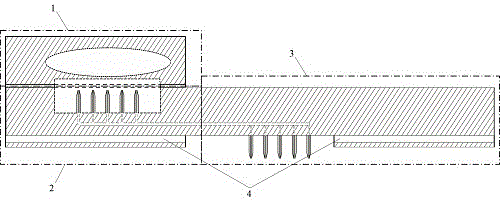

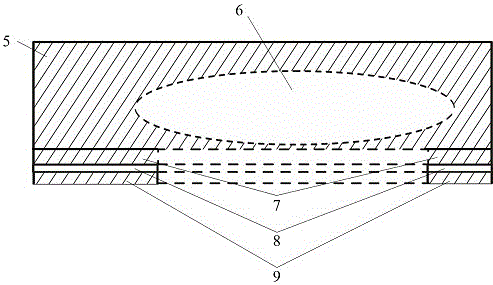

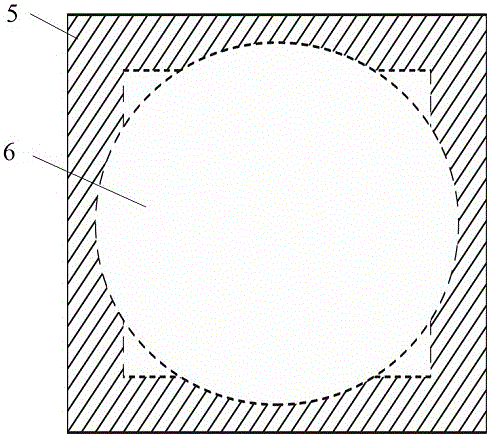

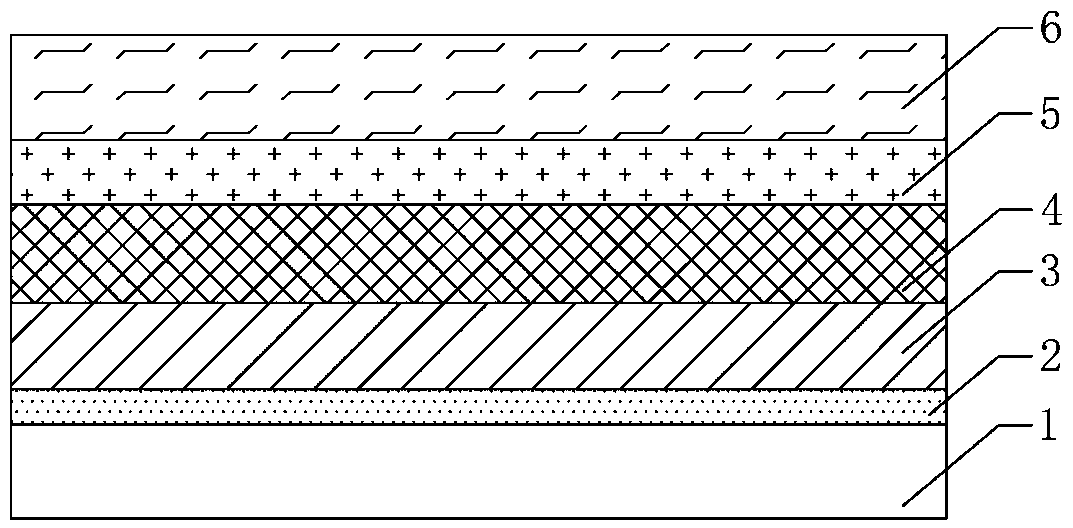

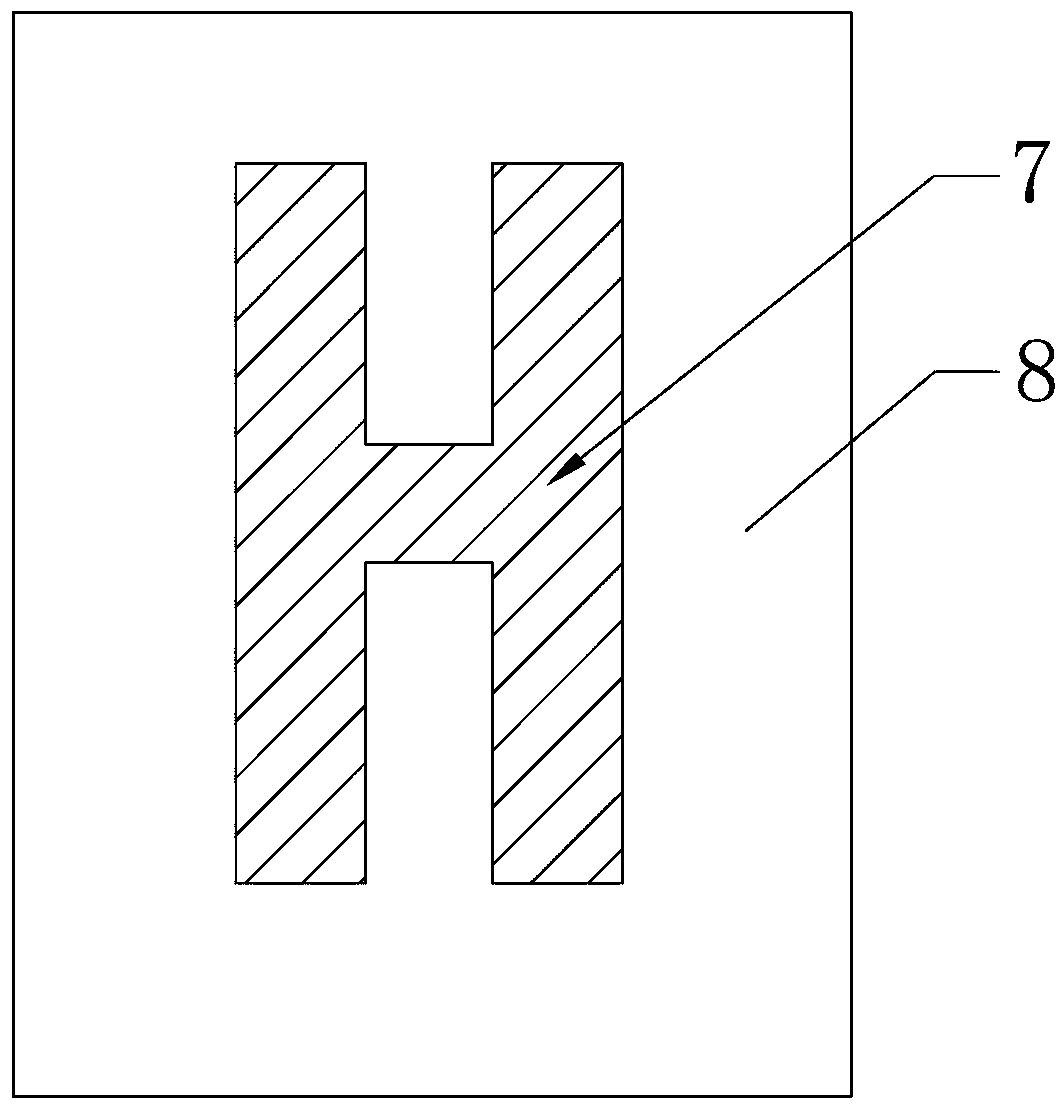

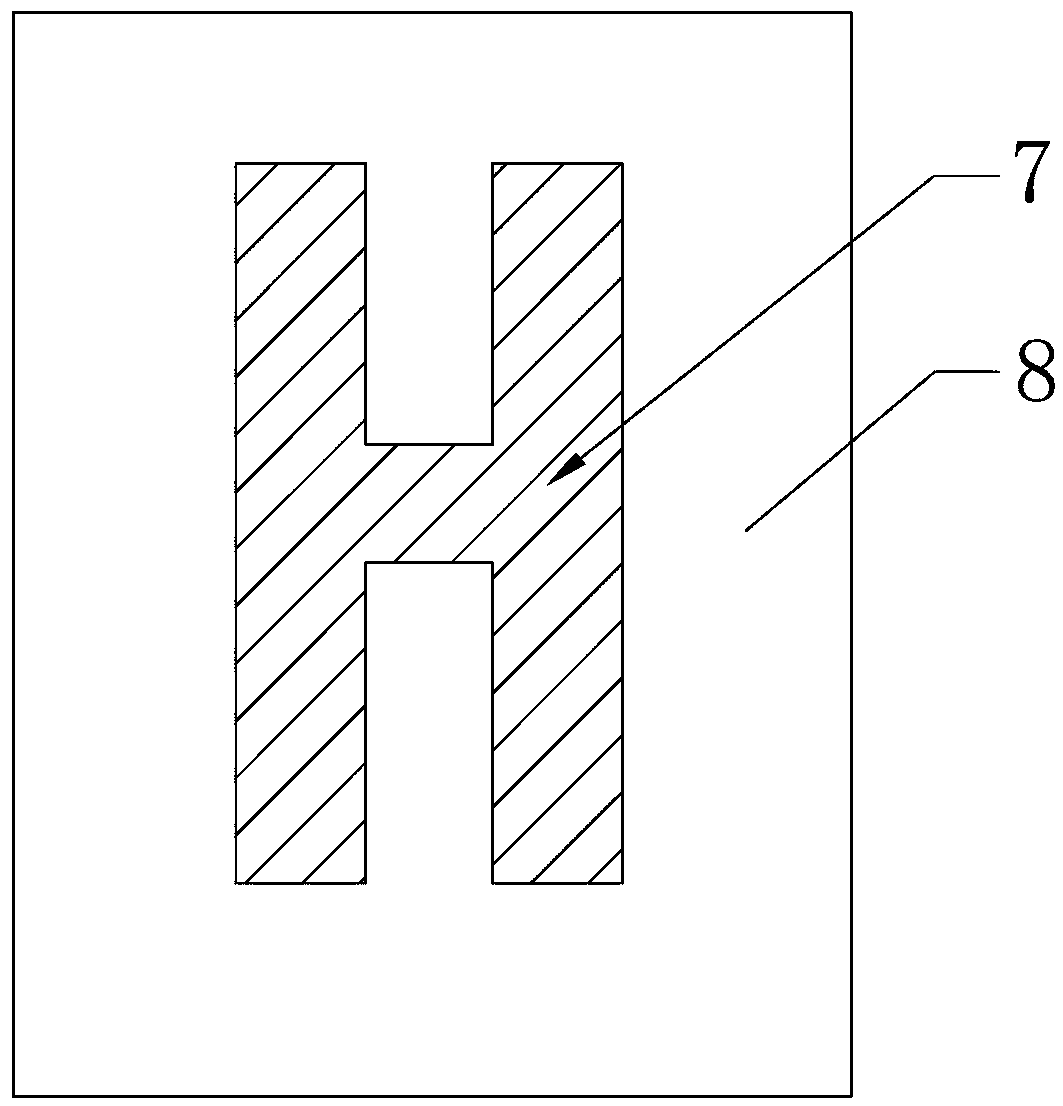

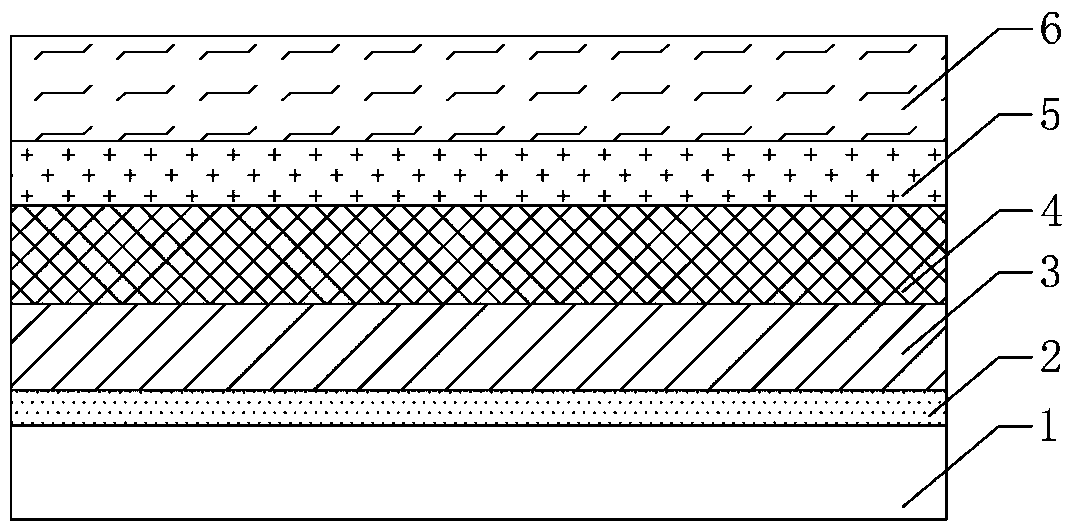

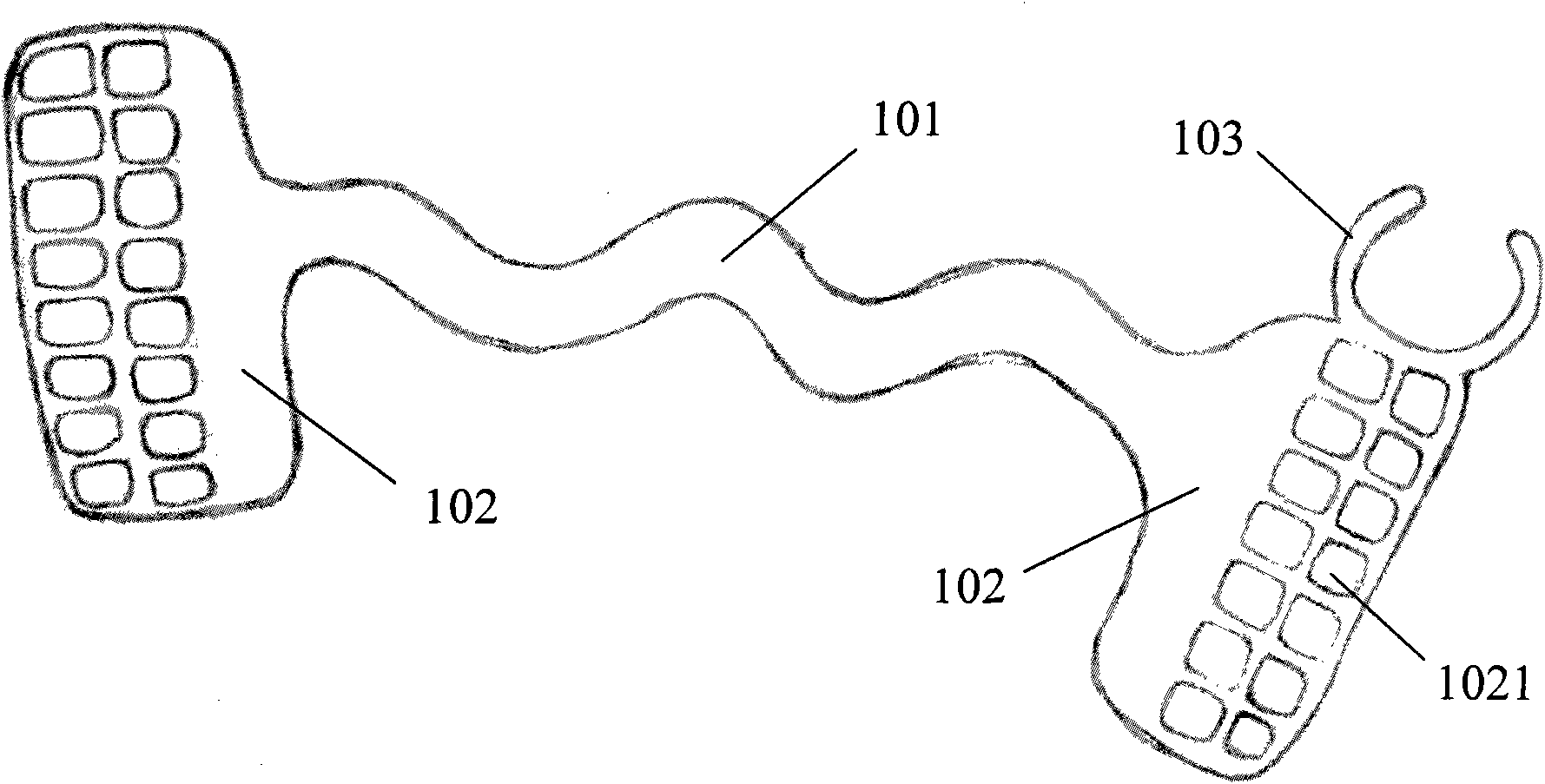

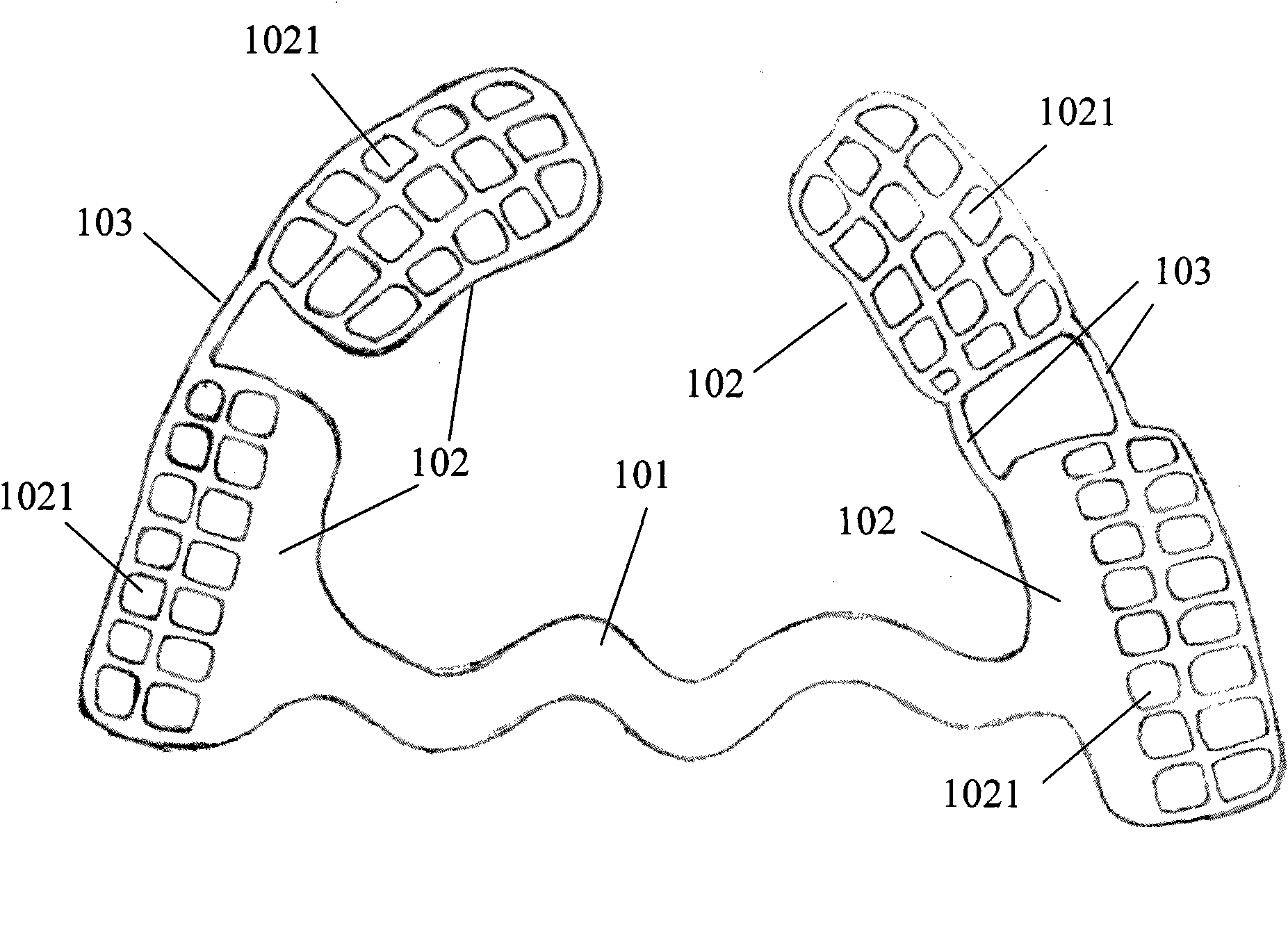

Microneedle drug delivery patch containing separable drug capsule

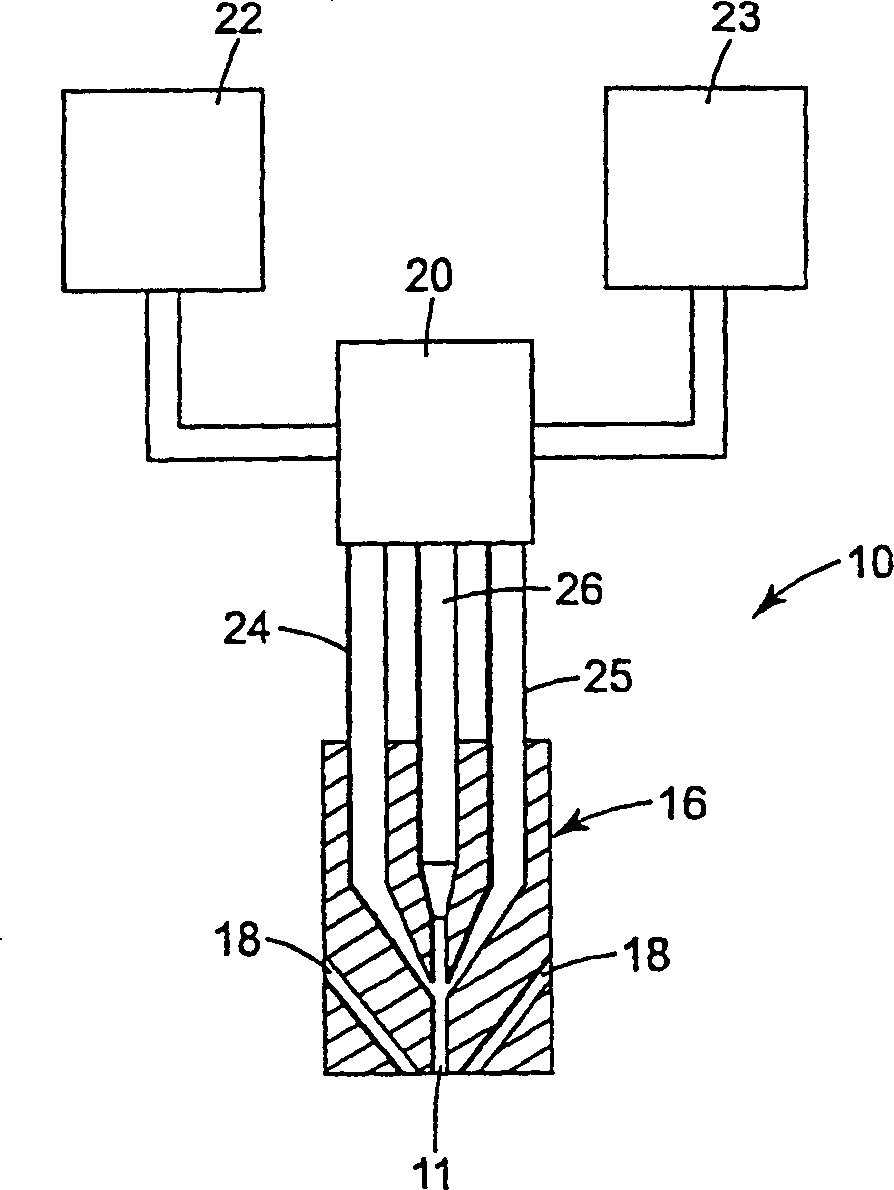

InactiveCN105963855AGood biocompatibilityDoes not cause allergiesMicroneedlesMedical devicesDrug capsuleDrug dispensing

The invention discloses a flexible microneedle drug delivery patch containing a separable drug capsule suitable for transdermal delivery of multiple drugs. The microneedle drug delivery patch has the advantages that pain level is low, infection risk is low and application is convenient. The microneedle drug delivery patch comprises the separable and replaceable drug capsule, a drug carrying end integrating a microneedle array with a microfluid flow passage network, a drug delivering end integrating the microneedle array with the microfluid flow passage network, and a sticky patch body allowing the microneedle drug delivery patch to be attached to skin, wherein the sticky patch body is made from a flexible polymer and is high in curvature and skin bonding property. In use, the drug delivery patch is attached to a joint of a user, the drug carrying end and the drug capsule of the drug delivery patch deform under the squeezing and stretching actions of the bent joint on the flexible microneedle drug delivery patch, so that a syringe needle at the drug carrying end pierces into the drug capsule and drugs are distributed to the drug delivering end through the microfluid flow passage network, and then drugs flow into the body through a passage formed on skin by a microneedle at the drug delivering end to finish drug delivery.

Owner:成都市亿泰科技有限公司

Marine organism functional cosmetic for nourishing skin around eyes

ActiveCN102366383ADoes not cause allergiesPromote absorptionCosmetic preparationsToilet preparationsBiotechnologySkin sensitization

The invention provides a marine organism functional cosmetic for nourishing skin around the eyes. The marine organism functional cosmetic comprises, on the basis of the total mass of the cosmetic, the following active components by mass: 0.1 to 10% of marine mollusk active peptide, 0.1 to 10% of marine animal collagen peptide, 0.05 to 5% of algal polysaccharide, 0.01 to 2% of chondroitin sulfate and 0.2 to 15% of pearl powder; the cosmetic can further comprises the following active components by mass: 0.05 to 0.6% of allantoin, 0.01 to 1% of coenzyme Q10, 0.1 to 5% of VC phosphate magnesium and 0.1 to 5% of VE acetate. According to the invention, pure natural marine organism extracts are used as main raw materials, and the extracts can absorbed by skin rapidly, are safe and mild, cause noirritation on skin and bring no burden to skin; stabilized synergism of marine biologically-active substances and other active substances is utilized in the invention, which enables a nourishing effect of the cosmetic on skin around the eyes to be substantially enhanced.

Owner:FOSHAN UNIVERSITY +2

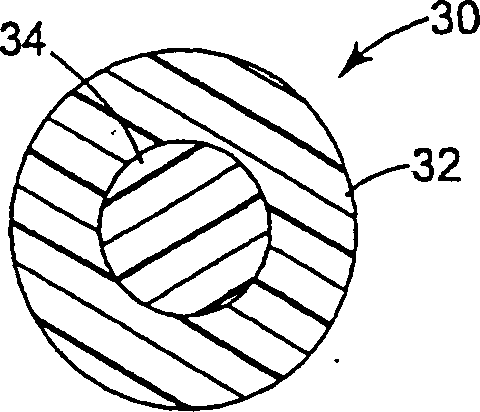

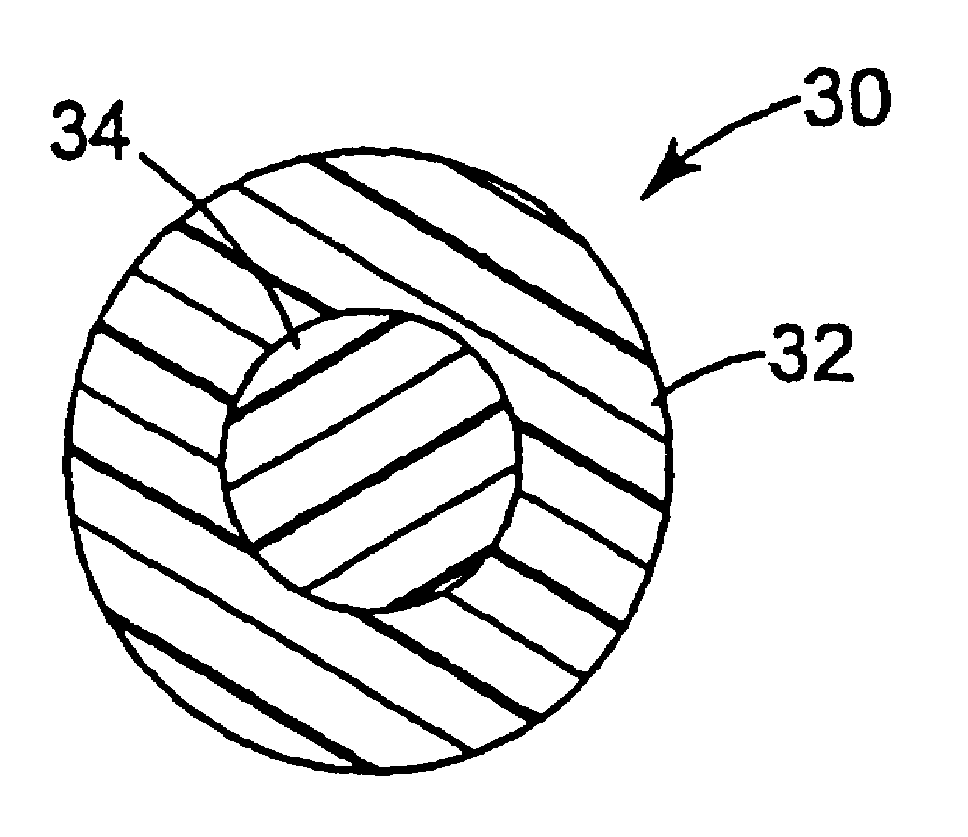

Bicomponent microfibers

InactiveCN1338010AEasy to manufactureDoes not cause allergiesSuture equipmentsSolid waste disposalWater soluble polymersMicrofiber

An alkali dispersible article comprises a sheath-core microfiber. The sheath layer comprises a hydrolytically degradable polymer, and the core layer comprises another polymer that is different than the sheath polymer. The core polymer may be a hydrolytically degradable polymer or more preferably a water soluble polymer.

Owner:3M INNOVATIVE PROPERTIES CO

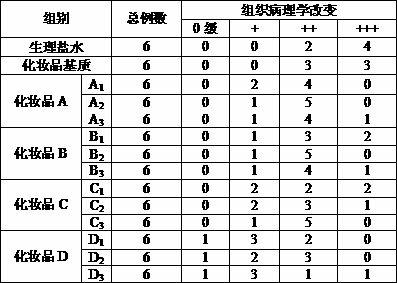

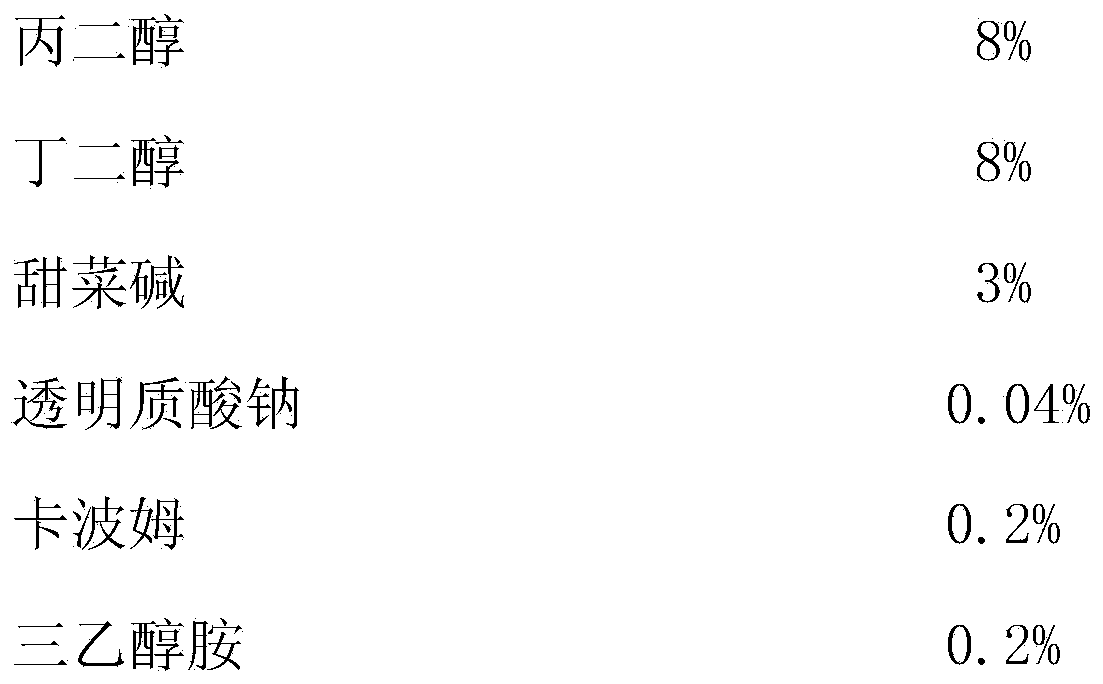

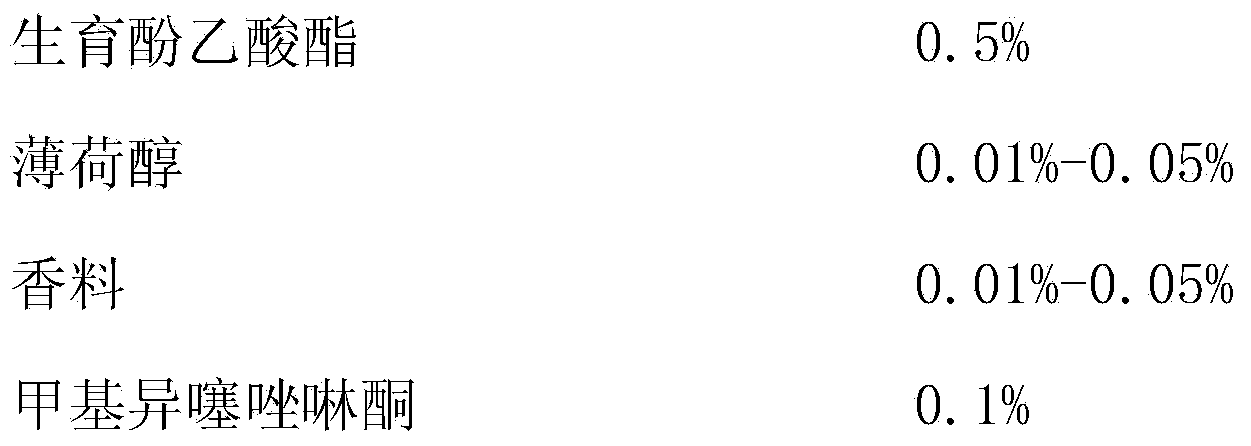

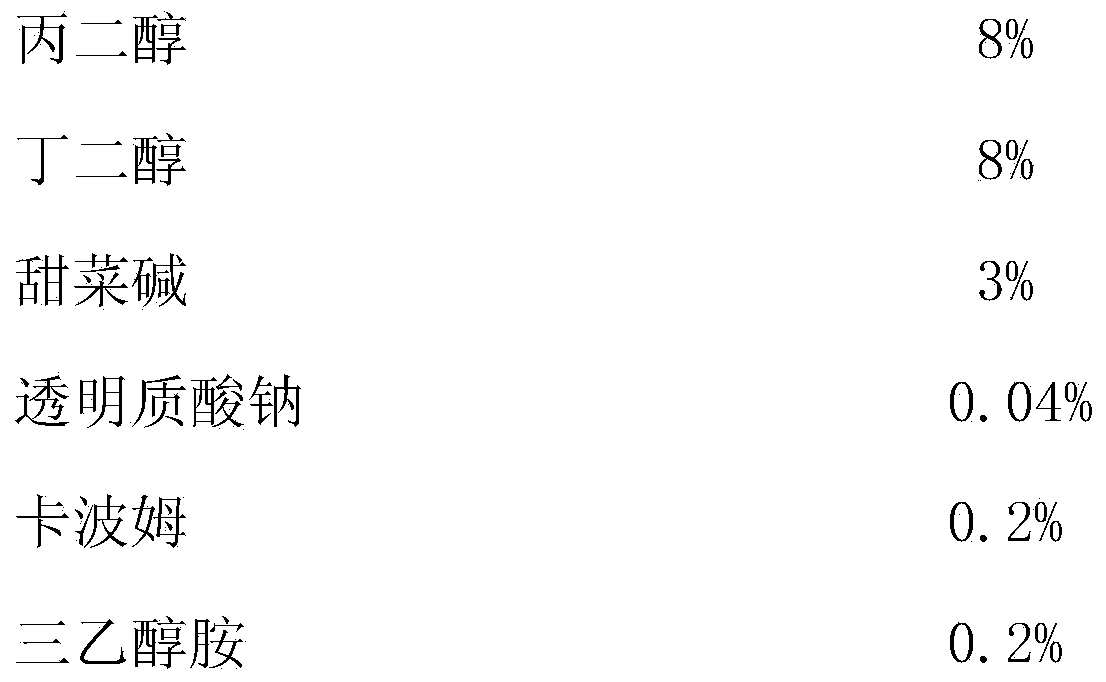

Eye cream and preparation method thereof

ActiveCN103860426AFirm skinReduce wrinklesCosmetic preparationsToilet preparationsCarthamusTocopheryl acetate

The invention discloses an eye cream. The eye cream is prepared from the components in percentage by weight: 19.44 percent of component A, 5.8-12.2 percent of component B, 6-15 percent of component C, 0.62-0.7 percent of component D and the balance of water, wherein the component A contains propylene glycol, butanediol, glycine betaine, sodium hyaluronate, carbomer and triethanolamine; the component B contains a tea extract, a saffron extract or a safflower extract and N-lauryl caprolactam; the component C contains bis-PEG (Polyethylene Glycol)-15 methyl ether polydimethylsiloxane and laureths-23; and the component D contains tocopheryl acetate, piperitol, spice and methylisothiazolinone. With the adoption of the eye cream, as raw materials of safflowers or saffrons, tea leaves, mints, organosilicone and the like are organically combined, are interworked and have synergistic effect, the eye cream has the efficacies of moisturizing, nourishing, reducing wrinkles by tightening a skin, relieving and eliminating eye fatigue, as well as preventing and eliminating black eyes and pouches. The invention also discloses a preparation method of the eye cream.

Owner:广州市名宇化妆品制造有限公司

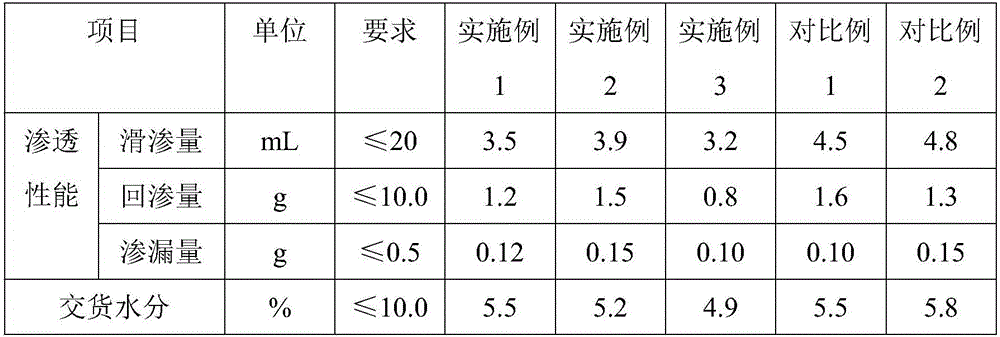

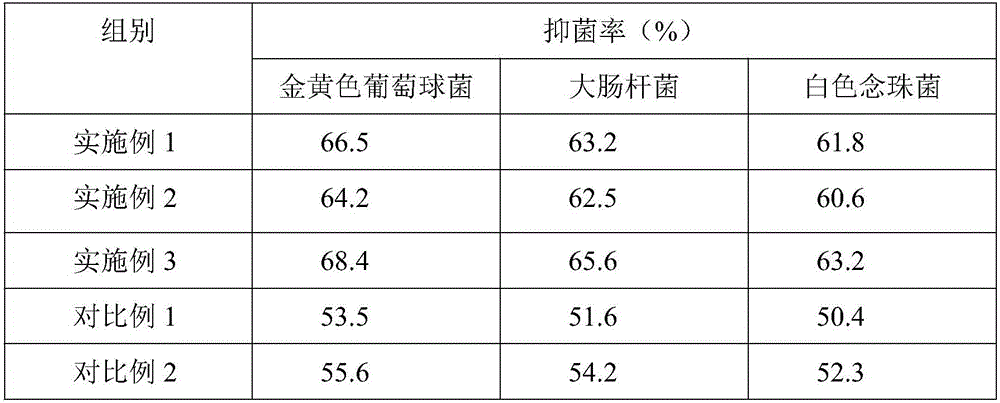

Infant diaper and preparation method thereof

The invention belongs to the technical field of sanitary care products, and particularly relates to an infant diaper and a preparation method thereof. The infant diaper comprises a diaper body which comprises a surface layer, a diversion layer, an absorbing core layer and a back layer from top to bottom, the surface layer is prepared from moxa, Lyocell fiber and ES fiber, the diversion layer is obtained by reinforcing ES fiber of 6D in thickness through hot air, the absorbing core layer comprises composite fiber, super absorbent resin and fluff pulp according to a weight ratio of 3-5:6-10:8-13, and the back layer is a breathable microporous thin film. The infant diaper is soft, comfortable, cool, breathable, good in antibacterial effect, easy to degrade, capable of removing peculiar smell and refusing bacterial contamination, safe and capable of inhibiting bacteria, preventing red buttock and taking care of skin of infants in an omnibearing manner.

Owner:GUANGZHOU JINAN BIOMEDICINE RES & DEV CENT

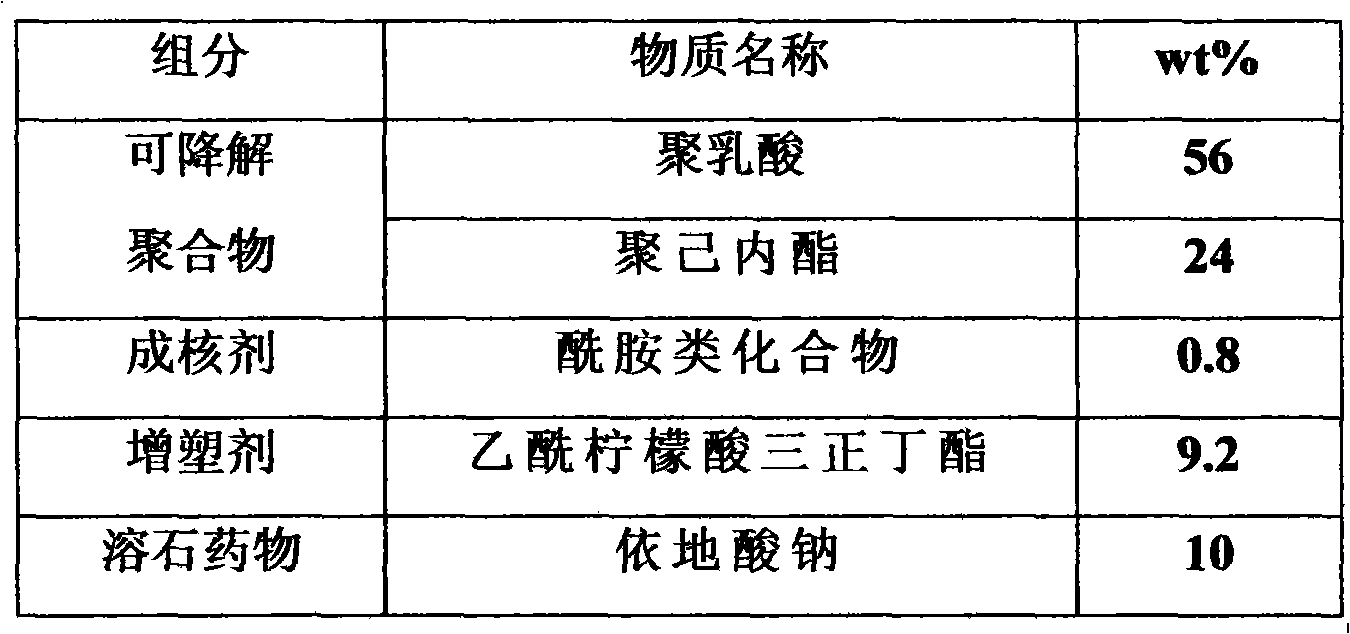

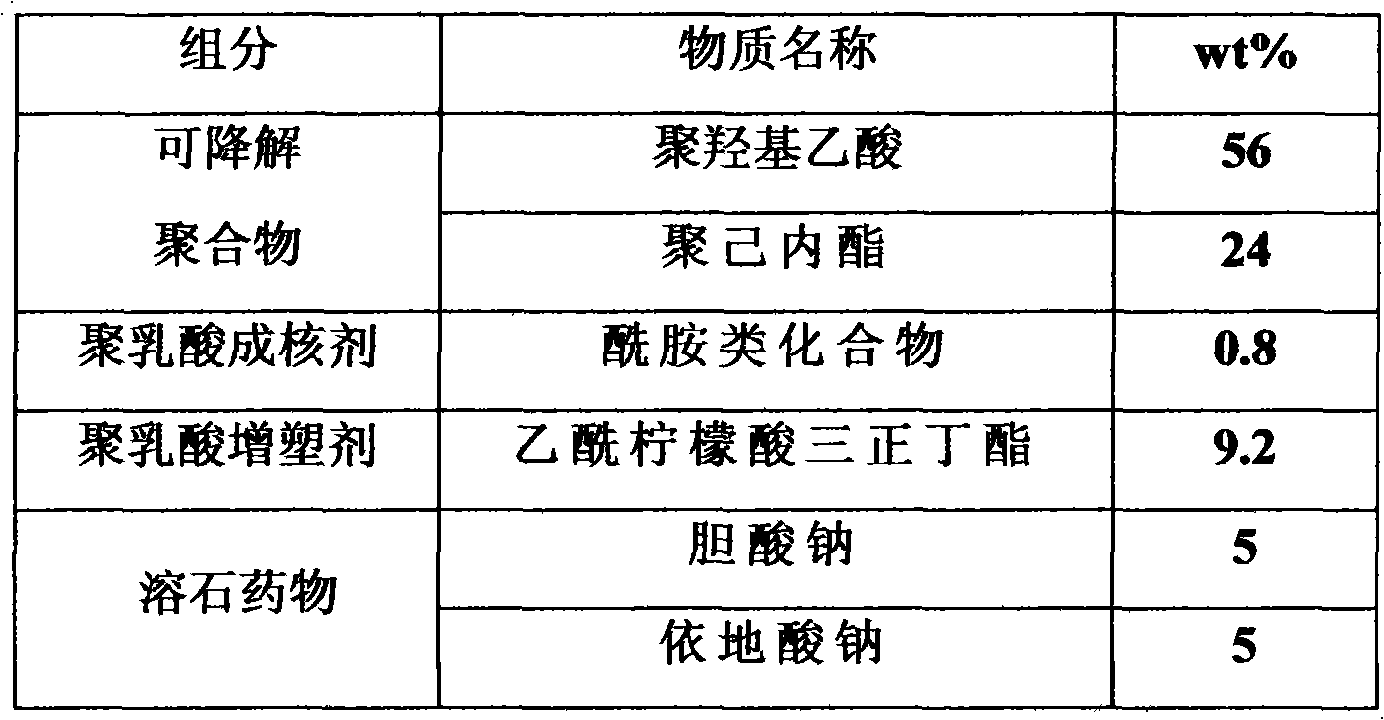

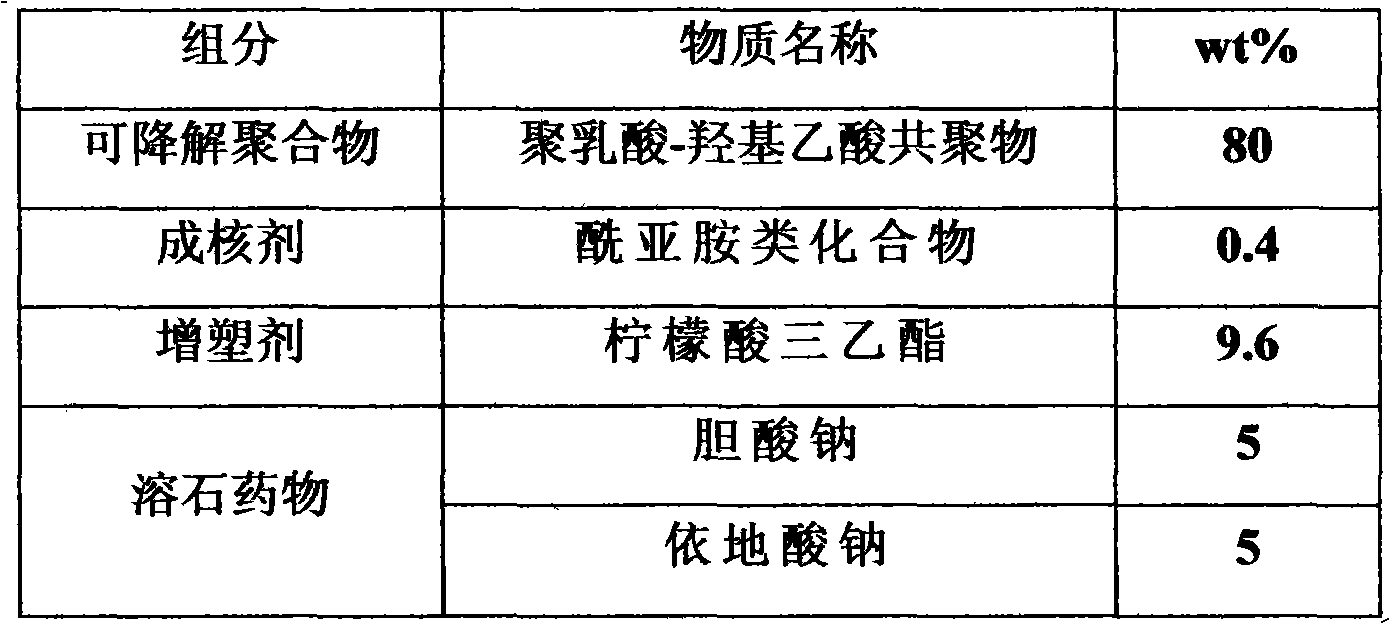

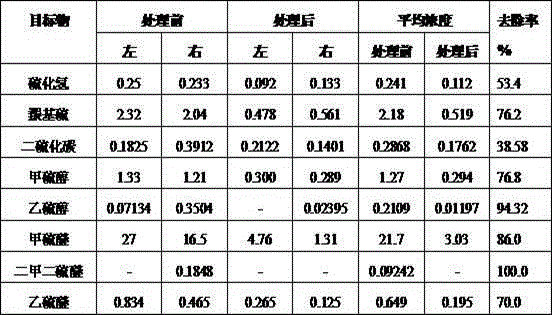

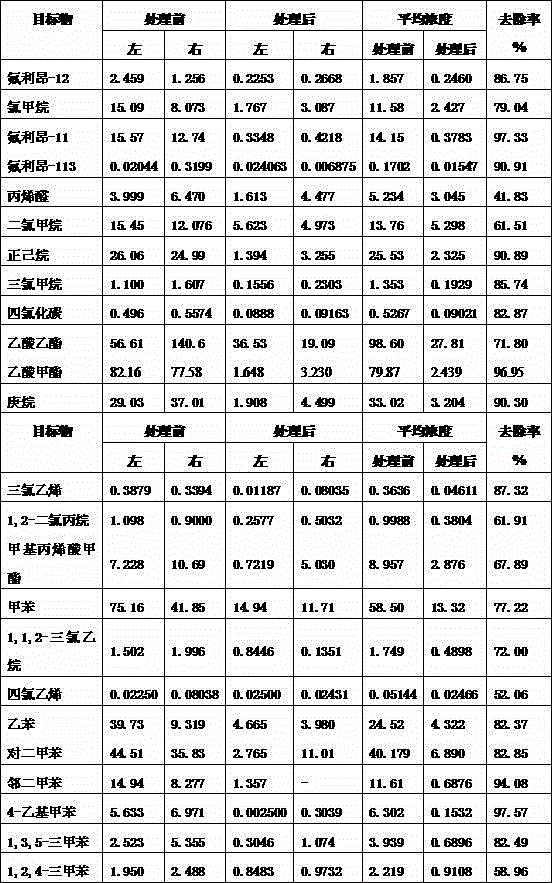

Degradable bile duct bracket with stone dissolution function and preparation method thereof

The invention relates to the technical field of medical instruments, in particular to a degradable bile duct bracket with stone dissolution function and a preparation method thereof. The degradable bile duct bracket is prepared by the following raw materials in proportion: 60-98% by weight (wt) of degradable polymer, 0.1-2.0 % by weight of nucleating agent, 1-15 % by weight of plasticizer, and the balance of stone dissolution drug, wherein the total weight amounts to 100%. The degradable bile duct bracket is obtained by evenly mixing the degradable polymer, the nucleating agent, the plasticizer and the stone dissolution drug, and then fusing and extruding the mixture through a medical catheter precise extruder; by successfully selecting proper degradable polymer, nucleating agent and plasticizer, the defects of the plastic bracket and metal bracket in the bile duct interventional therapy are overcome; moreover, by adding the stone dissolution drug, the curative effective of gall-stone is improved; therefore, the degradable bile duct bracket has wide application prospect.

Owner:苏州同科生物科技有限公司

Dry powder gel face mask formula

InactiveCN104490626AImprove stabilityIncrease elasticityCosmetic preparationsToilet preparationsVitamin CSulfate

The invention discloses a dry powder gel face mask formula. The dry powder gel comprises, 5% to 15% of calcium sulfate decahydrate, 15% to 25% of sodium alginate, 55% to 65% of glucose powder, 1.5% to 2.5% of tetrasodium pyrophosphate decahydrate, 1.2% to 2% of xanthan gum, 0.3% to 0.7% of amino acid, 0.5% to 0.9% of vitamin C, 0.6% to 1% of talcum powder, 3% to 5% of collagen, and 0.3% to 0.5% of sodium hyaluronate. The dry powder gel face mask has the advantages of being good in stability, elasticity, moisture retention and plasticity, stable in size, free of reactions with face non-woven materials chemically, low in price, convenient to use and the like.

Owner:董庆国

Method for preparing novel sun cream

ActiveCN101623240ADoes not cause allergiesEasy to useCosmetic preparationsToilet preparationsSide effectBeta-Carotene

The invention belongs to the field of articles used in the daily life, in particular to a method for preparing novel sun cream. The novel sun cream comprises the main components of tea polyphenol, zinc oxide, glycerol, beta-carotene, Tween-80 and vaseline. The method comprises the following steps: firstly, adding the zinc oxide into the glycerol, evenly stirring to obtain a mixture A, adding the Tween-80, the tea polyphenol and the beta-carotene into distilled water proportionally, evenly stirring to obtain a mixture B, adding the mixture B into the mixture A, then adding the vaseline, evenly stirring, emulsifying and packaging so as to obtain a product. Because the product prepared by adopting the method contains the three substances of the tea polyphenol, the zinc oxide and the beta-carotene which can effectively prohibit ultraviolet rays, the skin is effectively protected by the reflection and the absorption of the ultraviolet rays, the use effect is better, all the main raw materials of the sun cream are purely natural nutrient substances, and the invention has no stimulation to the skin, can not cause skin allergy, also has no toxic or side effect and has higher use safety.

Owner:南平植爱日用品有限公司

Natural plant deodorant and preparation process thereof

The invention discloses a natural plant deodorant. The natural plant deodorant is extracted from natural plants and maintains nontoxicity and innocuousness to the human body, various adverse reactions such as skin or respiratory system allergy cannot be caused, and the natural plant deodorant is a reliable and environment-friendly product which meets the international health standards. The natural plant deodorant is simple in processing process, separation of active substances can be improved by refitting domestic existing equipment and changing the fermentation mode, the purity is high, the totally-enclosed processing process is adopted, waste of the active substances is reduced, generated exhaust gas, waste liquid and solid residues can be recycled and made into deodorized organic fertilizers, and the waste materials are changed into things of value; the process can be designed for natural plant extract solutions in a pointed mode according to different work occasions and public places and different peculiar smell sources, peculiar smell is eliminated, and cleanliness of the air environment is maintained.

Owner:XIAMEN JINGPENG IND & TRADE CO LTD

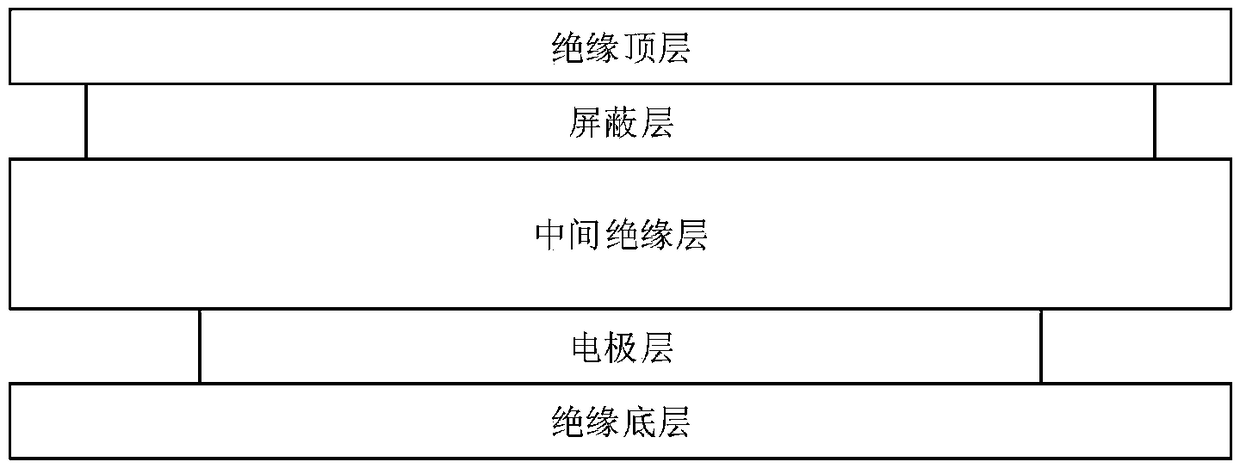

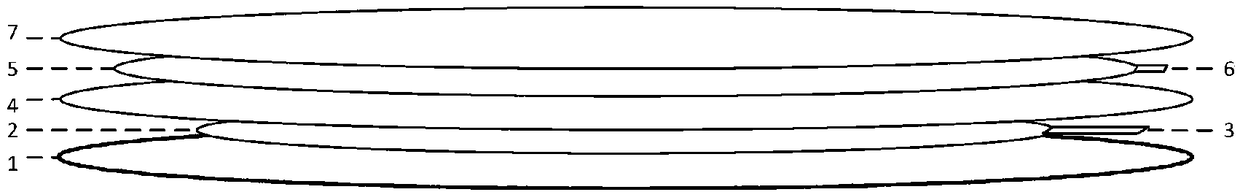

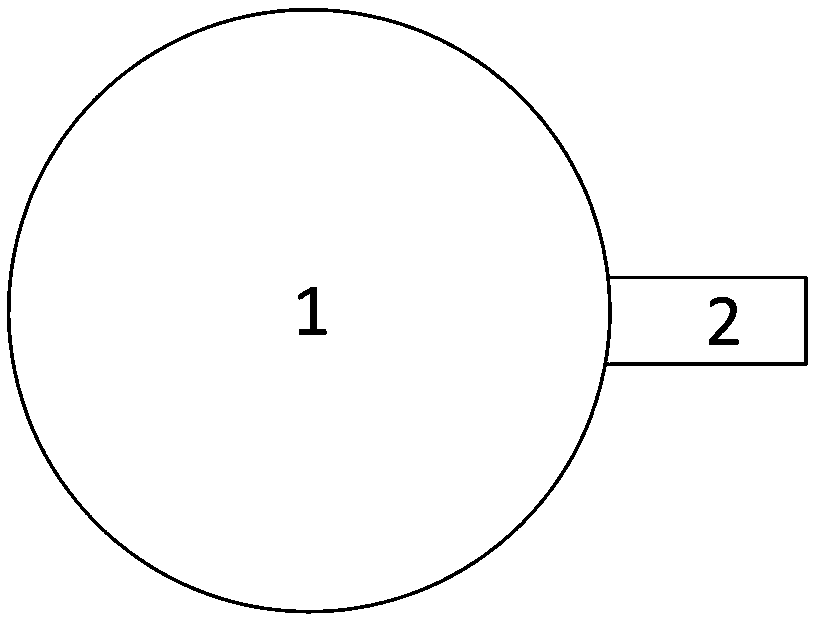

Flexible non-contact electrocardiogram sensor and making method thereof

PendingCN108784688ADoes not cause allergiesEasy to prepareDiagnostic recording/measuringSensorsCapacitanceHuman body

The invention relates to a flexible non-contact electrocardiogram sensor and a making method thereof. The flexible non-contact electrocardiogram sensor comprises a flexible non-contact electrode; electrocardiogram signals are coupled to the flexible non-contact electrode on the basis of a capacitor coupling principle, and human body skin serves as a polar plate of a capacitor while the electrode functions as an other polar plate; the electrocardiogram signals on the human body skin can be coupled to the electrode; the electrocardiogram signals, which are coupled, are weak and can be easily affected by external interference, therefore a shielding layer is arranged to shield the external interference; and since the human body, the electrode and the shielding layer cannot make into direct contact with each other, insulating layers are arranged between the human body and the electrode as well as between the electrode and the shielding layer. The flexible non-contact electrocardiogram sensor provided by the invention, which is free from the use of a conductive paste, can avoid skin allergy, the electrocardiogram sensor is suitable for long-term monitoring and can be repeatedly used. Theelectrode, which is designed as a round structure, can avoid discomfort in wearing caused by a square structure. The electrocardiogram sensor is simple in making method and low in cost. The flexiblenon-contact electrode is relatively thin and has certain flexibility; therefore, the electrode is firm in welding, and a lead cannot get fallen easily. Therefore, the electrocardiogram sensor has a shielding function and is low in interference by external signals.

Owner:NORTHEASTERN UNIV

Biscuit and preparation method thereof

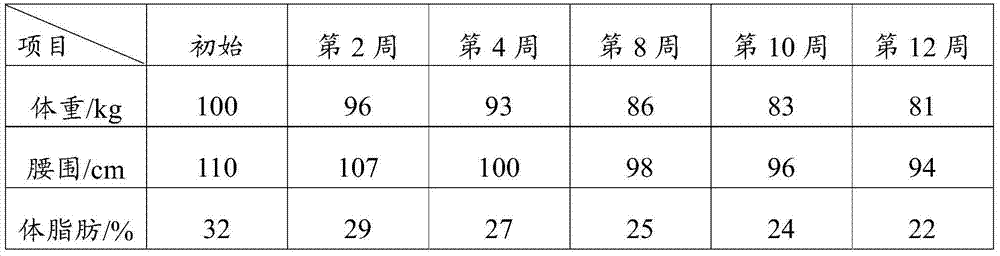

InactiveCN104705377ADoes not cause allergiesReduce contentDough treatmentBakery productsProtein isolateMaltitol

The invention relates to a biscuit and a preparation method thereof. Preparation materials of the biscuit comprise, by weight, 30-38 parts of cream, 15-25 parts of protein isolate, 10-15 parts of insoluble dietary fiber powder, 15-25 parts of soluble dietary fiber powder, 3-8 parts of maltitol, 0.5-1.0 part of baking powder, 15-20 parts of yolk powder, and 5-7 parts of water; the preparation method of the biscuit comprises the steps that 1 the yolk powder, the baking powder, the cream and the water are mixed and whipped until foam occurs, the protein isolate, the insoluble dietary fiber powder, the soluble dietary fiber powder and the maltitol are added, and then the mixture is stirred evenly; 2 the mixture is impressed and baked to form the biscuit. The preparation materials of the biscuit is free from flour, so that the risk of additives contained by the flour can be avoided, and meanwhile, the biscuit can not lead to the allergy of gluten; the content of carbohydrates in the biscuit is low, and the biscuit has ketogenic and anti-obesity functions.

Owner:GUANGZHOU CINJEP BIOTECH

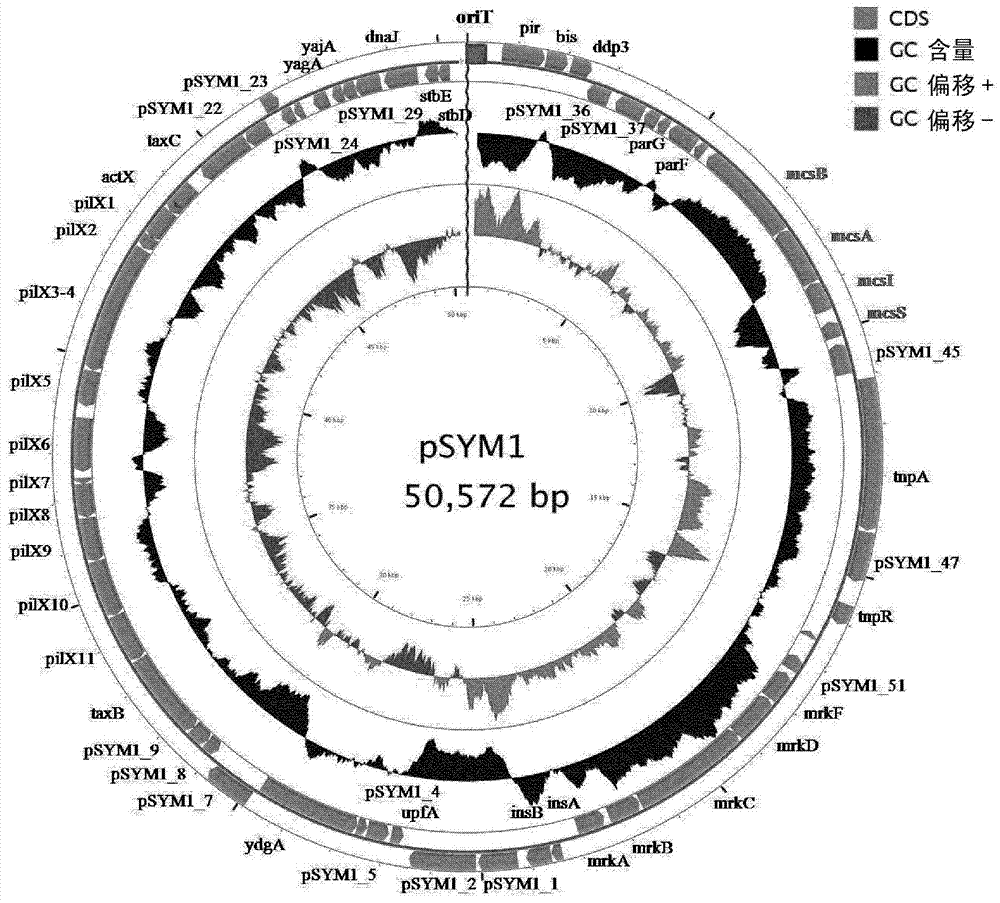

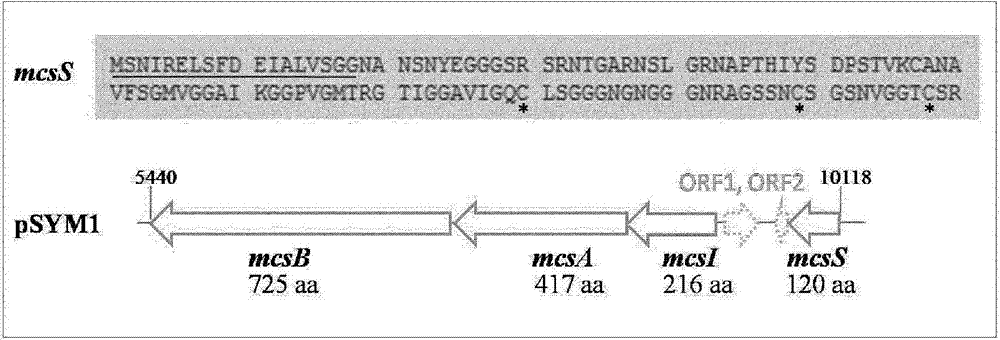

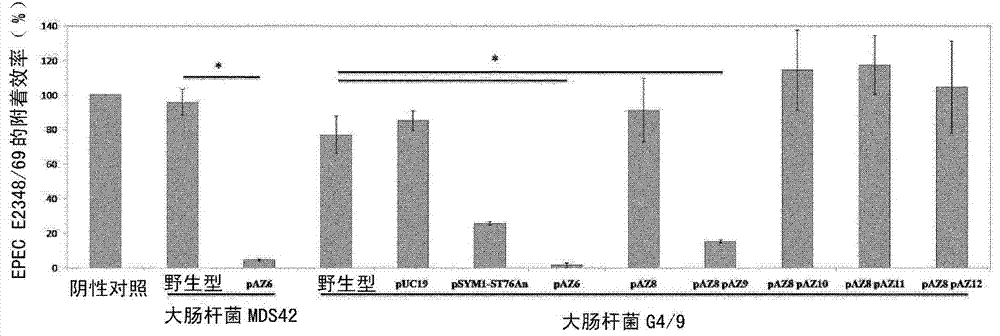

Bacterially formed microcin s, a new antimicrobial peptide, effective against pathogenic microorganisms, e.g. enterohemorrhagic escherichia coli (EHEC)

InactiveCN103717744APerformance inhibition effectDoes not cause allergiesAntibacterial agentsBiocideBacteroidesAntimicrobial peptides

The present invention relates to a new isolated polypeptide nominated microcin S, isolated nucleic acid molecules encoding the microcin S polypeptide and primers and probes hybridizing to the nucleic acid molecules. The invention also relates to plasmids and cells comprising the nucleic acid molecules, an antibody binding to the polypeptide, compositions as well as methods for producing and using the polypeptides. The present invention further relates to medical uses for treating or preventing microbial infections, functional gastrointestinal disorders or treating a tumor. The invention further relates to a method for preserving food and a method for coating dressing material.

Owner:SYMBIOGRUPPE

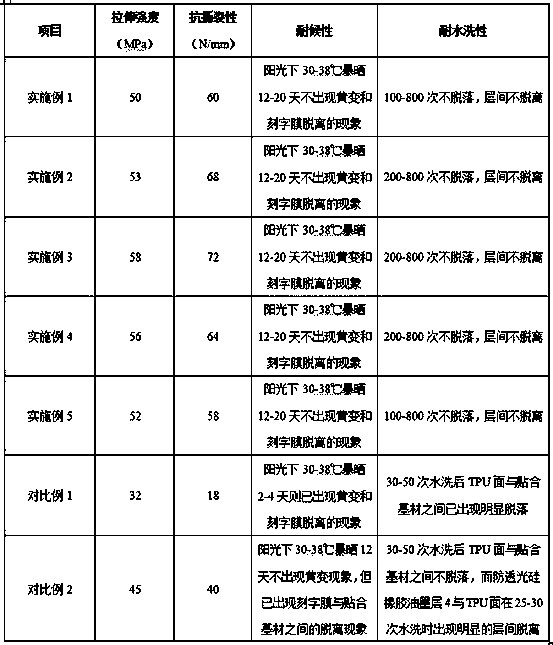

High elasticity silicone rubber heat transfer film and preparation method thereof

ActiveCN108690515AImprove water resistanceImprove processing efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSurface layer

The invention relates to the technical field of heat transfer films, and specifically relates to a high elasticity silicone rubber heat transfer film and a preparation method thereof. The high elasticity silicone rubber heat transfer film comprises following components from bottom to top: a bearing base material, a release layer, a silicone rubber surface layer, an interface bonding agent layer, and a TPU hot melt adhesive membrane; wherein the interface bonding agent layer is prepared an interface bonding agent, which comprises two resin components. The provided heat transfer film has the advantages of silicone rubber and TPU, such as excellent elasticity, high tearing resistant strength, weatherability, yellowing resistance, washing resistance, and the like. Layering is difficult to happen. Even if the heat transfer film is exposed under the sun, color change or fading is difficult to happen. The water washing fading rate is not more than 0.5%. When the color transfer film is washedwith materials with other colors, other materials will not be dyed easily. The stability is high. The heat transfer film can be easily adhered on multiple materials, the bonding strength is strong, the heat transfer film is not easy to peel off, the stability is good, the hand feeling is fine, the appearance is good, and the service life is long.

Owner:卢汉军

Rubber accelerator TMTM predispersion master batch and preparation method thereof

The invention discloses a rubber accelerator TMTM predispersion master batch which is composed of the following components in parts by weight: 75-85 parts of tetramethylthiuram monosulfide, 10-20 parts of rubber matrix, 1-10 parts of rubber oil and 1 part of fatty acid alcohol ester. The preparation method is simple and easy to operate. The rubber matrix is previously compounded and prepared to effectively shorten the compounding time required by the subsequent master batch preparation process. The prepared master batch has no impurity or dust, can effectively maintain the original activity of TMTM, does not cake at room temperature, is easy for proportioning and compounding, has the advantages of favorable flowability, no flying dust and high utilization ratio of raw materials, and can not cause skin allergy of operating personnel. The master batch is dispersed uniformly in the rubber product after proportioning and compounding, can ensure the production efficiency and quality of the rubber product, and has important meanings for sustainable development of rubber manufacturing industry.

Owner:NINGBO ACTMIX POLYMER

High-elasticity silicone rubber lettering film and preparation method and application method thereof

ActiveCN108610997AIncrease elasticityAvoid deformationPolyureas/polyurethane adhesivesInksRubber materialPolymer science

The invention relates to the technical field of thermal transfer printing lettering film, and in particular, relates to a high-elasticity silicone rubber lettering film and a preparation method and anapplication method thereof. The high-elasticity silicone rubber lettering film comprises a load-bearing substrate, a release layer, a surface layer silicone rubber ink layer, an anti-photopermeable silicone rubber ink layer, an adhesive interfacial agent layer and a TPU hot melt adhesive film which are connected from bottom to top successively; the adhesive interfacial agent layer is prepared from an adhesive interfacial agent, and the adhesive interfacial agent is an adhesive interfacial agent containing dual-resin components. The silicone rubber lettering film has the advantages of both thesilicone rubber material and the TPU material, has good elasticity, tearing strength, weatherability, yellowing resistance, water washing resistance and other comprehensive properties, has layers noteasy to separate, is not easy to discolor or fade by sunlight exposure, and has the water-washing fading rate not less than 0.5%, is not easy to dye when being mixed and washed with materials with other colors, and is high in stability, easy to bond with a variety of materials, high in bonding strength, not easy to peel off, good in stability, delicate in hand feeling, good in aesthetic degree, and long in service life.

Owner:卢汉军

Recovery essential oil for sensitive skin and preparation method of same

ActiveCN107281040AGood chemical stabilityEasy to useCosmetic preparationsToilet preparationsHelichrysum italicum flowerRosmarinus

The invention discloses recovery essential oil for sensitive skin and a preparation method of same. The recovery essential oil is prepared from, by mass, 50-65% of macadimia nut oil, 15-20% of squalane, 2-5% of phytosterol, 2-6% of wheat germ oil, 5-10% of chamomile essential oil, 2-5% of helichrysum italicum essential oil, 1-2% of rosemary leaf oil, 0.2-0.5% of opopanax oil, 1-2% of vitamin E, and 0.2-0.5% of blue chamomile. All the essential oil components in the invention are pure plant-sourced products, so that the recovery essential oil is safe and green and has good permeability, can moisten skin, effectively alleviates various discomforts due to sensitive skin and reduces skin allergic symptoms, such as red rash on facial skin, itching, stabbing pain, dull skin and the like. The essential oil has the refreshing smell of blue chamomile and can heal skin from interior to exterior.

Owner:广州科缇生物科技有限公司

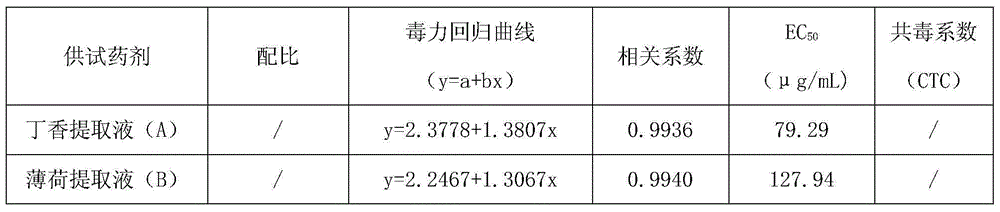

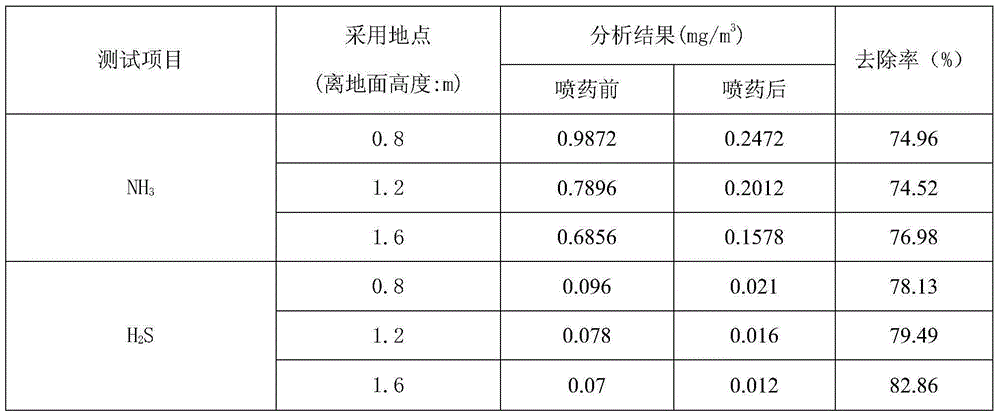

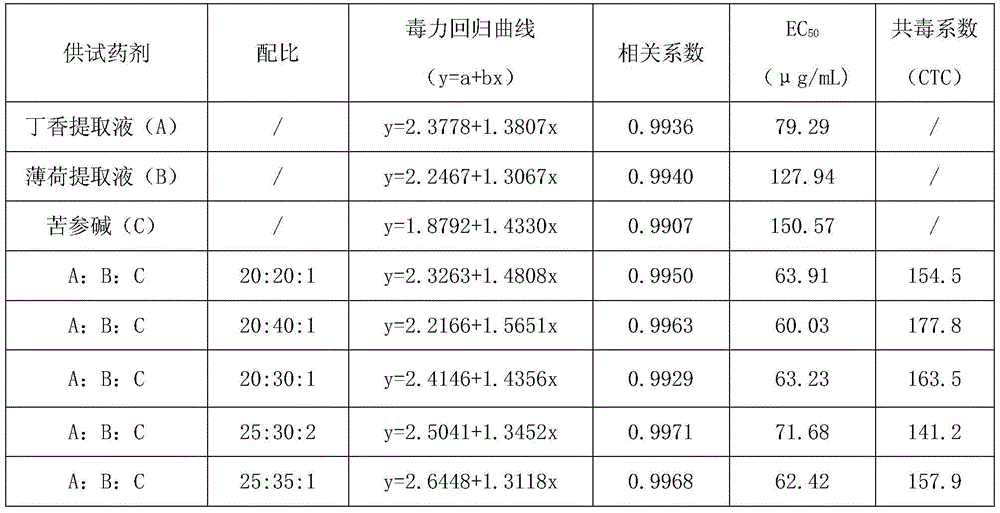

Plant source deodorant

InactiveCN105079845AAdvantages and significant technical effectsGood technical effectDeodrantsIllicium verumLitter

The invention relates to a plant source deodorant of which the effective constituents comprise a clove extracting solution, a mint extracting solution, matrine and an illicium verum extracting solution, wherein the mass ratio of the clove extracting solution to the mint extracting solution to matrine is (20-40):(20-40):(1-2). The plant source deodorant provided by the invention can be applied to treatment of odor gas generated by household garbage heaps, garbage-disposal sites and waste transfer stations in cities and towns, has the advantages of being non-toxic, harmless, safe and convenient in use, remarkable in the synergetic effect, high in the antibacterial and bactericidal activity, and at the same time can eliminate damage caused by aggregation of mosquitoes and flies, and further reduce breeding and transmission of germs.

Owner:GUANGXI NANNING YITU BIOLOGICAL SCI & TECH CO LTD

Compound antiseptic containing natamycin and application of compound antiseptic

InactiveCN104207956AInhibition of growth and reproductionSignificant synergistic effectCosmetic preparationsToilet preparationsCaprylyl GlycolIrritation

The invention discloses a compound antiseptic containing natamycin. The compound antiseptic comprises the following components in percentage by weight: 0.1-2% of a component A and 99.9-98% of a component B, wherein the component B is any one or a mixture of a component C and a component D at any proportion; the component A is natamycin; the component C is propylene glycol, pentanediol or butanediol; and the component D is caprylyl glycol, decamethylene glycol, hexanediol or phenoxyethanol. In daily chemical products, the compound antiseptic is used as an antiseptic additive for preventing corrosion and sterilizing and is capable of effectively preventing bacteria growing in storage and usage processes of the daily chemical products within a shelf life so as to protect the products from going bad or rotting; and the compound antiseptic is safe, efficient and low in irritation.

Owner:广州艾卓生物科技股份有限公司

Movable denture stent made of medical pure titanium metal

InactiveCN101647731ASolve the defects in the background technologyGood biocompatibilityFastening prosthesisTitanium metalMedicine

The invention provides a movable denture stent made of medical pure titanium metal. The whole stent is made of the medical pure titanium metal. The movable denture stent comprises a support part, wherein the tail end of the support part is provided with a bond part; a grid is arranged on the bond part; and two sides of the bond part are provided with a plurality of denture clasps. The medical puretitanium metal is made of pure titanium metal of which the purity is over 99.5 percent. The movable denture stent made of medical pure titanium metal has the advantages of light weight, high strength, denture steadiness, incapability of causing allergy, no discoloration and no off-flavor.

Owner:SHANGHAI I DENTAL TECH CO LTD

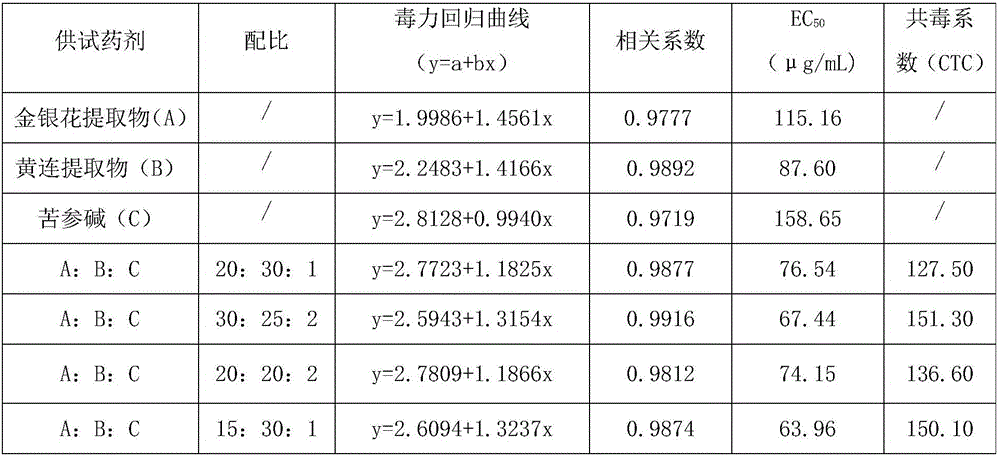

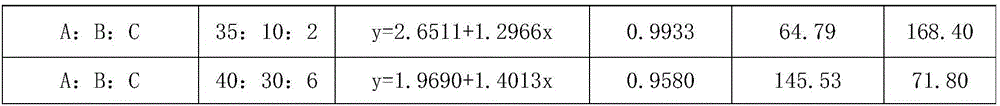

Honeysuckle-flower-containing plant-derived deodorizer

InactiveCN106729867ACause secondary pollutionNon-toxic useBiocideGas treatmentMatrineAdditive ingredient

The invention relates to a honeysuckle-flower-containing plant-derived deodorizer. The effective component is composed of the following ingredients in parts by mass: 15-35 parts of honeysuckle flower extract, 10-30 parts of coptis root extract and 1-2 parts of matrine. The effective component is composed of plant extracts, can be degraded automatically, and can not cause secondary environment pollution. The honeysuckle-flower-containing plant-derived deodorizer has obvious synergistic effects and high antibacterial and bactericidal activities, can expel mosquitoes and flies, reduces the generation and transmission of pathogenic bacteria, and has the advantages of favorable deodorizing effect, high safety, no toxicity, environment friendliness, low cost and the like. The honeysuckle-flower-containing plant-derived deodorizer is applicable to air stink treatment in urban domestic refuse dumps, refuse disposal stations and refuse transfer stations or applicable to peculiar smell control of public lavatories.

Owner:GUANGXI NANNING YITU BIOLOGICAL SCI & TECH CO LTD

Botanical disinfection deodorant

InactiveCN105597126AAdvantages and significant technical effectsGood technical effectBiocideDisinfectantsSyzygiumMatrine

The invention relates to a botanical disinfection deodorant. Effective components of the botanical disinfection deodorant are composed of a Syzygium aromaticum extract liquid, a mint extract liquid and matrine according to a mass ratio of 20-40:20-40:1-2. The effective components of the botanical disinfection deodorant can automatically degrade, so secondary pollution to environment is avoided. No skin or respiratory system allergy or various untoward effects are caused after the botanical disinfection deodorant is used, and the botanical disinfection deodorant has the advantages of non-toxicity, harmlessness, safe and convenient use, bacteriostasis and sterilization activity, obvious synergism, small dosage and high control efficiency.

Owner:GUANGXI NANNING YITU BIOLOGICAL SCI & TECH CO LTD

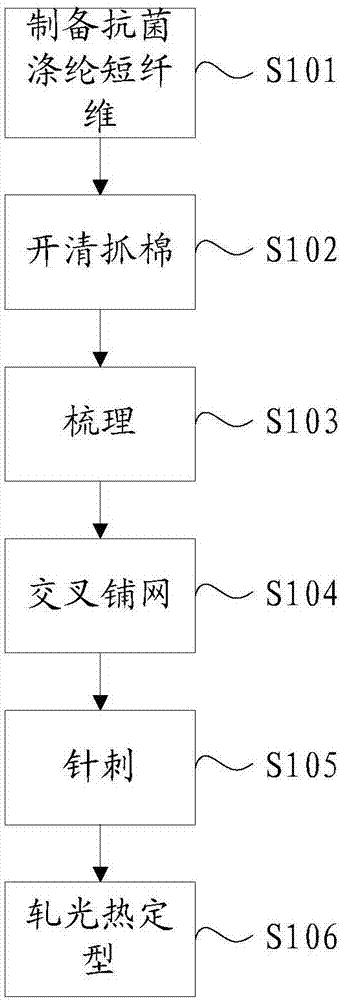

Antibacterial non-woven polyester cloth and preparation method thereof

InactiveCN107313178AStrongStrong enoughHeating/cooling textile fabricsNon-woven fabricsMasterbatchPolyester

The invention discloses antibacterial non-woven polyester cloth and a preparation method thereof. The preparation method of the antibacterial non-woven polyester cloth comprises the steps of preparing short-staple antibacterial polyester fibers, opening, cleaning and picking cotton, carding, conducting cross lapping, conducting needling, and rolling for photo-thermal molding. Since the antibacterial non-woven polyester cloth is prepared from the short-staple antibacterial polyester fibers and the short-staple antibacterial polyester fibers are prepared by blending masterbatch of three antibacterial particles including nano-bamboo carbon, nano-zinc and silver ions with polyester fibers, wherein the three antibacterial particles including the nano-bamboo carbon, the nano-zinc and the silver ions are great in bacterial resistance, and the normal polyester fibers have certain strength, the combination of the particles and the fibers can make the antibacterial non-woven polyester cloth prepared from the short-staple antibacterial polyester fibers have functions of bacterial resistance, deodorization and air purification, and the cloth has enough strength, stands wear and tear, resists corrosion and is stable in size; moreover, the short-staple antibacterial polyester fibers contain no harmful materials and are more sanitary and healthier, problems of allergies on human bodies and the like can not occur, and short-staple polypropylene fibers resist light and ultraviolet rays and are unlikely to be oxidized.

Owner:ZHAOQING JOFO WEBFORMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com